Denim Rope Dyeing Process . Cold dyeing methods have been used to blend indigo and sulfurs, eliminating the need for separate bottoming and topping, while. Slasher/ open warp/ sheet dyeing; Four denim dyeing methods with indigo are available. At least 95% of world denim production is done by rope and slasher dyeing. Rope dyeing consists of twisting the yarns into a rope that is then quickly dipped into indigo baths. The rope is then dipped into a vat of. The dyeing process is completed by threading the rope through a series of indigo dyeing vats. It involves running ropes of yarn through a vat of indigo dye before releasing them onto the factory’s roof to oxidize before returning them to the dye bath. Loop dyeing produces more consistent indigo colors and takes up less room than other dyeing methods.

from www.alamy.com

Rope dyeing consists of twisting the yarns into a rope that is then quickly dipped into indigo baths. It involves running ropes of yarn through a vat of indigo dye before releasing them onto the factory’s roof to oxidize before returning them to the dye bath. Cold dyeing methods have been used to blend indigo and sulfurs, eliminating the need for separate bottoming and topping, while. At least 95% of world denim production is done by rope and slasher dyeing. The rope is then dipped into a vat of. The dyeing process is completed by threading the rope through a series of indigo dyeing vats. Four denim dyeing methods with indigo are available. Loop dyeing produces more consistent indigo colors and takes up less room than other dyeing methods. Slasher/ open warp/ sheet dyeing;

