Assembly Line Balancing Is A One Time Activity . assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another, to organize tasks at those workstations so that the work at each takes about the same amount of time. In such a way that the. an unbalanced assembly line is a very common issue in manufacturing enterprises and it has been studied from different. the second procedure step consists of an innovative optimization model which defines tasks and accessory. alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time. assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a particular time frame. assembly line balancing is the problem of assigning operations to workstations along an assembly line; this research was conducted to determine the standard time and provide recommendations for achieving the.

from www.youtube.com

the second procedure step consists of an innovative optimization model which defines tasks and accessory. assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another, to organize tasks at those workstations so that the work at each takes about the same amount of time. assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a particular time frame. In such a way that the. this research was conducted to determine the standard time and provide recommendations for achieving the. alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time. assembly line balancing is the problem of assigning operations to workstations along an assembly line; an unbalanced assembly line is a very common issue in manufacturing enterprises and it has been studied from different.

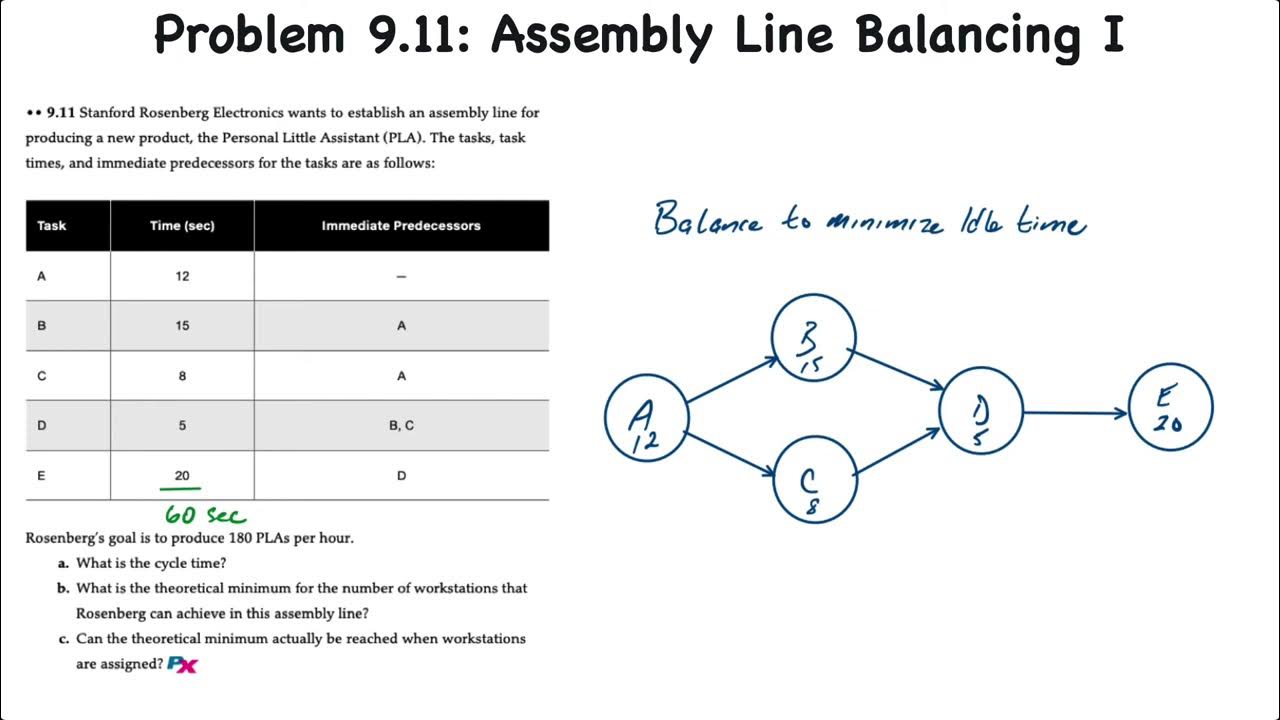

Operations Layout Assembly Line Balancing I YouTube

Assembly Line Balancing Is A One Time Activity In such a way that the. this research was conducted to determine the standard time and provide recommendations for achieving the. assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a particular time frame. assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another, to organize tasks at those workstations so that the work at each takes about the same amount of time. the second procedure step consists of an innovative optimization model which defines tasks and accessory. In such a way that the. an unbalanced assembly line is a very common issue in manufacturing enterprises and it has been studied from different. alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time. assembly line balancing is the problem of assigning operations to workstations along an assembly line;

