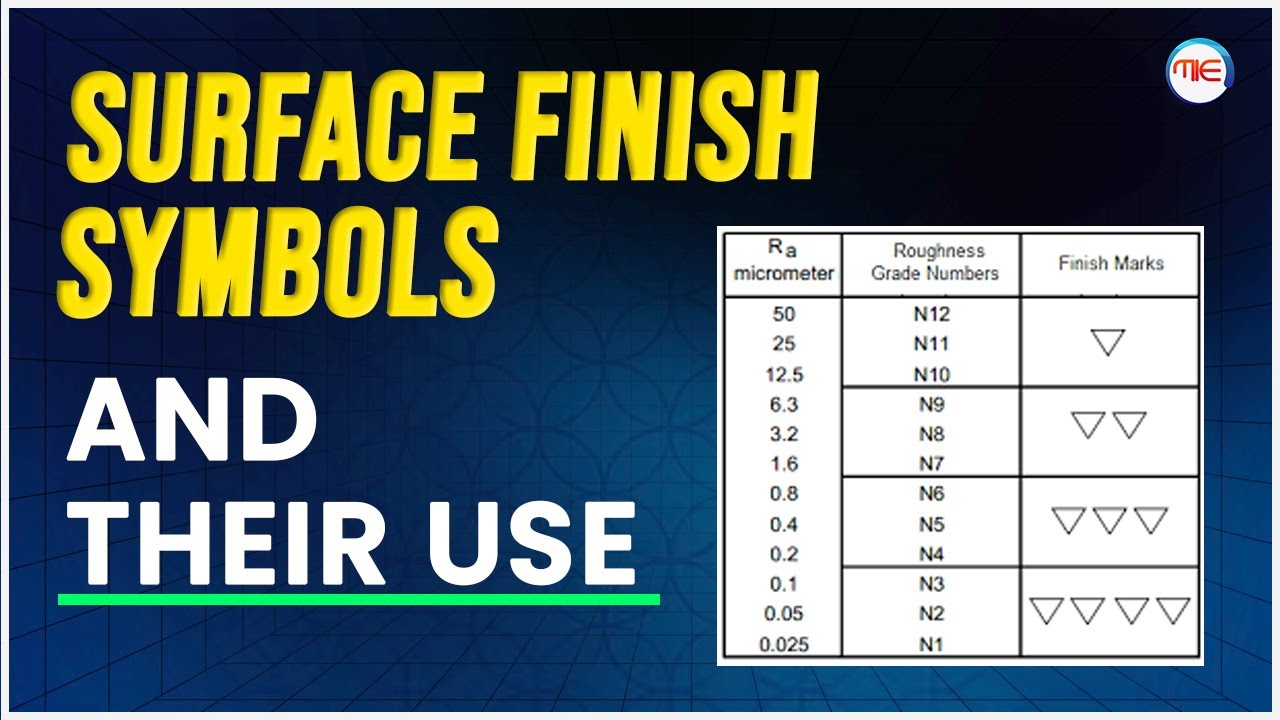

Surface Finish Symbol No Number . Numbers near the basic surface finish symbol are used to provide different surface finish parameters. To interchange between roughness grade. This surface roughness indication method pictorially displays information such as the surface roughness value, cutoff value, sampling length, machining method, crease direction symbol, and. The location of the number in relation. The bis recommended symbols for indicating the surface finish are shown in table a. Surface roughness symbols are used to communicate the required surface texture of machined and structural parts are used in industrial diagrams. The american society of mechanical engineers (asme) defines surface finish specifications in standards such as y14.36m, which outlines surface texture symbols for technical drawings, and b46.1, which details definitions and measurement methods for surface finish. Surface roughness classifications employ the conventional “n” notation, allocating a roughness grade number to distinguish various surface textures. Implementing asme y14.36 reduces errors and increases efficiency. Many factors affect the final surface roughness of a part. Factors that affect surface finish. It may be as simple as inadequate preparation of the workpiece surface before machining. This standard provides guidelines for scales and formats, lettering and line conventions, and provides symbols that indicate surface roughness.

from www.youtube.com

This surface roughness indication method pictorially displays information such as the surface roughness value, cutoff value, sampling length, machining method, crease direction symbol, and. To interchange between roughness grade. The american society of mechanical engineers (asme) defines surface finish specifications in standards such as y14.36m, which outlines surface texture symbols for technical drawings, and b46.1, which details definitions and measurement methods for surface finish. Factors that affect surface finish. Surface roughness classifications employ the conventional “n” notation, allocating a roughness grade number to distinguish various surface textures. This standard provides guidelines for scales and formats, lettering and line conventions, and provides symbols that indicate surface roughness. It may be as simple as inadequate preparation of the workpiece surface before machining. Surface roughness symbols are used to communicate the required surface texture of machined and structural parts are used in industrial diagrams. The location of the number in relation. Implementing asme y14.36 reduces errors and increases efficiency.

