Roller Bearings Analysis . Dimensional deviations in the cage pocket of a roller bearing can significantly affect the bearing’s dynamic performance, directly. With broad and deep expertise in material science and tribology, we’ve developed this guide to help you identify and analyze bearing damage,. It will help to determine if the bearing can be a candidate for. This guide will assist you in the initial diagnosis of the bearing condition. To judge the causes of failure, sufficient knowledge and experience in bearings and lubricants and a good understanding of the. Clean parts and record the manufacturers’ information from markings on the bearing rings (part number, serial number, date code). Bearing failure analysis the purpose of inspecting damaged bearings and their mating parts is to determine the probable causes of the damage. Whether you are interested in the mathematics behind the empirical values or methods for estimating the effects of complex stresses on fatigue endurance, rolling.

from bearing-analysis.info

Whether you are interested in the mathematics behind the empirical values or methods for estimating the effects of complex stresses on fatigue endurance, rolling. Bearing failure analysis the purpose of inspecting damaged bearings and their mating parts is to determine the probable causes of the damage. To judge the causes of failure, sufficient knowledge and experience in bearings and lubricants and a good understanding of the. With broad and deep expertise in material science and tribology, we’ve developed this guide to help you identify and analyze bearing damage,. Dimensional deviations in the cage pocket of a roller bearing can significantly affect the bearing’s dynamic performance, directly. It will help to determine if the bearing can be a candidate for. This guide will assist you in the initial diagnosis of the bearing condition. Clean parts and record the manufacturers’ information from markings on the bearing rings (part number, serial number, date code).

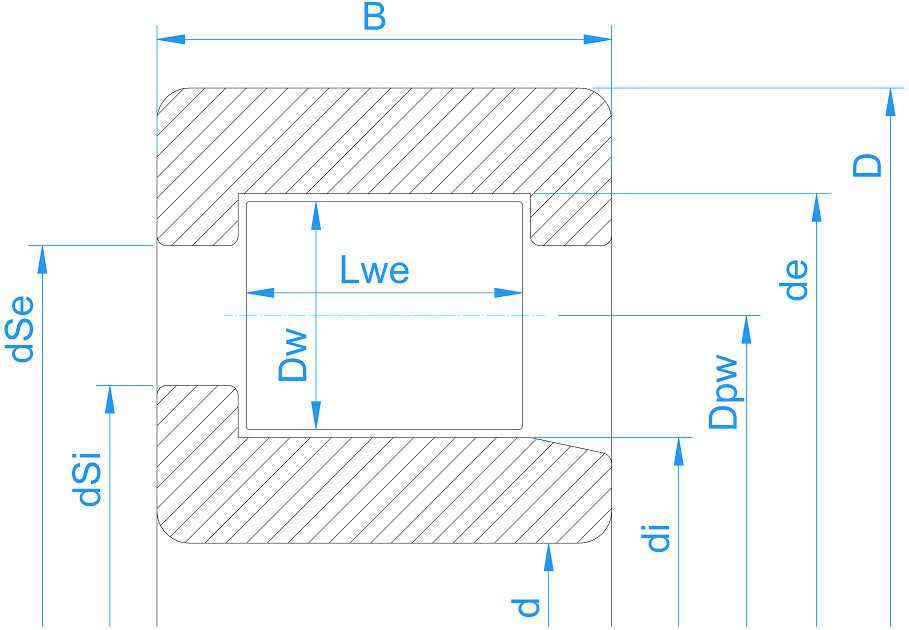

Bearing analysis Radial roller bearings

Roller Bearings Analysis Clean parts and record the manufacturers’ information from markings on the bearing rings (part number, serial number, date code). With broad and deep expertise in material science and tribology, we’ve developed this guide to help you identify and analyze bearing damage,. It will help to determine if the bearing can be a candidate for. This guide will assist you in the initial diagnosis of the bearing condition. Whether you are interested in the mathematics behind the empirical values or methods for estimating the effects of complex stresses on fatigue endurance, rolling. Bearing failure analysis the purpose of inspecting damaged bearings and their mating parts is to determine the probable causes of the damage. Clean parts and record the manufacturers’ information from markings on the bearing rings (part number, serial number, date code). To judge the causes of failure, sufficient knowledge and experience in bearings and lubricants and a good understanding of the. Dimensional deviations in the cage pocket of a roller bearing can significantly affect the bearing’s dynamic performance, directly.

