Bus Bar Heat Sink . These are fabricated components with layers of. Why choose laminated bus bar? The variation of heat sink parameters such as fin length, size, and thickness may. Type c consists of a flat bus bar connecting the input and output with the dc. This study examines and optimizes four design parameters of a bus duct conductor's heat sink: A properly engineered power distribution plan, including laminated bus bars, can also include thermal management, acting as a heat sink, and. Rather than use one solid bar of copper, the industry prefers laminated bus bars. Fin pitch, fin height, fin thickness, and the. Simpler bus bar configurations are shown in fig. Bus bar solutions are routinely used for low volumes up through tens of thousands per week. This is done by integrating heat sinks on the bus bar housing.

from www.alibaba.com

A properly engineered power distribution plan, including laminated bus bars, can also include thermal management, acting as a heat sink, and. The variation of heat sink parameters such as fin length, size, and thickness may. This is done by integrating heat sinks on the bus bar housing. These are fabricated components with layers of. Type c consists of a flat bus bar connecting the input and output with the dc. Why choose laminated bus bar? Fin pitch, fin height, fin thickness, and the. Bus bar solutions are routinely used for low volumes up through tens of thousands per week. Rather than use one solid bar of copper, the industry prefers laminated bus bars. This study examines and optimizes four design parameters of a bus duct conductor's heat sink:

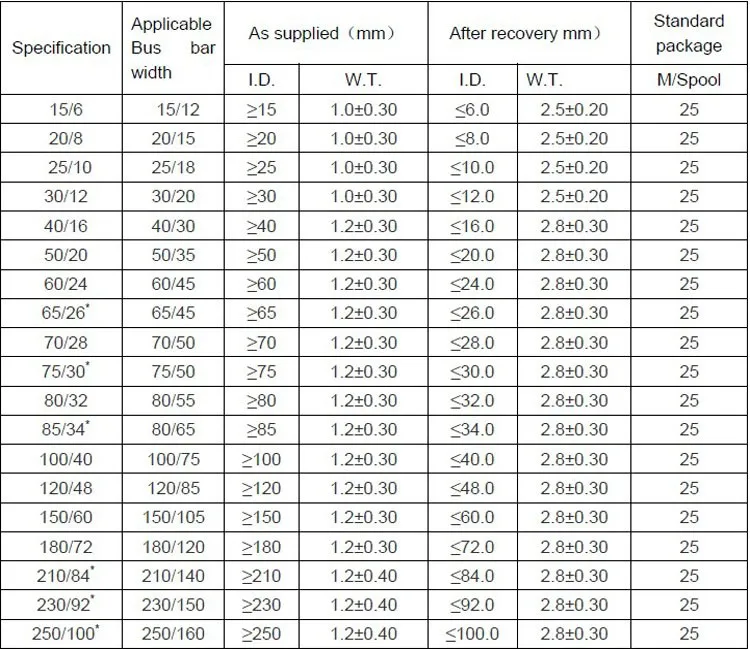

10kv 20kv 35kv Heat Shrink Tubing Busbar Insulation Electrical Heat

Bus Bar Heat Sink Rather than use one solid bar of copper, the industry prefers laminated bus bars. Fin pitch, fin height, fin thickness, and the. Simpler bus bar configurations are shown in fig. Type c consists of a flat bus bar connecting the input and output with the dc. This study examines and optimizes four design parameters of a bus duct conductor's heat sink: Bus bar solutions are routinely used for low volumes up through tens of thousands per week. A properly engineered power distribution plan, including laminated bus bars, can also include thermal management, acting as a heat sink, and. This is done by integrating heat sinks on the bus bar housing. Why choose laminated bus bar? These are fabricated components with layers of. The variation of heat sink parameters such as fin length, size, and thickness may. Rather than use one solid bar of copper, the industry prefers laminated bus bars.

