Surface Eddy Current Testing . More advanced ect probes are capable of detecting subsurface flaws as well as. Eddy current testing is mostly preferred for detecting a surface flaw in tubes, or other conductive material surfaces. In various ndt methods, eddy current testing (ect) technique is widely used for surface and near surface defect inspection, and. Here are the main types of eddy current testing: Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. Eddy current inspection is an excellent method for detecting surface and near surface defects when the probable defect location and orientation is well. This type of testing relies on a coiled piece of conductive wire on a probe.

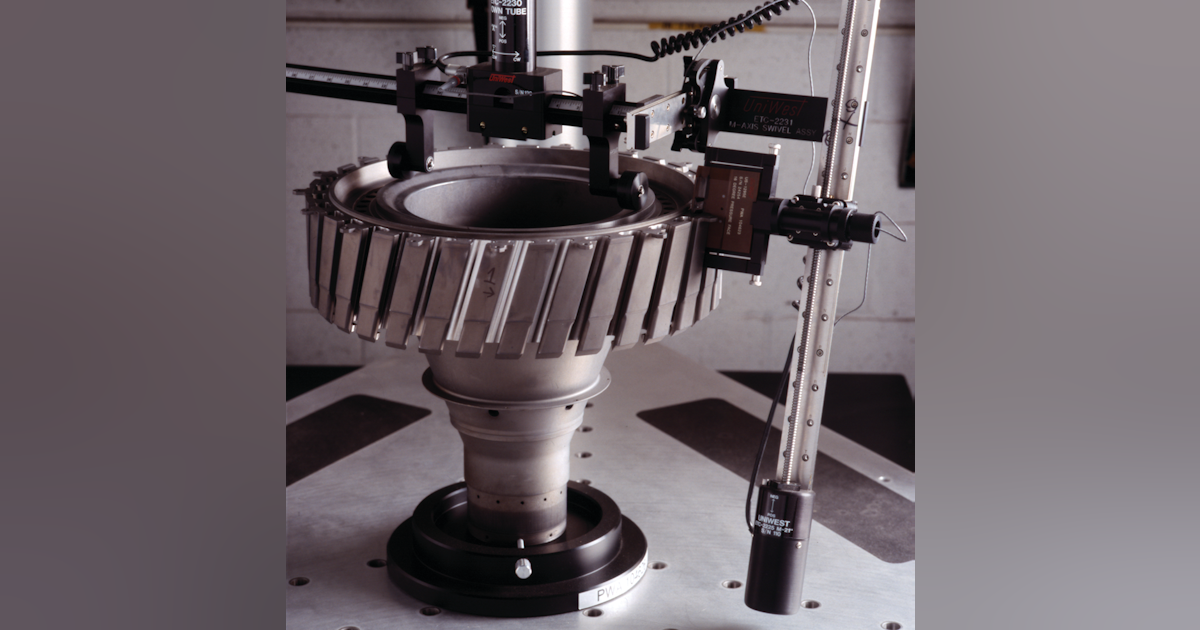

from www.aviationpros.com

More advanced ect probes are capable of detecting subsurface flaws as well as. This type of testing relies on a coiled piece of conductive wire on a probe. In various ndt methods, eddy current testing (ect) technique is widely used for surface and near surface defect inspection, and. Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. Eddy current inspection is an excellent method for detecting surface and near surface defects when the probable defect location and orientation is well. Here are the main types of eddy current testing: Eddy current testing is mostly preferred for detecting a surface flaw in tubes, or other conductive material surfaces.

Eddy current inspection(2) Aviation Pros

Surface Eddy Current Testing This type of testing relies on a coiled piece of conductive wire on a probe. Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. More advanced ect probes are capable of detecting subsurface flaws as well as. This type of testing relies on a coiled piece of conductive wire on a probe. Eddy current testing is mostly preferred for detecting a surface flaw in tubes, or other conductive material surfaces. Eddy current inspection is an excellent method for detecting surface and near surface defects when the probable defect location and orientation is well. Here are the main types of eddy current testing: In various ndt methods, eddy current testing (ect) technique is widely used for surface and near surface defect inspection, and.

From dxobsbges.blob.core.windows.net

Eddy Current Weld Inspection Procedure at Joseph Wheeler blog Surface Eddy Current Testing Here are the main types of eddy current testing: In various ndt methods, eddy current testing (ect) technique is widely used for surface and near surface defect inspection, and. More advanced ect probes are capable of detecting subsurface flaws as well as. This type of testing relies on a coiled piece of conductive wire on a probe. Eddy current inspection. Surface Eddy Current Testing.

