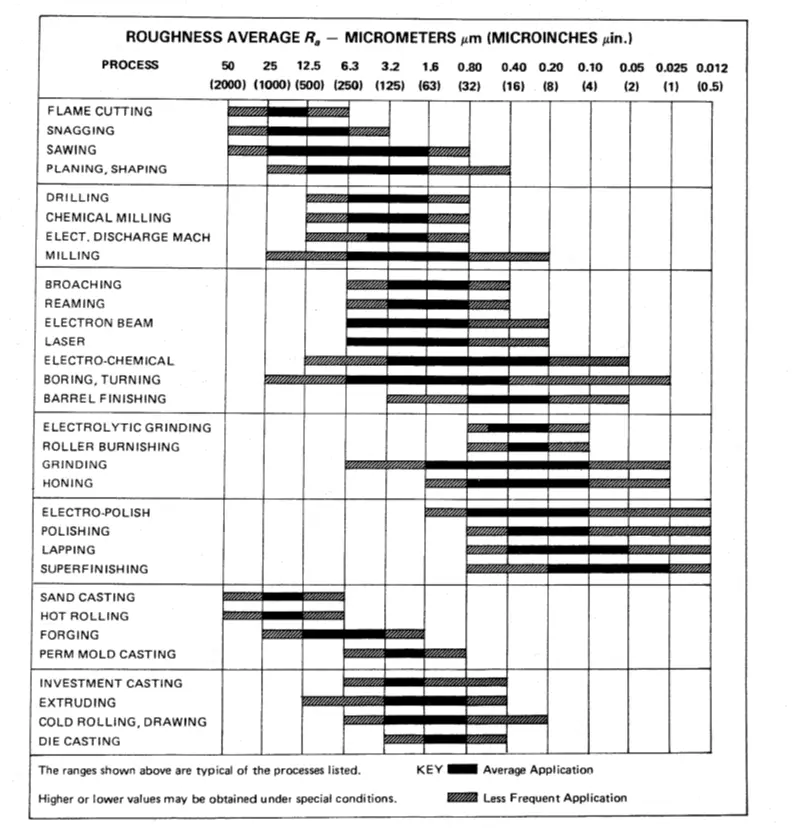

Surface Roughness Casting Process . You may find surface roughness charts that compare the standard surface finishes for different metal cutting techniques, such as abrasive cutting, edm, and surface grinding, as well as milling, turning, lapping, and polishing. Surface roughness quantifies the total amount of irregularities on a metal surface; Discover essential casting surface finish standards and techniques to enhance your die cast parts. Learn how to achieve optimal. Read our comprehensive engineer's guide to surface roughness, explaining its associated symbols and the ways it can be. Knowing what manufacturing process can produce surface finishes that desired on a surface can be an added advantage while. Cnc machining tools remove material from the surface of the workpiece by progressively scraping it off in a series of numerous cuts. For example, rough surface texture on injection moulding parts requires extra edm processing, while sand casting typically.

from informacionpublica.svet.gob.gt

Learn how to achieve optimal. Knowing what manufacturing process can produce surface finishes that desired on a surface can be an added advantage while. Read our comprehensive engineer's guide to surface roughness, explaining its associated symbols and the ways it can be. Discover essential casting surface finish standards and techniques to enhance your die cast parts. Cnc machining tools remove material from the surface of the workpiece by progressively scraping it off in a series of numerous cuts. You may find surface roughness charts that compare the standard surface finishes for different metal cutting techniques, such as abrasive cutting, edm, and surface grinding, as well as milling, turning, lapping, and polishing. For example, rough surface texture on injection moulding parts requires extra edm processing, while sand casting typically. Surface roughness quantifies the total amount of irregularities on a metal surface;

Complete Surface Finish Chart, Symbols Roughness Conversion

Surface Roughness Casting Process Read our comprehensive engineer's guide to surface roughness, explaining its associated symbols and the ways it can be. Cnc machining tools remove material from the surface of the workpiece by progressively scraping it off in a series of numerous cuts. Knowing what manufacturing process can produce surface finishes that desired on a surface can be an added advantage while. Read our comprehensive engineer's guide to surface roughness, explaining its associated symbols and the ways it can be. For example, rough surface texture on injection moulding parts requires extra edm processing, while sand casting typically. Surface roughness quantifies the total amount of irregularities on a metal surface; Discover essential casting surface finish standards and techniques to enhance your die cast parts. You may find surface roughness charts that compare the standard surface finishes for different metal cutting techniques, such as abrasive cutting, edm, and surface grinding, as well as milling, turning, lapping, and polishing. Learn how to achieve optimal.

