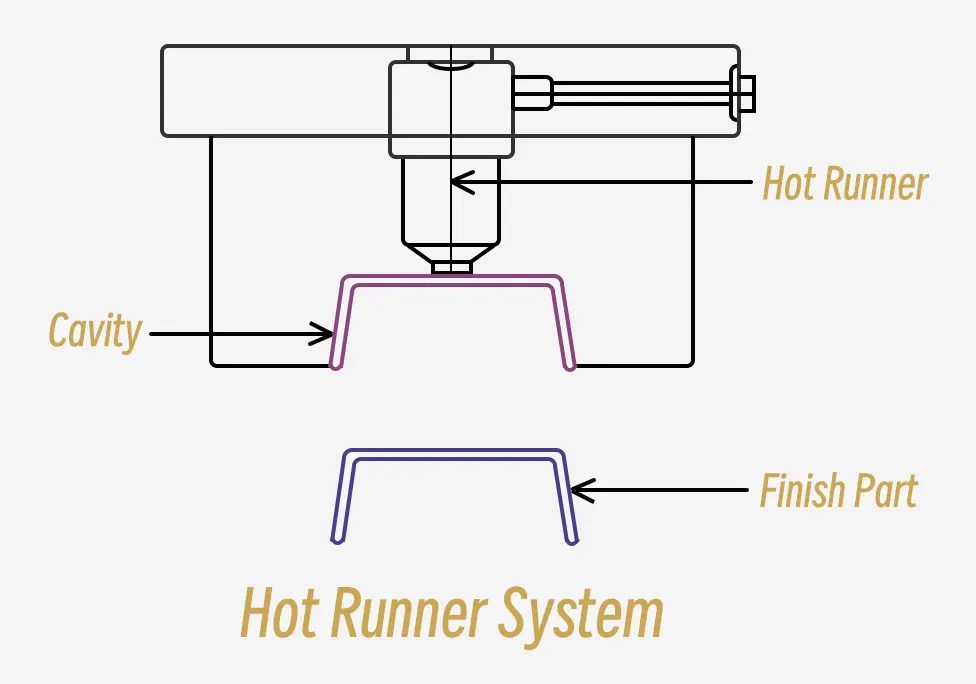

What Is Hot Runner And Cold Runner . Hot runner and cold runner molds are types of mold designs used for injection molding. What is the main difference between hot runner and cold runner moulds? In this post, we explore the hot runner and cold runner systems, shedding light on their mechanisms, advantages, and disadvantages. Learn about the key differences when comparing hot runner vs. Choosing the right runner system is crucial for optimizing production efficiency, cost, and part quality in plastic injection molding. Discover the key differences between hot and cold runner molds, their pros and cons, and how to choose the right system for. This article does the hot runner vs cold runner injection molding comparison by introducing both systems, how they work, and their differences. Runner systems are the vital pathways that direct molten material into molds, a fundamental component of the injection molding process. Hot runner mold systems are valued for their ability to produce consistent quality within faster cycle times. Furthermore, it shows how to choose the right mold for your project. Hot runner moulds use a heated runner to transfer molten material, while cold runner moulds use an unheated runner channel. Here is a checklist of several common hot runner challenges and sources of variation to consider in deciding between a hot runner or cold runner solution:

from cableties.cc

Runner systems are the vital pathways that direct molten material into molds, a fundamental component of the injection molding process. Choosing the right runner system is crucial for optimizing production efficiency, cost, and part quality in plastic injection molding. Learn about the key differences when comparing hot runner vs. Discover the key differences between hot and cold runner molds, their pros and cons, and how to choose the right system for. Hot runner moulds use a heated runner to transfer molten material, while cold runner moulds use an unheated runner channel. Hot runner and cold runner molds are types of mold designs used for injection molding. Furthermore, it shows how to choose the right mold for your project. What is the main difference between hot runner and cold runner moulds? Hot runner mold systems are valued for their ability to produce consistent quality within faster cycle times. This article does the hot runner vs cold runner injection molding comparison by introducing both systems, how they work, and their differences.

