Face Milling Process . Face milling is the most common milling operation, and can be performed using a wide range of different tools. Face milling plays a crucial role in the process of aerospace cnc machining where it is used for manufacturing complex parts that fairly require tight tolerances. Read on to learn all you should know. Face milling is ideal for precision machining requiring minimal material removal, providing a superior surface finish. Peripheral milling excels at efficiently removing large amounts of. Face milling is a key process for smooth surface and precision machining of parts, and selecting the appropriate face milling cutter and optimizing the process are crucial. Face milling is the first stage of machining a billet or workpiece. It is used for flattening and smoothing the upper and side surfaces of the work. The main characteristic of this process. In this article, we will focus on face milling,. Cutters with a 45º entering angle are most frequently used, but round. The accuracy is highly important for aircraft parts in which every micron points to the safety and performance factors. Face milling is a versatile procedure that flattens and smoothens surfaces of machined parts.

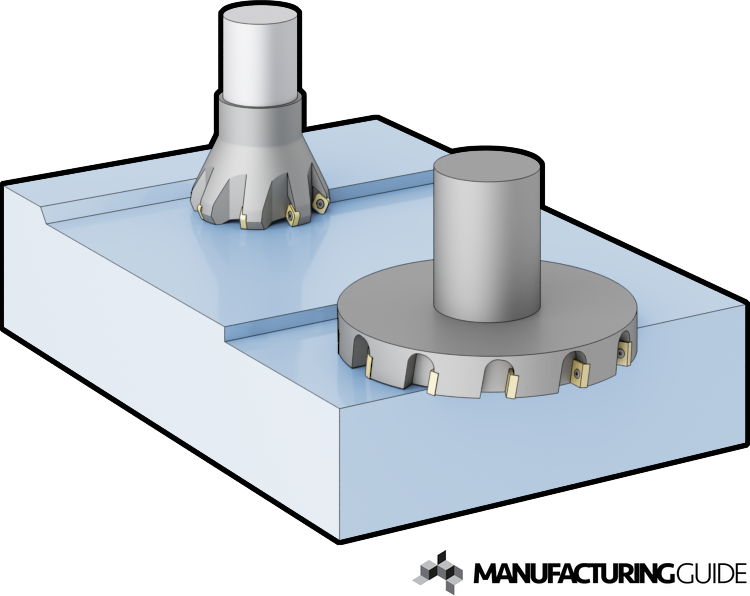

from www.manufacturingguide.com

The accuracy is highly important for aircraft parts in which every micron points to the safety and performance factors. Face milling is the most common milling operation, and can be performed using a wide range of different tools. Peripheral milling excels at efficiently removing large amounts of. Face milling is a key process for smooth surface and precision machining of parts, and selecting the appropriate face milling cutter and optimizing the process are crucial. Cutters with a 45º entering angle are most frequently used, but round. Face milling is ideal for precision machining requiring minimal material removal, providing a superior surface finish. Face milling is the first stage of machining a billet or workpiece. In this article, we will focus on face milling,. Read on to learn all you should know. It is used for flattening and smoothing the upper and side surfaces of the work.

Face milling Find suppliers, processes & material

Face Milling Process Face milling is ideal for precision machining requiring minimal material removal, providing a superior surface finish. Face milling plays a crucial role in the process of aerospace cnc machining where it is used for manufacturing complex parts that fairly require tight tolerances. In this article, we will focus on face milling,. Face milling is a versatile procedure that flattens and smoothens surfaces of machined parts. It is used for flattening and smoothing the upper and side surfaces of the work. Cutters with a 45º entering angle are most frequently used, but round. Peripheral milling excels at efficiently removing large amounts of. Face milling is a key process for smooth surface and precision machining of parts, and selecting the appropriate face milling cutter and optimizing the process are crucial. The main characteristic of this process. Read on to learn all you should know. The accuracy is highly important for aircraft parts in which every micron points to the safety and performance factors. Face milling is the first stage of machining a billet or workpiece. Face milling is the most common milling operation, and can be performed using a wide range of different tools. Face milling is ideal for precision machining requiring minimal material removal, providing a superior surface finish.

From www.linkedin.com

How to Optimize Your Face Milling Process for Superior Results Face Milling Process Face milling is the first stage of machining a billet or workpiece. Face milling is the most common milling operation, and can be performed using a wide range of different tools. Cutters with a 45º entering angle are most frequently used, but round. Face milling is a key process for smooth surface and precision machining of parts, and selecting the. Face Milling Process.