From bearing-analysis.info

Bearing analysis Radial roller bearings Roller Bearings Analysis Dimensional deviations in the cage pocket of a roller bearing can significantly affect the bearing’s dynamic performance, directly. Bearing failure analysis the purpose of inspecting damaged bearings and their mating parts is to determine the probable causes of the damage. It will help to determine if the bearing can be a candidate for. With broad and deep expertise in material. Roller Bearings Analysis.

From bearing-analysis.info

Bearing analysis Radial roller bearings Roller Bearings Analysis Whether you are interested in the mathematics behind the empirical values or methods for estimating the effects of complex stresses on fatigue endurance, rolling. With broad and deep expertise in material science and tribology, we’ve developed this guide to help you identify and analyze bearing damage,. Dimensional deviations in the cage pocket of a roller bearing can significantly affect the. Roller Bearings Analysis.

From www.maintenanceworld.com

Setting Techniques for Tapered Roller Bearings Maintenance Roller Bearings Analysis This guide will assist you in the initial diagnosis of the bearing condition. With broad and deep expertise in material science and tribology, we’ve developed this guide to help you identify and analyze bearing damage,. It will help to determine if the bearing can be a candidate for. Bearing failure analysis the purpose of inspecting damaged bearings and their mating. Roller Bearings Analysis.

From bearing-analysis.info

Bearing analysis Radial roller bearings Roller Bearings Analysis Whether you are interested in the mathematics behind the empirical values or methods for estimating the effects of complex stresses on fatigue endurance, rolling. Clean parts and record the manufacturers’ information from markings on the bearing rings (part number, serial number, date code). This guide will assist you in the initial diagnosis of the bearing condition. Bearing failure analysis the. Roller Bearings Analysis.

From www.youtube.com

Bearing Damage Analysis for Tapered Roller Bearings YouTube Roller Bearings Analysis Dimensional deviations in the cage pocket of a roller bearing can significantly affect the bearing’s dynamic performance, directly. This guide will assist you in the initial diagnosis of the bearing condition. Bearing failure analysis the purpose of inspecting damaged bearings and their mating parts is to determine the probable causes of the damage. Whether you are interested in the mathematics. Roller Bearings Analysis.

From www.youtube.com

TUTORIAL 9 FINITE ELEMENT ANALYSIS of a Roller bearing under load Roller Bearings Analysis It will help to determine if the bearing can be a candidate for. Dimensional deviations in the cage pocket of a roller bearing can significantly affect the bearing’s dynamic performance, directly. This guide will assist you in the initial diagnosis of the bearing condition. To judge the causes of failure, sufficient knowledge and experience in bearings and lubricants and a. Roller Bearings Analysis.

From www.youtube.com

Bearing Damage Analysis for Tapered Roller Bearings l SLS Partner Roller Bearings Analysis This guide will assist you in the initial diagnosis of the bearing condition. Bearing failure analysis the purpose of inspecting damaged bearings and their mating parts is to determine the probable causes of the damage. Clean parts and record the manufacturers’ information from markings on the bearing rings (part number, serial number, date code). It will help to determine if. Roller Bearings Analysis.

From www.researchgate.net

Sectional view of a cylindrical roller bearing. Download Scientific Roller Bearings Analysis To judge the causes of failure, sufficient knowledge and experience in bearings and lubricants and a good understanding of the. With broad and deep expertise in material science and tribology, we’ve developed this guide to help you identify and analyze bearing damage,. It will help to determine if the bearing can be a candidate for. Bearing failure analysis the purpose. Roller Bearings Analysis.