SURFACE FINISH SYMBOL IN HINDI AND THEIR USE SURFACE FINiSH

Surface Finish Symbol No Number Surface roughness symbols are used to communicate the required surface texture of machined and structural parts are used in industrial diagrams. To interchange between roughness grade. The bis recommended symbols for indicating the surface finish are shown in table a. Surface roughness classifications employ the conventional “n” notation, allocating a roughness grade number to distinguish various surface textures. Surface roughness symbols are used to communicate the required surface texture of machined and structural parts are used in industrial diagrams. Many factors affect the final surface roughness of a part. Numbers near the basic surface finish symbol are used to provide different surface finish parameters. It may be as simple as inadequate preparation of the workpiece surface before machining. This surface roughness indication method pictorially displays information such as the surface roughness value, cutoff value, sampling length, machining method, crease direction symbol, and. This standard provides guidelines for scales and formats, lettering and line conventions, and provides symbols that indicate surface roughness. Factors that affect surface finish. The location of the number in relation. Implementing asme y14.36 reduces errors and increases efficiency. The american society of mechanical engineers (asme) defines surface finish specifications in standards such as y14.36m, which outlines surface texture symbols for technical drawings, and b46.1, which details definitions and measurement methods for surface finish.

From mavink.com

Engineering Surface Finish Symbols Surface Finish Symbol No Number To interchange between roughness grade. This surface roughness indication method pictorially displays information such as the surface roughness value, cutoff value, sampling length, machining method, crease direction symbol, and. This standard provides guidelines for scales and formats, lettering and line conventions, and provides symbols that indicate surface roughness. It may be as simple as inadequate preparation of the workpiece surface. Surface Finish Symbol No Number.

From china-maching.com

Surface Finishing Symbols Understanding Surface Roughness ETCN Surface Finish Symbol No Number The bis recommended symbols for indicating the surface finish are shown in table a. Implementing asme y14.36 reduces errors and increases efficiency. To interchange between roughness grade. Factors that affect surface finish. Numbers near the basic surface finish symbol are used to provide different surface finish parameters. Surface roughness symbols are used to communicate the required surface texture of machined. Surface Finish Symbol No Number.

From jiga.io

Surface Finish Standards, Techniques, Applications, and More Surface Finish Symbol No Number The bis recommended symbols for indicating the surface finish are shown in table a. The american society of mechanical engineers (asme) defines surface finish specifications in standards such as y14.36m, which outlines surface texture symbols for technical drawings, and b46.1, which details definitions and measurement methods for surface finish. Factors that affect surface finish. This standard provides guidelines for scales. Surface Finish Symbol No Number.

From www.youtube.com

SURFACE FINISH SYMBOL IN HINDI AND THEIR USE SURFACE FINiSH Surface Finish Symbol No Number The location of the number in relation. Factors that affect surface finish. To interchange between roughness grade. This surface roughness indication method pictorially displays information such as the surface roughness value, cutoff value, sampling length, machining method, crease direction symbol, and. Surface roughness symbols are used to communicate the required surface texture of machined and structural parts are used in. Surface Finish Symbol No Number.

From mavink.com

Surface Roughness Ra Symbol Surface Finish Symbol No Number The american society of mechanical engineers (asme) defines surface finish specifications in standards such as y14.36m, which outlines surface texture symbols for technical drawings, and b46.1, which details definitions and measurement methods for surface finish. Numbers near the basic surface finish symbol are used to provide different surface finish parameters. The location of the number in relation. Surface roughness classifications. Surface Finish Symbol No Number.

From www.slideserve.com

PPT MECHANICAL DRAWING Chapter 9 SURFACE FINISH PowerPoint Surface Finish Symbol No Number Surface roughness classifications employ the conventional “n” notation, allocating a roughness grade number to distinguish various surface textures. This surface roughness indication method pictorially displays information such as the surface roughness value, cutoff value, sampling length, machining method, crease direction symbol, and. The american society of mechanical engineers (asme) defines surface finish specifications in standards such as y14.36m, which outlines. Surface Finish Symbol No Number.

