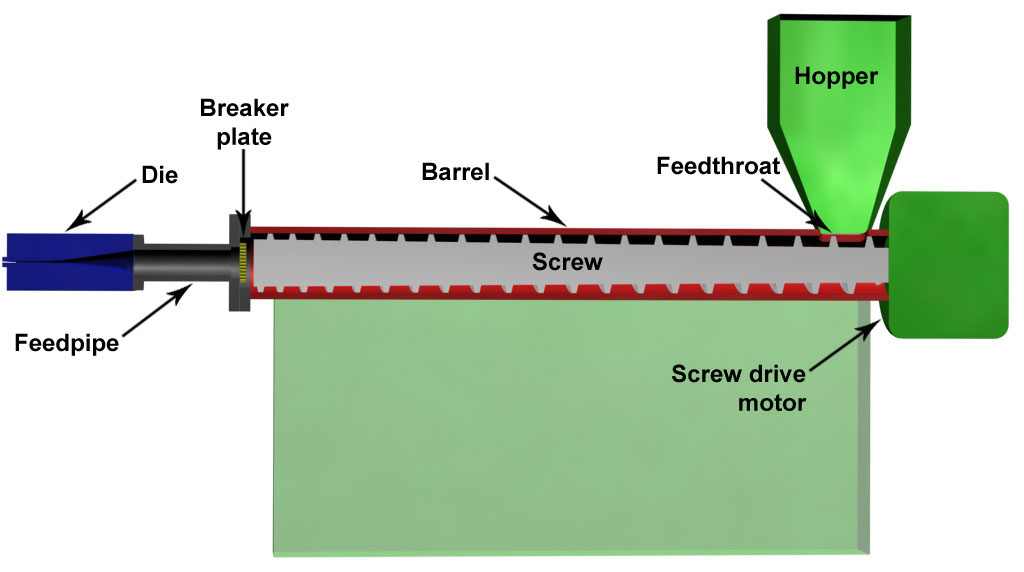

Plastic Extrusion Process Steps . The process involves melting plastic, shaping it, and then cooling it. However, it can be summed up in just five steps. First, raw plastic pellets or granules will be poured and stored in a hopper—the material will depend on what you’re. Raw plastic materials like granules, pellets, or powder are loaded into a. By understanding each step of the process—melting, shaping, cooling, and finishing—along with the properties of various. Regardless of the type of plastic extrusion, the process involves four key steps: Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. Plastic pellet selection, heating and melting, shaping through the die, and cooling.

from www.opusplastics.com

Plastic pellet selection, heating and melting, shaping through the die, and cooling. Raw plastic materials like granules, pellets, or powder are loaded into a. The process involves melting plastic, shaping it, and then cooling it. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. By understanding each step of the process—melting, shaping, cooling, and finishing—along with the properties of various. First, raw plastic pellets or granules will be poured and stored in a hopper—the material will depend on what you’re. Regardless of the type of plastic extrusion, the process involves four key steps: However, it can be summed up in just five steps.

What is Plastic Extrusion? Process Guide Opus Plastics

Plastic Extrusion Process Steps First, raw plastic pellets or granules will be poured and stored in a hopper—the material will depend on what you’re. Regardless of the type of plastic extrusion, the process involves four key steps: By understanding each step of the process—melting, shaping, cooling, and finishing—along with the properties of various. The process involves melting plastic, shaping it, and then cooling it. Plastic pellet selection, heating and melting, shaping through the die, and cooling. However, it can be summed up in just five steps. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. Raw plastic materials like granules, pellets, or powder are loaded into a. First, raw plastic pellets or granules will be poured and stored in a hopper—the material will depend on what you’re.

From mavink.com

Extrusion Processing Plastic Extrusion Process Steps First, raw plastic pellets or granules will be poured and stored in a hopper—the material will depend on what you’re. By understanding each step of the process—melting, shaping, cooling, and finishing—along with the properties of various. Regardless of the type of plastic extrusion, the process involves four key steps: The process involves melting plastic, shaping it, and then cooling it.. Plastic Extrusion Process Steps.

From www.bausano.com

Plastic Extrusion Process What it is and Function Bausano Plastic Extrusion Process Steps Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. Regardless of the type of plastic extrusion, the process involves four key steps: The process involves melting plastic, shaping it, and then cooling it. However, it can be summed up in just five steps. Plastic pellet selection, heating. Plastic Extrusion Process Steps.

