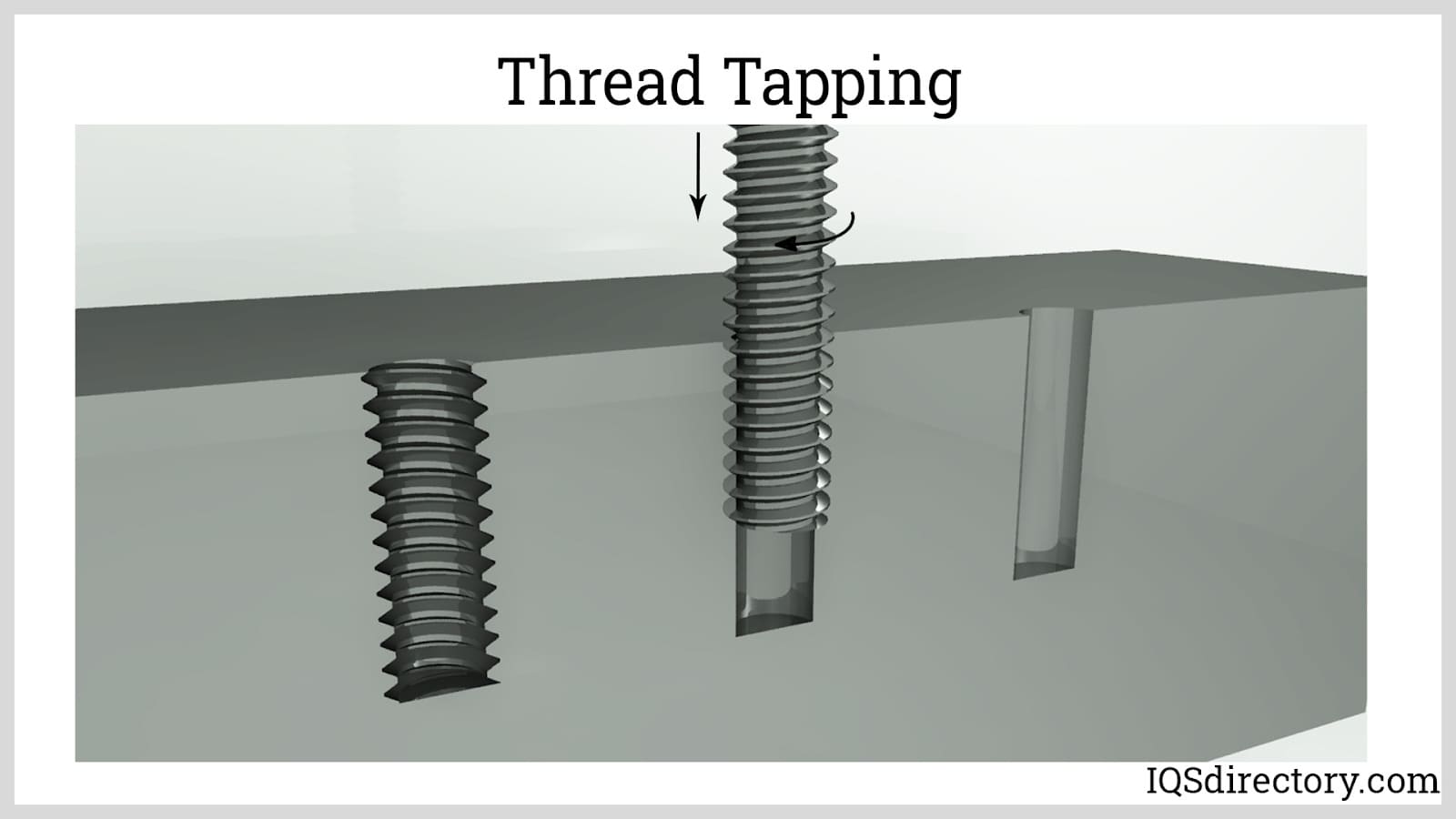

Thread Tapping Procedure . Also, it is used to make thread on nuts. See section how to choose the right type of tap. This article delves deep into the subject of taps for threads, highlighting the different types of taps for threading, their applications, and how to select the perfect tap for specific thread needs. For example, a 5mm hole can be ‘tapped’ for. Three thread taps area provided for each m12 to work your way through each of the taps to create a clean thread start with the thread with the single. Tapping is an easy, well known and highly efficient manufacturing process. Follow these steps to ensure a good tapping thread operation. Workpiece material, cutting speed, cutting. The purpose of the ‘tap’, is to cut a thread into a ‘hole’, that has been accurately drilled to a specific size. Tapping is the process of cutting an internal thread inside a hole in a workpiece using a tap. This method offers productive and economical threading, especially for smaller threads, through reduced. This process is achieved using a tool known as a tap, which is available in various types and sizes, each suited for specific applications. 1) factors that determine tap performance include: Select the correct tap for the component material and the type of hole to thread. Tapping is the process of cutting a thread inside a hole so that a cap screw or bolt can be threaded into the hole.

from www.iqsdirectory.com

Tapping is the process of cutting a thread inside a hole so that a cap screw or bolt can be threaded into the hole. This method offers productive and economical threading, especially for smaller threads, through reduced. Follow these steps to ensure a good tapping thread operation. Workpiece material, cutting speed, cutting. Tapping is the process of cutting an internal thread inside a hole in a workpiece using a tap. Select the correct tap for the component material and the type of hole to thread. The purpose of the ‘tap’, is to cut a thread into a ‘hole’, that has been accurately drilled to a specific size. For example, a 5mm hole can be ‘tapped’ for. 1) factors that determine tap performance include: This article delves deep into the subject of taps for threads, highlighting the different types of taps for threading, their applications, and how to select the perfect tap for specific thread needs.

Thread Rolling What Is It? How Does It Work? Process, Types

Thread Tapping Procedure Workpiece material, cutting speed, cutting. Tapping is the process of cutting a thread inside a hole so that a cap screw or bolt can be threaded into the hole. Also, it is used to make thread on nuts. This article delves deep into the subject of taps for threads, highlighting the different types of taps for threading, their applications, and how to select the perfect tap for specific thread needs. Three thread taps