Hot Runners vs Cold Runners in Cable Tie Production 4 Key Differences

What Is Hot Runner And Cold Runner Discover the key differences between hot and cold runner molds, their pros and cons, and how to choose the right system for. This article does the hot runner vs cold runner injection molding comparison by introducing both systems, how they work, and their differences. Here is a checklist of several common hot runner challenges and sources of variation to consider in deciding between a hot runner or cold runner solution: Hot runner and cold runner molds are types of mold designs used for injection molding. Learn about the key differences when comparing hot runner vs. Discover the key differences between hot and cold runner molds, their pros and cons, and how to choose the right system for. In this post, we explore the hot runner and cold runner systems, shedding light on their mechanisms, advantages, and disadvantages. What is the main difference between hot runner and cold runner moulds? Choosing the right runner system is crucial for optimizing production efficiency, cost, and part quality in plastic injection molding. Hot runner mold systems are valued for their ability to produce consistent quality within faster cycle times. Hot runner moulds use a heated runner to transfer molten material, while cold runner moulds use an unheated runner channel. Furthermore, it shows how to choose the right mold for your project. Runner systems are the vital pathways that direct molten material into molds, a fundamental component of the injection molding process.

From yongchuanplastic.com

Cold runner vs Hot runner YONG CHUAN PLASTIC What Is Hot Runner And Cold Runner In this post, we explore the hot runner and cold runner systems, shedding light on their mechanisms, advantages, and disadvantages. Hot runner and cold runner molds are types of mold designs used for injection molding. Choosing the right runner system is crucial for optimizing production efficiency, cost, and part quality in plastic injection molding. Runner systems are the vital pathways. What Is Hot Runner And Cold Runner.

From www.echosupply.com

Injection Molding Basics Cold Runner Systems Echo Engineering What Is Hot Runner And Cold Runner Hot runner moulds use a heated runner to transfer molten material, while cold runner moulds use an unheated runner channel. What is the main difference between hot runner and cold runner moulds? Discover the key differences between hot and cold runner molds, their pros and cons, and how to choose the right system for. Hot runner and cold runner molds. What Is Hot Runner And Cold Runner.

From www.grommetseal.com

LSR Injection Molding's Hot Runner and Cold Runner System What Is Hot Runner And Cold Runner Furthermore, it shows how to choose the right mold for your project. Hot runner and cold runner molds are types of mold designs used for injection molding. Runner systems are the vital pathways that direct molten material into molds, a fundamental component of the injection molding process. What is the main difference between hot runner and cold runner moulds? Choosing. What Is Hot Runner And Cold Runner.

From kehuimold.com

Hot Runner VS Cold RunnerKehui Mold Co., Limited What Is Hot Runner And Cold Runner What is the main difference between hot runner and cold runner moulds? Hot runner moulds use a heated runner to transfer molten material, while cold runner moulds use an unheated runner channel. Learn about the key differences when comparing hot runner vs. Hot runner mold systems are valued for their ability to produce consistent quality within faster cycle times. Discover. What Is Hot Runner And Cold Runner.

From www.grommetseal.com

LSR Injection Molding's Hot Runner and Cold Runner System What Is Hot Runner And Cold Runner This article does the hot runner vs cold runner injection molding comparison by introducing both systems, how they work, and their differences. Discover the key differences between hot and cold runner molds, their pros and cons, and how to choose the right system for. What is the main difference between hot runner and cold runner moulds? Furthermore, it shows how. What Is Hot Runner And Cold Runner.

From anantamouldsindia.com

Hot Runner Vs Cold Runner Injection Molding A Comprehensive Guide What Is Hot Runner And Cold Runner Hot runner and cold runner molds are types of mold designs used for injection molding. Choosing the right runner system is crucial for optimizing production efficiency, cost, and part quality in plastic injection molding. Hot runner moulds use a heated runner to transfer molten material, while cold runner moulds use an unheated runner channel. Runner systems are the vital pathways. What Is Hot Runner And Cold Runner.

From www.xiamenhuaye.com

Introduction of Runner System in Injection Plastic Mold HUAYE What Is Hot Runner And Cold Runner Runner systems are the vital pathways that direct molten material into molds, a fundamental component of the injection molding process. What is the main difference between hot runner and cold runner moulds? Learn about the key differences when comparing hot runner vs. Choosing the right runner system is crucial for optimizing production efficiency, cost, and part quality in plastic injection. What Is Hot Runner And Cold Runner.