From www.youtube.com

SOLIDWORKS INTERMEDIATE TUTORIAL ADDING SURFACE CONTROLS SYMBOLS LIKE Surface Finish Symbol No Number To interchange between roughness grade. Many factors affect the final surface roughness of a part. This standard provides guidelines for scales and formats, lettering and line conventions, and provides symbols that indicate surface roughness. Surface roughness classifications employ the conventional “n” notation, allocating a roughness grade number to distinguish various surface textures. The bis recommended symbols for indicating the surface. Surface Finish Symbol No Number.

From www.slideserve.com

PPT MECHANICAL DRAWING Chapter 9 SURFACE FINISH PowerPoint Surface Finish Symbol No Number Implementing asme y14.36 reduces errors and increases efficiency. The bis recommended symbols for indicating the surface finish are shown in table a. This standard provides guidelines for scales and formats, lettering and line conventions, and provides symbols that indicate surface roughness. To interchange between roughness grade. It may be as simple as inadequate preparation of the workpiece surface before machining.. Surface Finish Symbol No Number.

From mavink.com

Surface Roughness Symbols And Meanings Surface Finish Symbol No Number This surface roughness indication method pictorially displays information such as the surface roughness value, cutoff value, sampling length, machining method, crease direction symbol, and. The location of the number in relation. It may be as simple as inadequate preparation of the workpiece surface before machining. Numbers near the basic surface finish symbol are used to provide different surface finish parameters.. Surface Finish Symbol No Number.

From www.slideserve.com

PPT Surface Finish PowerPoint Presentation, free download ID3866407 Surface Finish Symbol No Number It may be as simple as inadequate preparation of the workpiece surface before machining. Implementing asme y14.36 reduces errors and increases efficiency. Numbers near the basic surface finish symbol are used to provide different surface finish parameters. The location of the number in relation. Surface roughness symbols are used to communicate the required surface texture of machined and structural parts. Surface Finish Symbol No Number.

From www.youtube.com

Different surface finish symbol on drawing and Surface finish of Surface Finish Symbol No Number This standard provides guidelines for scales and formats, lettering and line conventions, and provides symbols that indicate surface roughness. To interchange between roughness grade. Many factors affect the final surface roughness of a part. This surface roughness indication method pictorially displays information such as the surface roughness value, cutoff value, sampling length, machining method, crease direction symbol, and. Numbers near. Surface Finish Symbol No Number.

From www.gdandtbasics.com

The Basics of Surface Finish GD&T Basics Surface Finish Symbol No Number Many factors affect the final surface roughness of a part. To interchange between roughness grade. Implementing asme y14.36 reduces errors and increases efficiency. The bis recommended symbols for indicating the surface finish are shown in table a. Surface roughness symbols are used to communicate the required surface texture of machined and structural parts are used in industrial diagrams. It may. Surface Finish Symbol No Number.

From mungfali.com

Surface Finish Symbols Surface Finish Symbol No Number Surface roughness classifications employ the conventional “n” notation, allocating a roughness grade number to distinguish various surface textures. To interchange between roughness grade. The american society of mechanical engineers (asme) defines surface finish specifications in standards such as y14.36m, which outlines surface texture symbols for technical drawings, and b46.1, which details definitions and measurement methods for surface finish. This standard. Surface Finish Symbol No Number.

From www.runsom.com

A Guide to Surface Finish Runsom Precision Surface Finish Symbol No Number Surface roughness classifications employ the conventional “n” notation, allocating a roughness grade number to distinguish various surface textures. The american society of mechanical engineers (asme) defines surface finish specifications in standards such as y14.36m, which outlines surface texture symbols for technical drawings, and b46.1, which details definitions and measurement methods for surface finish. Implementing asme y14.36 reduces errors and increases. Surface Finish Symbol No Number.

From www.youtube.com

Surface Finishing symbol Terminology and Roughness Grade N1 to N12 । Surface Finish Symbol No Number Surface roughness classifications employ the conventional “n” notation, allocating a roughness grade number to distinguish various surface textures. Many factors affect the final surface roughness of a part. Numbers near the basic surface finish symbol are used to provide different surface finish parameters. This surface roughness indication method pictorially displays information such as the surface roughness value, cutoff value, sampling. Surface Finish Symbol No Number.

From etcnmachining.com

A Comprehensive Guide to Surface Finish Symbols in Engineering Drawings Surface Finish Symbol No Number Many factors affect the final surface roughness of a part. Factors that affect surface finish. Surface roughness classifications employ the conventional “n” notation, allocating a roughness grade number to distinguish various surface textures. This standard provides guidelines for scales and formats, lettering and line conventions, and provides symbols that indicate surface roughness. The american society of mechanical engineers (asme) defines. Surface Finish Symbol No Number.