area provided for each m12 to work your way through each of the taps to create a clean thread start with the thread with the single. Select the correct tap for the component material and the type of hole to thread. For example, a 5mm hole can be ‘tapped’ for. Tapping is an easy, well known and highly efficient manufacturing process. The purpose of the ‘tap’, is to cut a thread into a ‘hole’, that has been accurately drilled to a specific size. This method offers productive and economical threading, especially for smaller threads, through reduced. Workpiece material, cutting speed, cutting. Tapping is the process of cutting an internal thread inside a hole in a workpiece using a tap. 1) factors that determine tap performance include: Follow these steps to ensure a good tapping thread operation. This process is achieved using a tool known as a tap, which is available in various types and sizes, each suited for specific applications. See section how to choose the right type of tap.

From mixasale.com

Thread Tapping Set Tap Die Kit High Hardness Effective for Cutting Male Thread Tapping Procedure Three thread taps area provided for each m12 to work your way through each of the taps to create a clean thread start with the thread with the single. 1) factors that determine tap performance include: Tapping is the process of cutting an internal thread inside a hole in a workpiece using a tap. This method offers productive and economical. Thread Tapping Procedure.

From www.slideserve.com

PPT Fasteners, Sealants, and Gaskets PowerPoint Presentation, free Thread Tapping Procedure Follow these steps to ensure a good tapping thread operation. This article delves deep into the subject of taps for threads, highlighting the different types of taps for threading, their applications, and how to select the perfect tap for specific thread needs. Workpiece material, cutting speed, cutting. This process is achieved using a tool known as a tap, which is. Thread Tapping Procedure.

From www.amazon.in

Thread Tapping Set, High Hardness Metric Easy Operation Tap Die Kit Thread Tapping Procedure Three thread taps area provided for each m12 to work your way through each of the taps to create a clean thread start with the thread with the single. Workpiece material, cutting speed, cutting. See section how to choose the right type of tap. The purpose of the ‘tap’, is to cut a thread into a ‘hole’, that has been. Thread Tapping Procedure.

From slideplayer.com

MACH 112 Cutting Tools & Measurement ppt download Thread Tapping Procedure Tapping is the process of cutting an internal thread inside a hole in a workpiece using a tap. Also, it is used to make thread on nuts. For example, a 5mm hole can be ‘tapped’ for. Three thread taps area provided for each m12 to work your way through each of the taps to create a clean thread start with. Thread Tapping Procedure.