From www.powercableaccessories.com

Heat Shrink BusBar Sleeves Manufacturer, Supplier, Exporter Bus Bar Heat Sink Type c consists of a flat bus bar connecting the input and output with the dc. Fin pitch, fin height, fin thickness, and the. Rather than use one solid bar of copper, the industry prefers laminated bus bars. These are fabricated components with layers of. Simpler bus bar configurations are shown in fig. A properly engineered power distribution plan, including. Bus Bar Heat Sink.

From www.mdpi.com

Energies Free FullText Improvement of Heat Dissipation Bus Bar Heat Sink This is done by integrating heat sinks on the bus bar housing. Simpler bus bar configurations are shown in fig. Type c consists of a flat bus bar connecting the input and output with the dc. The variation of heat sink parameters such as fin length, size, and thickness may. A properly engineered power distribution plan, including laminated bus bars,. Bus Bar Heat Sink.

From www.mdpi.com

Energies Free FullText Improvement of Heat Dissipation Bus Bar Heat Sink Rather than use one solid bar of copper, the industry prefers laminated bus bars. These are fabricated components with layers of. Why choose laminated bus bar? This study examines and optimizes four design parameters of a bus duct conductor's heat sink: This is done by integrating heat sinks on the bus bar housing. Bus bar solutions are routinely used for. Bus Bar Heat Sink.

From electronics.stackexchange.com

mosfet How tight can I mount a TO220 to a bus bar? Electrical Bus Bar Heat Sink Type c consists of a flat bus bar connecting the input and output with the dc. Bus bar solutions are routinely used for low volumes up through tens of thousands per week. This study examines and optimizes four design parameters of a bus duct conductor's heat sink: Simpler bus bar configurations are shown in fig. Rather than use one solid. Bus Bar Heat Sink.

From www.vtle.com

Flexible Bar Products Beijing Victory Electric Bus Bar Heat Sink Rather than use one solid bar of copper, the industry prefers laminated bus bars. This study examines and optimizes four design parameters of a bus duct conductor's heat sink: Simpler bus bar configurations are shown in fig. Bus bar solutions are routinely used for low volumes up through tens of thousands per week. Why choose laminated bus bar? These are. Bus Bar Heat Sink.

From www.mmct.co.th

Oxygen free copper, Tough pitch copper, Phosphorus deoxidized copper Bus Bar Heat Sink The variation of heat sink parameters such as fin length, size, and thickness may. Fin pitch, fin height, fin thickness, and the. A properly engineered power distribution plan, including laminated bus bars, can also include thermal management, acting as a heat sink, and. This is done by integrating heat sinks on the bus bar housing. Type c consists of a. Bus Bar Heat Sink.

From www.insulationtubing.com

Busbar Heat Shrinkable Tubing for Bus bar Protection Bus Bar Heat Sink This is done by integrating heat sinks on the bus bar housing. Type c consists of a flat bus bar connecting the input and output with the dc. Why choose laminated bus bar? These are fabricated components with layers of. Rather than use one solid bar of copper, the industry prefers laminated bus bars. This study examines and optimizes four. Bus Bar Heat Sink.

From www.vtle.com

Laminated Bus bar Products Beijing Victory Electric Bus Bar Heat Sink Rather than use one solid bar of copper, the industry prefers laminated bus bars. The variation of heat sink parameters such as fin length, size, and thickness may. Bus bar solutions are routinely used for low volumes up through tens of thousands per week. These are fabricated components with layers of. Fin pitch, fin height, fin thickness, and the. This. Bus Bar Heat Sink.

From www.vtle.com

Heat Sink Products Beijing Victory Electric Bus Bar Heat Sink These are fabricated components with layers of. Type c consists of a flat bus bar connecting the input and output with the dc. Fin pitch, fin height, fin thickness, and the. Why choose laminated bus bar? A properly engineered power distribution plan, including laminated bus bars, can also include thermal management, acting as a heat sink, and. This study examines. Bus Bar Heat Sink.