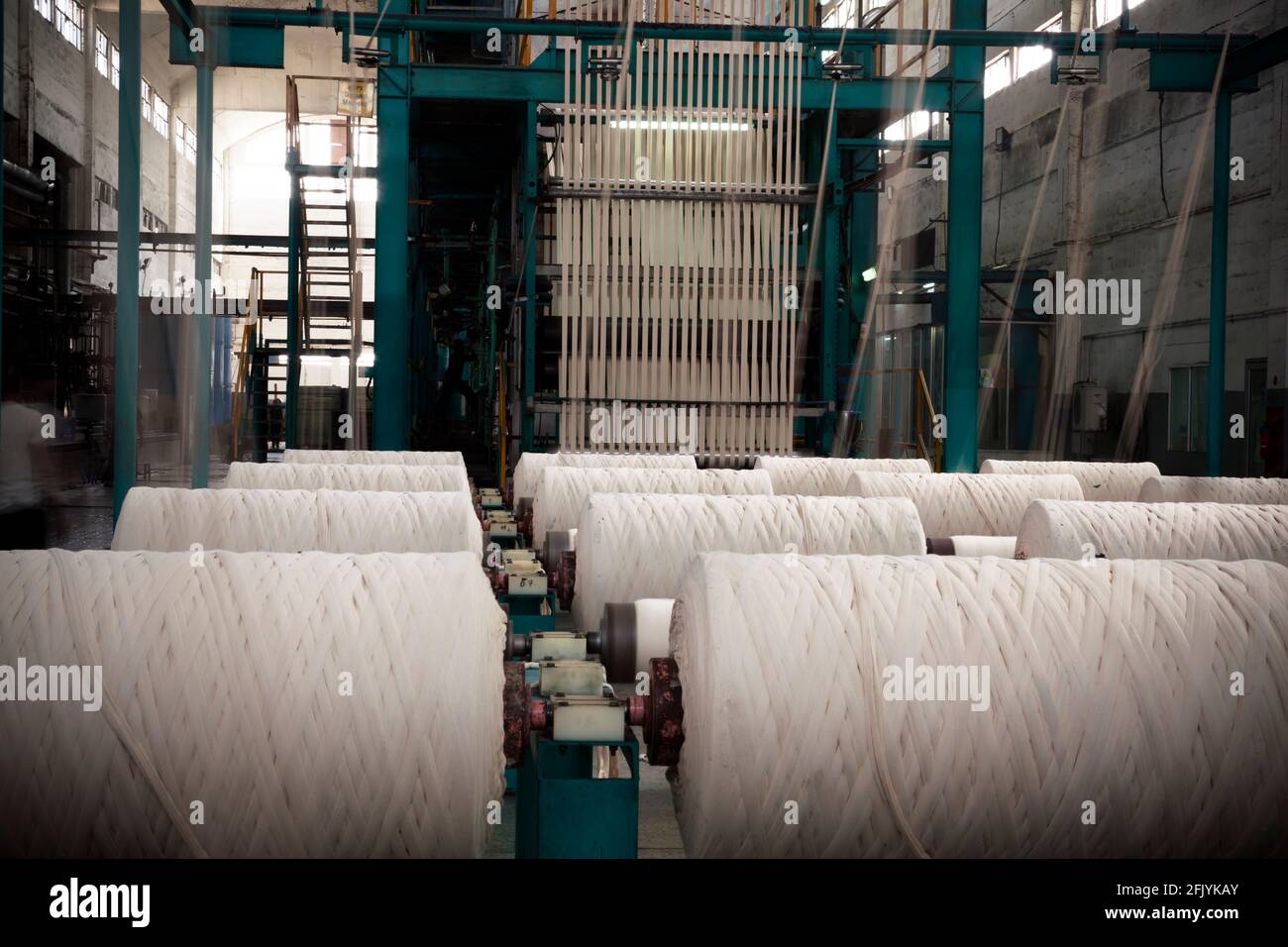

Gigantic rope dyeing machine for making denim fabric Stock Photo Alamy

Denim Rope Dyeing Process Loop dyeing produces more consistent indigo colors and takes up less room than other dyeing methods. Cold dyeing methods have been used to blend indigo and sulfurs, eliminating the need for separate bottoming and topping, while. Four denim dyeing methods with indigo are available. At least 95% of world denim production is done by rope and slasher dyeing. Loop dyeing produces more consistent indigo colors and takes up less room than other dyeing methods. The dyeing process is completed by threading the rope through a series of indigo dyeing vats. Rope dyeing consists of twisting the yarns into a rope that is then quickly dipped into indigo baths. Slasher/ open warp/ sheet dyeing; The rope is then dipped into a vat of. It involves running ropes of yarn through a vat of indigo dye before releasing them onto the factory’s roof to oxidize before returning them to the dye bath.

From www.youtube.com

Rope dyeing process for denim/Denim Yarn dyeing YouTube Denim Rope Dyeing Process Rope dyeing consists of twisting the yarns into a rope that is then quickly dipped into indigo baths. Cold dyeing methods have been used to blend indigo and sulfurs, eliminating the need for separate bottoming and topping, while. At least 95% of world denim production is done by rope and slasher dyeing. The dyeing process is completed by threading the. Denim Rope Dyeing Process.

From www.alamy.com

Gigantic rope dyeing machine for making denim fabric Stock Photo Alamy Denim Rope Dyeing Process Cold dyeing methods have been used to blend indigo and sulfurs, eliminating the need for separate bottoming and topping, while. Loop dyeing produces more consistent indigo colors and takes up less room than other dyeing methods. The dyeing process is completed by threading the rope through a series of indigo dyeing vats. Slasher/ open warp/ sheet dyeing; Rope dyeing consists. Denim Rope Dyeing Process.

From www.scribd.com

Rope Dyeing PDF Dyeing Rope Denim Rope Dyeing Process The dyeing process is completed by threading the rope through a series of indigo dyeing vats. Rope dyeing consists of twisting the yarns into a rope that is then quickly dipped into indigo baths. Cold dyeing methods have been used to blend indigo and sulfurs, eliminating the need for separate bottoming and topping, while. Slasher/ open warp/ sheet dyeing; At. Denim Rope Dyeing Process.

From denimhunters.com

What is dyeing? Denim FAQ answered by Denimhunters Denim Rope Dyeing Process It involves running ropes of yarn through a vat of indigo dye before releasing them onto the factory’s roof to oxidize before returning them to the dye bath. Rope dyeing consists of twisting the yarns into a rope that is then quickly dipped into indigo baths. Four denim dyeing methods with indigo are available. The dyeing process is completed by. Denim Rope Dyeing Process.

From www.textileblog.com

Cotton Dyeing Techniques with Indigo Textile Blog Denim Rope Dyeing Process The dyeing process is completed by threading the rope through a series of indigo dyeing vats. The rope is then dipped into a vat of. It involves running ropes of yarn through a vat of indigo dye before releasing them onto the factory’s roof to oxidize before returning them to the dye bath. Slasher/ open warp/ sheet dyeing; Loop dyeing. Denim Rope Dyeing Process.

From www.slideshare.net

Fundamentals of denim & faults in rope dyeing Denim Rope Dyeing Process At least 95% of world denim production is done by rope and slasher dyeing. Loop dyeing produces more consistent indigo colors and takes up less room than other dyeing methods. Cold dyeing methods have been used to blend indigo and sulfurs, eliminating the need for separate bottoming and topping, while. The dyeing process is completed by threading the rope through. Denim Rope Dyeing Process.

