Cat C15 Cylinder Head Bolt Torque Sequence . In a numerical sequence, tighten bolts 1 through 26. Follow step 7 for the correct tightening procedure. Torque settings for the following: Proper torque sequencing ensures an even distribution of clamping force, which is essential for maintaining a reliable seal between the. 7.tighten the cylinder head bolts according to the following procedure: Bolts, nuts, plugs, fittings, and clamps. Install the cylinder head bolts. Head bolt, connecting rod bolt & main bearing bolt torque specifications. In a numerical sequence, tighten bolts 1 through 26 to a torque of 270 ±. Learn the correct torque sequence and specifications for tightening the cylinder head bolts on a cat c15 engine for optimal. By following these torque specifications and steps, you can ensure the proper assembly and sealing of the cylinder head on your cat c15. Install cylinder head bolts (1) and (2). The cylinder head of your engine is torqued to the following specifications. Exceptions to these torques are given in the service. Caterpillar® 3406a • 3406b • 3406c • 3406e • c15 cummins® isx •.

from mavink.com

Head bolt, connecting rod bolt & main bearing bolt torque specifications. Install the cylinder head bolts. Torque settings for the following: 7.tighten the cylinder head bolts according to the following procedure: Tighten the cylinder head bolts, as follows. In a numerical sequence, tighten bolts 1 through 26 to a torque of 270 ±. Install cylinder head bolts (1) and (2). Bolts, nuts, plugs, fittings, and clamps. Learn the correct torque sequence and specifications for tightening the cylinder head bolts on a cat c15 engine for optimal. In a numerical sequence, tighten bolts 1 through 26.

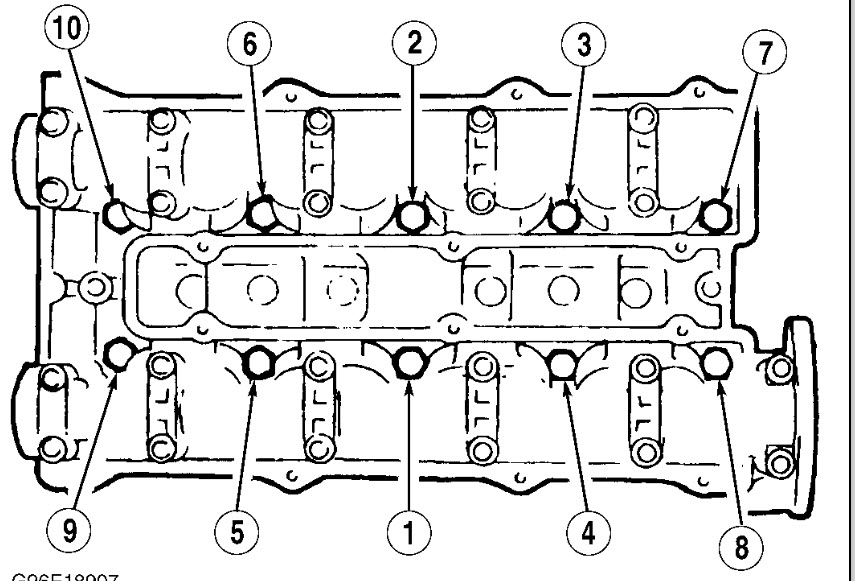

Cylinder Head Bolt Torque Chart

Cat C15 Cylinder Head Bolt Torque Sequence In a numerical sequence, tighten bolts 1 through 26 to a torque of 270 ±. Proper torque sequencing ensures an even distribution of clamping force, which is essential for maintaining a reliable seal between the. Learn the correct torque sequence and specifications for tightening the cylinder head bolts on a cat c15 engine for optimal. Caterpillar® 3406a • 3406b • 3406c • 3406e • c15 cummins® isx •. In a numerical sequence, tighten bolts 1 through 26 to a torque of 270 ±. In a numerical sequence, tighten bolts 1 through 26. Bolts, nuts, plugs, fittings, and clamps. Head bolt, connecting rod bolt & main bearing bolt torque specifications. The cylinder head of your engine is torqued to the following specifications. Install cylinder head bolts (1) and (2). By following these torque specifications and steps, you can ensure the proper assembly and sealing of the cylinder head on your cat c15. Tighten the cylinder head bolts, as follows. 7.tighten the cylinder head bolts according to the following procedure: Install the cylinder head bolts. Follow step 7 for the correct tightening procedure. Exceptions to these torques are given in the service.