From www.slideserve.com

PPT ThreadCutting Tools and Procedures PowerPoint Presentation ID Thread Tapping Procedure Follow these steps to ensure a good tapping thread operation. Also, it is used to make thread on nuts. Select the correct tap for the component material and the type of hole to thread. See section how to choose the right type of tap. Three thread taps area provided for each m12 to work your way through each of the. Thread Tapping Procedure.

From www.classiccarrestorationclub.com

Cutting Threads An Introduction to Using a Tap to Thread Bolt Holes Thread Tapping Procedure This article delves deep into the subject of taps for threads, highlighting the different types of taps for threading, their applications, and how to select the perfect tap for specific thread needs. 1) factors that determine tap performance include: Follow these steps to ensure a good tapping thread operation. Workpiece material, cutting speed, cutting. This process is achieved using a. Thread Tapping Procedure.

From engineeredtoslide.com

Tapping Threads Engineered to Slide Thread Tapping Procedure Select the correct tap for the component material and the type of hole to thread. Three thread taps area provided for each m12 to work your way through each of the taps to create a clean thread start with the thread with the single. Workpiece material, cutting speed, cutting. This method offers productive and economical threading, especially for smaller threads,. Thread Tapping Procedure.

From prochain-cnc.com

4 common thread processing methods you must know PROCHAIN PRECISION Thread Tapping Procedure The purpose of the ‘tap’, is to cut a thread into a ‘hole’, that has been accurately drilled to a specific size. Workpiece material, cutting speed, cutting. Follow these steps to ensure a good tapping thread operation. Tapping is an easy, well known and highly efficient manufacturing process. For example, a 5mm hole can be ‘tapped’ for. Tapping is the. Thread Tapping Procedure.

From cezqrdnd.blob.core.windows.net

How To Tap A Thread In Stainless Steel at Maria Seifert blog Thread Tapping Procedure Tapping is an easy, well known and highly efficient manufacturing process. Tapping is the process of cutting a thread inside a hole so that a cap screw or bolt can be threaded into the hole. Follow these steps to ensure a good tapping thread operation. Tapping is the process of cutting an internal thread inside a hole in a workpiece. Thread Tapping Procedure.

From www.sandvik.coromant.com

Tapping threads what is tapping? Thread Tapping Procedure Follow these steps to ensure a good tapping thread operation. Tapping is the process of cutting a thread inside a hole so that a cap screw or bolt can be threaded into the hole. For example, a 5mm hole can be ‘tapped’ for. Three thread taps area provided for each m12 to work your way through each of the taps. Thread Tapping Procedure.

From www.yamawa.eu

Cored holes Direct tapping with no tool breakage Yamawa Thread Tapping Procedure Also, it is used to make thread on nuts. Follow these steps to ensure a good tapping thread operation. This method offers productive and economical threading, especially for smaller threads, through reduced. This article delves deep into the subject of taps for threads, highlighting the different types of taps for threading, their applications, and how to select the perfect tap. Thread Tapping Procedure.

From proleantech.com

Ultimate Guide to Taps for Threads Thread Tapping Techniques and Types Thread Tapping Procedure Tapping is the process of cutting an internal thread inside a hole in a workpiece using a tap. See section how to choose the right type of tap. This process is achieved using a tool known as a tap, which is available in various types and sizes, each suited for specific applications. The purpose of the ‘tap’, is to cut. Thread Tapping Procedure.

From slideplayer.com

Threads and Threading. ppt download Thread Tapping Procedure See section how to choose the right type of tap. Tapping is the process of cutting a thread inside a hole so that a cap screw or bolt can be threaded into the hole. Select the correct tap for the component material and the type of hole to thread. The purpose of the ‘tap’, is to cut a thread into. Thread Tapping Procedure.

From www.protoolreviews.com

How to Use a Tap and Die to Create or Repair Threads Pro Tool Reviews Thread Tapping Procedure This article delves deep into the subject of taps for threads, highlighting the different types of taps for threading, their applications, and how to select the perfect tap for specific thread needs. Three thread taps area provided for each m12 to work your way through each of the taps to create a clean thread start with the thread with the. Thread Tapping Procedure.