From jupitercomtex.com

Rope Dying Machine for Denim, Indigo rope dyeing machine manufacturers Denim Rope Dyeing Process It involves running ropes of yarn through a vat of indigo dye before releasing them onto the factory’s roof to oxidize before returning them to the dye bath. Slasher/ open warp/ sheet dyeing; Rope dyeing consists of twisting the yarns into a rope that is then quickly dipped into indigo baths. At least 95% of world denim production is done. Denim Rope Dyeing Process.

From www.denimhunters.com

How Denim Is Made Indigo Dyeing Denim Rope Dyeing Process Rope dyeing consists of twisting the yarns into a rope that is then quickly dipped into indigo baths. The dyeing process is completed by threading the rope through a series of indigo dyeing vats. It involves running ropes of yarn through a vat of indigo dye before releasing them onto the factory’s roof to oxidize before returning them to the. Denim Rope Dyeing Process.

From stock.adobe.com

Industrial textile factory. The process of indigo dyeing .rope dyeing Denim Rope Dyeing Process The dyeing process is completed by threading the rope through a series of indigo dyeing vats. Loop dyeing produces more consistent indigo colors and takes up less room than other dyeing methods. Four denim dyeing methods with indigo are available. Slasher/ open warp/ sheet dyeing; Cold dyeing methods have been used to blend indigo and sulfurs, eliminating the need for. Denim Rope Dyeing Process.

From www.youtube.com

Denim manufacturing process with flowchart/Weaving process of denim Denim Rope Dyeing Process The rope is then dipped into a vat of. At least 95% of world denim production is done by rope and slasher dyeing. The dyeing process is completed by threading the rope through a series of indigo dyeing vats. It involves running ropes of yarn through a vat of indigo dye before releasing them onto the factory’s roof to oxidize. Denim Rope Dyeing Process.

From garmentswashing.blogspot.com

DENIM DYEING GARMENTS WASHING Denim Rope Dyeing Process At least 95% of world denim production is done by rope and slasher dyeing. Loop dyeing produces more consistent indigo colors and takes up less room than other dyeing methods. Four denim dyeing methods with indigo are available. Slasher/ open warp/ sheet dyeing; It involves running ropes of yarn through a vat of indigo dye before releasing them onto the. Denim Rope Dyeing Process.

From www.istockphoto.com

Denim Textile Industry Rope Dyeing Machine Stock Photo Download Image Denim Rope Dyeing Process Four denim dyeing methods with indigo are available. Slasher/ open warp/ sheet dyeing; Cold dyeing methods have been used to blend indigo and sulfurs, eliminating the need for separate bottoming and topping, while. Rope dyeing consists of twisting the yarns into a rope that is then quickly dipped into indigo baths. The rope is then dipped into a vat of.. Denim Rope Dyeing Process.

From robindenim.com

Robin Denim The fabric called denim Indigo dyeing Denim Rope Dyeing Process The rope is then dipped into a vat of. Rope dyeing consists of twisting the yarns into a rope that is then quickly dipped into indigo baths. Loop dyeing produces more consistent indigo colors and takes up less room than other dyeing methods. Four denim dyeing methods with indigo are available. Cold dyeing methods have been used to blend indigo. Denim Rope Dyeing Process.

From www.okayamadenim.com

DENIM GLOSSARY Okayama Denim Denim Rope Dyeing Process Four denim dyeing methods with indigo are available. Loop dyeing produces more consistent indigo colors and takes up less room than other dyeing methods. Rope dyeing consists of twisting the yarns into a rope that is then quickly dipped into indigo baths. The rope is then dipped into a vat of. At least 95% of world denim production is done. Denim Rope Dyeing Process.

From onedenimmills.com

One Denim Full Process One Denim Denim Rope Dyeing Process The dyeing process is completed by threading the rope through a series of indigo dyeing vats. Rope dyeing consists of twisting the yarns into a rope that is then quickly dipped into indigo baths. Loop dyeing produces more consistent indigo colors and takes up less room than other dyeing methods. Cold dyeing methods have been used to blend indigo and. Denim Rope Dyeing Process.

From denimhunters.com

What is indigo? Denim FAQ answered by Denimhunters Denim Rope Dyeing Process At least 95% of world denim production is done by rope and slasher dyeing. The rope is then dipped into a vat of. Four denim dyeing methods with indigo are available. Slasher/ open warp/ sheet dyeing; Loop dyeing produces more consistent indigo colors and takes up less room than other dyeing methods. Cold dyeing methods have been used to blend. Denim Rope Dyeing Process.

