Surface Finish And Polish . — three main types of polishing are used on machined parts surface finish; It aims to remove scratches and. surface finish is the visual appearance of the metal and is created through various processing methods, including rolling, polishing, and blasting. — surface finishes impact the effectiveness of treatments like shot peening, polishing, alodining, anodizing, notriding etc. — generally, polishing involves using an abrasive material to finish a metal surface. — surface finish is highly dependent on the process used to manufacture the part, and very smooth. The objective is to create a smooth, reflective, and visually appealing surface. Poor surface preparation and oxide residues can affect the depth of treatments and their resulting benefits. — common surface finishes: Conventional polishing, fire polishing, and. It’s commonly used for aesthetic purposes and in applications where minimal friction is required. — polishing refers to the surface finishing process of refining and enhancing a surface by removing or minimizing imperfections, such as scratches, marks, or unevenness.

from www.nextgentooling.com

— common surface finishes: — surface finish is highly dependent on the process used to manufacture the part, and very smooth. Conventional polishing, fire polishing, and. It’s commonly used for aesthetic purposes and in applications where minimal friction is required. — surface finishes impact the effectiveness of treatments like shot peening, polishing, alodining, anodizing, notriding etc. — three main types of polishing are used on machined parts surface finish; It aims to remove scratches and. Poor surface preparation and oxide residues can affect the depth of treatments and their resulting benefits. The objective is to create a smooth, reflective, and visually appealing surface. — polishing refers to the surface finishing process of refining and enhancing a surface by removing or minimizing imperfections, such as scratches, marks, or unevenness.

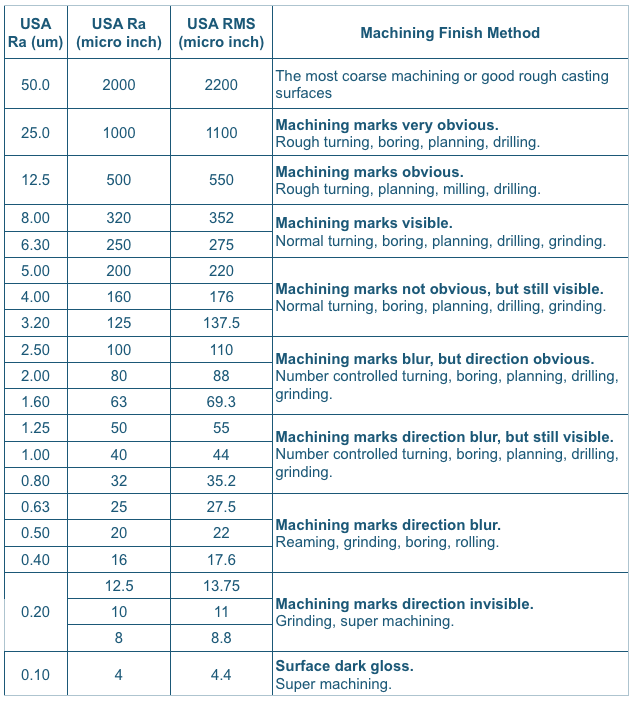

Understanding Surface Finish RMS vs Ra NEXT GENERATION TOOLING

Surface Finish And Polish — three main types of polishing are used on machined parts surface finish; — generally, polishing involves using an abrasive material to finish a metal surface. Poor surface preparation and oxide residues can affect the depth of treatments and their resulting benefits. — surface finish is highly dependent on the process used to manufacture the part, and very smooth. Conventional polishing, fire polishing, and. surface finish is the visual appearance of the metal and is created through various processing methods, including rolling, polishing, and blasting. — polishing refers to the surface finishing process of refining and enhancing a surface by removing or minimizing imperfections, such as scratches, marks, or unevenness. It aims to remove scratches and. It’s commonly used for aesthetic purposes and in applications where minimal friction is required. — surface finishes impact the effectiveness of treatments like shot peening, polishing, alodining, anodizing, notriding etc. — three main types of polishing are used on machined parts surface finish; The objective is to create a smooth, reflective, and visually appealing surface. — common surface finishes:

From www.vrogue.co

Understanding Surface Roughness And Surface Finish A vrogue.co Surface Finish And Polish The objective is to create a smooth, reflective, and visually appealing surface. — surface finishes impact the effectiveness of treatments like shot peening, polishing, alodining, anodizing, notriding etc. — polishing refers to the surface finishing process of refining and enhancing a surface by removing or minimizing imperfections, such as scratches, marks, or unevenness. — common surface finishes:. Surface Finish And Polish.

From sositarmould.com

Surface finish (polishing and texture) Sositar Surface Finish And Polish It’s commonly used for aesthetic purposes and in applications where minimal friction is required. — common surface finishes: The objective is to create a smooth, reflective, and visually appealing surface. Poor surface preparation and oxide residues can affect the depth of treatments and their resulting benefits. — generally, polishing involves using an abrasive material to finish a metal. Surface Finish And Polish.