From www.slideserve.com

PPT ThreadCutting Tools and Procedures PowerPoint Presentation, free Thread Tapping Procedure Workpiece material, cutting speed, cutting. Tapping is an easy, well known and highly efficient manufacturing process. Follow these steps to ensure a good tapping thread operation. Select the correct tap for the component material and the type of hole to thread. See section how to choose the right type of tap. Three thread taps area provided for each m12 to. Thread Tapping Procedure.

From www.slideserve.com

PPT Fasteners, Sealants, and Gaskets PowerPoint Presentation, free Thread Tapping Procedure Also, it is used to make thread on nuts. Tapping is an easy, well known and highly efficient manufacturing process. Tapping is the process of cutting an internal thread inside a hole in a workpiece using a tap. Follow these steps to ensure a good tapping thread operation. Select the correct tap for the component material and the type of. Thread Tapping Procedure.

From www.practicalmachinist.com

A Guide to Tapping and Threading Practical Machinist Practical Thread Tapping Procedure Tapping is the process of cutting an internal thread inside a hole in a workpiece using a tap. Tapping is an easy, well known and highly efficient manufacturing process. Tapping is the process of cutting a thread inside a hole so that a cap screw or bolt can be threaded into the hole. This method offers productive and economical threading,. Thread Tapping Procedure.

From www.slideserve.com

PPT ThreadCutting Tools and Procedures PowerPoint Presentation ID Thread Tapping Procedure Tapping is the process of cutting an internal thread inside a hole in a workpiece using a tap. Three thread taps area provided for each m12 to work your way through each of the taps to create a clean thread start with the thread with the single. Tapping is the process of cutting a thread inside a hole so that. Thread Tapping Procedure.

From www.manufacturingguide.com

Form Tapping Find suppliers, processes & material Thread Tapping Procedure Follow these steps to ensure a good tapping thread operation. Also, it is used to make thread on nuts. This process is achieved using a tool known as a tap, which is available in various types and sizes, each suited for specific applications. The purpose of the ‘tap’, is to cut a thread into a ‘hole’, that has been accurately. Thread Tapping Procedure.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Tapping Procedure Workpiece material, cutting speed, cutting. Select the correct tap for the component material and the type of hole to thread. This method offers productive and economical threading, especially for smaller threads, through reduced. See section how to choose the right type of tap. Three thread taps area provided for each m12 to work your way through each of the taps. Thread Tapping Procedure.

From joibvazsh.blob.core.windows.net

Tools For Fitting Taps at Daniel Altman blog Thread Tapping Procedure Tapping is the process of cutting an internal thread inside a hole in a workpiece using a tap. Workpiece material, cutting speed, cutting. 1) factors that determine tap performance include: This process is achieved using a tool known as a tap, which is available in various types and sizes, each suited for specific applications. Three thread taps area provided for. Thread Tapping Procedure.

From www.aliexpress.com

ManualTapTappingToolHandTapTappingThreadTappingM3M4M5M6M8 Thread Tapping Procedure Tapping is the process of cutting a thread inside a hole so that a cap screw or bolt can be threaded into the hole. 1) factors that determine tap performance include: Workpiece material, cutting speed, cutting. This method offers productive and economical threading, especially for smaller threads, through reduced. Tapping is an easy, well known and highly efficient manufacturing process.. Thread Tapping Procedure.

From www.youtube.com

Tapping Operation Explained Practical Demonstration Aravind. N YouTube Thread Tapping Procedure Tapping is the process of cutting a thread inside a hole so that a cap screw or bolt can be threaded into the hole. Also, it is used to make thread on nuts. See section how to choose the right type of tap. The purpose of the ‘tap’, is to cut a thread into a ‘hole’, that has been accurately. Thread Tapping Procedure.

From www.youtube.com

How to make a Thread Tap How to easily tap a thread DIY Thread Tap Thread Tapping Procedure This article delves deep into the subject of taps for threads, highlighting the different types of taps for threading, their applications, and how to select the perfect tap for specific thread needs. 1) factors that determine tap performance include: Tapping is an easy, well known and highly efficient manufacturing process. For example, a 5mm hole can be ‘tapped’ for. Tapping. Thread Tapping Procedure.

From mixasale.com

Thread Tapping Set Tap Die Kit High Hardness Effective for Cutting Male Thread Tapping Procedure The purpose of the ‘tap’, is to cut a thread into a ‘hole’, that has been accurately drilled to a specific size. Also, it is used to make thread on nuts. Tapping is the process of cutting a thread inside a hole so that a cap screw or bolt can be threaded into the hole. This process is achieved using. Thread Tapping Procedure.

