Lycoming Engine Mount Bolt Torque . All avco lycoming aircraft engines incorporate bolts and long thru studs that extend through the crankcase halves primarily for holding them. After the two lower bolts are installed, force the upper engine mount shock bushings into alignment one at a time and insert the upper. Service table of limits and torque value recommendations. Bolts are tightened to bottom. 1.84 inches is measured from. These superior connecting rod assemblies are approved replacements for those lycoming parts and engine model eligibilities. The original lycoming engine blueprints call out for the bolts to be torqued to 40 inch pounds.

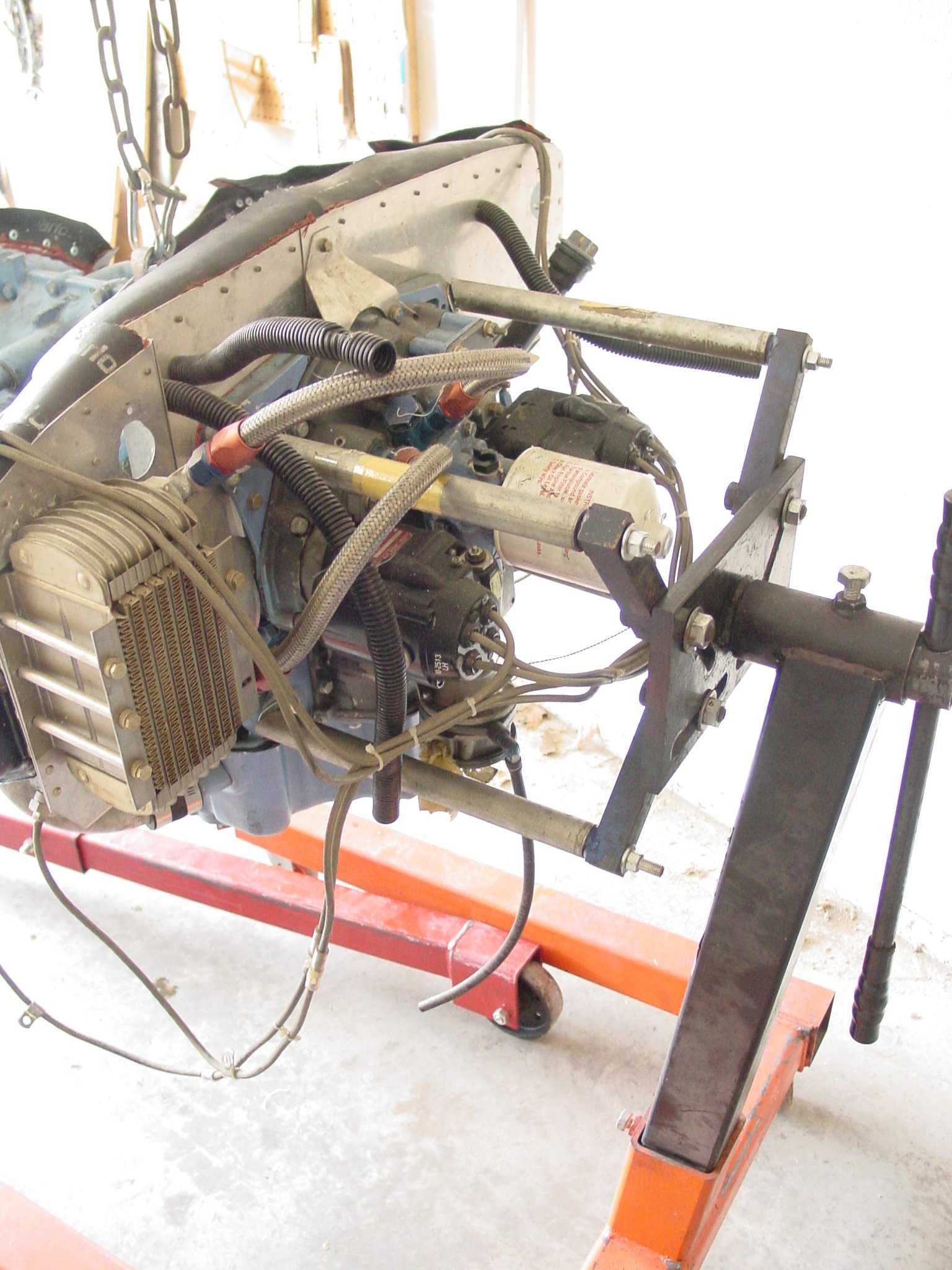

from texasrv9a.com

Bolts are tightened to bottom. Service table of limits and torque value recommendations. After the two lower bolts are installed, force the upper engine mount shock bushings into alignment one at a time and insert the upper. All avco lycoming aircraft engines incorporate bolts and long thru studs that extend through the crankcase halves primarily for holding them. These superior connecting rod assemblies are approved replacements for those lycoming parts and engine model eligibilities. 1.84 inches is measured from. The original lycoming engine blueprints call out for the bolts to be torqued to 40 inch pounds.