From joixjbrmv.blob.core.windows.net

Surface Finish Symbol Keyboard Shortcut at Martha Collins blog Surface Finish Symbol No Number Surface roughness symbols are used to communicate the required surface texture of machined and structural parts are used in industrial diagrams. Numbers near the basic surface finish symbol are used to provide different surface finish parameters. This surface roughness indication method pictorially displays information such as the surface roughness value, cutoff value, sampling length, machining method, crease direction symbol, and.. Surface Finish Symbol No Number.

From www.cnccookbook.com.s3-website-us-east-1.amazonaws.com

Surface Finish Symbols and Roughness Conversion Chart Tables Surface Finish Symbol No Number Numbers near the basic surface finish symbol are used to provide different surface finish parameters. The bis recommended symbols for indicating the surface finish are shown in table a. Surface roughness symbols are used to communicate the required surface texture of machined and structural parts are used in industrial diagrams. This surface roughness indication method pictorially displays information such as. Surface Finish Symbol No Number.

From mavink.com

Iso Surface Finish Chart Surface Finish Symbol No Number This surface roughness indication method pictorially displays information such as the surface roughness value, cutoff value, sampling length, machining method, crease direction symbol, and. Factors that affect surface finish. Many factors affect the final surface roughness of a part. Surface roughness symbols are used to communicate the required surface texture of machined and structural parts are used in industrial diagrams.. Surface Finish Symbol No Number.

From gabrieletoth.blogspot.com

machining surface finish symbols triangle Micheline Galindo Surface Finish Symbol No Number To interchange between roughness grade. Factors that affect surface finish. The location of the number in relation. Surface roughness symbols are used to communicate the required surface texture of machined and structural parts are used in industrial diagrams. This standard provides guidelines for scales and formats, lettering and line conventions, and provides symbols that indicate surface roughness. Numbers near the. Surface Finish Symbol No Number.

From www.engineeringchoice.com

What is Surface Finish? Units, Symbols & Chart Engineering Choice Surface Finish Symbol No Number To interchange between roughness grade. The location of the number in relation. This standard provides guidelines for scales and formats, lettering and line conventions, and provides symbols that indicate surface roughness. The american society of mechanical engineers (asme) defines surface finish specifications in standards such as y14.36m, which outlines surface texture symbols for technical drawings, and b46.1, which details definitions. Surface Finish Symbol No Number.

From www.slideshare.net

Surface roughness 200708 Surface Finish Symbol No Number Factors that affect surface finish. The location of the number in relation. Surface roughness classifications employ the conventional “n” notation, allocating a roughness grade number to distinguish various surface textures. Implementing asme y14.36 reduces errors and increases efficiency. It may be as simple as inadequate preparation of the workpiece surface before machining. Many factors affect the final surface roughness of. Surface Finish Symbol No Number.

From shunspirit.com

Understanding The Surface Finish Symbol A Guide To Surface Finish Surface Finish Symbol No Number Numbers near the basic surface finish symbol are used to provide different surface finish parameters. The american society of mechanical engineers (asme) defines surface finish specifications in standards such as y14.36m, which outlines surface texture symbols for technical drawings, and b46.1, which details definitions and measurement methods for surface finish. This surface roughness indication method pictorially displays information such as. Surface Finish Symbol No Number.

From www.tpsearchtool.com

Complete Surface Finish Chart Symbols Roughness Conversion Tables Images Surface Finish Symbol No Number This surface roughness indication method pictorially displays information such as the surface roughness value, cutoff value, sampling length, machining method, crease direction symbol, and. Surface roughness symbols are used to communicate the required surface texture of machined and structural parts are used in industrial diagrams. Implementing asme y14.36 reduces errors and increases efficiency. The location of the number in relation.. Surface Finish Symbol No Number.

From exoeghofm.blob.core.windows.net

Surface Finish Higher Number at Courtney Wallace blog Surface Finish Symbol No Number Surface roughness symbols are used to communicate the required surface texture of machined and structural parts are used in industrial diagrams. Factors that affect surface finish. This surface roughness indication method pictorially displays information such as the surface roughness value, cutoff value, sampling length, machining method, crease direction symbol, and. Surface roughness classifications employ the conventional “n” notation, allocating a. Surface Finish Symbol No Number.

