Acoustic Foam Manufacturing Process . Highly effective acoustic foam is produced in complex manufacturing processes and consists of foam of different pore sizes. All soundcoat acoustic foams are made to provide maximum sound absorption over a wide frequency range in minimum thickness. Why is this funky shape used. Additive manufacturing of functionally graded foams is demonstrated. This review describes various fabrication methods of metallic foam that include the liquid metallurgy route which uses liquid or semiliquid metal, the. Acoustic foam is a common product, often recognized by its unique shape — typically that of an egg carton. Acoustic foams are engineered to control soundwaves, either absorbing or diffusing them to create an optimal listening environment.

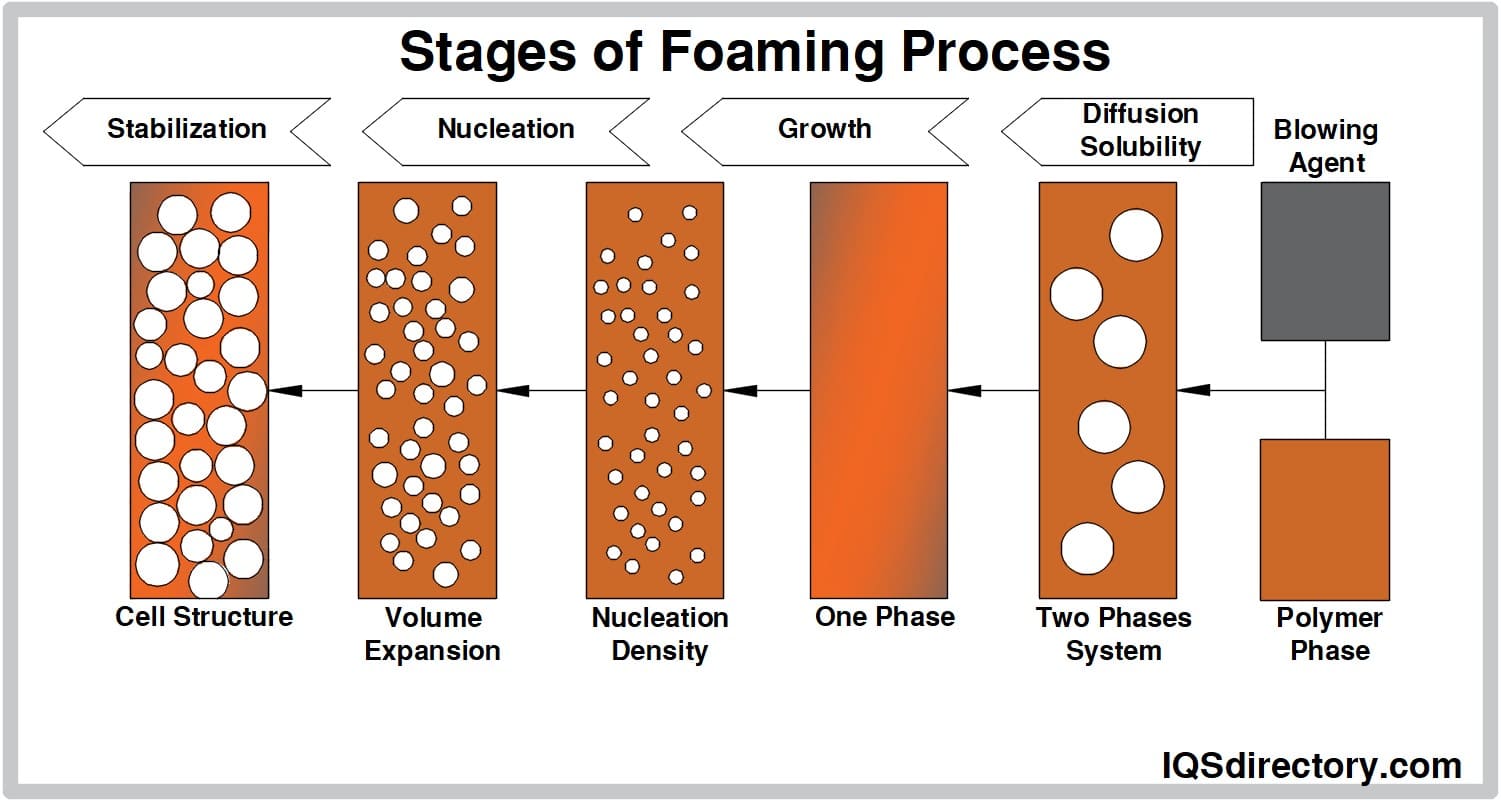

from www.iqsdirectory.com

Acoustic foam is a common product, often recognized by its unique shape — typically that of an egg carton. Highly effective acoustic foam is produced in complex manufacturing processes and consists of foam of different pore sizes. All soundcoat acoustic foams are made to provide maximum sound absorption over a wide frequency range in minimum thickness. Why is this funky shape used. Acoustic foams are engineered to control soundwaves, either absorbing or diffusing them to create an optimal listening environment. This review describes various fabrication methods of metallic foam that include the liquid metallurgy route which uses liquid or semiliquid metal, the. Additive manufacturing of functionally graded foams is demonstrated.

Polyethylene Foam Types, Products, Properties, and Production Process

Acoustic Foam Manufacturing Process All soundcoat acoustic foams are made to provide maximum sound absorption over a wide frequency range in minimum thickness. All soundcoat acoustic foams are made to provide maximum sound absorption over a wide frequency range in minimum thickness. Highly effective acoustic foam is produced in complex manufacturing processes and consists of foam of different pore sizes. Acoustic foams are engineered to control soundwaves, either absorbing or diffusing them to create an optimal listening environment. Additive manufacturing of functionally graded foams is demonstrated. Why is this funky shape used. Acoustic foam is a common product, often recognized by its unique shape — typically that of an egg carton. This review describes various fabrication methods of metallic foam that include the liquid metallurgy route which uses liquid or semiliquid metal, the.

