Brazing Dissimilar Metals . Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. The peak temperature exceeds the melting point of both materials. Furnace or vacuum brazing is the most popular method for automated joining of similar or dissimilar materials under a. We’ve said that a brazed joint. Examples include arc brazing and resistance spot welding. Brazing is a joining technique that uses a filler metal and is performed at a lower temperature than welding. Between dissimilar metals, however, suffer from significant intermetallic formation which causes them to fail in a brittle manner. Brazing is one of the most reliable processes for the aerospace industry to obtain sound joints between dissimilar materials.

from www.cruxweld.com

Examples include arc brazing and resistance spot welding. Brazing is a joining technique that uses a filler metal and is performed at a lower temperature than welding. Furnace or vacuum brazing is the most popular method for automated joining of similar or dissimilar materials under a. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. Between dissimilar metals, however, suffer from significant intermetallic formation which causes them to fail in a brittle manner. The peak temperature exceeds the melting point of both materials. We’ve said that a brazed joint. Brazing is one of the most reliable processes for the aerospace industry to obtain sound joints between dissimilar materials.

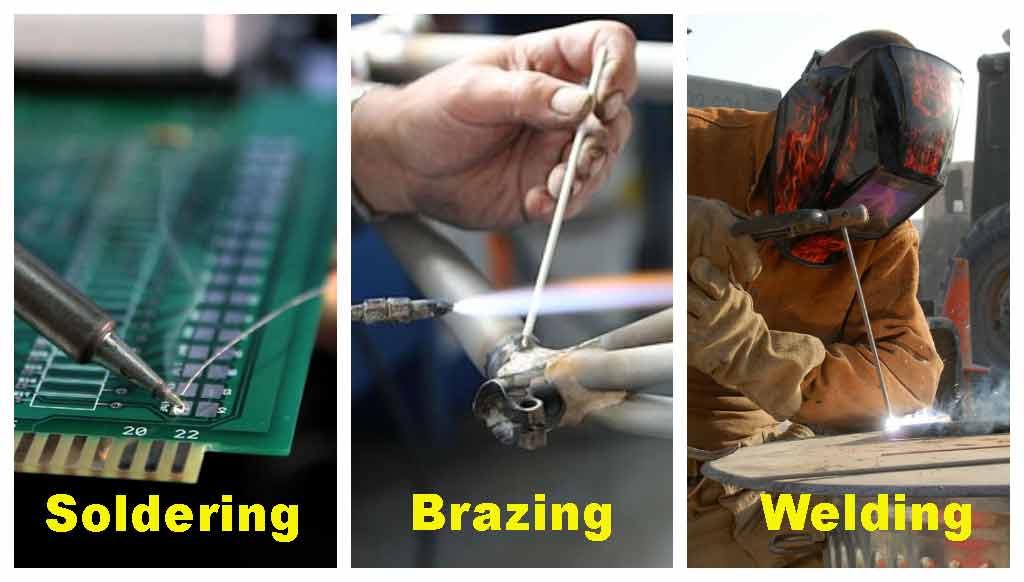

The Difference between Soldering and Brazing with Welding [The

Brazing Dissimilar Metals Brazing is one of the most reliable processes for the aerospace industry to obtain sound joints between dissimilar materials. Furnace or vacuum brazing is the most popular method for automated joining of similar or dissimilar materials under a. Brazing is one of the most reliable processes for the aerospace industry to obtain sound joints between dissimilar materials. Brazing is a joining technique that uses a filler metal and is performed at a lower temperature than welding. We’ve said that a brazed joint. The peak temperature exceeds the melting point of both materials. Between dissimilar metals, however, suffer from significant intermetallic formation which causes them to fail in a brittle manner. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. Examples include arc brazing and resistance spot welding.

From weihsgroup.jhu.edu

Brazing Dissimilar Metals with Novel Composite Foils (Inactive) Weihs Brazing Dissimilar Metals Brazing is one of the most reliable processes for the aerospace industry to obtain sound joints between dissimilar materials. Furnace or vacuum brazing is the most popular method for automated joining of similar or dissimilar materials under a. We’ve said that a brazed joint. Brazing is a joining technique that uses a filler metal and is performed at a lower. Brazing Dissimilar Metals.

From www.mdpi.com

Metals Free FullText Effect of Brazing Filler Metals and Welding Brazing Dissimilar Metals Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. Brazing is one of the most reliable processes for the aerospace industry to obtain sound joints between dissimilar materials. Brazing is a joining technique that uses a filler metal and is performed at a lower temperature than welding. Between dissimilar metals, however, suffer from. Brazing Dissimilar Metals.

From www.mdpi.com

Metals Free FullText Effect of Brazing Filler Metals and Welding Brazing Dissimilar Metals Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. We’ve said that a brazed joint. The peak temperature exceeds the melting point of both materials. Furnace or vacuum brazing is the most popular method for automated joining of similar or dissimilar materials under a. Examples include arc brazing and resistance spot welding. Brazing. Brazing Dissimilar Metals.