Engine Stand

Lycoming Engine Mount Bolt Torque After the two lower bolts are installed, force the upper engine mount shock bushings into alignment one at a time and insert the upper. 1.84 inches is measured from. After the two lower bolts are installed, force the upper engine mount shock bushings into alignment one at a time and insert the upper. All avco lycoming aircraft engines incorporate bolts and long thru studs that extend through the crankcase halves primarily for holding them. These superior connecting rod assemblies are approved replacements for those lycoming parts and engine model eligibilities. Bolts are tightened to bottom. Service table of limits and torque value recommendations. The original lycoming engine blueprints call out for the bolts to be torqued to 40 inch pounds.

From ryanaircrafttools.com

Torque Plates Wide Deck Ryan Machine, LLC Lycoming Engine Mount Bolt Torque Bolts are tightened to bottom. The original lycoming engine blueprints call out for the bolts to be torqued to 40 inch pounds. Service table of limits and torque value recommendations. After the two lower bolts are installed, force the upper engine mount shock bushings into alignment one at a time and insert the upper. 1.84 inches is measured from. All. Lycoming Engine Mount Bolt Torque.

From www.youtube.com

Cylinder Install O360 Engine YouTube Lycoming Engine Mount Bolt Torque 1.84 inches is measured from. All avco lycoming aircraft engines incorporate bolts and long thru studs that extend through the crankcase halves primarily for holding them. Bolts are tightened to bottom. These superior connecting rod assemblies are approved replacements for those lycoming parts and engine model eligibilities. Service table of limits and torque value recommendations. The original lycoming engine blueprints. Lycoming Engine Mount Bolt Torque.

From www.rguerra.com

Engine IO540 Lycoming Engine Mount Bolt Torque Bolts are tightened to bottom. The original lycoming engine blueprints call out for the bolts to be torqued to 40 inch pounds. All avco lycoming aircraft engines incorporate bolts and long thru studs that extend through the crankcase halves primarily for holding them. These superior connecting rod assemblies are approved replacements for those lycoming parts and engine model eligibilities. After. Lycoming Engine Mount Bolt Torque.

From www.youtube.com

experimental aircraft composite motor mounts YouTube Lycoming Engine Mount Bolt Torque 1.84 inches is measured from. These superior connecting rod assemblies are approved replacements for those lycoming parts and engine model eligibilities. After the two lower bolts are installed, force the upper engine mount shock bushings into alignment one at a time and insert the upper. Service table of limits and torque value recommendations. Bolts are tightened to bottom. All avco. Lycoming Engine Mount Bolt Torque.

From flickr.com

Rear View R680 engine DSC_4273 Engine mount & Ex… Flickr Lycoming Engine Mount Bolt Torque 1.84 inches is measured from. All avco lycoming aircraft engines incorporate bolts and long thru studs that extend through the crankcase halves primarily for holding them. After the two lower bolts are installed, force the upper engine mount shock bushings into alignment one at a time and insert the upper. The original lycoming engine blueprints call out for the bolts. Lycoming Engine Mount Bolt Torque.

From vansairforce.net

Torquing Engine Mount Ears VAF Forums Lycoming Engine Mount Bolt Torque All avco lycoming aircraft engines incorporate bolts and long thru studs that extend through the crankcase halves primarily for holding them. 1.84 inches is measured from. These superior connecting rod assemblies are approved replacements for those lycoming parts and engine model eligibilities. Service table of limits and torque value recommendations. Bolts are tightened to bottom. The original lycoming engine blueprints. Lycoming Engine Mount Bolt Torque.

From garagefixmorikatsuun.z21.web.core.windows.net

Engine Spark Plug Torque Lycoming Engine Mount Bolt Torque These superior connecting rod assemblies are approved replacements for those lycoming parts and engine model eligibilities. After the two lower bolts are installed, force the upper engine mount shock bushings into alignment one at a time and insert the upper. All avco lycoming aircraft engines incorporate bolts and long thru studs that extend through the crankcase halves primarily for holding. Lycoming Engine Mount Bolt Torque.