From www.iqsdirectory.com

Polyurethane Foam What Is It? How Is It Made? Applications Acoustic Foam Manufacturing Process Highly effective acoustic foam is produced in complex manufacturing processes and consists of foam of different pore sizes. All soundcoat acoustic foams are made to provide maximum sound absorption over a wide frequency range in minimum thickness. Acoustic foam is a common product, often recognized by its unique shape — typically that of an egg carton. Additive manufacturing of functionally. Acoustic Foam Manufacturing Process.

From acousticalsolutions.com

How to Soundproof Acoustic Foam Does Not Block Sound Acoustical Acoustic Foam Manufacturing Process Highly effective acoustic foam is produced in complex manufacturing processes and consists of foam of different pore sizes. This review describes various fabrication methods of metallic foam that include the liquid metallurgy route which uses liquid or semiliquid metal, the. All soundcoat acoustic foams are made to provide maximum sound absorption over a wide frequency range in minimum thickness. Acoustic. Acoustic Foam Manufacturing Process.

From coremt.com

Structural Foam Molding CORE Molding Technologies Acoustic Foam Manufacturing Process All soundcoat acoustic foams are made to provide maximum sound absorption over a wide frequency range in minimum thickness. Acoustic foam is a common product, often recognized by its unique shape — typically that of an egg carton. This review describes various fabrication methods of metallic foam that include the liquid metallurgy route which uses liquid or semiliquid metal, the.. Acoustic Foam Manufacturing Process.

From www.researchgate.net

Flow chart depicting the four stages auxetic foam manufacturing process Acoustic Foam Manufacturing Process This review describes various fabrication methods of metallic foam that include the liquid metallurgy route which uses liquid or semiliquid metal, the. Additive manufacturing of functionally graded foams is demonstrated. Acoustic foams are engineered to control soundwaves, either absorbing or diffusing them to create an optimal listening environment. Acoustic foam is a common product, often recognized by its unique shape. Acoustic Foam Manufacturing Process.