From www.diamondbritemetals.com

Major Benefits of Metal Polishing Surface Finish And Polish It’s commonly used for aesthetic purposes and in applications where minimal friction is required. surface finish is the visual appearance of the metal and is created through various processing methods, including rolling, polishing, and blasting. — polishing refers to the surface finishing process of refining and enhancing a surface by removing or minimizing imperfections, such as scratches, marks,. Surface Finish And Polish.

From blog.thepipingmart.com

Overview of Stainless Steel Surface Finishes ThePipingMart Blog Surface Finish And Polish — common surface finishes: — generally, polishing involves using an abrasive material to finish a metal surface. — three main types of polishing are used on machined parts surface finish; The objective is to create a smooth, reflective, and visually appealing surface. — surface finishes impact the effectiveness of treatments like shot peening, polishing, alodining, anodizing,. Surface Finish And Polish.

From www.fastradius.com

Comparing Different Types Of Polishing Surface Finishes Fast Radius Surface Finish And Polish — surface finish is highly dependent on the process used to manufacture the part, and very smooth. Poor surface preparation and oxide residues can affect the depth of treatments and their resulting benefits. — polishing refers to the surface finishing process of refining and enhancing a surface by removing or minimizing imperfections, such as scratches, marks, or unevenness.. Surface Finish And Polish.

From mavink.com

Iso Surface Finish Chart Surface Finish And Polish — three main types of polishing are used on machined parts surface finish; — generally, polishing involves using an abrasive material to finish a metal surface. — polishing refers to the surface finishing process of refining and enhancing a surface by removing or minimizing imperfections, such as scratches, marks, or unevenness. The objective is to create a. Surface Finish And Polish.

From www.rapiddirect.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect Surface Finish And Polish — surface finish is highly dependent on the process used to manufacture the part, and very smooth. — polishing refers to the surface finishing process of refining and enhancing a surface by removing or minimizing imperfections, such as scratches, marks, or unevenness. — generally, polishing involves using an abrasive material to finish a metal surface. —. Surface Finish And Polish.

From www.gdandtbasics.com

The Basics of Surface Finish GD&T Basics Surface Finish And Polish It aims to remove scratches and. — three main types of polishing are used on machined parts surface finish; — polishing refers to the surface finishing process of refining and enhancing a surface by removing or minimizing imperfections, such as scratches, marks, or unevenness. Conventional polishing, fire polishing, and. Poor surface preparation and oxide residues can affect the. Surface Finish And Polish.

From www.gearfxdriveline.com

REM Isotropic Surface Finishing GearFX Surface Finish And Polish — surface finishes impact the effectiveness of treatments like shot peening, polishing, alodining, anodizing, notriding etc. The objective is to create a smooth, reflective, and visually appealing surface. surface finish is the visual appearance of the metal and is created through various processing methods, including rolling, polishing, and blasting. — three main types of polishing are used. Surface Finish And Polish.

From wa.nlcs.gov.bt

Surface roughness chart Surface Finish And Polish — common surface finishes: — generally, polishing involves using an abrasive material to finish a metal surface. It aims to remove scratches and. It’s commonly used for aesthetic purposes and in applications where minimal friction is required. — three main types of polishing are used on machined parts surface finish; Poor surface preparation and oxide residues can. Surface Finish And Polish.

From www.engineeringchoice.com

What is Surface Finish? Units, Symbols & Chart Surface Finish And Polish The objective is to create a smooth, reflective, and visually appealing surface. It aims to remove scratches and. — polishing refers to the surface finishing process of refining and enhancing a surface by removing or minimizing imperfections, such as scratches, marks, or unevenness. surface finish is the visual appearance of the metal and is created through various processing. Surface Finish And Polish.

From craft-art.com

How to Polish Epoxy Resin A Step by Step Guide Surface Finish And Polish The objective is to create a smooth, reflective, and visually appealing surface. — three main types of polishing are used on machined parts surface finish; — polishing refers to the surface finishing process of refining and enhancing a surface by removing or minimizing imperfections, such as scratches, marks, or unevenness. — generally, polishing involves using an abrasive. Surface Finish And Polish.

From www.rapiddirect.com

Everything You Need to Know About Polishing Surface Finish RapidDirect Surface Finish And Polish — surface finish is highly dependent on the process used to manufacture the part, and very smooth. It’s commonly used for aesthetic purposes and in applications where minimal friction is required. — surface finishes impact the effectiveness of treatments like shot peening, polishing, alodining, anodizing, notriding etc. Conventional polishing, fire polishing, and. — generally, polishing involves using. Surface Finish And Polish.