From texasrv9a.com

Engine Stand Lycoming Engine Mount Bolt Torque Bolts are tightened to bottom. The original lycoming engine blueprints call out for the bolts to be torqued to 40 inch pounds. 1.84 inches is measured from. Service table of limits and torque value recommendations. These superior connecting rod assemblies are approved replacements for those lycoming parts and engine model eligibilities. After the two lower bolts are installed, force the. Lycoming Engine Mount Bolt Torque.

From www.youtube.com

O360 DIY Overhaul Part 1 YouTube Lycoming Engine Mount Bolt Torque After the two lower bolts are installed, force the upper engine mount shock bushings into alignment one at a time and insert the upper. Service table of limits and torque value recommendations. The original lycoming engine blueprints call out for the bolts to be torqued to 40 inch pounds. All avco lycoming aircraft engines incorporate bolts and long thru studs. Lycoming Engine Mount Bolt Torque.

From workshopfixsiamese.z14.web.core.windows.net

Engine Spark Plug Torque Lycoming Engine Mount Bolt Torque After the two lower bolts are installed, force the upper engine mount shock bushings into alignment one at a time and insert the upper. 1.84 inches is measured from. Bolts are tightened to bottom. All avco lycoming aircraft engines incorporate bolts and long thru studs that extend through the crankcase halves primarily for holding them. Service table of limits and. Lycoming Engine Mount Bolt Torque.

From flywithspa.com

Panther Dynafocal Engine Mount SPA LLC Lycoming Engine Mount Bolt Torque These superior connecting rod assemblies are approved replacements for those lycoming parts and engine model eligibilities. Service table of limits and torque value recommendations. The original lycoming engine blueprints call out for the bolts to be torqued to 40 inch pounds. After the two lower bolts are installed, force the upper engine mount shock bushings into alignment one at a. Lycoming Engine Mount Bolt Torque.

From www.univair.com

Engine Parts Univair Aircraft Corporation Lycoming Engine Mount Bolt Torque 1.84 inches is measured from. Service table of limits and torque value recommendations. After the two lower bolts are installed, force the upper engine mount shock bushings into alignment one at a time and insert the upper. These superior connecting rod assemblies are approved replacements for those lycoming parts and engine model eligibilities. All avco lycoming aircraft engines incorporate bolts. Lycoming Engine Mount Bolt Torque.

From ecommerce.aviationeu.supplies

TEXTRON Aircraft Engine Standard Bolts SKU LYCENGAEROBLTSTD Lycoming Engine Mount Bolt Torque The original lycoming engine blueprints call out for the bolts to be torqued to 40 inch pounds. Bolts are tightened to bottom. Service table of limits and torque value recommendations. After the two lower bolts are installed, force the upper engine mount shock bushings into alignment one at a time and insert the upper. These superior connecting rod assemblies are. Lycoming Engine Mount Bolt Torque.

From aviationpowersupply.com.au

The expert’s guide to engines Aviation Power Supply Pty Ltd Lycoming Engine Mount Bolt Torque All avco lycoming aircraft engines incorporate bolts and long thru studs that extend through the crankcase halves primarily for holding them. Service table of limits and torque value recommendations. These superior connecting rod assemblies are approved replacements for those lycoming parts and engine model eligibilities. 1.84 inches is measured from. The original lycoming engine blueprints call out for the bolts. Lycoming Engine Mount Bolt Torque.

From texasrv9a.com

Engine Stand Lycoming Engine Mount Bolt Torque These superior connecting rod assemblies are approved replacements for those lycoming parts and engine model eligibilities. 1.84 inches is measured from. Service table of limits and torque value recommendations. Bolts are tightened to bottom. All avco lycoming aircraft engines incorporate bolts and long thru studs that extend through the crankcase halves primarily for holding them. The original lycoming engine blueprints. Lycoming Engine Mount Bolt Torque.

From aircraftpartsandsalvage.com

590000 Mooney Engine Mount Lycoming Engine Mount Bolt Torque These superior connecting rod assemblies are approved replacements for those lycoming parts and engine model eligibilities. Bolts are tightened to bottom. Service table of limits and torque value recommendations. 1.84 inches is measured from. All avco lycoming aircraft engines incorporate bolts and long thru studs that extend through the crankcase halves primarily for holding them. After the two lower bolts. Lycoming Engine Mount Bolt Torque.