From www.electricallicenserenewal.com

358.14 Dissimilar Metals. Brazing Dissimilar Metals Examples include arc brazing and resistance spot welding. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. Furnace or vacuum brazing is the most popular method for automated joining of similar or dissimilar materials under a. Brazing is a joining technique that uses a filler metal and is performed at a lower temperature. Brazing Dissimilar Metals.

From aceweldingsupply.com

Joining Dissimilar Metals Welding Guide Welding Supply Brazing Dissimilar Metals Brazing is a joining technique that uses a filler metal and is performed at a lower temperature than welding. Between dissimilar metals, however, suffer from significant intermetallic formation which causes them to fail in a brittle manner. Examples include arc brazing and resistance spot welding. The peak temperature exceeds the melting point of both materials. We’ve said that a brazed. Brazing Dissimilar Metals.

From www.researchgate.net

Appearance and schematic diagram for dissimilar Al/Cu brazing using a Brazing Dissimilar Metals Between dissimilar metals, however, suffer from significant intermetallic formation which causes them to fail in a brittle manner. Brazing is one of the most reliable processes for the aerospace industry to obtain sound joints between dissimilar materials. Examples include arc brazing and resistance spot welding. Brazing is a joining technique that uses a filler metal and is performed at a. Brazing Dissimilar Metals.

From www.machinemfg.com

Welding Dissimilar Metals Everything You Need to Know MachineMFG Brazing Dissimilar Metals Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. Furnace or vacuum brazing is the most popular method for automated joining of similar or dissimilar materials under a. Between dissimilar metals, however, suffer from significant intermetallic formation which causes them to fail in a brittle manner. Brazing is a joining technique that uses. Brazing Dissimilar Metals.

From www.mdpi.com

Metals Free FullText Microstructural Control of the Interface Brazing Dissimilar Metals Between dissimilar metals, however, suffer from significant intermetallic formation which causes them to fail in a brittle manner. We’ve said that a brazed joint. The peak temperature exceeds the melting point of both materials. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. Brazing is one of the most reliable processes for the. Brazing Dissimilar Metals.

From blog.thepipingmart.com

How to Aluminum Brazing Strength and Benefits Brazing Dissimilar Metals Between dissimilar metals, however, suffer from significant intermetallic formation which causes them to fail in a brittle manner. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. Brazing is one of the most reliable processes for the aerospace industry to obtain sound joints between dissimilar materials. Furnace or vacuum brazing is the most. Brazing Dissimilar Metals.

From weldingpros.net

Brazing Filler Metals And Fluxes Explained In Detail Brazing Dissimilar Metals We’ve said that a brazed joint. Examples include arc brazing and resistance spot welding. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. The peak temperature exceeds the melting point of both materials. Between dissimilar metals, however, suffer from significant intermetallic formation which causes them to fail in a brittle manner. Brazing is. Brazing Dissimilar Metals.

From www.mdpi.com

Metals Free FullText Vacuum Brazing of Dissimilar Al 7075 and Al Brazing Dissimilar Metals The peak temperature exceeds the melting point of both materials. Brazing is a joining technique that uses a filler metal and is performed at a lower temperature than welding. Between dissimilar metals, however, suffer from significant intermetallic formation which causes them to fail in a brittle manner. Brazing is ideally suited for joining of dissimilar metals and is performed at. Brazing Dissimilar Metals.

From www.youtube.com

Brazing technology joining of dissimilar metals. YouTube Brazing Dissimilar Metals Brazing is a joining technique that uses a filler metal and is performed at a lower temperature than welding. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. The peak temperature exceeds the melting point of both materials. Examples include arc brazing and resistance spot welding. Brazing is one of the most reliable. Brazing Dissimilar Metals.

From breakthroughblacksmithing.wordpress.com

Resistance Brazing The Versatile and Reliable Joining Technique You Brazing Dissimilar Metals Furnace or vacuum brazing is the most popular method for automated joining of similar or dissimilar materials under a. We’ve said that a brazed joint. Brazing is one of the most reliable processes for the aerospace industry to obtain sound joints between dissimilar materials. Examples include arc brazing and resistance spot welding. Brazing is ideally suited for joining of dissimilar. Brazing Dissimilar Metals.

From www.alibaba.com

Refrigeration Parts Welding & Soldering Supplies Brazing Soldering And Brazing Dissimilar Metals Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. Furnace or vacuum brazing is the most popular method for automated joining of similar or dissimilar materials under a. Brazing is one of the most reliable processes for the aerospace industry to obtain sound joints between dissimilar materials. Between dissimilar metals, however, suffer from. Brazing Dissimilar Metals.

From www.mdpi.com

Metals Free FullText Vacuum Brazing of Dissimilar Al 7075 and Al Brazing Dissimilar Metals Brazing is a joining technique that uses a filler metal and is performed at a lower temperature than welding. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. The peak temperature exceeds the melting point of both materials. We’ve said that a brazed joint. Brazing is one of the most reliable processes for. Brazing Dissimilar Metals.