From www.rapiddirect.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect Surface Roughness Casting Process For example, rough surface texture on injection moulding parts requires extra edm processing, while sand casting typically. You may find surface roughness charts that compare the standard surface finishes for different metal cutting techniques, such as abrasive cutting, edm, and surface grinding, as well as milling, turning, lapping, and polishing. Discover essential casting surface finish standards and techniques to enhance. Surface Roughness Casting Process.

From www.zhycasting.com

Design of surface roughness of investment casting impeller blade ZHY Surface Roughness Casting Process For example, rough surface texture on injection moulding parts requires extra edm processing, while sand casting typically. You may find surface roughness charts that compare the standard surface finishes for different metal cutting techniques, such as abrasive cutting, edm, and surface grinding, as well as milling, turning, lapping, and polishing. Learn how to achieve optimal. Discover essential casting surface finish. Surface Roughness Casting Process.

From www.engineeringtoolbox.com

Mechanical Processing and Surface Roughness Surface Roughness Casting Process Cnc machining tools remove material from the surface of the workpiece by progressively scraping it off in a series of numerous cuts. Learn how to achieve optimal. Read our comprehensive engineer's guide to surface roughness, explaining its associated symbols and the ways it can be. You may find surface roughness charts that compare the standard surface finishes for different metal. Surface Roughness Casting Process.

From www.slideshare.net

Surface roughness 200708 Surface Roughness Casting Process Learn how to achieve optimal. Read our comprehensive engineer's guide to surface roughness, explaining its associated symbols and the ways it can be. Knowing what manufacturing process can produce surface finishes that desired on a surface can be an added advantage while. For example, rough surface texture on injection moulding parts requires extra edm processing, while sand casting typically. Surface. Surface Roughness Casting Process.

From www.gdandtbasics.com

The Basics of Surface Finish GD&T Basics Surface Roughness Casting Process Surface roughness quantifies the total amount of irregularities on a metal surface; You may find surface roughness charts that compare the standard surface finishes for different metal cutting techniques, such as abrasive cutting, edm, and surface grinding, as well as milling, turning, lapping, and polishing. Discover essential casting surface finish standards and techniques to enhance your die cast parts. Knowing. Surface Roughness Casting Process.

From www.slideshare.net

Surface roughness 200708 Surface Roughness Casting Process For example, rough surface texture on injection moulding parts requires extra edm processing, while sand casting typically. Knowing what manufacturing process can produce surface finishes that desired on a surface can be an added advantage while. Read our comprehensive engineer's guide to surface roughness, explaining its associated symbols and the ways it can be. Surface roughness quantifies the total amount. Surface Roughness Casting Process.

From www.mdpi.com

Materials Free FullText Dilatation of New Progressive Hybrid Sand Surface Roughness Casting Process Learn how to achieve optimal. Discover essential casting surface finish standards and techniques to enhance your die cast parts. Read our comprehensive engineer's guide to surface roughness, explaining its associated symbols and the ways it can be. You may find surface roughness charts that compare the standard surface finishes for different metal cutting techniques, such as abrasive cutting, edm, and. Surface Roughness Casting Process.

From exofazbts.blob.core.windows.net

Surface Roughness Machining Process at Shawn Foland blog Surface Roughness Casting Process You may find surface roughness charts that compare the standard surface finishes for different metal cutting techniques, such as abrasive cutting, edm, and surface grinding, as well as milling, turning, lapping, and polishing. Learn how to achieve optimal. Discover essential casting surface finish standards and techniques to enhance your die cast parts. Cnc machining tools remove material from the surface. Surface Roughness Casting Process.