From cableties.cc

Hot Runners vs Cold Runners in Cable Tie Production 4 Key Differences What Is Hot Runner And Cold Runner Hot runner moulds use a heated runner to transfer molten material, while cold runner moulds use an unheated runner channel. Discover the key differences between hot and cold runner molds, their pros and cons, and how to choose the right system for. Hot runner and cold runner molds are types of mold designs used for injection molding. Learn about the. What Is Hot Runner And Cold Runner.

From www.rodongroup.com

Injection Molds 101 Hot Runner Injection Molding The Rodon Group® What Is Hot Runner And Cold Runner What is the main difference between hot runner and cold runner moulds? Runner systems are the vital pathways that direct molten material into molds, a fundamental component of the injection molding process. Hot runner moulds use a heated runner to transfer molten material, while cold runner moulds use an unheated runner channel. Discover the key differences between hot and cold. What Is Hot Runner And Cold Runner.

From kehuimold.com

Hot Runner VS Cold RunnerKehui Mold Co., Limited What Is Hot Runner And Cold Runner Discover the key differences between hot and cold runner molds, their pros and cons, and how to choose the right system for. Learn about the key differences when comparing hot runner vs. Runner systems are the vital pathways that direct molten material into molds, a fundamental component of the injection molding process. In this post, we explore the hot runner. What Is Hot Runner And Cold Runner.

From www.ace-mold.com

Why hot runner system is better than the cold runner system? What Is Hot Runner And Cold Runner This article does the hot runner vs cold runner injection molding comparison by introducing both systems, how they work, and their differences. Hot runner and cold runner molds are types of mold designs used for injection molding. In this post, we explore the hot runner and cold runner systems, shedding light on their mechanisms, advantages, and disadvantages. Discover the key. What Is Hot Runner And Cold Runner.

From nbplastics.com

Cold Runner and Hot Runner Injection Molds New Berlin Plastics What Is Hot Runner And Cold Runner Here is a checklist of several common hot runner challenges and sources of variation to consider in deciding between a hot runner or cold runner solution: Runner systems are the vital pathways that direct molten material into molds, a fundamental component of the injection molding process. Hot runner and cold runner molds are types of mold designs used for injection. What Is Hot Runner And Cold Runner.

From www.wundermold.com

Cold Runner vs. Hot Runner Molds 🥇 Plastic Injection Molding Company What Is Hot Runner And Cold Runner Hot runner and cold runner molds are types of mold designs used for injection molding. Furthermore, it shows how to choose the right mold for your project. Here is a checklist of several common hot runner challenges and sources of variation to consider in deciding between a hot runner or cold runner solution: Learn about the key differences when comparing. What Is Hot Runner And Cold Runner.

From ko.chapmanmaker.com

News Hot Runner VS Cold Runner What Is Hot Runner And Cold Runner Hot runner moulds use a heated runner to transfer molten material, while cold runner moulds use an unheated runner channel. In this post, we explore the hot runner and cold runner systems, shedding light on their mechanisms, advantages, and disadvantages. What is the main difference between hot runner and cold runner moulds? Hot runner mold systems are valued for their. What Is Hot Runner And Cold Runner.

From klakluopq.blob.core.windows.net

Difference Between Hot Runner And Cold Runner Injection Molding at What Is Hot Runner And Cold Runner Hot runner moulds use a heated runner to transfer molten material, while cold runner moulds use an unheated runner channel. Hot runner mold systems are valued for their ability to produce consistent quality within faster cycle times. This article does the hot runner vs cold runner injection molding comparison by introducing both systems, how they work, and their differences. Discover. What Is Hot Runner And Cold Runner.

From lgdsilicone.com

Hot Runner Vs Cold Runner What is the Difference? LDGSilicone What Is Hot Runner And Cold Runner Here is a checklist of several common hot runner challenges and sources of variation to consider in deciding between a hot runner or cold runner solution: Hot runner moulds use a heated runner to transfer molten material, while cold runner moulds use an unheated runner channel. Hot runner mold systems are valued for their ability to produce consistent quality within. What Is Hot Runner And Cold Runner.