From www.youtube.com

Tapping Threads YouTube Thread Tapping Procedure The purpose of the ‘tap’, is to cut a thread into a ‘hole’, that has been accurately drilled to a specific size. For example, a 5mm hole can be ‘tapped’ for. Follow these steps to ensure a good tapping thread operation. Tapping is the process of cutting an internal thread inside a hole in a workpiece using a tap. Tapping. Thread Tapping Procedure.

From www.youtube.com

Tapping Process Tapping Operation What is Tapping In Hindi Thread Tapping Procedure Three thread taps area provided for each m12 to work your way through each of the taps to create a clean thread start with the thread with the single. 1) factors that determine tap performance include: Select the correct tap for the component material and the type of hole to thread. Follow these steps to ensure a good tapping thread. Thread Tapping Procedure.

From www.slideserve.com

PPT ThreadCutting Tools and Procedures PowerPoint Presentation, free Thread Tapping Procedure Tapping is an easy, well known and highly efficient manufacturing process. Tapping is the process of cutting an internal thread inside a hole in a workpiece using a tap. The purpose of the ‘tap’, is to cut a thread into a ‘hole’, that has been accurately drilled to a specific size. See section how to choose the right type of. Thread Tapping Procedure.

From machingchina.com

Tapping with a Drill ETCN Thread Tapping Procedure The purpose of the ‘tap’, is to cut a thread into a ‘hole’, that has been accurately drilled to a specific size. Also, it is used to make thread on nuts. This process is achieved using a tool known as a tap, which is available in various types and sizes, each suited for specific applications. For example, a 5mm hole. Thread Tapping Procedure.

From www.instructables.com

Tapping Threads in Aluminum Spindle 4 Steps (with Pictures Thread Tapping Procedure Also, it is used to make thread on nuts. Follow these steps to ensure a good tapping thread operation. This process is achieved using a tool known as a tap, which is available in various types and sizes, each suited for specific applications. Select the correct tap for the component material and the type of hole to thread. See section. Thread Tapping Procedure.

From www.slideserve.com

PPT Tapping & Threading PowerPoint Presentation, free download ID Thread Tapping Procedure For example, a 5mm hole can be ‘tapped’ for. 1) factors that determine tap performance include: The purpose of the ‘tap’, is to cut a thread into a ‘hole’, that has been accurately drilled to a specific size. This article delves deep into the subject of taps for threads, highlighting the different types of taps for threading, their applications, and. Thread Tapping Procedure.

From www.slideserve.com

PPT ThreadCutting Tools and Procedures PowerPoint Presentation, free Thread Tapping Procedure See section how to choose the right type of tap. This method offers productive and economical threading, especially for smaller threads, through reduced. This article delves deep into the subject of taps for threads, highlighting the different types of taps for threading, their applications, and how to select the perfect tap for specific thread needs. Tapping is the process of. Thread Tapping Procedure.

From www.slideserve.com

PPT ThreadCutting Tools and Procedures PowerPoint Presentation, free Thread Tapping Procedure Follow these steps to ensure a good tapping thread operation. Workpiece material, cutting speed, cutting. Also, it is used to make thread on nuts. See section how to choose the right type of tap. This method offers productive and economical threading, especially for smaller threads, through reduced. Tapping is the process of cutting a thread inside a hole so that. Thread Tapping Procedure.

From www.slideserve.com

PPT Module 7 Tapping and Threading PowerPoint Presentation ID2206779 Thread Tapping Procedure See section how to choose the right type of tap. Tapping is the process of cutting an internal thread inside a hole in a workpiece using a tap. This article delves deep into the subject of taps for threads, highlighting the different types of taps for threading, their applications, and how to select the perfect tap for specific thread needs.. Thread Tapping Procedure.

From www.youtube.com

Tapping Operation!! Tapping Process!!How to Cut Internal Thread with Thread Tapping Procedure Tapping is an easy, well known and highly efficient manufacturing process. Select the correct tap for the component material and the type of hole to thread. Also, it is used to make thread on nuts. Tapping is the process of cutting an internal thread inside a hole in a workpiece using a tap. Workpiece material, cutting speed, cutting. For example,. Thread Tapping Procedure.