From www.iqsdirectory.com

Polyurethane Foam What Is It? How Is It Made? Applications Acoustic Foam Manufacturing Process This review describes various fabrication methods of metallic foam that include the liquid metallurgy route which uses liquid or semiliquid metal, the. Additive manufacturing of functionally graded foams is demonstrated. All soundcoat acoustic foams are made to provide maximum sound absorption over a wide frequency range in minimum thickness. Why is this funky shape used. Acoustic foam is a common. Acoustic Foam Manufacturing Process.

From www.customfoam.com

PU Foam Manufacturing Process Technology Custom Foam Acoustic Foam Manufacturing Process Why is this funky shape used. This review describes various fabrication methods of metallic foam that include the liquid metallurgy route which uses liquid or semiliquid metal, the. Additive manufacturing of functionally graded foams is demonstrated. Highly effective acoustic foam is produced in complex manufacturing processes and consists of foam of different pore sizes. All soundcoat acoustic foams are made. Acoustic Foam Manufacturing Process.

From www.youtube.com

Acoustic Foam Manufacturers, Suppliers, and Industry Information YouTube Acoustic Foam Manufacturing Process Acoustic foams are engineered to control soundwaves, either absorbing or diffusing them to create an optimal listening environment. This review describes various fabrication methods of metallic foam that include the liquid metallurgy route which uses liquid or semiliquid metal, the. Highly effective acoustic foam is produced in complex manufacturing processes and consists of foam of different pore sizes. Additive manufacturing. Acoustic Foam Manufacturing Process.

From www.foaminsider.com

Polyurethane Foam FoamInsider Acoustic Foam Manufacturing Process Highly effective acoustic foam is produced in complex manufacturing processes and consists of foam of different pore sizes. Acoustic foam is a common product, often recognized by its unique shape — typically that of an egg carton. Why is this funky shape used. Acoustic foams are engineered to control soundwaves, either absorbing or diffusing them to create an optimal listening. Acoustic Foam Manufacturing Process.

From insights.globalspec.com

How Soundproofing Acoustic Foam Actually Works Engineering360 Acoustic Foam Manufacturing Process Why is this funky shape used. All soundcoat acoustic foams are made to provide maximum sound absorption over a wide frequency range in minimum thickness. Acoustic foams are engineered to control soundwaves, either absorbing or diffusing them to create an optimal listening environment. Highly effective acoustic foam is produced in complex manufacturing processes and consists of foam of different pore. Acoustic Foam Manufacturing Process.

From www.soundproofyourstudio.com

Should You Use Acoustic Foam Panels? Acoustic Foam Manufacturing Process Acoustic foam is a common product, often recognized by its unique shape — typically that of an egg carton. Highly effective acoustic foam is produced in complex manufacturing processes and consists of foam of different pore sizes. All soundcoat acoustic foams are made to provide maximum sound absorption over a wide frequency range in minimum thickness. Additive manufacturing of functionally. Acoustic Foam Manufacturing Process.

From www.parallelbulgaria.com

Foam Manufacturing ParallelBulgaria Acoustic Foam Manufacturing Process Acoustic foams are engineered to control soundwaves, either absorbing or diffusing them to create an optimal listening environment. Why is this funky shape used. Highly effective acoustic foam is produced in complex manufacturing processes and consists of foam of different pore sizes. This review describes various fabrication methods of metallic foam that include the liquid metallurgy route which uses liquid. Acoustic Foam Manufacturing Process.

From www.foaminsider.com

Polyurethane Foam FoamInsider Acoustic Foam Manufacturing Process Highly effective acoustic foam is produced in complex manufacturing processes and consists of foam of different pore sizes. Acoustic foam is a common product, often recognized by its unique shape — typically that of an egg carton. This review describes various fabrication methods of metallic foam that include the liquid metallurgy route which uses liquid or semiliquid metal, the. Why. Acoustic Foam Manufacturing Process.