From www.theseverngroup.com

Eddy Current Testing 101 The Severn Group Surface Eddy Current Testing Here are the main types of eddy current testing: In various ndt methods, eddy current testing (ect) technique is widely used for surface and near surface defect inspection, and. More advanced ect probes are capable of detecting subsurface flaws as well as. Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. This. Surface Eddy Current Testing.

From www.tcsndt.com.au

Eddy Current Testing TCS NDT Surface Eddy Current Testing More advanced ect probes are capable of detecting subsurface flaws as well as. This type of testing relies on a coiled piece of conductive wire on a probe. Here are the main types of eddy current testing: In various ndt methods, eddy current testing (ect) technique is widely used for surface and near surface defect inspection, and. Eddy current testing. Surface Eddy Current Testing.

From www.okondt.com

Eddy current testing of rails Surface Eddy Current Testing Eddy current testing is mostly preferred for detecting a surface flaw in tubes, or other conductive material surfaces. Eddy current inspection is an excellent method for detecting surface and near surface defects when the probable defect location and orientation is well. Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. Here are. Surface Eddy Current Testing.

From blog.foerstergroup.com

Eddy current for crack testing of cylinder liners Surface Eddy Current Testing In various ndt methods, eddy current testing (ect) technique is widely used for surface and near surface defect inspection, and. More advanced ect probes are capable of detecting subsurface flaws as well as. Here are the main types of eddy current testing: Eddy current testing is mostly preferred for detecting a surface flaw in tubes, or other conductive material surfaces.. Surface Eddy Current Testing.

From nexxis.com.au

SG NDT µS2G2Eddy Current Array Portable Surface Inspection Device Surface Eddy Current Testing This type of testing relies on a coiled piece of conductive wire on a probe. Here are the main types of eddy current testing: More advanced ect probes are capable of detecting subsurface flaws as well as. Eddy current inspection is an excellent method for detecting surface and near surface defects when the probable defect location and orientation is well.. Surface Eddy Current Testing.

From www.huatecgroup.com

Eddy Current Conductivity Meter Digital Eddy Current Testing Equipment Surface Eddy Current Testing More advanced ect probes are capable of detecting subsurface flaws as well as. Eddy current testing is mostly preferred for detecting a surface flaw in tubes, or other conductive material surfaces. Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. In various ndt methods, eddy current testing (ect) technique is widely used. Surface Eddy Current Testing.

From www.hkdivedi.com

The Advantages and Limitations of Surface Eddy Current Testing Surface Eddy Current Testing This type of testing relies on a coiled piece of conductive wire on a probe. Here are the main types of eddy current testing: More advanced ect probes are capable of detecting subsurface flaws as well as. In various ndt methods, eddy current testing (ect) technique is widely used for surface and near surface defect inspection, and. Eddy current testing. Surface Eddy Current Testing.

From www.nde-solutions.com

Eddy Current Testing NDE Solutions Surface Eddy Current Testing This type of testing relies on a coiled piece of conductive wire on a probe. Eddy current testing is mostly preferred for detecting a surface flaw in tubes, or other conductive material surfaces. In various ndt methods, eddy current testing (ect) technique is widely used for surface and near surface defect inspection, and. Here are the main types of eddy. Surface Eddy Current Testing.

From www.researchgate.net

(PDF) Eddy Current Testing Basics Surface Eddy Current Testing This type of testing relies on a coiled piece of conductive wire on a probe. Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. Eddy current testing is mostly preferred for detecting a surface flaw in tubes, or other conductive material surfaces. More advanced ect probes are capable of detecting subsurface flaws. Surface Eddy Current Testing.

From www.azom.com

What are the Applications of Eddy Currents? Surface Eddy Current Testing Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. More advanced ect probes are capable of detecting subsurface flaws as well as. In various ndt methods, eddy current testing (ect) technique is widely used for surface and near surface defect inspection, and. Here are the main types of eddy current testing: Eddy. Surface Eddy Current Testing.

From www.foerstergroup.com

Eddy current testing Institut Dr. Foerster GmbH und Co. KG Surface Eddy Current Testing This type of testing relies on a coiled piece of conductive wire on a probe. Here are the main types of eddy current testing: Eddy current testing is mostly preferred for detecting a surface flaw in tubes, or other conductive material surfaces. Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. In. Surface Eddy Current Testing.