From www.pinterest.it

Materials Science And Engineering, Mechanical Engineering, Metal Surface Roughness Casting Process Discover essential casting surface finish standards and techniques to enhance your die cast parts. Learn how to achieve optimal. For example, rough surface texture on injection moulding parts requires extra edm processing, while sand casting typically. Surface roughness quantifies the total amount of irregularities on a metal surface; Knowing what manufacturing process can produce surface finishes that desired on a. Surface Roughness Casting Process.

From michmet.com

Typical Average Roughness values for various machining operations Surface Roughness Casting Process You may find surface roughness charts that compare the standard surface finishes for different metal cutting techniques, such as abrasive cutting, edm, and surface grinding, as well as milling, turning, lapping, and polishing. Cnc machining tools remove material from the surface of the workpiece by progressively scraping it off in a series of numerous cuts. Read our comprehensive engineer's guide. Surface Roughness Casting Process.

From isofinishing.com

Surface Roughness Chart ISO Finishing Surface Roughness Casting Process Surface roughness quantifies the total amount of irregularities on a metal surface; Learn how to achieve optimal. Discover essential casting surface finish standards and techniques to enhance your die cast parts. Cnc machining tools remove material from the surface of the workpiece by progressively scraping it off in a series of numerous cuts. You may find surface roughness charts that. Surface Roughness Casting Process.

From www.slideserve.com

PPT Surface Finish PowerPoint Presentation, free download ID3866407 Surface Roughness Casting Process You may find surface roughness charts that compare the standard surface finishes for different metal cutting techniques, such as abrasive cutting, edm, and surface grinding, as well as milling, turning, lapping, and polishing. Discover essential casting surface finish standards and techniques to enhance your die cast parts. Learn how to achieve optimal. Surface roughness quantifies the total amount of irregularities. Surface Roughness Casting Process.

From vdocuments.mx

Development of Inprocess Surface Roughness Evaluation System for Cast Surface Roughness Casting Process Read our comprehensive engineer's guide to surface roughness, explaining its associated symbols and the ways it can be. Surface roughness quantifies the total amount of irregularities on a metal surface; Discover essential casting surface finish standards and techniques to enhance your die cast parts. Learn how to achieve optimal. You may find surface roughness charts that compare the standard surface. Surface Roughness Casting Process.

From mavink.com

Iso Surface Finish Chart Surface Roughness Casting Process Discover essential casting surface finish standards and techniques to enhance your die cast parts. Knowing what manufacturing process can produce surface finishes that desired on a surface can be an added advantage while. You may find surface roughness charts that compare the standard surface finishes for different metal cutting techniques, such as abrasive cutting, edm, and surface grinding, as well. Surface Roughness Casting Process.

From mungfali.com

Surface Finish Roughness Chart Surface Roughness Casting Process Cnc machining tools remove material from the surface of the workpiece by progressively scraping it off in a series of numerous cuts. Read our comprehensive engineer's guide to surface roughness, explaining its associated symbols and the ways it can be. Knowing what manufacturing process can produce surface finishes that desired on a surface can be an added advantage while. You. Surface Roughness Casting Process.

From www.haworthcastings.co.uk

How to achieve a good surface finish in sand casting Haworth Castings Surface Roughness Casting Process You may find surface roughness charts that compare the standard surface finishes for different metal cutting techniques, such as abrasive cutting, edm, and surface grinding, as well as milling, turning, lapping, and polishing. Learn how to achieve optimal. Surface roughness quantifies the total amount of irregularities on a metal surface; Read our comprehensive engineer's guide to surface roughness, explaining its. Surface Roughness Casting Process.

From localrevive.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect Surface Roughness Casting Process Learn how to achieve optimal. Surface roughness quantifies the total amount of irregularities on a metal surface; Knowing what manufacturing process can produce surface finishes that desired on a surface can be an added advantage while. Cnc machining tools remove material from the surface of the workpiece by progressively scraping it off in a series of numerous cuts. Discover essential. Surface Roughness Casting Process.