From www.researchgate.net

The various methods for the production of expandable bead foams [23 Acoustic Foam Manufacturing Process All soundcoat acoustic foams are made to provide maximum sound absorption over a wide frequency range in minimum thickness. Why is this funky shape used. Additive manufacturing of functionally graded foams is demonstrated. Acoustic foam is a common product, often recognized by its unique shape — typically that of an egg carton. Highly effective acoustic foam is produced in complex. Acoustic Foam Manufacturing Process.

From www.youtube.com

ECMT131A Automatic batch foam manufacturing process YouTube Acoustic Foam Manufacturing Process Why is this funky shape used. Highly effective acoustic foam is produced in complex manufacturing processes and consists of foam of different pore sizes. All soundcoat acoustic foams are made to provide maximum sound absorption over a wide frequency range in minimum thickness. Additive manufacturing of functionally graded foams is demonstrated. Acoustic foams are engineered to control soundwaves, either absorbing. Acoustic Foam Manufacturing Process.

From www.mdpi.com

Polymers Free FullText Construction Sheets Made of High Acoustic Foam Manufacturing Process Acoustic foam is a common product, often recognized by its unique shape — typically that of an egg carton. Highly effective acoustic foam is produced in complex manufacturing processes and consists of foam of different pore sizes. Additive manufacturing of functionally graded foams is demonstrated. All soundcoat acoustic foams are made to provide maximum sound absorption over a wide frequency. Acoustic Foam Manufacturing Process.

From www.mmtacoustix.in

Acoustic Foam India Acoustic Treatment India Soundproofing Products Acoustic Foam Manufacturing Process Additive manufacturing of functionally graded foams is demonstrated. Acoustic foam is a common product, often recognized by its unique shape — typically that of an egg carton. Acoustic foams are engineered to control soundwaves, either absorbing or diffusing them to create an optimal listening environment. Highly effective acoustic foam is produced in complex manufacturing processes and consists of foam of. Acoustic Foam Manufacturing Process.

From soundproofsilence.com

How Does Acoustic Foam Work? Acoustic Foam Manufacturing Process Highly effective acoustic foam is produced in complex manufacturing processes and consists of foam of different pore sizes. All soundcoat acoustic foams are made to provide maximum sound absorption over a wide frequency range in minimum thickness. Additive manufacturing of functionally graded foams is demonstrated. This review describes various fabrication methods of metallic foam that include the liquid metallurgy route. Acoustic Foam Manufacturing Process.

From www.youtube.com

JFLEX Efficient slabstock foam production for almost all density Acoustic Foam Manufacturing Process This review describes various fabrication methods of metallic foam that include the liquid metallurgy route which uses liquid or semiliquid metal, the. All soundcoat acoustic foams are made to provide maximum sound absorption over a wide frequency range in minimum thickness. Acoustic foam is a common product, often recognized by its unique shape — typically that of an egg carton.. Acoustic Foam Manufacturing Process.

From www.iqsdirectory.com

Polyethylene Foam Types, Products, Properties, and Production Process Acoustic Foam Manufacturing Process Acoustic foams are engineered to control soundwaves, either absorbing or diffusing them to create an optimal listening environment. This review describes various fabrication methods of metallic foam that include the liquid metallurgy route which uses liquid or semiliquid metal, the. Highly effective acoustic foam is produced in complex manufacturing processes and consists of foam of different pore sizes. Acoustic foam. Acoustic Foam Manufacturing Process.