From www.xometry.com

All About Plastic Extrusion Xometry Plastic Extrusion Process Steps First, raw plastic pellets or granules will be poured and stored in a hopper—the material will depend on what you’re. However, it can be summed up in just five steps. By understanding each step of the process—melting, shaping, cooling, and finishing—along with the properties of various. Regardless of the type of plastic extrusion, the process involves four key steps: The. Plastic Extrusion Process Steps.

From pubs.rsc.org

Expanding plastics recycling technologies chemical aspects, technology status and challenges Plastic Extrusion Process Steps The process involves melting plastic, shaping it, and then cooling it. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. By understanding each step of the process—melting, shaping, cooling, and finishing—along with the properties of various. Regardless of the type of plastic extrusion, the process involves four. Plastic Extrusion Process Steps.

From www.iqsdirectory.com

Plastic Trim Types, Extrusion Methods, Applications, and Benefits Plastic Extrusion Process Steps The process involves melting plastic, shaping it, and then cooling it. First, raw plastic pellets or granules will be poured and stored in a hopper—the material will depend on what you’re. Regardless of the type of plastic extrusion, the process involves four key steps: However, it can be summed up in just five steps. Raw plastic materials like granules, pellets,. Plastic Extrusion Process Steps.

From seashorerubber.com

Plastic Extrusion Process Definitive Guide Plastic Extrusion Process Steps The process involves melting plastic, shaping it, and then cooling it. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. First, raw plastic pellets or granules will be poured and stored in a hopper—the material will depend on what you’re. However, it can be summed up in. Plastic Extrusion Process Steps.

From www.rainbowbelts.com

What Is The Profile Extrusion Process? Plastic Extrusion Process Steps Plastic pellet selection, heating and melting, shaping through the die, and cooling. The process involves melting plastic, shaping it, and then cooling it. By understanding each step of the process—melting, shaping, cooling, and finishing—along with the properties of various. First, raw plastic pellets or granules will be poured and stored in a hopper—the material will depend on what you’re. However,. Plastic Extrusion Process Steps.

From www.weetect.com

Polycarbonate Extrusion A Complete Guide Wee Tect Plastic Extrusion Process Steps First, raw plastic pellets or granules will be poured and stored in a hopper—the material will depend on what you’re. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. Plastic pellet selection, heating and melting, shaping through the die, and cooling. Raw plastic materials like granules, pellets,. Plastic Extrusion Process Steps.

From resource.download.wjec.co.uk.s3.amazonaws.com

Design and Technology Plastic Extrusion Process Steps Regardless of the type of plastic extrusion, the process involves four key steps: First, raw plastic pellets or granules will be poured and stored in a hopper—the material will depend on what you’re. However, it can be summed up in just five steps. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder. Plastic Extrusion Process Steps.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process Plastic Extrusion Process Steps By understanding each step of the process—melting, shaping, cooling, and finishing—along with the properties of various. The process involves melting plastic, shaping it, and then cooling it. Regardless of the type of plastic extrusion, the process involves four key steps: Raw plastic materials like granules, pellets, or powder are loaded into a. However, it can be summed up in just. Plastic Extrusion Process Steps.

From fabacademy.org

Plastic Extrusion Process Steps Plastic pellet selection, heating and melting, shaping through the die, and cooling. First, raw plastic pellets or granules will be poured and stored in a hopper—the material will depend on what you’re. By understanding each step of the process—melting, shaping, cooling, and finishing—along with the properties of various. The process involves melting plastic, shaping it, and then cooling it. However,. Plastic Extrusion Process Steps.

From paulmurphyplastics.com

Ultimate Guide to The Plastic Extrusion Process • Paul Murphy Plastics Plastic Extrusion Process Steps The process involves melting plastic, shaping it, and then cooling it. Raw plastic materials like granules, pellets, or powder are loaded into a. First, raw plastic pellets or granules will be poured and stored in a hopper—the material will depend on what you’re. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder. Plastic Extrusion Process Steps.

From mechanicstips.blogspot.com

Plastic Extrusion MechanicsTips Plastic Extrusion Process Steps Raw plastic materials like granules, pellets, or powder are loaded into a. The process involves melting plastic, shaping it, and then cooling it. Plastic pellet selection, heating and melting, shaping through the die, and cooling. Regardless of the type of plastic extrusion, the process involves four key steps: First, raw plastic pellets or granules will be poured and stored in. Plastic Extrusion Process Steps.