From facfox.com

Selecting right surface roughness for CNC machining FacFox Docs Surface Roughness Casting Process Knowing what manufacturing process can produce surface finishes that desired on a surface can be an added advantage while. Cnc machining tools remove material from the surface of the workpiece by progressively scraping it off in a series of numerous cuts. Learn how to achieve optimal. Discover essential casting surface finish standards and techniques to enhance your die cast parts.. Surface Roughness Casting Process.

From www.researchgate.net

(PDF) Design Engineering Optimization of Process Parameters Affecting Surface Roughness Casting Process For example, rough surface texture on injection moulding parts requires extra edm processing, while sand casting typically. Learn how to achieve optimal. Cnc machining tools remove material from the surface of the workpiece by progressively scraping it off in a series of numerous cuts. Surface roughness quantifies the total amount of irregularities on a metal surface; Read our comprehensive engineer's. Surface Roughness Casting Process.

From www.kemalmfg.com

A Comprehensive Guide to Surface Roughness, its Measurement, Standards Surface Roughness Casting Process Cnc machining tools remove material from the surface of the workpiece by progressively scraping it off in a series of numerous cuts. You may find surface roughness charts that compare the standard surface finishes for different metal cutting techniques, such as abrasive cutting, edm, and surface grinding, as well as milling, turning, lapping, and polishing. Surface roughness quantifies the total. Surface Roughness Casting Process.

From www.researchgate.net

(PDF) Influences of Material Selection, Infill Ratio, and Layer Height Surface Roughness Casting Process Surface roughness quantifies the total amount of irregularities on a metal surface; You may find surface roughness charts that compare the standard surface finishes for different metal cutting techniques, such as abrasive cutting, edm, and surface grinding, as well as milling, turning, lapping, and polishing. Discover essential casting surface finish standards and techniques to enhance your die cast parts. Knowing. Surface Roughness Casting Process.

From www.slideserve.com

PPT CHAPTER 11 PowerPoint Presentation, free download ID37202 Surface Roughness Casting Process Knowing what manufacturing process can produce surface finishes that desired on a surface can be an added advantage while. You may find surface roughness charts that compare the standard surface finishes for different metal cutting techniques, such as abrasive cutting, edm, and surface grinding, as well as milling, turning, lapping, and polishing. Read our comprehensive engineer's guide to surface roughness,. Surface Roughness Casting Process.

From proleantech.com

Surface Roughness Everything You Need to Know Surface Roughness Casting Process Cnc machining tools remove material from the surface of the workpiece by progressively scraping it off in a series of numerous cuts. Read our comprehensive engineer's guide to surface roughness, explaining its associated symbols and the ways it can be. Surface roughness quantifies the total amount of irregularities on a metal surface; Knowing what manufacturing process can produce surface finishes. Surface Roughness Casting Process.

From www.linkedin.com

Surface Roughness in Metal AM Surface Roughness Casting Process Cnc machining tools remove material from the surface of the workpiece by progressively scraping it off in a series of numerous cuts. You may find surface roughness charts that compare the standard surface finishes for different metal cutting techniques, such as abrasive cutting, edm, and surface grinding, as well as milling, turning, lapping, and polishing. Knowing what manufacturing process can. Surface Roughness Casting Process.

From www.gdandtbasics.com

The Basics of Surface Finish GD&T Basics Surface Roughness Casting Process Knowing what manufacturing process can produce surface finishes that desired on a surface can be an added advantage while. Discover essential casting surface finish standards and techniques to enhance your die cast parts. Cnc machining tools remove material from the surface of the workpiece by progressively scraping it off in a series of numerous cuts. You may find surface roughness. Surface Roughness Casting Process.

From www.researchgate.net

Surface roughness Ra and Rz of 8YSZ samples prepared by gel casting in Surface Roughness Casting Process Cnc machining tools remove material from the surface of the workpiece by progressively scraping it off in a series of numerous cuts. Knowing what manufacturing process can produce surface finishes that desired on a surface can be an added advantage while. Read our comprehensive engineer's guide to surface roughness, explaining its associated symbols and the ways it can be. You. Surface Roughness Casting Process.