From www.youtube.com

How to Polish Solid Surface Countertops Gloss Finish YouTube Surface Finish And Polish The objective is to create a smooth, reflective, and visually appealing surface. It’s commonly used for aesthetic purposes and in applications where minimal friction is required. — three main types of polishing are used on machined parts surface finish; Conventional polishing, fire polishing, and. — polishing refers to the surface finishing process of refining and enhancing a surface. Surface Finish And Polish.

From www.mirka.com

Solid Surface Sanding Finishing and Polishing Mirka Surface Finish And Polish — generally, polishing involves using an abrasive material to finish a metal surface. — surface finishes impact the effectiveness of treatments like shot peening, polishing, alodining, anodizing, notriding etc. Conventional polishing, fire polishing, and. Poor surface preparation and oxide residues can affect the depth of treatments and their resulting benefits. It’s commonly used for aesthetic purposes and in. Surface Finish And Polish.

From jiga.io

Surface Finish Standards, Techniques, Applications, and More Surface Finish And Polish — common surface finishes: — three main types of polishing are used on machined parts surface finish; Conventional polishing, fire polishing, and. — generally, polishing involves using an abrasive material to finish a metal surface. The objective is to create a smooth, reflective, and visually appealing surface. — surface finish is highly dependent on the process. Surface Finish And Polish.

From jiga.io

Surface Finish Standards, Techniques, Applications, and More Surface Finish And Polish Poor surface preparation and oxide residues can affect the depth of treatments and their resulting benefits. It aims to remove scratches and. It’s commonly used for aesthetic purposes and in applications where minimal friction is required. surface finish is the visual appearance of the metal and is created through various processing methods, including rolling, polishing, and blasting. —. Surface Finish And Polish.

From www.alamy.com

Metal surface finishing texture realistic icons collection with satin Surface Finish And Polish — polishing refers to the surface finishing process of refining and enhancing a surface by removing or minimizing imperfections, such as scratches, marks, or unevenness. — surface finishes impact the effectiveness of treatments like shot peening, polishing, alodining, anodizing, notriding etc. surface finish is the visual appearance of the metal and is created through various processing methods,. Surface Finish And Polish.

From www.amazon.com

Quick Shine MultiSurface Floor Finish and Polish, 64 oz Surface Finish And Polish It aims to remove scratches and. — surface finishes impact the effectiveness of treatments like shot peening, polishing, alodining, anodizing, notriding etc. — common surface finishes: It’s commonly used for aesthetic purposes and in applications where minimal friction is required. — three main types of polishing are used on machined parts surface finish; — surface finish. Surface Finish And Polish.

From www.youtube.com

How to Sand and Polish Solid Surface Countertops Matte Finish YouTube Surface Finish And Polish The objective is to create a smooth, reflective, and visually appealing surface. — generally, polishing involves using an abrasive material to finish a metal surface. — surface finishes impact the effectiveness of treatments like shot peening, polishing, alodining, anodizing, notriding etc. — three main types of polishing are used on machined parts surface finish; — polishing. Surface Finish And Polish.

From www.nextgentooling.com

Understanding Surface Finish RMS vs Ra NEXT GENERATION TOOLING Surface Finish And Polish — common surface finishes: It aims to remove scratches and. — surface finish is highly dependent on the process used to manufacture the part, and very smooth. — surface finishes impact the effectiveness of treatments like shot peening, polishing, alodining, anodizing, notriding etc. — generally, polishing involves using an abrasive material to finish a metal surface.. Surface Finish And Polish.

From www.sexizpix.com

Surface Roughness Chart Comparison Iso Finishing Sexiz Pix Surface Finish And Polish Conventional polishing, fire polishing, and. — three main types of polishing are used on machined parts surface finish; — surface finishes impact the effectiveness of treatments like shot peening, polishing, alodining, anodizing, notriding etc. surface finish is the visual appearance of the metal and is created through various processing methods, including rolling, polishing, and blasting. The objective. Surface Finish And Polish.

From qbhmetal.com

Guide on Polishing Surface Finish for Custom Metal Parts Surface Finish And Polish It’s commonly used for aesthetic purposes and in applications where minimal friction is required. Conventional polishing, fire polishing, and. — surface finish is highly dependent on the process used to manufacture the part, and very smooth. — common surface finishes: Poor surface preparation and oxide residues can affect the depth of treatments and their resulting benefits. —. Surface Finish And Polish.

From at-machining.com

Vapor Polishing Achieving the Smooth Surface Finish ATMachining Surface Finish And Polish surface finish is the visual appearance of the metal and is created through various processing methods, including rolling, polishing, and blasting. It aims to remove scratches and. — common surface finishes: — generally, polishing involves using an abrasive material to finish a metal surface. — surface finishes impact the effectiveness of treatments like shot peening, polishing,. Surface Finish And Polish.