From www.canadianmetalworking.com

About face milling Face Milling Process Face milling is ideal for precision machining requiring minimal material removal, providing a superior surface finish. It is used for flattening and smoothing the upper and side surfaces of the work. Face milling is the first stage of machining a billet or workpiece. Face milling is a key process for smooth surface and precision machining of parts, and selecting the. Face Milling Process.

From www.xometry.com

The Differences Between Face Milling and End Milling Xometry Face Milling Process Face milling is the most common milling operation, and can be performed using a wide range of different tools. Face milling is a versatile procedure that flattens and smoothens surfaces of machined parts. The accuracy is highly important for aircraft parts in which every micron points to the safety and performance factors. Face milling is ideal for precision machining requiring. Face Milling Process.

From www.slideserve.com

PPT Machining and Machine Tools PowerPoint Presentation, free Face Milling Process Face milling is the most common milling operation, and can be performed using a wide range of different tools. In this article, we will focus on face milling,. Face milling plays a crucial role in the process of aerospace cnc machining where it is used for manufacturing complex parts that fairly require tight tolerances. The main characteristic of this process.. Face Milling Process.

From www.kemalmfg.com

Face Milling 101 Process, Differences, And Practical Tips Kemal Face Milling Process It is used for flattening and smoothing the upper and side surfaces of the work. Face milling plays a crucial role in the process of aerospace cnc machining where it is used for manufacturing complex parts that fairly require tight tolerances. Cutters with a 45º entering angle are most frequently used, but round. Face milling is a versatile procedure that. Face Milling Process.

From chansmachining.com

Face Milling A Comprehensive Guide to Techniques, Tools, and Face Milling Process Peripheral milling excels at efficiently removing large amounts of. Face milling is a versatile procedure that flattens and smoothens surfaces of machined parts. Read on to learn all you should know. In this article, we will focus on face milling,. The accuracy is highly important for aircraft parts in which every micron points to the safety and performance factors. Face. Face Milling Process.

From www.youtube.com

02_04_P4 Calculating Cutting Speed, Feed, and Machining Time for Face Face Milling Process Face milling plays a crucial role in the process of aerospace cnc machining where it is used for manufacturing complex parts that fairly require tight tolerances. Face milling is the first stage of machining a billet or workpiece. The main characteristic of this process. In this article, we will focus on face milling,. Face milling is a key process for. Face Milling Process.

From www.rtprototype.com

Face Milling Definition, Machining, Tools, Tech Tips Ruitai Mould Face Milling Process Face milling is a key process for smooth surface and precision machining of parts, and selecting the appropriate face milling cutter and optimizing the process are crucial. Face milling is ideal for precision machining requiring minimal material removal, providing a superior surface finish. Face milling is the first stage of machining a billet or workpiece. It is used for flattening. Face Milling Process.

From www.youtube.com

Crash Course in Milling Chapter 7 Face Milling, by Glacern Machine Face Milling Process Face milling is a key process for smooth surface and precision machining of parts, and selecting the appropriate face milling cutter and optimizing the process are crucial. Cutters with a 45º entering angle are most frequently used, but round. The accuracy is highly important for aircraft parts in which every micron points to the safety and performance factors. Peripheral milling. Face Milling Process.

From themechanicalengineering.com

Milling Machine Definition, Parts, Operation, Working Principle Face Milling Process Face milling is a key process for smooth surface and precision machining of parts, and selecting the appropriate face milling cutter and optimizing the process are crucial. Face milling is ideal for precision machining requiring minimal material removal, providing a superior surface finish. It is used for flattening and smoothing the upper and side surfaces of the work. Face milling. Face Milling Process.

From www.manufacturingguide.com

Face milling Find suppliers, processes & material Face Milling Process The accuracy is highly important for aircraft parts in which every micron points to the safety and performance factors. Face milling is ideal for precision machining requiring minimal material removal, providing a superior surface finish. Cutters with a 45º entering angle are most frequently used, but round. Face milling plays a crucial role in the process of aerospace cnc machining. Face Milling Process.

From prototool.com

Face Milling Basics and Advancements Face Milling Process In this article, we will focus on face milling,. Face milling plays a crucial role in the process of aerospace cnc machining where it is used for manufacturing complex parts that fairly require tight tolerances. Face milling is the first stage of machining a billet or workpiece. Face milling is the most common milling operation, and can be performed using. Face Milling Process.