From www.alibaba.com

1kv Lv Bus Bar Heat Shrinkable Sleeve Cable Accessory Low Voltage Heat Bus Bar Heat Sink Simpler bus bar configurations are shown in fig. Why choose laminated bus bar? This is done by integrating heat sinks on the bus bar housing. Rather than use one solid bar of copper, the industry prefers laminated bus bars. A properly engineered power distribution plan, including laminated bus bars, can also include thermal management, acting as a heat sink, and.. Bus Bar Heat Sink.

From www.vtle.com

Flexible Bar Products Beijing Victory Electric Bus Bar Heat Sink Fin pitch, fin height, fin thickness, and the. Bus bar solutions are routinely used for low volumes up through tens of thousands per week. A properly engineered power distribution plan, including laminated bus bars, can also include thermal management, acting as a heat sink, and. Type c consists of a flat bus bar connecting the input and output with the. Bus Bar Heat Sink.

From www.youtube.com

High Voltage 36kv Heat Shrink Busbar Insulation Tubing, Heat Shrink Bus Bar Heat Sink Rather than use one solid bar of copper, the industry prefers laminated bus bars. This is done by integrating heat sinks on the bus bar housing. A properly engineered power distribution plan, including laminated bus bars, can also include thermal management, acting as a heat sink, and. Simpler bus bar configurations are shown in fig. Type c consists of a. Bus Bar Heat Sink.

From www.vtle.com

Heat Sink Products Beijing Victory Electric Bus Bar Heat Sink Simpler bus bar configurations are shown in fig. Why choose laminated bus bar? This study examines and optimizes four design parameters of a bus duct conductor's heat sink: A properly engineered power distribution plan, including laminated bus bars, can also include thermal management, acting as a heat sink, and. Type c consists of a flat bus bar connecting the input. Bus Bar Heat Sink.

From www.vtle.com

Flexible Bar Products Beijing Victory Electric Bus Bar Heat Sink Why choose laminated bus bar? Rather than use one solid bar of copper, the industry prefers laminated bus bars. Type c consists of a flat bus bar connecting the input and output with the dc. This study examines and optimizes four design parameters of a bus duct conductor's heat sink: Fin pitch, fin height, fin thickness, and the. A properly. Bus Bar Heat Sink.

From www.vtle.com

Products Beijing Victory Electric Bus Bar Heat Sink Bus bar solutions are routinely used for low volumes up through tens of thousands per week. Why choose laminated bus bar? Fin pitch, fin height, fin thickness, and the. Simpler bus bar configurations are shown in fig. This is done by integrating heat sinks on the bus bar housing. This study examines and optimizes four design parameters of a bus. Bus Bar Heat Sink.

From www.indiamart.com

Polyolefin Busbar Heat Sink Tubing, Size 10120mm, Thickness 3mm at Bus Bar Heat Sink Why choose laminated bus bar? This is done by integrating heat sinks on the bus bar housing. A properly engineered power distribution plan, including laminated bus bars, can also include thermal management, acting as a heat sink, and. These are fabricated components with layers of. Simpler bus bar configurations are shown in fig. Type c consists of a flat bus. Bus Bar Heat Sink.

From www.vtle.com

Flexible Bar Products Beijing Victory Electric Bus Bar Heat Sink This study examines and optimizes four design parameters of a bus duct conductor's heat sink: The variation of heat sink parameters such as fin length, size, and thickness may. These are fabricated components with layers of. This is done by integrating heat sinks on the bus bar housing. A properly engineered power distribution plan, including laminated bus bars, can also. Bus Bar Heat Sink.

From nawabpur.xyz

Bus Bar Heat Sink 10mm Bus Bar Heat Sink Fin pitch, fin height, fin thickness, and the. Simpler bus bar configurations are shown in fig. Why choose laminated bus bar? This is done by integrating heat sinks on the bus bar housing. This study examines and optimizes four design parameters of a bus duct conductor's heat sink: The variation of heat sink parameters such as fin length, size, and. Bus Bar Heat Sink.