From mavink.com

Cylinder Head Bolt Torque Chart Cat C15 Cylinder Head Bolt Torque Sequence Caterpillar® 3406a • 3406b • 3406c • 3406e • c15 cummins® isx •. Follow step 7 for the correct tightening procedure. Learn the correct torque sequence and specifications for tightening the cylinder head bolts on a cat c15 engine for optimal. In a numerical sequence, tighten bolts 1 through 26 to a torque of 270 ±. Exceptions to these torques. Cat C15 Cylinder Head Bolt Torque Sequence.

From help.summitracing.com

How do I install my LS cylinder heads? · Help Center Cat C15 Cylinder Head Bolt Torque Sequence Bolts, nuts, plugs, fittings, and clamps. By following these torque specifications and steps, you can ensure the proper assembly and sealing of the cylinder head on your cat c15. Install cylinder head bolts (1) and (2). In a numerical sequence, tighten bolts 1 through 26. Install the cylinder head bolts. Torque settings for the following: Head bolt, connecting rod bolt. Cat C15 Cylinder Head Bolt Torque Sequence.

From enginefixadrienne.z19.web.core.windows.net

Cat C15 6nz Bolt Torque Specs Cat C15 Cylinder Head Bolt Torque Sequence Install the cylinder head bolts. In a numerical sequence, tighten bolts 1 through 26. The cylinder head of your engine is torqued to the following specifications. Tighten the cylinder head bolts, as follows. 7.tighten the cylinder head bolts according to the following procedure: Head bolt, connecting rod bolt & main bearing bolt torque specifications. Exceptions to these torques are given. Cat C15 Cylinder Head Bolt Torque Sequence.

From www.youtube.com

Caterpillar C15 Cylinder Head Problems? HHP Can Help! YouTube Cat C15 Cylinder Head Bolt Torque Sequence In a numerical sequence, tighten bolts 1 through 26 to a torque of 270 ±. Torque settings for the following: Follow step 7 for the correct tightening procedure. Tighten the cylinder head bolts, as follows. 7.tighten the cylinder head bolts according to the following procedure: Exceptions to these torques are given in the service. Proper torque sequencing ensures an even. Cat C15 Cylinder Head Bolt Torque Sequence.

From mavink.com

Cylinder Head Bolt Torque Chart Cat C15 Cylinder Head Bolt Torque Sequence Torque settings for the following: 7.tighten the cylinder head bolts according to the following procedure: Head bolt, connecting rod bolt & main bearing bolt torque specifications. The cylinder head of your engine is torqued to the following specifications. Learn the correct torque sequence and specifications for tightening the cylinder head bolts on a cat c15 engine for optimal. Proper torque. Cat C15 Cylinder Head Bolt Torque Sequence.

From www.heavydutykits.com

Caterpillar C15 Cylinder Head / CAT C15 6NZ Cylinder Head Cat C15 Cylinder Head Bolt Torque Sequence Proper torque sequencing ensures an even distribution of clamping force, which is essential for maintaining a reliable seal between the. In a numerical sequence, tighten bolts 1 through 26. Head bolt, connecting rod bolt & main bearing bolt torque specifications. In a numerical sequence, tighten bolts 1 through 26 to a torque of 270 ±. Caterpillar® 3406a • 3406b •. Cat C15 Cylinder Head Bolt Torque Sequence.