From iskbearing.com

InDepth Analysis of Thrust Roller Bearings ISK BEARINGS Roller Bearings Analysis To judge the causes of failure, sufficient knowledge and experience in bearings and lubricants and a good understanding of the. With broad and deep expertise in material science and tribology, we’ve developed this guide to help you identify and analyze bearing damage,. It will help to determine if the bearing can be a candidate for. Bearing failure analysis the purpose. Roller Bearings Analysis.

From www.researchgate.net

(PDF) Thermal NonNewtonian EHL Analysis of RibRoller End Contact in Roller Bearings Analysis Bearing failure analysis the purpose of inspecting damaged bearings and their mating parts is to determine the probable causes of the damage. This guide will assist you in the initial diagnosis of the bearing condition. Clean parts and record the manufacturers’ information from markings on the bearing rings (part number, serial number, date code). Whether you are interested in the. Roller Bearings Analysis.

From empoweringpumps.com

Tips for Examining Rolling Element Bearings Prepping for a Root Cause Roller Bearings Analysis This guide will assist you in the initial diagnosis of the bearing condition. With broad and deep expertise in material science and tribology, we’ve developed this guide to help you identify and analyze bearing damage,. Bearing failure analysis the purpose of inspecting damaged bearings and their mating parts is to determine the probable causes of the damage. To judge the. Roller Bearings Analysis.

From www.simscale.com

Static Roller Bearing Analysis Project Spotlight SimScale CAE Forum Roller Bearings Analysis Clean parts and record the manufacturers’ information from markings on the bearing rings (part number, serial number, date code). With broad and deep expertise in material science and tribology, we’ve developed this guide to help you identify and analyze bearing damage,. It will help to determine if the bearing can be a candidate for. Dimensional deviations in the cage pocket. Roller Bearings Analysis.

From www.mdpi.com

Lubricants Free FullText An Investigation for the Friction Torque Roller Bearings Analysis This guide will assist you in the initial diagnosis of the bearing condition. Bearing failure analysis the purpose of inspecting damaged bearings and their mating parts is to determine the probable causes of the damage. With broad and deep expertise in material science and tribology, we’ve developed this guide to help you identify and analyze bearing damage,. To judge the. Roller Bearings Analysis.

From necyberteam.org

Bearing Condition Monitoring using Machine Learning Northeast Cyberteam Roller Bearings Analysis This guide will assist you in the initial diagnosis of the bearing condition. It will help to determine if the bearing can be a candidate for. To judge the causes of failure, sufficient knowledge and experience in bearings and lubricants and a good understanding of the. Whether you are interested in the mathematics behind the empirical values or methods for. Roller Bearings Analysis.

From bearing-analysis.info

Bearing analysis Radial roller bearings Roller Bearings Analysis With broad and deep expertise in material science and tribology, we’ve developed this guide to help you identify and analyze bearing damage,. It will help to determine if the bearing can be a candidate for. To judge the causes of failure, sufficient knowledge and experience in bearings and lubricants and a good understanding of the. Dimensional deviations in the cage. Roller Bearings Analysis.

From www.mdpi.com

Applied Sciences Free FullText Study on the Thermal Performance Roller Bearings Analysis To judge the causes of failure, sufficient knowledge and experience in bearings and lubricants and a good understanding of the. It will help to determine if the bearing can be a candidate for. With broad and deep expertise in material science and tribology, we’ve developed this guide to help you identify and analyze bearing damage,. Clean parts and record the. Roller Bearings Analysis.

From www.simscale.com

Roller bearing Dynamic analysis Solid Mechanics / FEA SimScale Roller Bearings Analysis With broad and deep expertise in material science and tribology, we’ve developed this guide to help you identify and analyze bearing damage,. To judge the causes of failure, sufficient knowledge and experience in bearings and lubricants and a good understanding of the. Dimensional deviations in the cage pocket of a roller bearing can significantly affect the bearing’s dynamic performance, directly.. Roller Bearings Analysis.

