Depth Of Cut For End Mills . Get accurate results with cnc cookbook. The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular to its axis direction and the axial depth of cut (ap. Ball end mills can be used for both roughing and finishing operations — as well as in 3d contouring applications — simply by varying cut depth and feed rate. The optimal depth of cut for a. Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and test the cut before milling the entire. Available machine type and frequency of operation determine whether an end mill,. Tool selection is normally determined by the width and depth of the groove and, to some extent, length. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. I am curious what other experienced machinist use to determine an end mill depth of. Take control of your cnc machining projects with two powerful tools for calculating cut depth, cut width, and stepover.

from www.mscdirect.com

Take control of your cnc machining projects with two powerful tools for calculating cut depth, cut width, and stepover. The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular to its axis direction and the axial depth of cut (ap. The optimal depth of cut for a. Available machine type and frequency of operation determine whether an end mill,. I am curious what other experienced machinist use to determine an end mill depth of. Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and test the cut before milling the entire. Ball end mills can be used for both roughing and finishing operations — as well as in 3d contouring applications — simply by varying cut depth and feed rate. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. Tool selection is normally determined by the width and depth of the groove and, to some extent, length. Get accurate results with cnc cookbook.

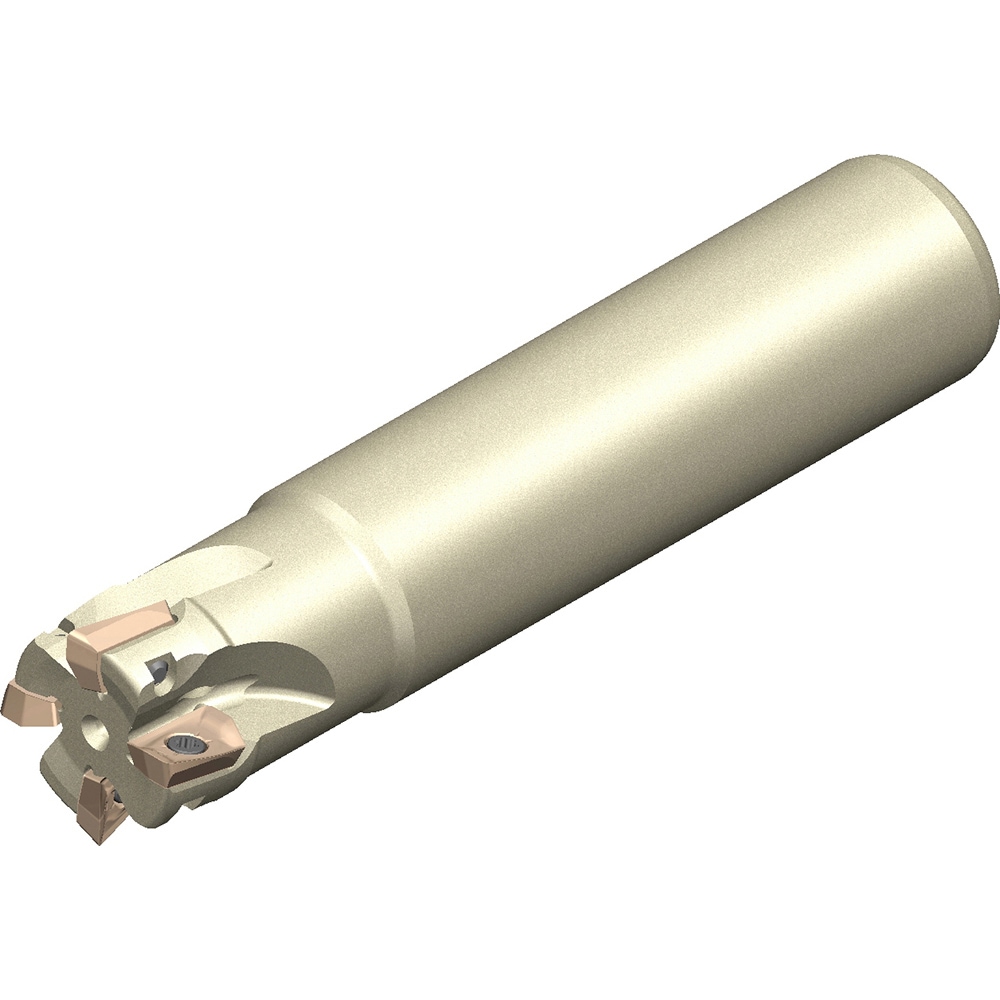

Sumitomo Indexable SquareShoulder End Mill WEZ11025E0420, 25 mm

Depth Of Cut For End Mills I am curious what other experienced machinist use to determine an end mill depth of. Tool selection is normally determined by the width and depth of the groove and, to some extent, length. Get accurate results with cnc cookbook. Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and test the cut before milling the entire. Ball end mills can be used for both roughing and finishing operations — as well as in 3d contouring applications — simply by varying cut depth and feed rate. The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular to its axis direction and the axial depth of cut (ap. Available machine type and frequency of operation determine whether an end mill,. Take control of your cnc machining projects with two powerful tools for calculating cut depth, cut width, and stepover. I am curious what other experienced machinist use to determine an end mill depth of. The optimal depth of cut for a. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts.

From www.mscdirect.com

Seco Indexable SquareShoulder End Mills; Minimum Cutting Diameter 2 Depth Of Cut For End Mills Available machine type and frequency of operation determine whether an end mill,. I am curious what other experienced machinist use to determine an end mill depth of. Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and test the cut before milling the entire. The optimal depth. Depth Of Cut For End Mills.

From www.mscdirect.com

Tungaloy Indexable SquareShoulder End Mills; Minimum Cutting Depth Of Cut For End Mills Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and test the cut before milling the entire. I am curious what other experienced machinist use to determine an end mill depth of. Tool selection is normally determined by the width and depth of the groove and, to. Depth Of Cut For End Mills.