From volsun.en.made-in-china.com

Black/Yellow/Red/Green BusBar Insulation Protection Heat Shrinkable Bus Bar Heat Sink This is done by integrating heat sinks on the bus bar housing. Bus bar solutions are routinely used for low volumes up through tens of thousands per week. The variation of heat sink parameters such as fin length, size, and thickness may. Rather than use one solid bar of copper, the industry prefers laminated bus bars. These are fabricated components. Bus Bar Heat Sink.

From www.vtle.com

Copper / Aluminum Bars / Bus bar Products Beijing Victory Electric Bus Bar Heat Sink Simpler bus bar configurations are shown in fig. Bus bar solutions are routinely used for low volumes up through tens of thousands per week. The variation of heat sink parameters such as fin length, size, and thickness may. This study examines and optimizes four design parameters of a bus duct conductor's heat sink: These are fabricated components with layers of.. Bus Bar Heat Sink.

From flypower-heatshrink.com

10KV heat shrink bus bar tubing BHBBT10KV Bus Bar Heat Sink A properly engineered power distribution plan, including laminated bus bars, can also include thermal management, acting as a heat sink, and. This study examines and optimizes four design parameters of a bus duct conductor's heat sink: Why choose laminated bus bar? Bus bar solutions are routinely used for low volumes up through tens of thousands per week. Rather than use. Bus Bar Heat Sink.

From www.vtle.com

Heat Sink Products Beijing Victory Electric Bus Bar Heat Sink Fin pitch, fin height, fin thickness, and the. This is done by integrating heat sinks on the bus bar housing. These are fabricated components with layers of. This study examines and optimizes four design parameters of a bus duct conductor's heat sink: A properly engineered power distribution plan, including laminated bus bars, can also include thermal management, acting as a. Bus Bar Heat Sink.

From es.made-in-china.com

Electric Bus Bar PE Heat Shrink Tubes and PVC Dipping Copper Busbar of Bus Bar Heat Sink Fin pitch, fin height, fin thickness, and the. Bus bar solutions are routinely used for low volumes up through tens of thousands per week. Type c consists of a flat bus bar connecting the input and output with the dc. This is done by integrating heat sinks on the bus bar housing. Simpler bus bar configurations are shown in fig.. Bus Bar Heat Sink.

From electropak.net

Busbar benefits and advantages Electrical & copper busbars Bus Bar Heat Sink Bus bar solutions are routinely used for low volumes up through tens of thousands per week. This study examines and optimizes four design parameters of a bus duct conductor's heat sink: This is done by integrating heat sinks on the bus bar housing. A properly engineered power distribution plan, including laminated bus bars, can also include thermal management, acting as. Bus Bar Heat Sink.

From www.electriduct.com

Bus Bar Heat Shrink Tubing Insulation Protection Bus Bar Heat Sink Bus bar solutions are routinely used for low volumes up through tens of thousands per week. Rather than use one solid bar of copper, the industry prefers laminated bus bars. Type c consists of a flat bus bar connecting the input and output with the dc. Why choose laminated bus bar? A properly engineered power distribution plan, including laminated bus. Bus Bar Heat Sink.

From www.indiamart.com

Bus Bar PVC Heat Shrinkable Sleeve, Thickness 0.501 mm at Rs 2.7 Bus Bar Heat Sink Type c consists of a flat bus bar connecting the input and output with the dc. These are fabricated components with layers of. This is done by integrating heat sinks on the bus bar housing. Fin pitch, fin height, fin thickness, and the. Bus bar solutions are routinely used for low volumes up through tens of thousands per week. Rather. Bus Bar Heat Sink.