From www.researchgate.net

(PDF) Thermal Modeling of a Railroad TaperedRoller Bearing Using Roller Bearings Analysis Bearing failure analysis the purpose of inspecting damaged bearings and their mating parts is to determine the probable causes of the damage. Clean parts and record the manufacturers’ information from markings on the bearing rings (part number, serial number, date code). To judge the causes of failure, sufficient knowledge and experience in bearings and lubricants and a good understanding of. Roller Bearings Analysis.

From www.mdpi.com

Lubricants Free FullText Mixed Lubrication Analysis of Tapered Roller Bearings Analysis Dimensional deviations in the cage pocket of a roller bearing can significantly affect the bearing’s dynamic performance, directly. Clean parts and record the manufacturers’ information from markings on the bearing rings (part number, serial number, date code). Whether you are interested in the mathematics behind the empirical values or methods for estimating the effects of complex stresses on fatigue endurance,. Roller Bearings Analysis.

From www.scientific.net

Failure Analysis of Spherical Roller Bearing Roller Bearings Analysis This guide will assist you in the initial diagnosis of the bearing condition. To judge the causes of failure, sufficient knowledge and experience in bearings and lubricants and a good understanding of the. Dimensional deviations in the cage pocket of a roller bearing can significantly affect the bearing’s dynamic performance, directly. Clean parts and record the manufacturers’ information from markings. Roller Bearings Analysis.

From www.researchgate.net

Force analysis of the doublerow selfaligning ball bearing. Download Roller Bearings Analysis Clean parts and record the manufacturers’ information from markings on the bearing rings (part number, serial number, date code). With broad and deep expertise in material science and tribology, we’ve developed this guide to help you identify and analyze bearing damage,. Dimensional deviations in the cage pocket of a roller bearing can significantly affect the bearing’s dynamic performance, directly. It. Roller Bearings Analysis.

From www.slideserve.com

PPT Engine Bearings PowerPoint Presentation, free download ID164107 Roller Bearings Analysis Whether you are interested in the mathematics behind the empirical values or methods for estimating the effects of complex stresses on fatigue endurance, rolling. Bearing failure analysis the purpose of inspecting damaged bearings and their mating parts is to determine the probable causes of the damage. To judge the causes of failure, sufficient knowledge and experience in bearings and lubricants. Roller Bearings Analysis.

From www.youtube.com

Spherical roller bearing analysis YouTube Roller Bearings Analysis Clean parts and record the manufacturers’ information from markings on the bearing rings (part number, serial number, date code). It will help to determine if the bearing can be a candidate for. This guide will assist you in the initial diagnosis of the bearing condition. With broad and deep expertise in material science and tribology, we’ve developed this guide to. Roller Bearings Analysis.

From www.power-mi.com

Rolling element bearing components and failing frequencies PowerMI Roller Bearings Analysis To judge the causes of failure, sufficient knowledge and experience in bearings and lubricants and a good understanding of the. It will help to determine if the bearing can be a candidate for. With broad and deep expertise in material science and tribology, we’ve developed this guide to help you identify and analyze bearing damage,. This guide will assist you. Roller Bearings Analysis.

From www.youtube.com

SKF32306 Taper Roller Bearing Analysis in Ansys YouTube Roller Bearings Analysis It will help to determine if the bearing can be a candidate for. Bearing failure analysis the purpose of inspecting damaged bearings and their mating parts is to determine the probable causes of the damage. Clean parts and record the manufacturers’ information from markings on the bearing rings (part number, serial number, date code). With broad and deep expertise in. Roller Bearings Analysis.

From koyo.jtekt.co.jp

Calculation of loads Basic Bearing Knowledge Koyo Bearings /JTEKT Roller Bearings Analysis It will help to determine if the bearing can be a candidate for. With broad and deep expertise in material science and tribology, we’ve developed this guide to help you identify and analyze bearing damage,. Bearing failure analysis the purpose of inspecting damaged bearings and their mating parts is to determine the probable causes of the damage. This guide will. Roller Bearings Analysis.