From www.slideshare.net

Lec 3 Plastic Extrusion Process Steps First, raw plastic pellets or granules will be poured and stored in a hopper—the material will depend on what you’re. Regardless of the type of plastic extrusion, the process involves four key steps: Raw plastic materials like granules, pellets, or powder are loaded into a. Plastic pellet selection, heating and melting, shaping through the die, and cooling. However, it can. Plastic Extrusion Process Steps.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process Plastic Extrusion Process Steps However, it can be summed up in just five steps. Plastic pellet selection, heating and melting, shaping through the die, and cooling. Regardless of the type of plastic extrusion, the process involves four key steps: First, raw plastic pellets or granules will be poured and stored in a hopper—the material will depend on what you’re. The process involves melting plastic,. Plastic Extrusion Process Steps.

From www.prmmold.com

How Does Plastic Extrusion Work? Plastic Extrusion Process Steps Raw plastic materials like granules, pellets, or powder are loaded into a. By understanding each step of the process—melting, shaping, cooling, and finishing—along with the properties of various. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. However, it can be summed up in just five steps.. Plastic Extrusion Process Steps.

From xometry.eu

Plastic Extrusion Technology Overview Xometry Europe Plastic Extrusion Process Steps By understanding each step of the process—melting, shaping, cooling, and finishing—along with the properties of various. Raw plastic materials like granules, pellets, or powder are loaded into a. The process involves melting plastic, shaping it, and then cooling it. Plastic pellet selection, heating and melting, shaping through the die, and cooling. Plastic extrusion is a process where granular pieces of. Plastic Extrusion Process Steps.

From www.essaii.com

What is a plastic extrusion process in a stepbystep guide? Plastic Extrusion Process Steps By understanding each step of the process—melting, shaping, cooling, and finishing—along with the properties of various. The process involves melting plastic, shaping it, and then cooling it. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. First, raw plastic pellets or granules will be poured and stored. Plastic Extrusion Process Steps.

From hitechextrusions.com

Understanding the Extrusion Process A StepbyStep Guide Plastic Extrusion Process Steps The process involves melting plastic, shaping it, and then cooling it. By understanding each step of the process—melting, shaping, cooling, and finishing—along with the properties of various. First, raw plastic pellets or granules will be poured and stored in a hopper—the material will depend on what you’re. Plastic extrusion is a process where granular pieces of plastics go through different. Plastic Extrusion Process Steps.

From infotohow.com

The Ultimate Guide On The Plastic Extrusion Process InfoToHow Plastic Extrusion Process Steps Regardless of the type of plastic extrusion, the process involves four key steps: The process involves melting plastic, shaping it, and then cooling it. By understanding each step of the process—melting, shaping, cooling, and finishing—along with the properties of various. However, it can be summed up in just five steps. Raw plastic materials like granules, pellets, or powder are loaded. Plastic Extrusion Process Steps.

From mavink.com

Plastic Extrusion Diagram Plastic Extrusion Process Steps By understanding each step of the process—melting, shaping, cooling, and finishing—along with the properties of various. Plastic pellet selection, heating and melting, shaping through the die, and cooling. The process involves melting plastic, shaping it, and then cooling it. Raw plastic materials like granules, pellets, or powder are loaded into a. Regardless of the type of plastic extrusion, the process. Plastic Extrusion Process Steps.

From www.scribd.com

Plastic Extrusion Process PDF Extrusion Process Engineering Plastic Extrusion Process Steps The process involves melting plastic, shaping it, and then cooling it. First, raw plastic pellets or granules will be poured and stored in a hopper—the material will depend on what you’re. Regardless of the type of plastic extrusion, the process involves four key steps: Plastic pellet selection, heating and melting, shaping through the die, and cooling. Plastic extrusion is a. Plastic Extrusion Process Steps.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process Plastic Extrusion Process Steps However, it can be summed up in just five steps. First, raw plastic pellets or granules will be poured and stored in a hopper—the material will depend on what you’re. Plastic pellet selection, heating and melting, shaping through the die, and cooling. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to. Plastic Extrusion Process Steps.

From www.opusplastics.com

What is Plastic Extrusion? Process Guide Opus Plastics Plastic Extrusion Process Steps Regardless of the type of plastic extrusion, the process involves four key steps: First, raw plastic pellets or granules will be poured and stored in a hopper—the material will depend on what you’re. The process involves melting plastic, shaping it, and then cooling it. By understanding each step of the process—melting, shaping, cooling, and finishing—along with the properties of various.. Plastic Extrusion Process Steps.