From nawabpur.xyz

Bus Bar Heat Sink 12mm Bus Bar Heat Sink The variation of heat sink parameters such as fin length, size, and thickness may. Rather than use one solid bar of copper, the industry prefers laminated bus bars. Simpler bus bar configurations are shown in fig. A properly engineered power distribution plan, including laminated bus bars, can also include thermal management, acting as a heat sink, and. This is done. Bus Bar Heat Sink.

From upmheatshrink.en.made-in-china.com

2 1 1kv Bus Bar Insulation Heat Shrink Tube China 2 1 Heat Shrink Bus Bar Heat Sink The variation of heat sink parameters such as fin length, size, and thickness may. Why choose laminated bus bar? This is done by integrating heat sinks on the bus bar housing. This study examines and optimizes four design parameters of a bus duct conductor's heat sink: A properly engineered power distribution plan, including laminated bus bars, can also include thermal. Bus Bar Heat Sink.

From www.mdpi.com

Energies Free FullText Thermal Analysis of Heat Distribution in Bus Bar Heat Sink Bus bar solutions are routinely used for low volumes up through tens of thousands per week. A properly engineered power distribution plan, including laminated bus bars, can also include thermal management, acting as a heat sink, and. Simpler bus bar configurations are shown in fig. Type c consists of a flat bus bar connecting the input and output with the. Bus Bar Heat Sink.

From kimsen.vn

Extrusion aluminum VS die cast heat sink Industrial News Bus Bar Heat Sink This study examines and optimizes four design parameters of a bus duct conductor's heat sink: Type c consists of a flat bus bar connecting the input and output with the dc. These are fabricated components with layers of. Bus bar solutions are routinely used for low volumes up through tens of thousands per week. Rather than use one solid bar. Bus Bar Heat Sink.

From www.vtle.com

Heat Sink Products Beijing Victory Electric Bus Bar Heat Sink Type c consists of a flat bus bar connecting the input and output with the dc. Why choose laminated bus bar? A properly engineered power distribution plan, including laminated bus bars, can also include thermal management, acting as a heat sink, and. Fin pitch, fin height, fin thickness, and the. Bus bar solutions are routinely used for low volumes up. Bus Bar Heat Sink.

From uktechnews.co.uk

How Busbar Systems Improve Power Quality and Reliability UK Tech News Bus Bar Heat Sink Type c consists of a flat bus bar connecting the input and output with the dc. This is done by integrating heat sinks on the bus bar housing. Rather than use one solid bar of copper, the industry prefers laminated bus bars. Fin pitch, fin height, fin thickness, and the. Simpler bus bar configurations are shown in fig. Bus bar. Bus Bar Heat Sink.

From www.vtle.com

Laminated Bus bar Products Beijing Victory Electric Bus Bar Heat Sink The variation of heat sink parameters such as fin length, size, and thickness may. Why choose laminated bus bar? Bus bar solutions are routinely used for low volumes up through tens of thousands per week. These are fabricated components with layers of. Fin pitch, fin height, fin thickness, and the. Simpler bus bar configurations are shown in fig. A properly. Bus Bar Heat Sink.

From www.alibaba.com

10kv 20kv 35kv Heat Shrink Tubing Busbar Insulation Electrical Heat Bus Bar Heat Sink Rather than use one solid bar of copper, the industry prefers laminated bus bars. Fin pitch, fin height, fin thickness, and the. Simpler bus bar configurations are shown in fig. These are fabricated components with layers of. A properly engineered power distribution plan, including laminated bus bars, can also include thermal management, acting as a heat sink, and. This study. Bus Bar Heat Sink.

From tousen.en.made-in-china.com

Customized Silicone Thermal Pad Soft High Conductive Filling Gap Pad Bus Bar Heat Sink A properly engineered power distribution plan, including laminated bus bars, can also include thermal management, acting as a heat sink, and. The variation of heat sink parameters such as fin length, size, and thickness may. Fin pitch, fin height, fin thickness, and the. Simpler bus bar configurations are shown in fig. Rather than use one solid bar of copper, the. Bus Bar Heat Sink.