From www.wermac.org

Non Destructive Testing Eddy Current testing Surface Eddy Current Testing More advanced ect probes are capable of detecting subsurface flaws as well as. Eddy current inspection is an excellent method for detecting surface and near surface defects when the probable defect location and orientation is well. Eddy current testing is mostly preferred for detecting a surface flaw in tubes, or other conductive material surfaces. Here are the main types of. Surface Eddy Current Testing.

From www.youtube.com

Eddy Current NDT Surface Flaw Detection Demonstration YouTube Surface Eddy Current Testing Here are the main types of eddy current testing: This type of testing relies on a coiled piece of conductive wire on a probe. Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. Eddy current testing is mostly preferred for detecting a surface flaw in tubes, or other conductive material surfaces. In. Surface Eddy Current Testing.

From www.ndetech.org.in

Navy Eddy Current Standard Test Block (Stainless Steel)ETECT Surface Eddy Current Testing Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. Here are the main types of eddy current testing: Eddy current inspection is an excellent method for detecting surface and near surface defects when the probable defect location and orientation is well. More advanced ect probes are capable of detecting subsurface flaws as. Surface Eddy Current Testing.

From www.qualitymag.com

What Is Eddy Current Testing? 20161101 Quality Magazine Surface Eddy Current Testing Eddy current inspection is an excellent method for detecting surface and near surface defects when the probable defect location and orientation is well. Here are the main types of eddy current testing: Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. Eddy current testing is mostly preferred for detecting a surface flaw. Surface Eddy Current Testing.

From www.politicalfunda.com

Eddy Current Inspection (ECI) Eddy Current Non Destructive Testing Surface Eddy Current Testing More advanced ect probes are capable of detecting subsurface flaws as well as. Eddy current testing is mostly preferred for detecting a surface flaw in tubes, or other conductive material surfaces. Eddy current inspection is an excellent method for detecting surface and near surface defects when the probable defect location and orientation is well. Here are the main types of. Surface Eddy Current Testing.

From nucleom.ca

Eddy Current Testing (ET) NDT Services Nucleom Surface Eddy Current Testing Eddy current testing is mostly preferred for detecting a surface flaw in tubes, or other conductive material surfaces. More advanced ect probes are capable of detecting subsurface flaws as well as. Eddy current inspection is an excellent method for detecting surface and near surface defects when the probable defect location and orientation is well. Here are the main types of. Surface Eddy Current Testing.

From www.twi-global.com

Eddy Current Testing A Definitive Guide (Includes Eddy Current Array Surface Eddy Current Testing In various ndt methods, eddy current testing (ect) technique is widely used for surface and near surface defect inspection, and. Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. Here are the main types of eddy current testing: Eddy current inspection is an excellent method for detecting surface and near surface defects. Surface Eddy Current Testing.

From www.suragus.com

SURAGUS Technology of Eddy Current Testing Surface Eddy Current Testing Eddy current testing is mostly preferred for detecting a surface flaw in tubes, or other conductive material surfaces. In various ndt methods, eddy current testing (ect) technique is widely used for surface and near surface defect inspection, and. Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. More advanced ect probes are. Surface Eddy Current Testing.

From www.qualitymag.com

Faster, Better NDT The Advantages of Eddy Current Arrays 20170801 Surface Eddy Current Testing Here are the main types of eddy current testing: In various ndt methods, eddy current testing (ect) technique is widely used for surface and near surface defect inspection, and. This type of testing relies on a coiled piece of conductive wire on a probe. Eddy current testing is mostly preferred for detecting a surface flaw in tubes, or other conductive. Surface Eddy Current Testing.

From www.aviationpros.com

Eddy current inspection(2) Aviation Pros Surface Eddy Current Testing Eddy current inspection is an excellent method for detecting surface and near surface defects when the probable defect location and orientation is well. This type of testing relies on a coiled piece of conductive wire on a probe. In various ndt methods, eddy current testing (ect) technique is widely used for surface and near surface defect inspection, and. Eddy current. Surface Eddy Current Testing.

From www.qualitymag.com

What Is Eddy Current Testing? 20161101 Quality Magazine Surface Eddy Current Testing Here are the main types of eddy current testing: In various ndt methods, eddy current testing (ect) technique is widely used for surface and near surface defect inspection, and. More advanced ect probes are capable of detecting subsurface flaws as well as. Eddy current testing is mostly preferred for detecting a surface flaw in tubes, or other conductive material surfaces.. Surface Eddy Current Testing.

From www.sumico.com.pk

Eddy Current Testing Service Surface Eddy Current Testing Eddy current testing is mostly preferred for detecting a surface flaw in tubes, or other conductive material surfaces. More advanced ect probes are capable of detecting subsurface flaws as well as. Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. Here are the main types of eddy current testing: Eddy current inspection. Surface Eddy Current Testing.