From www.moldchina.com

Hot runner system types and their application in plastic injection mold What Is Hot Runner And Cold Runner This article does the hot runner vs cold runner injection molding comparison by introducing both systems, how they work, and their differences. Choosing the right runner system is crucial for optimizing production efficiency, cost, and part quality in plastic injection molding. Hot runner moulds use a heated runner to transfer molten material, while cold runner moulds use an unheated runner. What Is Hot Runner And Cold Runner.

From www.pioneerplastics.com

Hot Runner Systems vs. Cold Runner Systems What Is Hot Runner And Cold Runner Furthermore, it shows how to choose the right mold for your project. Hot runner moulds use a heated runner to transfer molten material, while cold runner moulds use an unheated runner channel. Here is a checklist of several common hot runner challenges and sources of variation to consider in deciding between a hot runner or cold runner solution: Choosing the. What Is Hot Runner And Cold Runner.

From www.smlease.com

Hot Runner vs Cold Runner Injection Mold Injection Mold Type What Is Hot Runner And Cold Runner Furthermore, it shows how to choose the right mold for your project. Runner systems are the vital pathways that direct molten material into molds, a fundamental component of the injection molding process. Hot runner and cold runner molds are types of mold designs used for injection molding. Discover the key differences between hot and cold runner molds, their pros and. What Is Hot Runner And Cold Runner.

From www.youtube.com

Hot runner mold vs cold runner mold ( two plate mold vs three plate What Is Hot Runner And Cold Runner Hot runner moulds use a heated runner to transfer molten material, while cold runner moulds use an unheated runner channel. Learn about the key differences when comparing hot runner vs. Runner systems are the vital pathways that direct molten material into molds, a fundamental component of the injection molding process. Discover the key differences between hot and cold runner molds,. What Is Hot Runner And Cold Runner.

From www.csmolding.com

Comparing Hot Runner and Cold Runner Molds for Injection Molding CS MOLD What Is Hot Runner And Cold Runner Hot runner and cold runner molds are types of mold designs used for injection molding. Hot runner mold systems are valued for their ability to produce consistent quality within faster cycle times. This article does the hot runner vs cold runner injection molding comparison by introducing both systems, how they work, and their differences. Hot runner moulds use a heated. What Is Hot Runner And Cold Runner.

From klakluopq.blob.core.windows.net

Difference Between Hot Runner And Cold Runner Injection Molding at What Is Hot Runner And Cold Runner Choosing the right runner system is crucial for optimizing production efficiency, cost, and part quality in plastic injection molding. Hot runner and cold runner molds are types of mold designs used for injection molding. What is the main difference between hot runner and cold runner moulds? Here is a checklist of several common hot runner challenges and sources of variation. What Is Hot Runner And Cold Runner.

From www.teamrapidtooling.com

Hot Runner vs Cold Runner Injection Mold, Differences? What Is Hot Runner And Cold Runner Choosing the right runner system is crucial for optimizing production efficiency, cost, and part quality in plastic injection molding. This article does the hot runner vs cold runner injection molding comparison by introducing both systems, how they work, and their differences. Hot runner moulds use a heated runner to transfer molten material, while cold runner moulds use an unheated runner. What Is Hot Runner And Cold Runner.

From richfieldsplastics.com

Different Types and Applications of Hot Runners Richfield Blog What Is Hot Runner And Cold Runner Choosing the right runner system is crucial for optimizing production efficiency, cost, and part quality in plastic injection molding. What is the main difference between hot runner and cold runner moulds? Discover the key differences between hot and cold runner molds, their pros and cons, and how to choose the right system for. Learn about the key differences when comparing. What Is Hot Runner And Cold Runner.

From www.basilius.com

A Guide to Hot and Cold Runner Systems Basilius Inc. What Is Hot Runner And Cold Runner Hot runner mold systems are valued for their ability to produce consistent quality within faster cycle times. Hot runner moulds use a heated runner to transfer molten material, while cold runner moulds use an unheated runner channel. Hot runner and cold runner molds are types of mold designs used for injection molding. In this post, we explore the hot runner. What Is Hot Runner And Cold Runner.

From www.fictiv.com

Hot Runner vs. Cold Runner Molds Fictiv What Is Hot Runner And Cold Runner Hot runner moulds use a heated runner to transfer molten material, while cold runner moulds use an unheated runner channel. Discover the key differences between hot and cold runner molds, their pros and cons, and how to choose the right system for. Runner systems are the vital pathways that direct molten material into molds, a fundamental component of the injection. What Is Hot Runner And Cold Runner.