From www.paylesstruckparts.com

Cat C15 Cylinder Head Payless Truck Parts Cat C15 Cylinder Head Bolt Torque Sequence Torque settings for the following: Bolts, nuts, plugs, fittings, and clamps. By following these torque specifications and steps, you can ensure the proper assembly and sealing of the cylinder head on your cat c15. Proper torque sequencing ensures an even distribution of clamping force, which is essential for maintaining a reliable seal between the. Follow step 7 for the correct. Cat C15 Cylinder Head Bolt Torque Sequence.

From www.2carpros.com

Torque Sequence for Head Bolts Needed Need to Know the Torque Cat C15 Cylinder Head Bolt Torque Sequence Install cylinder head bolts (1) and (2). Follow step 7 for the correct tightening procedure. 7.tighten the cylinder head bolts according to the following procedure: Learn the correct torque sequence and specifications for tightening the cylinder head bolts on a cat c15 engine for optimal. Exceptions to these torques are given in the service. Install the cylinder head bolts. Caterpillar®. Cat C15 Cylinder Head Bolt Torque Sequence.

From diagramfixpublicly.z14.web.core.windows.net

Cat C15 6nz Bolt Torque Specs Cat C15 Cylinder Head Bolt Torque Sequence The cylinder head of your engine is torqued to the following specifications. Tighten the cylinder head bolts, as follows. By following these torque specifications and steps, you can ensure the proper assembly and sealing of the cylinder head on your cat c15. Follow step 7 for the correct tightening procedure. Exceptions to these torques are given in the service. Caterpillar®. Cat C15 Cylinder Head Bolt Torque Sequence.

From constructionbulldozers.tpub.com

Figure 4. Cylinder Head Bolts Torque Sequence. Cat C15 Cylinder Head Bolt Torque Sequence Install cylinder head bolts (1) and (2). The cylinder head of your engine is torqued to the following specifications. Learn the correct torque sequence and specifications for tightening the cylinder head bolts on a cat c15 engine for optimal. Caterpillar® 3406a • 3406b • 3406c • 3406e • c15 cummins® isx •. Torque settings for the following: Install the cylinder. Cat C15 Cylinder Head Bolt Torque Sequence.

From motormission.com

Cat C15 3406E Diesel Cylinder Head Cleaning, Magnafluxing and Pressure Cat C15 Cylinder Head Bolt Torque Sequence Tighten the cylinder head bolts, as follows. Bolts, nuts, plugs, fittings, and clamps. The cylinder head of your engine is torqued to the following specifications. 7.tighten the cylinder head bolts according to the following procedure: Install cylinder head bolts (1) and (2). Exceptions to these torques are given in the service. Torque settings for the following: Learn the correct torque. Cat C15 Cylinder Head Bolt Torque Sequence.

From mavink.com

Cat C15 Head Bolt Torque Specs Cat C15 Cylinder Head Bolt Torque Sequence Follow step 7 for the correct tightening procedure. 7.tighten the cylinder head bolts according to the following procedure: Exceptions to these torques are given in the service. Install the cylinder head bolts. Torque settings for the following: Caterpillar® 3406a • 3406b • 3406c • 3406e • c15 cummins® isx •. Learn the correct torque sequence and specifications for tightening the. Cat C15 Cylinder Head Bolt Torque Sequence.

From guidedbterry.z21.web.core.windows.net

C15 6nz Cat Engine Torque Specs Cat C15 Cylinder Head Bolt Torque Sequence Install the cylinder head bolts. Head bolt, connecting rod bolt & main bearing bolt torque specifications. Proper torque sequencing ensures an even distribution of clamping force, which is essential for maintaining a reliable seal between the. Install cylinder head bolts (1) and (2). In a numerical sequence, tighten bolts 1 through 26 to a torque of 270 ±. Torque settings. Cat C15 Cylinder Head Bolt Torque Sequence.