From www.youtube.com

DoQuadMill Face milling cutter with minimum interference YouTube Face Milling Process Face milling plays a crucial role in the process of aerospace cnc machining where it is used for manufacturing complex parts that fairly require tight tolerances. Read on to learn all you should know. The accuracy is highly important for aircraft parts in which every micron points to the safety and performance factors. Face milling is a versatile procedure that. Face Milling Process.

From www.easiahome.com

Face MillingDefinition, Process,Operations,Differences Face Milling Process Peripheral milling excels at efficiently removing large amounts of. In this article, we will focus on face milling,. The main characteristic of this process. Face milling is the most common milling operation, and can be performed using a wide range of different tools. The accuracy is highly important for aircraft parts in which every micron points to the safety and. Face Milling Process.

From www.researchgate.net

Designation of force components of face milling process. Download Face Milling Process It is used for flattening and smoothing the upper and side surfaces of the work. Face milling plays a crucial role in the process of aerospace cnc machining where it is used for manufacturing complex parts that fairly require tight tolerances. The accuracy is highly important for aircraft parts in which every micron points to the safety and performance factors.. Face Milling Process.

From www.slideserve.com

PPT Machining Processes Used to Produce Various Shapes Milling Face Milling Process Face milling is ideal for precision machining requiring minimal material removal, providing a superior surface finish. Read on to learn all you should know. Peripheral milling excels at efficiently removing large amounts of. Face milling is the first stage of machining a billet or workpiece. In this article, we will focus on face milling,. Face milling is a key process. Face Milling Process.

From kreasimudaindonesia.com

Pahami Metode Pemotongan Pada Mesin Milling CNC, yuk! Kreasi Muda Face Milling Process Face milling is the first stage of machining a billet or workpiece. Face milling is a versatile procedure that flattens and smoothens surfaces of machined parts. In this article, we will focus on face milling,. Face milling is the most common milling operation, and can be performed using a wide range of different tools. Face milling is ideal for precision. Face Milling Process.

From www.canadianmetalworking.com

About face milling Face Milling Process Face milling is a versatile procedure that flattens and smoothens surfaces of machined parts. It is used for flattening and smoothing the upper and side surfaces of the work. The main characteristic of this process. Read on to learn all you should know. Face milling is the first stage of machining a billet or workpiece. In this article, we will. Face Milling Process.

From www.sumipol.com

FaceMilling Sumipol Face Milling Process Read on to learn all you should know. Face milling is a versatile procedure that flattens and smoothens surfaces of machined parts. Face milling is a key process for smooth surface and precision machining of parts, and selecting the appropriate face milling cutter and optimizing the process are crucial. Cutters with a 45º entering angle are most frequently used, but. Face Milling Process.

From www.youtube.com

Ansys Workbench thermal analysis of face milling process (cutter Face Milling Process Peripheral milling excels at efficiently removing large amounts of. Read on to learn all you should know. It is used for flattening and smoothing the upper and side surfaces of the work. The accuracy is highly important for aircraft parts in which every micron points to the safety and performance factors. Face milling is the first stage of machining a. Face Milling Process.

From www.youtube.com

FACE MILLING PROCESS YouTube Face Milling Process In this article, we will focus on face milling,. Face milling is a versatile procedure that flattens and smoothens surfaces of machined parts. Face milling is the most common milling operation, and can be performed using a wide range of different tools. It is used for flattening and smoothing the upper and side surfaces of the work. The main characteristic. Face Milling Process.

From www.senlisweld.com

End Face Milling Machine SENLISWELD Face Milling Process Face milling is ideal for precision machining requiring minimal material removal, providing a superior surface finish. It is used for flattening and smoothing the upper and side surfaces of the work. Cutters with a 45º entering angle are most frequently used, but round. Peripheral milling excels at efficiently removing large amounts of. Face milling plays a crucial role in the. Face Milling Process.

From mellowpine.com

Face Milling in Machining How's it Done? MellowPine Face Milling Process In this article, we will focus on face milling,. The accuracy is highly important for aircraft parts in which every micron points to the safety and performance factors. Face milling plays a crucial role in the process of aerospace cnc machining where it is used for manufacturing complex parts that fairly require tight tolerances. Face milling is a versatile procedure. Face Milling Process.

From www.researchgate.net

Schematic of face milling and tool. Download Scientific Diagram Face Milling Process Face milling is a key process for smooth surface and precision machining of parts, and selecting the appropriate face milling cutter and optimizing the process are crucial. Face milling is a versatile procedure that flattens and smoothens surfaces of machined parts. Face milling is the most common milling operation, and can be performed using a wide range of different tools.. Face Milling Process.