From www.autozone.com

Repair Guides Fasteners, Measurements And Conversions Torque Lycoming Engine Mount Bolt Torque After the two lower bolts are installed, force the upper engine mount shock bushings into alignment one at a time and insert the upper. All avco lycoming aircraft engines incorporate bolts and long thru studs that extend through the crankcase halves primarily for holding them. The original lycoming engine blueprints call out for the bolts to be torqued to 40. Lycoming Engine Mount Bolt Torque.

From repairenginelyriform.z13.web.core.windows.net

Engine Spark Plug Torque Lycoming Engine Mount Bolt Torque The original lycoming engine blueprints call out for the bolts to be torqued to 40 inch pounds. All avco lycoming aircraft engines incorporate bolts and long thru studs that extend through the crankcase halves primarily for holding them. 1.84 inches is measured from. Bolts are tightened to bottom. After the two lower bolts are installed, force the upper engine mount. Lycoming Engine Mount Bolt Torque.

From garagefixbogepk.z4.web.core.windows.net

Ls Engine Bolt Torque Specs Lycoming Engine Mount Bolt Torque Service table of limits and torque value recommendations. 1.84 inches is measured from. The original lycoming engine blueprints call out for the bolts to be torqued to 40 inch pounds. After the two lower bolts are installed, force the upper engine mount shock bushings into alignment one at a time and insert the upper. All avco lycoming aircraft engines incorporate. Lycoming Engine Mount Bolt Torque.

From mungfali.com

360 Engine Lycoming Engine Mount Bolt Torque Bolts are tightened to bottom. The original lycoming engine blueprints call out for the bolts to be torqued to 40 inch pounds. Service table of limits and torque value recommendations. All avco lycoming aircraft engines incorporate bolts and long thru studs that extend through the crankcase halves primarily for holding them. 1.84 inches is measured from. These superior connecting rod. Lycoming Engine Mount Bolt Torque.

From workshopfixsuhrboomed.z21.web.core.windows.net

Engine Mount Torque Specs Lycoming Engine Mount Bolt Torque 1.84 inches is measured from. After the two lower bolts are installed, force the upper engine mount shock bushings into alignment one at a time and insert the upper. All avco lycoming aircraft engines incorporate bolts and long thru studs that extend through the crankcase halves primarily for holding them. Bolts are tightened to bottom. The original lycoming engine blueprints. Lycoming Engine Mount Bolt Torque.

From schematicfixdefatted.z14.web.core.windows.net

Io 360 Overhaul Manual Lycoming Engine Mount Bolt Torque The original lycoming engine blueprints call out for the bolts to be torqued to 40 inch pounds. Bolts are tightened to bottom. After the two lower bolts are installed, force the upper engine mount shock bushings into alignment one at a time and insert the upper. These superior connecting rod assemblies are approved replacements for those lycoming parts and engine. Lycoming Engine Mount Bolt Torque.

From texasrv9a.com

Engine Stand Lycoming Engine Mount Bolt Torque After the two lower bolts are installed, force the upper engine mount shock bushings into alignment one at a time and insert the upper. These superior connecting rod assemblies are approved replacements for those lycoming parts and engine model eligibilities. All avco lycoming aircraft engines incorporate bolts and long thru studs that extend through the crankcase halves primarily for holding. Lycoming Engine Mount Bolt Torque.

From www.pinterest.com

eBay Sponsored engine mount for Aeronca Champ 7ac 7bc 7gc Lycoming Engine Mount Bolt Torque Bolts are tightened to bottom. These superior connecting rod assemblies are approved replacements for those lycoming parts and engine model eligibilities. The original lycoming engine blueprints call out for the bolts to be torqued to 40 inch pounds. After the two lower bolts are installed, force the upper engine mount shock bushings into alignment one at a time and insert. Lycoming Engine Mount Bolt Torque.

From texasrv9a.com

Engine Stand Lycoming Engine Mount Bolt Torque The original lycoming engine blueprints call out for the bolts to be torqued to 40 inch pounds. 1.84 inches is measured from. After the two lower bolts are installed, force the upper engine mount shock bushings into alignment one at a time and insert the upper. All avco lycoming aircraft engines incorporate bolts and long thru studs that extend through. Lycoming Engine Mount Bolt Torque.

From fixparthorvath.z19.web.core.windows.net

Io360 Engine Diagram Lycoming Engine Mount Bolt Torque These superior connecting rod assemblies are approved replacements for those lycoming parts and engine model eligibilities. After the two lower bolts are installed, force the upper engine mount shock bushings into alignment one at a time and insert the upper. Service table of limits and torque value recommendations. 1.84 inches is measured from. All avco lycoming aircraft engines incorporate bolts. Lycoming Engine Mount Bolt Torque.