From mellowpine.com

Speeds and Feeds Beginner Guide with Table MellowPine Depth Of Cut For End Mills Take control of your cnc machining projects with two powerful tools for calculating cut depth, cut width, and stepover. Ball end mills can be used for both roughing and finishing operations — as well as in 3d contouring applications — simply by varying cut depth and feed rate. Secure the workpiece, choose the right speed and feed rate, use the. Depth Of Cut For End Mills.

From www.ar15.com

Bits for 80... Depth Of Cut For End Mills Take control of your cnc machining projects with two powerful tools for calculating cut depth, cut width, and stepover. I am curious what other experienced machinist use to determine an end mill depth of. The optimal depth of cut for a. Ball end mills can be used for both roughing and finishing operations — as well as in 3d contouring. Depth Of Cut For End Mills.

From www.youtube.com

Axial and radial depth of cut in milling operations YouTube Depth Of Cut For End Mills Available machine type and frequency of operation determine whether an end mill,. The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular to its axis direction and the axial depth of cut (ap. Take control of your cnc machining projects with two powerful tools for calculating cut depth, cut width, and stepover.. Depth Of Cut For End Mills.

From www.mscdirect.com

Walter Indexable Copy End Mill 8 to 16 mm Cut Dia, 3.99 mm Max Depth Depth Of Cut For End Mills I am curious what other experienced machinist use to determine an end mill depth of. The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular to its axis direction and the axial depth of cut (ap. Tool selection is normally determined by the width and depth of the groove and, to some. Depth Of Cut For End Mills.

From www.mscdirect.com

Iscar Indexable HighFeed End Mills; Cutting Diameter (mm) 7.70 Depth Of Cut For End Mills Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. Ball end mills can be used for both roughing and finishing operations — as well as in 3d contouring applications — simply by varying cut depth and feed rate. Take control of your cnc machining projects with two. Depth Of Cut For End Mills.

From femjoy-virtuagirl-hd-25.blogspot.com

roughing end mill depth of cut Big History Blogger Photography Depth Of Cut For End Mills Tool selection is normally determined by the width and depth of the groove and, to some extent, length. The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular to its axis direction and the axial depth of cut (ap. The optimal depth of cut for a. Generally, a shallow depth of cut. Depth Of Cut For End Mills.

From www.canadianmetalworking.com

End mill geometry boosts trochoidal milling Canadian Metalworking Depth Of Cut For End Mills Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and test the cut before milling the entire. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. The radial depth of cut (ae or rdoc),. Depth Of Cut For End Mills.

From www.mscdirect.com

Walter Indexable Copy End Mill 13 to 19.99 mm Cut Dia, 3.51 mm Max Depth Of Cut For End Mills I am curious what other experienced machinist use to determine an end mill depth of. Tool selection is normally determined by the width and depth of the groove and, to some extent, length. The optimal depth of cut for a. Get accurate results with cnc cookbook. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater. Depth Of Cut For End Mills.