From infotohow.com

The Ultimate Guide On The Plastic Extrusion Process » InfoToHow Plastic Extrusion Process Steps Plastic pellet selection, heating and melting, shaping through the die, and cooling. First, raw plastic pellets or granules will be poured and stored in a hopper—the material will depend on what you’re. Regardless of the type of plastic extrusion, the process involves four key steps: By understanding each step of the process—melting, shaping, cooling, and finishing—along with the properties of. Plastic Extrusion Process Steps.

From www.slideserve.com

PPT Plastic Manufacturing Processes PowerPoint Presentation ID4176129 Plastic Extrusion Process Steps Regardless of the type of plastic extrusion, the process involves four key steps: By understanding each step of the process—melting, shaping, cooling, and finishing—along with the properties of various. First, raw plastic pellets or granules will be poured and stored in a hopper—the material will depend on what you’re. Plastic pellet selection, heating and melting, shaping through the die, and. Plastic Extrusion Process Steps.

From www.plasticmoulds.net

Various Plastic Molding Process Plastic Extrusion Process Steps By understanding each step of the process—melting, shaping, cooling, and finishing—along with the properties of various. Raw plastic materials like granules, pellets, or powder are loaded into a. The process involves melting plastic, shaping it, and then cooling it. However, it can be summed up in just five steps. First, raw plastic pellets or granules will be poured and stored. Plastic Extrusion Process Steps.

From www.rutlandplastics.co.uk

How does injection moulding work Rutland Plastics Plastic Extrusion Process Steps Raw plastic materials like granules, pellets, or powder are loaded into a. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. Regardless of the type of plastic extrusion, the process involves four key steps: The process involves melting plastic, shaping it, and then cooling it. However, it. Plastic Extrusion Process Steps.

From proleantech.com

Plastic Extrusion Process Overview, Benefits, Applications Plastic Extrusion Process Steps Plastic pellet selection, heating and melting, shaping through the die, and cooling. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. However, it can be summed up in just five steps. By understanding each step of the process—melting, shaping, cooling, and finishing—along with the properties of various.. Plastic Extrusion Process Steps.

From www.researchgate.net

2. Flow chart of the extrusion process. Download Scientific Diagram Plastic Extrusion Process Steps The process involves melting plastic, shaping it, and then cooling it. Raw plastic materials like granules, pellets, or powder are loaded into a. Plastic pellet selection, heating and melting, shaping through the die, and cooling. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. However, it can. Plastic Extrusion Process Steps.

From www.iqsdirectory.com

Plastic Rods Definition, Types, Applications, and Benefits Plastic Extrusion Process Steps Regardless of the type of plastic extrusion, the process involves four key steps: Raw plastic materials like granules, pellets, or powder are loaded into a. First, raw plastic pellets or granules will be poured and stored in a hopper—the material will depend on what you’re. The process involves melting plastic, shaping it, and then cooling it. Plastic pellet selection, heating. Plastic Extrusion Process Steps.

From www.extrudedplastics.com

Plastic Rod Manufacturers Plasic Rod Suppliers Plastic Extrusion Process Steps Raw plastic materials like granules, pellets, or powder are loaded into a. First, raw plastic pellets or granules will be poured and stored in a hopper—the material will depend on what you’re. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. By understanding each step of the. Plastic Extrusion Process Steps.

From www.wanhan-plastic.com

Cooling process of extrusion molding process Plastic Extrusion Process Steps By understanding each step of the process—melting, shaping, cooling, and finishing—along with the properties of various. The process involves melting plastic, shaping it, and then cooling it. Plastic pellet selection, heating and melting, shaping through the die, and cooling. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in. Plastic Extrusion Process Steps.

From plastic-extrusionmachines.com

Plastic Extrusion Machine Cost Factors and Pricing Explained Plastic Extrusion Machines Plastic Extrusion Process Steps Plastic pellet selection, heating and melting, shaping through the die, and cooling. Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a. Regardless of the type of plastic extrusion, the process involves four key steps: By understanding each step of the process—melting, shaping, cooling, and finishing—along with the. Plastic Extrusion Process Steps.

From www.oberk.com

Plastic Bottle Production What is Extrusion Blow Molding (EBM) Plastic Extrusion Process Steps Plastic pellet selection, heating and melting, shaping through the die, and cooling. However, it can be summed up in just five steps. First, raw plastic pellets or granules will be poured and stored in a hopper—the material will depend on what you’re. Raw plastic materials like granules, pellets, or powder are loaded into a. Regardless of the type of plastic. Plastic Extrusion Process Steps.