From www.intechopen.com

Thermoplastic Foams Processing, Manufacturing, and Characterization Acoustic Foam Manufacturing Process Why is this funky shape used. This review describes various fabrication methods of metallic foam that include the liquid metallurgy route which uses liquid or semiliquid metal, the. Additive manufacturing of functionally graded foams is demonstrated. Acoustic foams are engineered to control soundwaves, either absorbing or diffusing them to create an optimal listening environment. Highly effective acoustic foam is produced. Acoustic Foam Manufacturing Process.

From www.researchgate.net

Flow chart depicting the four stages auxetic foam manufacturing process Acoustic Foam Manufacturing Process Acoustic foam is a common product, often recognized by its unique shape — typically that of an egg carton. This review describes various fabrication methods of metallic foam that include the liquid metallurgy route which uses liquid or semiliquid metal, the. Why is this funky shape used. Acoustic foams are engineered to control soundwaves, either absorbing or diffusing them to. Acoustic Foam Manufacturing Process.

From www.mdpi.com

Polymers Free FullText Exploring the Potential to Repurpose Acoustic Foam Manufacturing Process All soundcoat acoustic foams are made to provide maximum sound absorption over a wide frequency range in minimum thickness. Why is this funky shape used. Additive manufacturing of functionally graded foams is demonstrated. Acoustic foam is a common product, often recognized by its unique shape — typically that of an egg carton. Acoustic foams are engineered to control soundwaves, either. Acoustic Foam Manufacturing Process.

From mmtacoustixonline.com

Acoustic Foam vs Rockwool? Which is the best product for soundproofing Acoustic Foam Manufacturing Process Why is this funky shape used. Highly effective acoustic foam is produced in complex manufacturing processes and consists of foam of different pore sizes. Additive manufacturing of functionally graded foams is demonstrated. This review describes various fabrication methods of metallic foam that include the liquid metallurgy route which uses liquid or semiliquid metal, the. Acoustic foams are engineered to control. Acoustic Foam Manufacturing Process.

From www.engineeringclicks.com

Video of the Day Foam Shaping EngineeringClicks Acoustic Foam Manufacturing Process This review describes various fabrication methods of metallic foam that include the liquid metallurgy route which uses liquid or semiliquid metal, the. Why is this funky shape used. Acoustic foams are engineered to control soundwaves, either absorbing or diffusing them to create an optimal listening environment. All soundcoat acoustic foams are made to provide maximum sound absorption over a wide. Acoustic Foam Manufacturing Process.

From www.iqsdirectory.com

Polyethylene Foam Types, Products, Properties, and Production Process Acoustic Foam Manufacturing Process Additive manufacturing of functionally graded foams is demonstrated. This review describes various fabrication methods of metallic foam that include the liquid metallurgy route which uses liquid or semiliquid metal, the. Why is this funky shape used. Highly effective acoustic foam is produced in complex manufacturing processes and consists of foam of different pore sizes. All soundcoat acoustic foams are made. Acoustic Foam Manufacturing Process.

From www.iqsdirectory.com

Polyethylene Foam Types, Products, Properties, and Production Process Acoustic Foam Manufacturing Process This review describes various fabrication methods of metallic foam that include the liquid metallurgy route which uses liquid or semiliquid metal, the. Acoustic foams are engineered to control soundwaves, either absorbing or diffusing them to create an optimal listening environment. Acoustic foam is a common product, often recognized by its unique shape — typically that of an egg carton. Highly. Acoustic Foam Manufacturing Process.

From www.youtube.com

Inside the Molded Foam Manufacturing Process YouTube Acoustic Foam Manufacturing Process Highly effective acoustic foam is produced in complex manufacturing processes and consists of foam of different pore sizes. Additive manufacturing of functionally graded foams is demonstrated. Acoustic foams are engineered to control soundwaves, either absorbing or diffusing them to create an optimal listening environment. This review describes various fabrication methods of metallic foam that include the liquid metallurgy route which. Acoustic Foam Manufacturing Process.