From www.qualitytechtool.com

General Purpose End Mills Metric Quality Tech Tool Depth Of Cut For End Mills Get accurate results with cnc cookbook. The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular to its axis direction and the axial depth of cut (ap. I am curious what other experienced machinist use to determine an end mill depth of. The optimal depth of cut for a. Available machine type. Depth Of Cut For End Mills.

From toolnotes.com

End Mills ToolNotes Depth Of Cut For End Mills The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular to its axis direction and the axial depth of cut (ap. Get accurate results with cnc cookbook. Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and test the. Depth Of Cut For End Mills.

From www.semanticscholar.org

Figure 3 from Optimization of Machining Parameters for Face Milling Depth Of Cut For End Mills Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. I am curious what other experienced machinist use to determine an end mill depth of. Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and. Depth Of Cut For End Mills.

From www.mscdirect.com

Indexable Plunge End Mills Indexable End Mills MSC Industrial Supply Depth Of Cut For End Mills I am curious what other experienced machinist use to determine an end mill depth of. Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and test the cut before milling the entire. The radial depth of cut (ae or rdoc), is the length that the tool engages. Depth Of Cut For End Mills.

From www.practicalmachinist.com

Wavy Cut End Mill Useage / Tips? Depth Of Cut For End Mills Tool selection is normally determined by the width and depth of the groove and, to some extent, length. Take control of your cnc machining projects with two powerful tools for calculating cut depth, cut width, and stepover. Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and. Depth Of Cut For End Mills.

From www.speedtigertools.com

End Mill Size Standards Chart & IntroductionSPEED TIGER Depth Of Cut For End Mills The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular to its axis direction and the axial depth of cut (ap. Available machine type and frequency of operation determine whether an end mill,. Tool selection is normally determined by the width and depth of the groove and, to some extent, length. Ball. Depth Of Cut For End Mills.

From toolnotes.com

Cutting Parameters for Milling ToolNotes Depth Of Cut For End Mills Available machine type and frequency of operation determine whether an end mill,. Tool selection is normally determined by the width and depth of the groove and, to some extent, length. I am curious what other experienced machinist use to determine an end mill depth of. The optimal depth of cut for a. The radial depth of cut (ae or rdoc),. Depth Of Cut For End Mills.

From www.mscdirect.com

Kennametal 11/2" Cut Diam, 0.433" Max Depth of Cut, Indexable Plunge Depth Of Cut For End Mills The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular to its axis direction and the axial depth of cut (ap. Tool selection is normally determined by the width and depth of the groove and, to some extent, length. Ball end mills can be used for both roughing and finishing operations —. Depth Of Cut For End Mills.

From earthasowers.blogspot.com

end mill shank types Eartha Sowers Depth Of Cut For End Mills Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and test the cut before milling the entire. Ball end mills can be used for both roughing and finishing operations — as well as in 3d contouring applications — simply by varying cut depth and feed rate. Tool. Depth Of Cut For End Mills.

From www.cnccookbook.com

Ball Nose End Mill [Easy Guide to Ball Cutters] CNCCookbook Be A Depth Of Cut For End Mills Available machine type and frequency of operation determine whether an end mill,. I am curious what other experienced machinist use to determine an end mill depth of. The optimal depth of cut for a. Ball end mills can be used for both roughing and finishing operations — as well as in 3d contouring applications — simply by varying cut depth. Depth Of Cut For End Mills.

From www.endmill.com.au

Choosing the right end mill for the job Adam's Bits Depth Of Cut For End Mills Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and test the cut before milling the entire. Get accurate results with cnc cookbook. Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. Ball end. Depth Of Cut For End Mills.

From www.precisionbits.com

CNC Router Bits Up Cut End Mills 1/4" Dia 2 Flute Low Helix Upcut Depth Of Cut For End Mills Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. Take control of your cnc machining projects with two powerful tools for calculating cut depth, cut width, and stepover. Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate. Depth Of Cut For End Mills.

From mungfali.com

End Mill Speed And Feed Chart Depth Of Cut For End Mills Tool selection is normally determined by the width and depth of the groove and, to some extent, length. The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular to its axis direction and the axial depth of cut (ap. Available machine type and frequency of operation determine whether an end mill,. The. Depth Of Cut For End Mills.

From www.mscdirect.com

Ceratizit Indexable SquareShoulder End Mills; Minimum Cutting Depth Of Cut For End Mills Get accurate results with cnc cookbook. Available machine type and frequency of operation determine whether an end mill,. I am curious what other experienced machinist use to determine an end mill depth of. The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular to its axis direction and the axial depth of. Depth Of Cut For End Mills.