From www.autodesk.com

6face milling Fusion Blog Face Milling Process Face milling is ideal for precision machining requiring minimal material removal, providing a superior surface finish. Cutters with a 45º entering angle are most frequently used, but round. In this article, we will focus on face milling,. Face milling is the most common milling operation, and can be performed using a wide range of different tools. It is used for. Face Milling Process.

From fractory.com

CNC Milling a Complete Guide to Understand the Process Face Milling Process Face milling is a versatile procedure that flattens and smoothens surfaces of machined parts. Face milling is the most common milling operation, and can be performed using a wide range of different tools. Peripheral milling excels at efficiently removing large amounts of. Face milling is the first stage of machining a billet or workpiece. Face milling is a key process. Face Milling Process.

From www.china-machining.com

Face Milling 101 Here is What You Need to Know Face Milling Process Peripheral milling excels at efficiently removing large amounts of. Face milling is a versatile procedure that flattens and smoothens surfaces of machined parts. It is used for flattening and smoothing the upper and side surfaces of the work. The accuracy is highly important for aircraft parts in which every micron points to the safety and performance factors. Face milling plays. Face Milling Process.

From einvoice.fpt.com.vn

Face Milling Definition, Process, Differences, Practical, 50 OFF Face Milling Process The main characteristic of this process. Face milling is a versatile procedure that flattens and smoothens surfaces of machined parts. In this article, we will focus on face milling,. Face milling is ideal for precision machining requiring minimal material removal, providing a superior surface finish. Face milling is a key process for smooth surface and precision machining of parts, and. Face Milling Process.

From www.youtube.com

The Science of Face Milling YouTube Face Milling Process Face milling is a versatile procedure that flattens and smoothens surfaces of machined parts. The accuracy is highly important for aircraft parts in which every micron points to the safety and performance factors. Face milling is ideal for precision machining requiring minimal material removal, providing a superior surface finish. Face milling is a key process for smooth surface and precision. Face Milling Process.

From www.lathematters.com

Face Mill vs. End Mill Main Differences Explained! Face Milling Process Face milling is ideal for precision machining requiring minimal material removal, providing a superior surface finish. Face milling is the first stage of machining a billet or workpiece. It is used for flattening and smoothing the upper and side surfaces of the work. Peripheral milling excels at efficiently removing large amounts of. Face milling is a versatile procedure that flattens. Face Milling Process.

From www.slideserve.com

PPT Chapter4 MILLING PROCESS PowerPoint Presentation, free download Face Milling Process Face milling is a versatile procedure that flattens and smoothens surfaces of machined parts. The main characteristic of this process. In this article, we will focus on face milling,. Face milling is ideal for precision machining requiring minimal material removal, providing a superior surface finish. Face milling plays a crucial role in the process of aerospace cnc machining where it. Face Milling Process.

From mechutopia.com

Milling & Face Milling Ultimate Guide Mechutopia Face Milling Process Face milling is ideal for precision machining requiring minimal material removal, providing a superior surface finish. Cutters with a 45º entering angle are most frequently used, but round. Face milling plays a crucial role in the process of aerospace cnc machining where it is used for manufacturing complex parts that fairly require tight tolerances. Face milling is a key process. Face Milling Process.

From www.researchgate.net

(a) Face milling setup with the cutting tool and force dynamometer, and Face Milling Process Peripheral milling excels at efficiently removing large amounts of. Face milling is ideal for precision machining requiring minimal material removal, providing a superior surface finish. Face milling plays a crucial role in the process of aerospace cnc machining where it is used for manufacturing complex parts that fairly require tight tolerances. Face milling is a versatile procedure that flattens and. Face Milling Process.

From step.manufacturingtransformation.io

The Face Milling Series Seco Online Academy Face Milling Process Cutters with a 45º entering angle are most frequently used, but round. Read on to learn all you should know. The main characteristic of this process. Face milling is the first stage of machining a billet or workpiece. Face milling is the most common milling operation, and can be performed using a wide range of different tools. Face milling is. Face Milling Process.

From at-machining.com

Face Milling Everything You Need to Know ATMachining Face Milling Process Face milling is the first stage of machining a billet or workpiece. In this article, we will focus on face milling,. Face milling is ideal for precision machining requiring minimal material removal, providing a superior surface finish. Face milling is a key process for smooth surface and precision machining of parts, and selecting the appropriate face milling cutter and optimizing. Face Milling Process.