From www.smlease.com

What is production Line Balancing and How to implement it? Assembly Line Balancing Is A One Time Activity the second procedure step consists of an innovative optimization model which defines tasks and accessory. In such a way that the. assembly line balancing is the problem of assigning operations to workstations along an assembly line; assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a. Assembly Line Balancing Is A One Time Activity.

From slideplayer.com

Assembly line balancing ppt download Assembly Line Balancing Is A One Time Activity In such a way that the. assembly line balancing is the problem of assigning operations to workstations along an assembly line; the second procedure step consists of an innovative optimization model which defines tasks and accessory. alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time.. Assembly Line Balancing Is A One Time Activity.

From slidetodoc.com

Assembly Line Balance 1 Assembly analysis Assembly Chart Assembly Line Balancing Is A One Time Activity assembly line balancing is the problem of assigning operations to workstations along an assembly line; In such a way that the. the second procedure step consists of an innovative optimization model which defines tasks and accessory. alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time.. Assembly Line Balancing Is A One Time Activity.

From www.slideserve.com

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation, free Assembly Line Balancing Is A One Time Activity the second procedure step consists of an innovative optimization model which defines tasks and accessory. assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another, to organize tasks at those workstations so that the work at each. Assembly Line Balancing Is A One Time Activity.

From mungfali.com

Line Balancing Diagram Assembly Line Balancing Is A One Time Activity the second procedure step consists of an innovative optimization model which defines tasks and accessory. assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a particular time frame. assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and. Assembly Line Balancing Is A One Time Activity.

From www.chegg.com

Solved 1. Assembly Line Balancing (10+5+5+5+5 points) (a) Assembly Line Balancing Is A One Time Activity In such a way that the. assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a particular time frame. alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time. assembly line balancing (alb) is a. Assembly Line Balancing Is A One Time Activity.

From www.slideserve.com

PPT Assembly Line Balancing PowerPoint Presentation, free download Assembly Line Balancing Is A One Time Activity assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a particular time frame. an unbalanced assembly line is a very common issue in manufacturing enterprises and it has been studied from different. assembly line balancing is the problem of assigning operations to workstations along an assembly. Assembly Line Balancing Is A One Time Activity.

From www.youtube.com

Assembly Line Balancing largest production time heuristic YouTube Assembly Line Balancing Is A One Time Activity this research was conducted to determine the standard time and provide recommendations for achieving the. the second procedure step consists of an innovative optimization model which defines tasks and accessory. an unbalanced assembly line is a very common issue in manufacturing enterprises and it has been studied from different. assembly line balancing is a production strategy. Assembly Line Balancing Is A One Time Activity.

From www.slideshare.net

Assembly Line Balancing Example Assembly Line Balancing Is A One Time Activity assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a particular time frame. In such a way that the. assembly line balancing is the problem of assigning operations to workstations along an assembly line; this research was conducted to determine the standard time and provide recommendations. Assembly Line Balancing Is A One Time Activity.

From www.youtube.com

Tutorial 6 Assembly line balancing YouTube Assembly Line Balancing Is A One Time Activity assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another, to organize tasks at those workstations so that the work at each takes about the same amount of time. this research was conducted to determine the standard. Assembly Line Balancing Is A One Time Activity.

From www.slideserve.com

PPT Assembly Line Balancing PowerPoint Presentation, free download Assembly Line Balancing Is A One Time Activity In such a way that the. assembly line balancing is the problem of assigning operations to workstations along an assembly line; assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another, to organize tasks at those workstations. Assembly Line Balancing Is A One Time Activity.

From www.scribd.com

Assembly Line Balancing Technology Business Assembly Line Balancing Is A One Time Activity an unbalanced assembly line is a very common issue in manufacturing enterprises and it has been studied from different. assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a particular time frame. In such a way that the. this research was conducted to determine the standard. Assembly Line Balancing Is A One Time Activity.