From www.power-mi.com

Rolling element bearing components and failing frequencies PowerMI Roller Bearings Analysis This guide will assist you in the initial diagnosis of the bearing condition. Clean parts and record the manufacturers’ information from markings on the bearing rings (part number, serial number, date code). It will help to determine if the bearing can be a candidate for. Dimensional deviations in the cage pocket of a roller bearing can significantly affect the bearing’s. Roller Bearings Analysis.

From www.scribd.com

Analysis of Rolling Bearing Macrogeometry Parameters for Ball Bearings Roller Bearings Analysis It will help to determine if the bearing can be a candidate for. To judge the causes of failure, sufficient knowledge and experience in bearings and lubricants and a good understanding of the. Whether you are interested in the mathematics behind the empirical values or methods for estimating the effects of complex stresses on fatigue endurance, rolling. Bearing failure analysis. Roller Bearings Analysis.

From www.researchgate.net

Comprehensive stiffness analysis of cylindrical roller bearing under Roller Bearings Analysis It will help to determine if the bearing can be a candidate for. Bearing failure analysis the purpose of inspecting damaged bearings and their mating parts is to determine the probable causes of the damage. Dimensional deviations in the cage pocket of a roller bearing can significantly affect the bearing’s dynamic performance, directly. This guide will assist you in the. Roller Bearings Analysis.

From bearing-analysis.info

Bearing analysis Radial roller bearings Roller Bearings Analysis With broad and deep expertise in material science and tribology, we’ve developed this guide to help you identify and analyze bearing damage,. It will help to determine if the bearing can be a candidate for. This guide will assist you in the initial diagnosis of the bearing condition. Clean parts and record the manufacturers’ information from markings on the bearing. Roller Bearings Analysis.

From www.researchgate.net

(PDF) Thermal EHL analysis of the inner ring rib and roller end in Roller Bearings Analysis Clean parts and record the manufacturers’ information from markings on the bearing rings (part number, serial number, date code). Bearing failure analysis the purpose of inspecting damaged bearings and their mating parts is to determine the probable causes of the damage. Whether you are interested in the mathematics behind the empirical values or methods for estimating the effects of complex. Roller Bearings Analysis.

From maintenanceworld.com

Setting Techniques for Tapered Roller Bearings Maintenance World Roller Bearings Analysis To judge the causes of failure, sufficient knowledge and experience in bearings and lubricants and a good understanding of the. It will help to determine if the bearing can be a candidate for. This guide will assist you in the initial diagnosis of the bearing condition. Bearing failure analysis the purpose of inspecting damaged bearings and their mating parts is. Roller Bearings Analysis.

From bearing-analysis.info

Bearing analysis Information about rolling bearing analysis and Roller Bearings Analysis It will help to determine if the bearing can be a candidate for. Bearing failure analysis the purpose of inspecting damaged bearings and their mating parts is to determine the probable causes of the damage. Dimensional deviations in the cage pocket of a roller bearing can significantly affect the bearing’s dynamic performance, directly. Clean parts and record the manufacturers’ information. Roller Bearings Analysis.

From bearing-analysis.info

Bearing analysis Radial roller bearings Roller Bearings Analysis Dimensional deviations in the cage pocket of a roller bearing can significantly affect the bearing’s dynamic performance, directly. Bearing failure analysis the purpose of inspecting damaged bearings and their mating parts is to determine the probable causes of the damage. This guide will assist you in the initial diagnosis of the bearing condition. It will help to determine if the. Roller Bearings Analysis.

From www.scribd.com

Bearing Failure Analysis PDF Roller Bearings Analysis It will help to determine if the bearing can be a candidate for. To judge the causes of failure, sufficient knowledge and experience in bearings and lubricants and a good understanding of the. Whether you are interested in the mathematics behind the empirical values or methods for estimating the effects of complex stresses on fatigue endurance, rolling. Dimensional deviations in. Roller Bearings Analysis.