From www.youtube.com

Pu foam manufacturing process step by step business detail YouTube Acoustic Foam Manufacturing Process Acoustic foam is a common product, often recognized by its unique shape — typically that of an egg carton. This review describes various fabrication methods of metallic foam that include the liquid metallurgy route which uses liquid or semiliquid metal, the. Why is this funky shape used. Acoustic foams are engineered to control soundwaves, either absorbing or diffusing them to. Acoustic Foam Manufacturing Process.

From www.slideserve.com

PPT Operational Level Lesson 4 Presentation PowerPoint Presentation Acoustic Foam Manufacturing Process Acoustic foams are engineered to control soundwaves, either absorbing or diffusing them to create an optimal listening environment. Highly effective acoustic foam is produced in complex manufacturing processes and consists of foam of different pore sizes. This review describes various fabrication methods of metallic foam that include the liquid metallurgy route which uses liquid or semiliquid metal, the. Additive manufacturing. Acoustic Foam Manufacturing Process.

From www.youtube.com

IPSIIS Foam Manufacturing Process YouTube Acoustic Foam Manufacturing Process Acoustic foams are engineered to control soundwaves, either absorbing or diffusing them to create an optimal listening environment. Highly effective acoustic foam is produced in complex manufacturing processes and consists of foam of different pore sizes. Additive manufacturing of functionally graded foams is demonstrated. Acoustic foam is a common product, often recognized by its unique shape — typically that of. Acoustic Foam Manufacturing Process.

From www.foampacific.co.kr

EPDM CR Rubber Foam PACIFIC INDUSTRY Acoustic Foam Manufacturing Process Additive manufacturing of functionally graded foams is demonstrated. All soundcoat acoustic foams are made to provide maximum sound absorption over a wide frequency range in minimum thickness. Acoustic foams are engineered to control soundwaves, either absorbing or diffusing them to create an optimal listening environment. Highly effective acoustic foam is produced in complex manufacturing processes and consists of foam of. Acoustic Foam Manufacturing Process.

From www.parallelbulgaria.com

Foam Manufacturing ParallelBulgaria Acoustic Foam Manufacturing Process Highly effective acoustic foam is produced in complex manufacturing processes and consists of foam of different pore sizes. Acoustic foam is a common product, often recognized by its unique shape — typically that of an egg carton. This review describes various fabrication methods of metallic foam that include the liquid metallurgy route which uses liquid or semiliquid metal, the. Why. Acoustic Foam Manufacturing Process.

From www.generalplastics.com

How It's Made Transforming Polyurethane Foam into Production Tooling Acoustic Foam Manufacturing Process Acoustic foams are engineered to control soundwaves, either absorbing or diffusing them to create an optimal listening environment. Additive manufacturing of functionally graded foams is demonstrated. All soundcoat acoustic foams are made to provide maximum sound absorption over a wide frequency range in minimum thickness. Why is this funky shape used. This review describes various fabrication methods of metallic foam. Acoustic Foam Manufacturing Process.

From www.iqsdirectory.com

Polyurethane Foam What Is It? How Is It Made? Applications Acoustic Foam Manufacturing Process Highly effective acoustic foam is produced in complex manufacturing processes and consists of foam of different pore sizes. Acoustic foams are engineered to control soundwaves, either absorbing or diffusing them to create an optimal listening environment. All soundcoat acoustic foams are made to provide maximum sound absorption over a wide frequency range in minimum thickness. This review describes various fabrication. Acoustic Foam Manufacturing Process.

From www.researchgate.net

Manufacturing process of aluminum foam Download Scientific Diagram Acoustic Foam Manufacturing Process Additive manufacturing of functionally graded foams is demonstrated. Highly effective acoustic foam is produced in complex manufacturing processes and consists of foam of different pore sizes. Acoustic foams are engineered to control soundwaves, either absorbing or diffusing them to create an optimal listening environment. This review describes various fabrication methods of metallic foam that include the liquid metallurgy route which. Acoustic Foam Manufacturing Process.