From www.scribd.com

Caterpillar C15 Engine Specs Horsepower Torque Cat C15 Cylinder Head Bolt Torque Sequence 7.tighten the cylinder head bolts according to the following procedure: Install cylinder head bolts (1) and (2). Head bolt, connecting rod bolt & main bearing bolt torque specifications. Learn the correct torque sequence and specifications for tightening the cylinder head bolts on a cat c15 engine for optimal. By following these torque specifications and steps, you can ensure the proper. Cat C15 Cylinder Head Bolt Torque Sequence.

From www.hotzxgirl.com

Cat C C Cylinder Head Tightening Torque And Sequence Hot Sex Picture Cat C15 Cylinder Head Bolt Torque Sequence Exceptions to these torques are given in the service. The cylinder head of your engine is torqued to the following specifications. Torque settings for the following: In a numerical sequence, tighten bolts 1 through 26. 7.tighten the cylinder head bolts according to the following procedure: Proper torque sequencing ensures an even distribution of clamping force, which is essential for maintaining. Cat C15 Cylinder Head Bolt Torque Sequence.

From www.heavydutykits.com

Caterpillar C15 Cylinder Head / CAT C15 6NZ Cylinder Head Cat C15 Cylinder Head Bolt Torque Sequence Caterpillar® 3406a • 3406b • 3406c • 3406e • c15 cummins® isx •. In a numerical sequence, tighten bolts 1 through 26. Proper torque sequencing ensures an even distribution of clamping force, which is essential for maintaining a reliable seal between the. In a numerical sequence, tighten bolts 1 through 26 to a torque of 270 ±. By following these. Cat C15 Cylinder Head Bolt Torque Sequence.

From mungfali.com

Cylinder Head Torque Sequence Cat C15 Cylinder Head Bolt Torque Sequence Install the cylinder head bolts. Torque settings for the following: 7.tighten the cylinder head bolts according to the following procedure: Proper torque sequencing ensures an even distribution of clamping force, which is essential for maintaining a reliable seal between the. Caterpillar® 3406a • 3406b • 3406c • 3406e • c15 cummins® isx •. Exceptions to these torques are given in. Cat C15 Cylinder Head Bolt Torque Sequence.

From truckguider.com

Cat C15 Bolt Torque Specs Truck Guider Cat C15 Cylinder Head Bolt Torque Sequence The cylinder head of your engine is torqued to the following specifications. Follow step 7 for the correct tightening procedure. Proper torque sequencing ensures an even distribution of clamping force, which is essential for maintaining a reliable seal between the. Caterpillar® 3406a • 3406b • 3406c • 3406e • c15 cummins® isx •. Torque settings for the following: In a. Cat C15 Cylinder Head Bolt Torque Sequence.

From mavink.com

Cylinder Head Bolt Torque Chart Cat C15 Cylinder Head Bolt Torque Sequence Torque settings for the following: 7.tighten the cylinder head bolts according to the following procedure: Follow step 7 for the correct tightening procedure. In a numerical sequence, tighten bolts 1 through 26. The cylinder head of your engine is torqued to the following specifications. Head bolt, connecting rod bolt & main bearing bolt torque specifications. Learn the correct torque sequence. Cat C15 Cylinder Head Bolt Torque Sequence.

From www.youtube.com

Removing a Cat C15 Cylinder Head, Start To Finish. How To Remove A Cat Cat C15 Cylinder Head Bolt Torque Sequence Exceptions to these torques are given in the service. Caterpillar® 3406a • 3406b • 3406c • 3406e • c15 cummins® isx •. Learn the correct torque sequence and specifications for tightening the cylinder head bolts on a cat c15 engine for optimal. Torque settings for the following: Install the cylinder head bolts. Install cylinder head bolts (1) and (2). Tighten. Cat C15 Cylinder Head Bolt Torque Sequence.

From lite-cat.blogspot.com

Cat C15 Bolt Torque Specs Cat C15 Cylinder Head Bolt Torque Sequence Bolts, nuts, plugs, fittings, and clamps. Tighten the cylinder head bolts, as follows. Head bolt, connecting rod bolt & main bearing bolt torque specifications. Torque settings for the following: Install the cylinder head bolts. Caterpillar® 3406a • 3406b • 3406c • 3406e • c15 cummins® isx •. Exceptions to these torques are given in the service. Follow step 7 for. Cat C15 Cylinder Head Bolt Torque Sequence.