From www.slideserve.com

PPT Assembly Line Balance PowerPoint Presentation, free download ID Assembly Line Balancing Is A One Time Activity assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a particular time frame. assembly line balancing is the problem of assigning operations to workstations along an assembly line; In such a way that the. assembly line balancing (alb) is a process used in mass production facility. Assembly Line Balancing Is A One Time Activity.

From www.slideserve.com

PPT Product layout PowerPoint Presentation, free download ID526491 Assembly Line Balancing Is A One Time Activity In such a way that the. alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time. assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another,. Assembly Line Balancing Is A One Time Activity.

From pt.slideshare.net

assembly line balancing Assembly Line Balancing Is A One Time Activity In such a way that the. an unbalanced assembly line is a very common issue in manufacturing enterprises and it has been studied from different. assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a particular time frame. the second procedure step consists of an innovative. Assembly Line Balancing Is A One Time Activity.

From www.researchgate.net

Assembly line balancing problem. Download Scientific Diagram Assembly Line Balancing Is A One Time Activity this research was conducted to determine the standard time and provide recommendations for achieving the. In such a way that the. assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a particular time frame. the second procedure step consists of an innovative optimization model which defines. Assembly Line Balancing Is A One Time Activity.

From www.slideserve.com

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation, free Assembly Line Balancing Is A One Time Activity this research was conducted to determine the standard time and provide recommendations for achieving the. assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a particular time frame. an unbalanced assembly line is a very common issue in manufacturing enterprises and it has been studied from. Assembly Line Balancing Is A One Time Activity.

From www.slideserve.com

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation, free Assembly Line Balancing Is A One Time Activity In such a way that the. this research was conducted to determine the standard time and provide recommendations for achieving the. an unbalanced assembly line is a very common issue in manufacturing enterprises and it has been studied from different. assembly line balancing is a production strategy that sets an intended rate of production to produce a. Assembly Line Balancing Is A One Time Activity.

From www.youtube.com

Operations Layout Assembly Line Balancing I YouTube Assembly Line Balancing Is A One Time Activity this research was conducted to determine the standard time and provide recommendations for achieving the. assembly line balancing is the problem of assigning operations to workstations along an assembly line; the second procedure step consists of an innovative optimization model which defines tasks and accessory. assembly line balancing is a production strategy that sets an intended. Assembly Line Balancing Is A One Time Activity.

From www.alfredmfg.com

assembly line balancing Alfred Manufacturing Assembly Line Balancing Is A One Time Activity this research was conducted to determine the standard time and provide recommendations for achieving the. an unbalanced assembly line is a very common issue in manufacturing enterprises and it has been studied from different. the second procedure step consists of an innovative optimization model which defines tasks and accessory. In such a way that the. alb,. Assembly Line Balancing Is A One Time Activity.

From studylib.net

ASSEMBLY LINE BALANCING AND PROCESS LAYOUT Assembly Line Balancing Is A One Time Activity assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a particular time frame. the second procedure step consists of an innovative optimization model which defines tasks and accessory. an unbalanced assembly line is a very common issue in manufacturing enterprises and it has been studied from. Assembly Line Balancing Is A One Time Activity.

From www.youtube.com

Operations & Supply Chain Management Assembly Line Balancing I YouTube Assembly Line Balancing Is A One Time Activity this research was conducted to determine the standard time and provide recommendations for achieving the. alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time. assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a. Assembly Line Balancing Is A One Time Activity.

From www.slideserve.com

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation, free Assembly Line Balancing Is A One Time Activity In such a way that the. assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another, to organize tasks at those workstations so that the work at each takes about the same amount of time. this research. Assembly Line Balancing Is A One Time Activity.

From www.semanticscholar.org

Figure 2.1 from Twosided assembly line balancing using teaching Assembly Line Balancing Is A One Time Activity assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another, to organize tasks at those workstations so that the work at each takes about the same amount of time. assembly line balancing is a production strategy that. Assembly Line Balancing Is A One Time Activity.