From www.denimhunters.com

How Denim Is Made Indigo Dyeing Denim Rope Dyeing Process It involves running ropes of yarn through a vat of indigo dye before releasing them onto the factory’s roof to oxidize before returning them to the dye bath. The dyeing process is completed by threading the rope through a series of indigo dyeing vats. Loop dyeing produces more consistent indigo colors and takes up less room than other dyeing methods.. Denim Rope Dyeing Process.

From textileapex.blogspot.com.tr

Denim Textile Apex Denim Rope Dyeing Process At least 95% of world denim production is done by rope and slasher dyeing. The dyeing process is completed by threading the rope through a series of indigo dyeing vats. The rope is then dipped into a vat of. Rope dyeing consists of twisting the yarns into a rope that is then quickly dipped into indigo baths. Slasher/ open warp/. Denim Rope Dyeing Process.

From aarondenimltd.com

Record Production on Dyeing Machines Aaron Denim Limited Denim Rope Dyeing Process It involves running ropes of yarn through a vat of indigo dye before releasing them onto the factory’s roof to oxidize before returning them to the dye bath. The rope is then dipped into a vat of. At least 95% of world denim production is done by rope and slasher dyeing. Cold dyeing methods have been used to blend indigo. Denim Rope Dyeing Process.

From www.zevadenim.com

How Denim Is Made Dyeing Process in Denim Production ZEVA DENIM Denim Rope Dyeing Process The dyeing process is completed by threading the rope through a series of indigo dyeing vats. Loop dyeing produces more consistent indigo colors and takes up less room than other dyeing methods. It involves running ropes of yarn through a vat of indigo dye before releasing them onto the factory’s roof to oxidize before returning them to the dye bath.. Denim Rope Dyeing Process.

From www.denimhunters.com

How Denim Is Made Indigo Dyeing Denim Rope Dyeing Process At least 95% of world denim production is done by rope and slasher dyeing. The dyeing process is completed by threading the rope through a series of indigo dyeing vats. It involves running ropes of yarn through a vat of indigo dye before releasing them onto the factory’s roof to oxidize before returning them to the dye bath. The rope. Denim Rope Dyeing Process.

From www.alamy.com

Process of denim jeans manufacturing hires stock photography and Denim Rope Dyeing Process Cold dyeing methods have been used to blend indigo and sulfurs, eliminating the need for separate bottoming and topping, while. Loop dyeing produces more consistent indigo colors and takes up less room than other dyeing methods. Four denim dyeing methods with indigo are available. The rope is then dipped into a vat of. It involves running ropes of yarn through. Denim Rope Dyeing Process.

From www.instructables.com

Denim Rope 4 Steps (with Pictures) Instructables Denim Rope Dyeing Process The dyeing process is completed by threading the rope through a series of indigo dyeing vats. Slasher/ open warp/ sheet dyeing; Rope dyeing consists of twisting the yarns into a rope that is then quickly dipped into indigo baths. The rope is then dipped into a vat of. At least 95% of world denim production is done by rope and. Denim Rope Dyeing Process.

From www.slideshare.net

production of denim fabrics using rope dyeing and slasher dyeing meth… Denim Rope Dyeing Process Cold dyeing methods have been used to blend indigo and sulfurs, eliminating the need for separate bottoming and topping, while. It involves running ropes of yarn through a vat of indigo dye before releasing them onto the factory’s roof to oxidize before returning them to the dye bath. Slasher/ open warp/ sheet dyeing; Loop dyeing produces more consistent indigo colors. Denim Rope Dyeing Process.

From www.denimhunters.com

How Denim Is Made Indigo Dyeing Denim Rope Dyeing Process Four denim dyeing methods with indigo are available. Slasher/ open warp/ sheet dyeing; It involves running ropes of yarn through a vat of indigo dye before releasing them onto the factory’s roof to oxidize before returning them to the dye bath. The rope is then dipped into a vat of. Cold dyeing methods have been used to blend indigo and. Denim Rope Dyeing Process.

From www.youtube.com

How Denim is Dyed Rope Dyeing Process (Creeling to Coiling Denim Rope Dyeing Process At least 95% of world denim production is done by rope and slasher dyeing. Loop dyeing produces more consistent indigo colors and takes up less room than other dyeing methods. It involves running ropes of yarn through a vat of indigo dye before releasing them onto the factory’s roof to oxidize before returning them to the dye bath. The dyeing. Denim Rope Dyeing Process.