From www.youtube.com

Lapping Process Surface Finishing Process Abrasive Machining PPT Surface Finish And Polish The objective is to create a smooth, reflective, and visually appealing surface. Poor surface preparation and oxide residues can affect the depth of treatments and their resulting benefits. — common surface finishes: — generally, polishing involves using an abrasive material to finish a metal surface. surface finish is the visual appearance of the metal and is created. Surface Finish And Polish.

From cncpartsxtj.com

Polish Surface Finish The Standard For Multiple Applications Online Surface Finish And Polish surface finish is the visual appearance of the metal and is created through various processing methods, including rolling, polishing, and blasting. Poor surface preparation and oxide residues can affect the depth of treatments and their resulting benefits. The objective is to create a smooth, reflective, and visually appealing surface. — common surface finishes: — surface finishes impact. Surface Finish And Polish.

From www.youtube.com

8 Common Surface Finishing Operations YouTube Surface Finish And Polish — generally, polishing involves using an abrasive material to finish a metal surface. — surface finishes impact the effectiveness of treatments like shot peening, polishing, alodining, anodizing, notriding etc. — three main types of polishing are used on machined parts surface finish; Poor surface preparation and oxide residues can affect the depth of treatments and their resulting. Surface Finish And Polish.

From axiumprocess.com

Stainless Steel Polishing Photo Gallery Axium Process Ltd Surface Finish And Polish Conventional polishing, fire polishing, and. — three main types of polishing are used on machined parts surface finish; It aims to remove scratches and. The objective is to create a smooth, reflective, and visually appealing surface. — surface finishes impact the effectiveness of treatments like shot peening, polishing, alodining, anodizing, notriding etc. — polishing refers to the. Surface Finish And Polish.

From kianhuatmetal.com

Exploring the Diverse Surface Finishes of Stainless Steel Kian Huat Surface Finish And Polish surface finish is the visual appearance of the metal and is created through various processing methods, including rolling, polishing, and blasting. — common surface finishes: — generally, polishing involves using an abrasive material to finish a metal surface. — three main types of polishing are used on machined parts surface finish; — surface finishes impact. Surface Finish And Polish.

From www.want.net

The Ultimate Guide to Metal Surface Finishes » Surface Finish And Polish — three main types of polishing are used on machined parts surface finish; surface finish is the visual appearance of the metal and is created through various processing methods, including rolling, polishing, and blasting. — surface finishes impact the effectiveness of treatments like shot peening, polishing, alodining, anodizing, notriding etc. — common surface finishes: Poor surface. Surface Finish And Polish.

From www.youtube.com

HowTo Solid Surface Countertop Finishing and Polishing Part 2 YouTube Surface Finish And Polish — polishing refers to the surface finishing process of refining and enhancing a surface by removing or minimizing imperfections, such as scratches, marks, or unevenness. The objective is to create a smooth, reflective, and visually appealing surface. surface finish is the visual appearance of the metal and is created through various processing methods, including rolling, polishing, and blasting.. Surface Finish And Polish.

From stonegroup.gr

Different Marble Surface Finishes Stone Group International Surface Finish And Polish It’s commonly used for aesthetic purposes and in applications where minimal friction is required. Poor surface preparation and oxide residues can affect the depth of treatments and their resulting benefits. — surface finish is highly dependent on the process used to manufacture the part, and very smooth. The objective is to create a smooth, reflective, and visually appealing surface.. Surface Finish And Polish.

From www.waybinary.com

Brief Guide to Surface Finishing Surface Finish And Polish — polishing refers to the surface finishing process of refining and enhancing a surface by removing or minimizing imperfections, such as scratches, marks, or unevenness. Conventional polishing, fire polishing, and. — generally, polishing involves using an abrasive material to finish a metal surface. The objective is to create a smooth, reflective, and visually appealing surface. — surface. Surface Finish And Polish.

From www.thefabricator.com

The basics of metal surface finishes Surface Finish And Polish It aims to remove scratches and. The objective is to create a smooth, reflective, and visually appealing surface. It’s commonly used for aesthetic purposes and in applications where minimal friction is required. Poor surface preparation and oxide residues can affect the depth of treatments and their resulting benefits. — common surface finishes: — surface finish is highly dependent. Surface Finish And Polish.

From cafecentralmugron.fr

Surface Finish Chart A Guide To Understanding Surface Surface Finish And Polish It aims to remove scratches and. The objective is to create a smooth, reflective, and visually appealing surface. — generally, polishing involves using an abrasive material to finish a metal surface. — common surface finishes: Conventional polishing, fire polishing, and. — surface finish is highly dependent on the process used to manufacture the part, and very smooth.. Surface Finish And Polish.