From www.youtube.com

Assembly Line Balancing English YouTube Assembly Line Balancing Is A One Time Activity assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a particular time frame. this research was conducted to determine the standard time and provide recommendations for achieving the. assembly line balancing is the problem of assigning operations to workstations along an assembly line; an unbalanced. Assembly Line Balancing Is A One Time Activity.

From www.youtube.com

Assembly line balancing part3 Line balancing Target IES YouTube Assembly Line Balancing Is A One Time Activity In such a way that the. assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a particular time frame. this research was conducted to determine the standard time and provide recommendations for achieving the. alb, or simply line balancing, is arranging the individual processing and assembly. Assembly Line Balancing Is A One Time Activity.

From www.slideserve.com

PPT Assembly Line Balancing PowerPoint Presentation, free download Assembly Line Balancing Is A One Time Activity assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another, to organize tasks at those workstations so that the work at each takes about the same amount of time. assembly line balancing is a production strategy that. Assembly Line Balancing Is A One Time Activity.

From studylib.net

Assembly Line Balancing Assembly Line Balancing Is A One Time Activity alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time. an unbalanced assembly line is a very common issue in manufacturing enterprises and it has been studied from different. assembly line balancing is the problem of assigning operations to workstations along an assembly line; In such. Assembly Line Balancing Is A One Time Activity.

From www.youtube.com

Assembly Line Balancing YouTube Assembly Line Balancing Is A One Time Activity assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another, to organize tasks at those workstations so that the work at each takes about the same amount of time. alb, or simply line balancing, is arranging the. Assembly Line Balancing Is A One Time Activity.

From www.slideserve.com

PPT Assembly Line Balance PowerPoint Presentation, free download ID Assembly Line Balancing Is A One Time Activity the second procedure step consists of an innovative optimization model which defines tasks and accessory. assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a particular time frame. assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and. Assembly Line Balancing Is A One Time Activity.

From www.tetrahedron.in

Line Balancing in Manufacturing Training Tetrahedron Assembly Line Balancing Is A One Time Activity alb, or simply line balancing, is arranging the individual processing and assembly tasks at the workstations so that the total time. assembly line balancing is the problem of assigning operations to workstations along an assembly line; an unbalanced assembly line is a very common issue in manufacturing enterprises and it has been studied from different. assembly. Assembly Line Balancing Is A One Time Activity.

From exotpugop.blob.core.windows.net

Production Balancing at Sam Porter blog Assembly Line Balancing Is A One Time Activity assembly line balancing is a production strategy that sets an intended rate of production to produce a particular product within a particular time frame. an unbalanced assembly line is a very common issue in manufacturing enterprises and it has been studied from different. alb, or simply line balancing, is arranging the individual processing and assembly tasks at. Assembly Line Balancing Is A One Time Activity.

From mungfali.com

Line Balancing Formula Assembly Line Balancing Is A One Time Activity assembly line balancing is the problem of assigning operations to workstations along an assembly line; this research was conducted to determine the standard time and provide recommendations for achieving the. the second procedure step consists of an innovative optimization model which defines tasks and accessory. assembly line balancing (alb) is a process used in mass production. Assembly Line Balancing Is A One Time Activity.

From www.slideserve.com

PPT Chapter 7 Assembly Line Balancing PowerPoint Presentation, free Assembly Line Balancing Is A One Time Activity assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another, to organize tasks at those workstations so that the work at each takes about the same amount of time. alb, or simply line balancing, is arranging the. Assembly Line Balancing Is A One Time Activity.

From www.youtube.com

𝐋𝐢𝐧𝐞 𝐁𝐚𝐥𝐚𝐧𝐜𝐢𝐧𝐠 Production Line Balancing ? Assembly Line Balancing Assembly Line Balancing Is A One Time Activity assembly line balancing is the problem of assigning operations to workstations along an assembly line; assembly line balancing (alb) is a process used in mass production facility layouts, where parts are assembled and made into final products as the unit moves from one workstation to another, to organize tasks at those workstations so that the work at each. Assembly Line Balancing Is A One Time Activity.