From kehuimold.com

Hot Runner VS Cold RunnerKehui Mold Co., Limited What Is Hot Runner And Cold Runner Choosing the right runner system is crucial for optimizing production efficiency, cost, and part quality in plastic injection molding. Hot runner and cold runner molds are types of mold designs used for injection molding. Hot runner mold systems are valued for their ability to produce consistent quality within faster cycle times. Furthermore, it shows how to choose the right mold. What Is Hot Runner And Cold Runner.

From www.kemalmfg.com

Hot Runner vs Cold Runner Injection Mold What’s the Difference? Kemal What Is Hot Runner And Cold Runner What is the main difference between hot runner and cold runner moulds? This article does the hot runner vs cold runner injection molding comparison by introducing both systems, how they work, and their differences. Hot runner and cold runner molds are types of mold designs used for injection molding. Hot runner moulds use a heated runner to transfer molten material,. What Is Hot Runner And Cold Runner.

From www.jatco.com

Hot Runner Vs. Cold Runner in Plastics Production JATCO What Is Hot Runner And Cold Runner Runner systems are the vital pathways that direct molten material into molds, a fundamental component of the injection molding process. Furthermore, it shows how to choose the right mold for your project. Choosing the right runner system is crucial for optimizing production efficiency, cost, and part quality in plastic injection molding. What is the main difference between hot runner and. What Is Hot Runner And Cold Runner.

From klakluopq.blob.core.windows.net

Difference Between Hot Runner And Cold Runner Injection Molding at What Is Hot Runner And Cold Runner Discover the key differences between hot and cold runner molds, their pros and cons, and how to choose the right system for. Choosing the right runner system is crucial for optimizing production efficiency, cost, and part quality in plastic injection molding. Hot runner and cold runner molds are types of mold designs used for injection molding. Learn about the key. What Is Hot Runner And Cold Runner.

From klakluopq.blob.core.windows.net

Difference Between Hot Runner And Cold Runner Injection Molding at What Is Hot Runner And Cold Runner Learn about the key differences when comparing hot runner vs. Discover the key differences between hot and cold runner molds, their pros and cons, and how to choose the right system for. This article does the hot runner vs cold runner injection molding comparison by introducing both systems, how they work, and their differences. Hot runner and cold runner molds. What Is Hot Runner And Cold Runner.

From www.hordrt.com

A Comprehensive Comparison Hot Runner vs. Cold Runner Molds What Is Hot Runner And Cold Runner Discover the key differences between hot and cold runner molds, their pros and cons, and how to choose the right system for. Hot runner mold systems are valued for their ability to produce consistent quality within faster cycle times. Furthermore, it shows how to choose the right mold for your project. Choosing the right runner system is crucial for optimizing. What Is Hot Runner And Cold Runner.

From www.rapiddirect.com

Hot Runner vs Cold Runner Injection Mold Key Differences RapidDirect What Is Hot Runner And Cold Runner Choosing the right runner system is crucial for optimizing production efficiency, cost, and part quality in plastic injection molding. Discover the key differences between hot and cold runner molds, their pros and cons, and how to choose the right system for. Hot runner and cold runner molds are types of mold designs used for injection molding. Here is a checklist. What Is Hot Runner And Cold Runner.

From www.teamrapidtooling.com

Hot Runner vs Cold Runner Injection Mold, Differences? What Is Hot Runner And Cold Runner What is the main difference between hot runner and cold runner moulds? This article does the hot runner vs cold runner injection molding comparison by introducing both systems, how they work, and their differences. Hot runner mold systems are valued for their ability to produce consistent quality within faster cycle times. In this post, we explore the hot runner and. What Is Hot Runner And Cold Runner.

From www.grefeemold.com

How to select the right hot runner types for injection molding dies What Is Hot Runner And Cold Runner Hot runner mold systems are valued for their ability to produce consistent quality within faster cycle times. In this post, we explore the hot runner and cold runner systems, shedding light on their mechanisms, advantages, and disadvantages. Hot runner moulds use a heated runner to transfer molten material, while cold runner moulds use an unheated runner channel. Learn about the. What Is Hot Runner And Cold Runner.