From swdieselpower.net

SW Diesel Power New Cylinder Head C15 Caterpillar Cat C15 Cylinder Head Bolt Torque Sequence In a numerical sequence, tighten bolts 1 through 26. 7.tighten the cylinder head bolts according to the following procedure: Head bolt, connecting rod bolt & main bearing bolt torque specifications. By following these torque specifications and steps, you can ensure the proper assembly and sealing of the cylinder head on your cat c15. In a numerical sequence, tighten bolts 1. Cat C15 Cylinder Head Bolt Torque Sequence.

From lite-cat.blogspot.com

Cat C15 Bolt Torque Specs Cat C15 Cylinder Head Bolt Torque Sequence Proper torque sequencing ensures an even distribution of clamping force, which is essential for maintaining a reliable seal between the. Tighten the cylinder head bolts, as follows. Caterpillar® 3406a • 3406b • 3406c • 3406e • c15 cummins® isx •. Install cylinder head bolts (1) and (2). Exceptions to these torques are given in the service. In a numerical sequence,. Cat C15 Cylinder Head Bolt Torque Sequence.

From guidelistutvenography.z5.web.core.windows.net

Cat 3406e Head Bolt Torque Cat C15 Cylinder Head Bolt Torque Sequence In a numerical sequence, tighten bolts 1 through 26. Install cylinder head bolts (1) and (2). Exceptions to these torques are given in the service. The cylinder head of your engine is torqued to the following specifications. Torque settings for the following: In a numerical sequence, tighten bolts 1 through 26 to a torque of 270 ±. Learn the correct. Cat C15 Cylinder Head Bolt Torque Sequence.

From www.paylesstruckparts.com

Cat C15 Cylinder Head Payless Truck Parts Cat C15 Cylinder Head Bolt Torque Sequence Exceptions to these torques are given in the service. Proper torque sequencing ensures an even distribution of clamping force, which is essential for maintaining a reliable seal between the. Learn the correct torque sequence and specifications for tightening the cylinder head bolts on a cat c15 engine for optimal. Follow step 7 for the correct tightening procedure. Tighten the cylinder. Cat C15 Cylinder Head Bolt Torque Sequence.

From www.sbmar.com

How to Torque a Cummins Marine CSeries Cylinder Head Seaboard Marine Cat C15 Cylinder Head Bolt Torque Sequence Install the cylinder head bolts. Torque settings for the following: The cylinder head of your engine is torqued to the following specifications. Follow step 7 for the correct tightening procedure. By following these torque specifications and steps, you can ensure the proper assembly and sealing of the cylinder head on your cat c15. In a numerical sequence, tighten bolts 1. Cat C15 Cylinder Head Bolt Torque Sequence.

From ch-part.com

C15 Onhighway Engine Caterpillar Cat C15 Cylinder Head Bolt Torque Sequence Exceptions to these torques are given in the service. Learn the correct torque sequence and specifications for tightening the cylinder head bolts on a cat c15 engine for optimal. Follow step 7 for the correct tightening procedure. Install cylinder head bolts (1) and (2). Head bolt, connecting rod bolt & main bearing bolt torque specifications. The cylinder head of your. Cat C15 Cylinder Head Bolt Torque Sequence.

From www.2carpros.com

Torque Setting for Cylinder Head Specs I Need to Know Torque Cat C15 Cylinder Head Bolt Torque Sequence Install cylinder head bolts (1) and (2). Bolts, nuts, plugs, fittings, and clamps. Proper torque sequencing ensures an even distribution of clamping force, which is essential for maintaining a reliable seal between the. Exceptions to these torques are given in the service. Learn the correct torque sequence and specifications for tightening the cylinder head bolts on a cat c15 engine. Cat C15 Cylinder Head Bolt Torque Sequence.