From www.alamy.com

Variation visible as thread color changes in rope dyeing machine for Denim Rope Dyeing Process Cold dyeing methods have been used to blend indigo and sulfurs, eliminating the need for separate bottoming and topping, while. At least 95% of world denim production is done by rope and slasher dyeing. Loop dyeing produces more consistent indigo colors and takes up less room than other dyeing methods. Slasher/ open warp/ sheet dyeing; Four denim dyeing methods with. Denim Rope Dyeing Process.

From www.indiamart.com

Denim Rope at best price in Beawar by Shiv Shankar Enterprises ID Denim Rope Dyeing Process Slasher/ open warp/ sheet dyeing; Rope dyeing consists of twisting the yarns into a rope that is then quickly dipped into indigo baths. At least 95% of world denim production is done by rope and slasher dyeing. Cold dyeing methods have been used to blend indigo and sulfurs, eliminating the need for separate bottoming and topping, while. Loop dyeing produces. Denim Rope Dyeing Process.

From denimfocus.net

INDIGO DYE IN DENIM INDUSTRY Denim Rope Dyeing Process Cold dyeing methods have been used to blend indigo and sulfurs, eliminating the need for separate bottoming and topping, while. Loop dyeing produces more consistent indigo colors and takes up less room than other dyeing methods. Four denim dyeing methods with indigo are available. It involves running ropes of yarn through a vat of indigo dye before releasing them onto. Denim Rope Dyeing Process.

From blog.denimlabo.com

ヴィンテージジーンズと言ったら、ロープ染色!|JAPAN BLUE JEANS JAPAN BLUE JEANS 渋谷店公式ブログ Denim Rope Dyeing Process Slasher/ open warp/ sheet dyeing; Cold dyeing methods have been used to blend indigo and sulfurs, eliminating the need for separate bottoming and topping, while. Four denim dyeing methods with indigo are available. Loop dyeing produces more consistent indigo colors and takes up less room than other dyeing methods. The rope is then dipped into a vat of. The dyeing. Denim Rope Dyeing Process.

From mavink.com

Denim Process Flow Chart Denim Rope Dyeing Process Loop dyeing produces more consistent indigo colors and takes up less room than other dyeing methods. It involves running ropes of yarn through a vat of indigo dye before releasing them onto the factory’s roof to oxidize before returning them to the dye bath. Rope dyeing consists of twisting the yarns into a rope that is then quickly dipped into. Denim Rope Dyeing Process.

From elements.envato.com

indigo rope dyeing machine. Rope Dyeing Process. Denim dyeing process Denim Rope Dyeing Process Rope dyeing consists of twisting the yarns into a rope that is then quickly dipped into indigo baths. Four denim dyeing methods with indigo are available. At least 95% of world denim production is done by rope and slasher dyeing. The dyeing process is completed by threading the rope through a series of indigo dyeing vats. Slasher/ open warp/ sheet. Denim Rope Dyeing Process.

From www.zevadenim.com

Is Denim a Color or Fabric? ZEVA DENIM Denim Rope Dyeing Process The dyeing process is completed by threading the rope through a series of indigo dyeing vats. Rope dyeing consists of twisting the yarns into a rope that is then quickly dipped into indigo baths. At least 95% of world denim production is done by rope and slasher dyeing. Loop dyeing produces more consistent indigo colors and takes up less room. Denim Rope Dyeing Process.

From waste-management-world.com

Advance Denim BioBlue eliminates chemicals from dyeing process WMW Denim Rope Dyeing Process The rope is then dipped into a vat of. It involves running ropes of yarn through a vat of indigo dye before releasing them onto the factory’s roof to oxidize before returning them to the dye bath. Four denim dyeing methods with indigo are available. Slasher/ open warp/ sheet dyeing; Loop dyeing produces more consistent indigo colors and takes up. Denim Rope Dyeing Process.

From www.dreamstime.com

Denim Fabric Dyeing Process in a Textile Factory Stock Illustration Denim Rope Dyeing Process It involves running ropes of yarn through a vat of indigo dye before releasing them onto the factory’s roof to oxidize before returning them to the dye bath. Cold dyeing methods have been used to blend indigo and sulfurs, eliminating the need for separate bottoming and topping, while. At least 95% of world denim production is done by rope and. Denim Rope Dyeing Process.