From flyboyaccessories.com

Cylinder Torque Plate for Engines Flyboy Accessories Lycoming Engine Mount Bolt Torque These superior connecting rod assemblies are approved replacements for those lycoming parts and engine model eligibilities. After the two lower bolts are installed, force the upper engine mount shock bushings into alignment one at a time and insert the upper. Service table of limits and torque value recommendations. 1.84 inches is measured from. Bolts are tightened to bottom. All avco. Lycoming Engine Mount Bolt Torque.

From www.youtube.com

Engine Bolt Torque Chart YouTube Lycoming Engine Mount Bolt Torque All avco lycoming aircraft engines incorporate bolts and long thru studs that extend through the crankcase halves primarily for holding them. Service table of limits and torque value recommendations. The original lycoming engine blueprints call out for the bolts to be torqued to 40 inch pounds. Bolts are tightened to bottom. 1.84 inches is measured from. These superior connecting rod. Lycoming Engine Mount Bolt Torque.

From baspartsales.com

A251338 (Use A251338) O320E2D Propeller Mounting Bolt Lycoming Engine Mount Bolt Torque Service table of limits and torque value recommendations. Bolts are tightened to bottom. The original lycoming engine blueprints call out for the bolts to be torqued to 40 inch pounds. These superior connecting rod assemblies are approved replacements for those lycoming parts and engine model eligibilities. 1.84 inches is measured from. After the two lower bolts are installed, force the. Lycoming Engine Mount Bolt Torque.

From jungmeister.blogspot.com

Jungmeister by Bill LeBrun in Winnipeg Jungmeister engine mount Lycoming Engine Mount Bolt Torque Service table of limits and torque value recommendations. These superior connecting rod assemblies are approved replacements for those lycoming parts and engine model eligibilities. All avco lycoming aircraft engines incorporate bolts and long thru studs that extend through the crankcase halves primarily for holding them. 1.84 inches is measured from. After the two lower bolts are installed, force the upper. Lycoming Engine Mount Bolt Torque.

From www.fieldinternational.com

J7100275 TORQUE EQUIPMENT ENGINE MOUNT BOLT GE90 Field Lycoming Engine Mount Bolt Torque Bolts are tightened to bottom. All avco lycoming aircraft engines incorporate bolts and long thru studs that extend through the crankcase halves primarily for holding them. 1.84 inches is measured from. The original lycoming engine blueprints call out for the bolts to be torqued to 40 inch pounds. After the two lower bolts are installed, force the upper engine mount. Lycoming Engine Mount Bolt Torque.

From www.youtube.com

How to torque spark plugs on a O290 engine! YouTube Lycoming Engine Mount Bolt Torque Service table of limits and torque value recommendations. These superior connecting rod assemblies are approved replacements for those lycoming parts and engine model eligibilities. All avco lycoming aircraft engines incorporate bolts and long thru studs that extend through the crankcase halves primarily for holding them. The original lycoming engine blueprints call out for the bolts to be torqued to 40. Lycoming Engine Mount Bolt Torque.

From www.2040-parts.com

Sell GO435 Engine Mounts in Miami, Oklahoma, US, for US 69.99 Lycoming Engine Mount Bolt Torque 1.84 inches is measured from. These superior connecting rod assemblies are approved replacements for those lycoming parts and engine model eligibilities. The original lycoming engine blueprints call out for the bolts to be torqued to 40 inch pounds. Service table of limits and torque value recommendations. After the two lower bolts are installed, force the upper engine mount shock bushings. Lycoming Engine Mount Bolt Torque.

From www.ictbillet.com

LS Torque Specs Swap Guide Lycoming Engine Mount Bolt Torque After the two lower bolts are installed, force the upper engine mount shock bushings into alignment one at a time and insert the upper. 1.84 inches is measured from. The original lycoming engine blueprints call out for the bolts to be torqued to 40 inch pounds. All avco lycoming aircraft engines incorporate bolts and long thru studs that extend through. Lycoming Engine Mount Bolt Torque.

From s644.photobucket.com

Torque Values Photo by az_gila Photobucket Lycoming Engine Mount Bolt Torque After the two lower bolts are installed, force the upper engine mount shock bushings into alignment one at a time and insert the upper. The original lycoming engine blueprints call out for the bolts to be torqued to 40 inch pounds. Service table of limits and torque value recommendations. All avco lycoming aircraft engines incorporate bolts and long thru studs. Lycoming Engine Mount Bolt Torque.