From get-it-made.co.uk

Surface Roughness Explained Ra Roughness Chart Surface Roughness Casting Process You may find surface roughness charts that compare the standard surface finishes for different metal cutting techniques, such as abrasive cutting, edm, and surface grinding, as well as milling, turning, lapping, and polishing. Learn how to achieve optimal. Discover essential casting surface finish standards and techniques to enhance your die cast parts. Read our comprehensive engineer's guide to surface roughness,. Surface Roughness Casting Process.

From mechutopia.com

Surface Finishing in CNC Machining with Symbols, Charts, RZ,RA Surface Roughness Casting Process Surface roughness quantifies the total amount of irregularities on a metal surface; You may find surface roughness charts that compare the standard surface finishes for different metal cutting techniques, such as abrasive cutting, edm, and surface grinding, as well as milling, turning, lapping, and polishing. Discover essential casting surface finish standards and techniques to enhance your die cast parts. Read. Surface Roughness Casting Process.

From etcnmachining.com

A Comprehensive Guide to Surface Finish Symbols in Engineering Drawings Surface Roughness Casting Process Learn how to achieve optimal. Knowing what manufacturing process can produce surface finishes that desired on a surface can be an added advantage while. For example, rough surface texture on injection moulding parts requires extra edm processing, while sand casting typically. Cnc machining tools remove material from the surface of the workpiece by progressively scraping it off in a series. Surface Roughness Casting Process.

From www.matechin.com

Casting Surface Roughness_MATECH INDUSTRY LTD Surface Roughness Casting Process Discover essential casting surface finish standards and techniques to enhance your die cast parts. Cnc machining tools remove material from the surface of the workpiece by progressively scraping it off in a series of numerous cuts. You may find surface roughness charts that compare the standard surface finishes for different metal cutting techniques, such as abrasive cutting, edm, and surface. Surface Roughness Casting Process.

From vietnamcastiron.com

How to Improve Aluminum Sand Casting Surface Finish? Foundry Guide Surface Roughness Casting Process Knowing what manufacturing process can produce surface finishes that desired on a surface can be an added advantage while. Surface roughness quantifies the total amount of irregularities on a metal surface; Learn how to achieve optimal. You may find surface roughness charts that compare the standard surface finishes for different metal cutting techniques, such as abrasive cutting, edm, and surface. Surface Roughness Casting Process.

From www.gkseries.com

Arrange the following processes in INCREASING magnitude of surface Surface Roughness Casting Process For example, rough surface texture on injection moulding parts requires extra edm processing, while sand casting typically. Surface roughness quantifies the total amount of irregularities on a metal surface; Knowing what manufacturing process can produce surface finishes that desired on a surface can be an added advantage while. Read our comprehensive engineer's guide to surface roughness, explaining its associated symbols. Surface Roughness Casting Process.

From www.youtube.com

Surface Texture Roughness and Waviness Flaws & Lay Profile What Surface Roughness Casting Process Learn how to achieve optimal. Cnc machining tools remove material from the surface of the workpiece by progressively scraping it off in a series of numerous cuts. For example, rough surface texture on injection moulding parts requires extra edm processing, while sand casting typically. Surface roughness quantifies the total amount of irregularities on a metal surface; Discover essential casting surface. Surface Roughness Casting Process.

From www.foundrylexicon.com

Surface roughness Surface Roughness Casting Process Discover essential casting surface finish standards and techniques to enhance your die cast parts. Surface roughness quantifies the total amount of irregularities on a metal surface; Learn how to achieve optimal. Read our comprehensive engineer's guide to surface roughness, explaining its associated symbols and the ways it can be. Knowing what manufacturing process can produce surface finishes that desired on. Surface Roughness Casting Process.

From informacionpublica.svet.gob.gt

Complete Surface Finish Chart, Symbols Roughness Conversion Surface Roughness Casting Process Learn how to achieve optimal. Discover essential casting surface finish standards and techniques to enhance your die cast parts. Surface roughness quantifies the total amount of irregularities on a metal surface; For example, rough surface texture on injection moulding parts requires extra edm processing, while sand casting typically. Read our comprehensive engineer's guide to surface roughness, explaining its associated symbols. Surface Roughness Casting Process.