From www.heavydutykits.com

Caterpillar C15 Cylinder Head / CAT C15 6NZ Cylinder Head Cat C15 Cylinder Head Bolt Torque Sequence Torque settings for the following: Head bolt, connecting rod bolt & main bearing bolt torque specifications. Bolts, nuts, plugs, fittings, and clamps. Tighten the cylinder head bolts, as follows. Install cylinder head bolts (1) and (2). 7.tighten the cylinder head bolts according to the following procedure: Caterpillar® 3406a • 3406b • 3406c • 3406e • c15 cummins® isx •. Proper. Cat C15 Cylinder Head Bolt Torque Sequence.

From wiringfixindite.z13.web.core.windows.net

Cat C15 6nz Bolt Torque Specs Cat C15 Cylinder Head Bolt Torque Sequence 7.tighten the cylinder head bolts according to the following procedure: Tighten the cylinder head bolts, as follows. Bolts, nuts, plugs, fittings, and clamps. The cylinder head of your engine is torqued to the following specifications. Install cylinder head bolts (1) and (2). By following these torque specifications and steps, you can ensure the proper assembly and sealing of the cylinder. Cat C15 Cylinder Head Bolt Torque Sequence.

From ar.inspiredpencil.com

Cylinder Head Bolt Tightening Sequence Cat C15 Cylinder Head Bolt Torque Sequence Install the cylinder head bolts. Proper torque sequencing ensures an even distribution of clamping force, which is essential for maintaining a reliable seal between the. The cylinder head of your engine is torqued to the following specifications. Install cylinder head bolts (1) and (2). Bolts, nuts, plugs, fittings, and clamps. Tighten the cylinder head bolts, as follows. Follow step 7. Cat C15 Cylinder Head Bolt Torque Sequence.

From www.2carpros.com

Torque Sequence for Head Bolts Needed Need to Know the Torque Cat C15 Cylinder Head Bolt Torque Sequence Follow step 7 for the correct tightening procedure. Torque settings for the following: Proper torque sequencing ensures an even distribution of clamping force, which is essential for maintaining a reliable seal between the. Head bolt, connecting rod bolt & main bearing bolt torque specifications. 7.tighten the cylinder head bolts according to the following procedure: Install cylinder head bolts (1) and. Cat C15 Cylinder Head Bolt Torque Sequence.

From www.youtube.com

Check Out This Caterpillar C15 Engine, C15 Acert, 3406E Stage 2 Cat C15 Cylinder Head Bolt Torque Sequence Install the cylinder head bolts. Tighten the cylinder head bolts, as follows. Follow step 7 for the correct tightening procedure. Learn the correct torque sequence and specifications for tightening the cylinder head bolts on a cat c15 engine for optimal. Install cylinder head bolts (1) and (2). The cylinder head of your engine is torqued to the following specifications. Caterpillar®. Cat C15 Cylinder Head Bolt Torque Sequence.

From truckguider.com

Cat C15 Bolt Torque Specs Truck Guider Cat C15 Cylinder Head Bolt Torque Sequence In a numerical sequence, tighten bolts 1 through 26. Install the cylinder head bolts. The cylinder head of your engine is torqued to the following specifications. Exceptions to these torques are given in the service. Torque settings for the following: 7.tighten the cylinder head bolts according to the following procedure: Learn the correct torque sequence and specifications for tightening the. Cat C15 Cylinder Head Bolt Torque Sequence.

From www.pinnaxis.com

Q&A Caterpillar Bolt Torque Chart Cat C7, C15, 3126 Specs, 50 OFF Cat C15 Cylinder Head Bolt Torque Sequence The cylinder head of your engine is torqued to the following specifications. Head bolt, connecting rod bolt & main bearing bolt torque specifications. Exceptions to these torques are given in the service. Tighten the cylinder head bolts, as follows. Install cylinder head bolts (1) and (2). In a numerical sequence, tighten bolts 1 through 26 to a torque of 270. Cat C15 Cylinder Head Bolt Torque Sequence.