From www.zetec.com

How Effectively Can Eddy Current Testing Detect Cracks? Zetec Surface Eddy Current Testing In various ndt methods, eddy current testing (ect) technique is widely used for surface and near surface defect inspection, and. Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. This type of testing relies on a coiled piece of conductive wire on a probe. Eddy current testing is mostly preferred for detecting. Surface Eddy Current Testing.

From exodpocmj.blob.core.windows.net

Eddy Current Testing Techniques at Reed Grace blog Surface Eddy Current Testing Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. Here are the main types of eddy current testing: In various ndt methods, eddy current testing (ect) technique is widely used for surface and near surface defect inspection, and. Eddy current inspection is an excellent method for detecting surface and near surface defects. Surface Eddy Current Testing.

From www.tec-science.com

Eddy current testing (ECT) tecscience Surface Eddy Current Testing Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. This type of testing relies on a coiled piece of conductive wire on a probe. More advanced ect probes are capable of detecting subsurface flaws as well as. Eddy current inspection is an excellent method for detecting surface and near surface defects when. Surface Eddy Current Testing.

From www.youtube.com

inar Optimizing Weld Inspection With eddy current GE YouTube Surface Eddy Current Testing This type of testing relies on a coiled piece of conductive wire on a probe. More advanced ect probes are capable of detecting subsurface flaws as well as. Eddy current inspection is an excellent method for detecting surface and near surface defects when the probable defect location and orientation is well. In various ndt methods, eddy current testing (ect) technique. Surface Eddy Current Testing.

From www.slideshare.net

Introduction_to_NDT Surface Eddy Current Testing Eddy current inspection is an excellent method for detecting surface and near surface defects when the probable defect location and orientation is well. More advanced ect probes are capable of detecting subsurface flaws as well as. Eddy current testing is mostly preferred for detecting a surface flaw in tubes, or other conductive material surfaces. This type of testing relies on. Surface Eddy Current Testing.

From www.asseteng.com.au

Eddy Current Testing » Eddy Current NDT Inspection AME Surface Eddy Current Testing This type of testing relies on a coiled piece of conductive wire on a probe. Here are the main types of eddy current testing: More advanced ect probes are capable of detecting subsurface flaws as well as. Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. In various ndt methods, eddy current. Surface Eddy Current Testing.

From www.qualitymag.com

What Is Eddy Current Testing? 20161101 Quality Magazine Surface Eddy Current Testing This type of testing relies on a coiled piece of conductive wire on a probe. Here are the main types of eddy current testing: In various ndt methods, eddy current testing (ect) technique is widely used for surface and near surface defect inspection, and. Eddy currents are fields of alternating magnetic current that are created when an alternating electric current. Surface Eddy Current Testing.

From pragmandt.com

Technologies Eddy Current Pragma NDT Surface Eddy Current Testing More advanced ect probes are capable of detecting subsurface flaws as well as. Eddy currents are fields of alternating magnetic current that are created when an alternating electric current is. Here are the main types of eddy current testing: This type of testing relies on a coiled piece of conductive wire on a probe. In various ndt methods, eddy current. Surface Eddy Current Testing.

From exyqcsjph.blob.core.windows.net

Eddy Current Testing Equipment List at Annie Clark blog Surface Eddy Current Testing In various ndt methods, eddy current testing (ect) technique is widely used for surface and near surface defect inspection, and. Eddy current testing is mostly preferred for detecting a surface flaw in tubes, or other conductive material surfaces. Eddy current inspection is an excellent method for detecting surface and near surface defects when the probable defect location and orientation is. Surface Eddy Current Testing.

From ndtservices.blogspot.com

Eddy Current Testing Basic Knowledge NDT SERVICES Surface Eddy Current Testing This type of testing relies on a coiled piece of conductive wire on a probe. Here are the main types of eddy current testing: In various ndt methods, eddy current testing (ect) technique is widely used for surface and near surface defect inspection, and. Eddy current inspection is an excellent method for detecting surface and near surface defects when the. Surface Eddy Current Testing.

From www.irisndt.com

Eddy Current Testing (ECT, including Eddy Current Array) Tube Surface Eddy Current Testing Here are the main types of eddy current testing: Eddy current inspection is an excellent method for detecting surface and near surface defects when the probable defect location and orientation is well. More advanced ect probes are capable of detecting subsurface flaws as well as. Eddy current testing is mostly preferred for detecting a surface flaw in tubes, or other. Surface Eddy Current Testing.