From www.indiamart.com

Dormer Tungsten Carbide Solid End Milling Cutters, Rs 600 /unit ID Depth Of Cut For End Mills Ball end mills can be used for both roughing and finishing operations — as well as in 3d contouring applications — simply by varying cut depth and feed rate. Get accurate results with cnc cookbook. Available machine type and frequency of operation determine whether an end mill,. Secure the workpiece, choose the right speed and feed rate, use the right. Depth Of Cut For End Mills.

From dansdiscounttools.com

KENNAMETAL Indexable Square Shoulder End Mill 11/2″ 3FL Depth Of Cut For End Mills Generally, a shallow depth of cut is recommended for finishing cuts, whereas a greater depth of cut is recommended for roughing cuts. Available machine type and frequency of operation determine whether an end mill,. The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular to its axis direction and the axial depth. Depth Of Cut For End Mills.

From www.mscdirect.com

Sumitomo Indexable SquareShoulder End Mill WEZ11025E0420, 25 mm Depth Of Cut For End Mills Ball end mills can be used for both roughing and finishing operations — as well as in 3d contouring applications — simply by varying cut depth and feed rate. The optimal depth of cut for a. I am curious what other experienced machinist use to determine an end mill depth of. Secure the workpiece, choose the right speed and feed. Depth Of Cut For End Mills.

From www.mscdirect.com

Ingersoll Cutting Tools Indexable SquareShoulder End Mill 12S1X Depth Of Cut For End Mills Get accurate results with cnc cookbook. Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and test the cut before milling the entire. Available machine type and frequency of operation determine whether an end mill,. Take control of your cnc machining projects with two powerful tools for. Depth Of Cut For End Mills.

From www.icarbide.com

1/4" X 3" 3FLUTE SOLID CARBIDE SQUARE END MILL ALUMINUM icarbide Depth Of Cut For End Mills Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and test the cut before milling the entire. I am curious what other experienced machinist use to determine an end mill depth of. The optimal depth of cut for a. Take control of your cnc machining projects with. Depth Of Cut For End Mills.

From www.redlinetools.com

Endmill Selection Guide RedLine Tools Redline Tools Depth Of Cut For End Mills Tool selection is normally determined by the width and depth of the groove and, to some extent, length. Get accurate results with cnc cookbook. The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular to its axis direction and the axial depth of cut (ap. Available machine type and frequency of operation. Depth Of Cut For End Mills.

From www.mscdirect.com

Walter Indexable Copy End Mill 24 to 32 mm Cut Dia, 3.99 mm Max Depth Of Cut For End Mills Available machine type and frequency of operation determine whether an end mill,. Take control of your cnc machining projects with two powerful tools for calculating cut depth, cut width, and stepover. Ball end mills can be used for both roughing and finishing operations — as well as in 3d contouring applications — simply by varying cut depth and feed rate.. Depth Of Cut For End Mills.

From www.mscdirect.com

Sumitomo Indexable SquareShoulder End Mill WEZ17030M16Z2, 30 mm Cut Depth Of Cut For End Mills Take control of your cnc machining projects with two powerful tools for calculating cut depth, cut width, and stepover. Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and test the cut before milling the entire. The radial depth of cut (ae or rdoc), is the length. Depth Of Cut For End Mills.

From www.mscdirect.com

Walter Indexable Copy End Mill 16 to 32 mm Cut Dia, 8 mm Max Depth Depth Of Cut For End Mills I am curious what other experienced machinist use to determine an end mill depth of. Available machine type and frequency of operation determine whether an end mill,. Tool selection is normally determined by the width and depth of the groove and, to some extent, length. Ball end mills can be used for both roughing and finishing operations — as well. Depth Of Cut For End Mills.

From ifconnect.ifsuldeminas.edu.br

?Types Of High Precision Cutting Tools?? Tech Technology??, 58 OFF Depth Of Cut For End Mills Tool selection is normally determined by the width and depth of the groove and, to some extent, length. Take control of your cnc machining projects with two powerful tools for calculating cut depth, cut width, and stepover. The optimal depth of cut for a. Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear. Depth Of Cut For End Mills.

From dansdiscounttools.com

CLEVELAND C32644 1.5" Cobalt Single End Center Cutting End Mill Depth Of Cut For End Mills Secure the workpiece, choose the right speed and feed rate, use the right cutting depth, clear chips often, lubricate the end mill, and test the cut before milling the entire. The optimal depth of cut for a. Tool selection is normally determined by the width and depth of the groove and, to some extent, length. Get accurate results with cnc. Depth Of Cut For End Mills.