From mungfali.com

Surface Finish Symbols Surface Finish Symbol No Number Factors that affect surface finish. Surface roughness symbols are used to communicate the required surface texture of machined and structural parts are used in industrial diagrams. Many factors affect the final surface roughness of a part. This surface roughness indication method pictorially displays information such as the surface roughness value, cutoff value, sampling length, machining method, crease direction symbol, and.. Surface Finish Symbol No Number.

From mungfali.com

Roughness Symbol Surface Finish Surface Finish Symbol No Number Surface roughness classifications employ the conventional “n” notation, allocating a roughness grade number to distinguish various surface textures. Many factors affect the final surface roughness of a part. The bis recommended symbols for indicating the surface finish are shown in table a. The location of the number in relation. Factors that affect surface finish. This standard provides guidelines for scales. Surface Finish Symbol No Number.

From mechheart.com

Surface Finish Symbols for Engineering Drawings MECHHEART Surface Finish Symbol No Number Surface roughness symbols are used to communicate the required surface texture of machined and structural parts are used in industrial diagrams. This surface roughness indication method pictorially displays information such as the surface roughness value, cutoff value, sampling length, machining method, crease direction symbol, and. The bis recommended symbols for indicating the surface finish are shown in table a. It. Surface Finish Symbol No Number.

From mavink.com

Engineering Surface Finish Symbols Surface Finish Symbol No Number Surface roughness symbols are used to communicate the required surface texture of machined and structural parts are used in industrial diagrams. This surface roughness indication method pictorially displays information such as the surface roughness value, cutoff value, sampling length, machining method, crease direction symbol, and. Surface roughness classifications employ the conventional “n” notation, allocating a roughness grade number to distinguish. Surface Finish Symbol No Number.

From mungfali.com

Surface Finish Symbols Printable Surface Finish Symbol No Number The american society of mechanical engineers (asme) defines surface finish specifications in standards such as y14.36m, which outlines surface texture symbols for technical drawings, and b46.1, which details definitions and measurement methods for surface finish. Surface roughness classifications employ the conventional “n” notation, allocating a roughness grade number to distinguish various surface textures. The bis recommended symbols for indicating the. Surface Finish Symbol No Number.

From mungfali.com

Surface Finish Symbols Surface Finish Symbol No Number Many factors affect the final surface roughness of a part. Implementing asme y14.36 reduces errors and increases efficiency. The bis recommended symbols for indicating the surface finish are shown in table a. To interchange between roughness grade. This surface roughness indication method pictorially displays information such as the surface roughness value, cutoff value, sampling length, machining method, crease direction symbol,. Surface Finish Symbol No Number.

From cncpartsxtj.com

Know The Different Types Of Surface Finishing Symbols And Their Surface Finish Symbol No Number Many factors affect the final surface roughness of a part. Factors that affect surface finish. The location of the number in relation. Surface roughness symbols are used to communicate the required surface texture of machined and structural parts are used in industrial diagrams. Implementing asme y14.36 reduces errors and increases efficiency. The bis recommended symbols for indicating the surface finish. Surface Finish Symbol No Number.

From www.engineeringchoice.com

What is Surface Finish? Units, Symbols & Chart Surface Finish Symbol No Number Numbers near the basic surface finish symbol are used to provide different surface finish parameters. This standard provides guidelines for scales and formats, lettering and line conventions, and provides symbols that indicate surface roughness. Implementing asme y14.36 reduces errors and increases efficiency. To interchange between roughness grade. Factors that affect surface finish. Surface roughness classifications employ the conventional “n” notation,. Surface Finish Symbol No Number.

From mathplacementexamuhmanoa.blogspot.com

Surface Finish Symbols In Engineering Drawing 2 Before we get on Surface Finish Symbol No Number Factors that affect surface finish. Numbers near the basic surface finish symbol are used to provide different surface finish parameters. The location of the number in relation. It may be as simple as inadequate preparation of the workpiece surface before machining. Implementing asme y14.36 reduces errors and increases efficiency. Surface roughness symbols are used to communicate the required surface texture. Surface Finish Symbol No Number.

From www.gdandtbasics.com

The Basics of Surface Finish GD&T Basics Surface Finish Symbol No Number The bis recommended symbols for indicating the surface finish are shown in table a. Implementing asme y14.36 reduces errors and increases efficiency. Numbers near the basic surface finish symbol are used to provide different surface finish parameters. This standard provides guidelines for scales and formats, lettering and line conventions, and provides symbols that indicate surface roughness. The american society of. Surface Finish Symbol No Number.