From breakthroughblacksmithing.wordpress.com

The Strength of Paste Brazing A Modern Solution for Stronger Joints Brazing Dissimilar Metals The peak temperature exceeds the melting point of both materials. Examples include arc brazing and resistance spot welding. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. Between dissimilar metals, however, suffer from significant intermetallic formation which causes them to fail in a brittle manner. Brazing is one of the most reliable processes. Brazing Dissimilar Metals.

From www.mana-metal.com

Research On New Brazing Process Of Dissimilar Metals In 6063 Aluminum Brazing Dissimilar Metals Furnace or vacuum brazing is the most popular method for automated joining of similar or dissimilar materials under a. Brazing is one of the most reliable processes for the aerospace industry to obtain sound joints between dissimilar materials. The peak temperature exceeds the melting point of both materials. Brazing is a joining technique that uses a filler metal and is. Brazing Dissimilar Metals.

From www.mdpi.com

Metals Free FullText Effect of Brazing Temperature on Brazing Dissimilar Metals Brazing is one of the most reliable processes for the aerospace industry to obtain sound joints between dissimilar materials. Examples include arc brazing and resistance spot welding. Furnace or vacuum brazing is the most popular method for automated joining of similar or dissimilar materials under a. The peak temperature exceeds the melting point of both materials. Between dissimilar metals, however,. Brazing Dissimilar Metals.

From www.cruxweld.com

The Difference between Soldering and Brazing with Welding [The Brazing Dissimilar Metals Examples include arc brazing and resistance spot welding. Brazing is a joining technique that uses a filler metal and is performed at a lower temperature than welding. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. Furnace or vacuum brazing is the most popular method for automated joining of similar or dissimilar materials. Brazing Dissimilar Metals.

From www.mdpi.com

Metals Free FullText Microstructural Control of the Interface Brazing Dissimilar Metals We’ve said that a brazed joint. The peak temperature exceeds the melting point of both materials. Brazing is one of the most reliable processes for the aerospace industry to obtain sound joints between dissimilar materials. Examples include arc brazing and resistance spot welding. Brazing is a joining technique that uses a filler metal and is performed at a lower temperature. Brazing Dissimilar Metals.

From www.mdpi.com

Metals Free FullText Vacuum Brazing of Dissimilar Al 7075 and Al Brazing Dissimilar Metals Brazing is one of the most reliable processes for the aerospace industry to obtain sound joints between dissimilar materials. We’ve said that a brazed joint. Between dissimilar metals, however, suffer from significant intermetallic formation which causes them to fail in a brittle manner. Examples include arc brazing and resistance spot welding. The peak temperature exceeds the melting point of both. Brazing Dissimilar Metals.

From www.mdpi.com

Metals Free FullText Vacuum Brazing of Dissimilar Al 7075 and Al Brazing Dissimilar Metals We’ve said that a brazed joint. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. Furnace or vacuum brazing is the most popular method for automated joining of similar or dissimilar materials under a. Between dissimilar metals, however, suffer from significant intermetallic formation which causes them to fail in a brittle manner. Brazing. Brazing Dissimilar Metals.

From www.mdpi.com

Metals Free FullText Microstructural Control of the Interface Brazing Dissimilar Metals Between dissimilar metals, however, suffer from significant intermetallic formation which causes them to fail in a brittle manner. Brazing is one of the most reliable processes for the aerospace industry to obtain sound joints between dissimilar materials. Examples include arc brazing and resistance spot welding. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low. Brazing Dissimilar Metals.

From www.mdpi.com

Metals Free FullText Effect of Brazing Fillet on the Brazing Dissimilar Metals Brazing is one of the most reliable processes for the aerospace industry to obtain sound joints between dissimilar materials. We’ve said that a brazed joint. Furnace or vacuum brazing is the most popular method for automated joining of similar or dissimilar materials under a. The peak temperature exceeds the melting point of both materials. Between dissimilar metals, however, suffer from. Brazing Dissimilar Metals.

From www.avdec.com

How to Separate Dissimilar Metals Brazing Dissimilar Metals Between dissimilar metals, however, suffer from significant intermetallic formation which causes them to fail in a brittle manner. Furnace or vacuum brazing is the most popular method for automated joining of similar or dissimilar materials under a. Brazing is a joining technique that uses a filler metal and is performed at a lower temperature than welding. Brazing is ideally suited. Brazing Dissimilar Metals.

From rickyswelding.com

What Are Some Welding Techniques For Joining Dissimilar Metals? Ricky Brazing Dissimilar Metals Between dissimilar metals, however, suffer from significant intermetallic formation which causes them to fail in a brittle manner. Examples include arc brazing and resistance spot welding. Brazing is a joining technique that uses a filler metal and is performed at a lower temperature than welding. Brazing is one of the most reliable processes for the aerospace industry to obtain sound. Brazing Dissimilar Metals.

From www.cpvmfg.com

Joining Metals Your Frequently Asked Questions About Brazing, Answered Brazing Dissimilar Metals Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. Brazing is a joining technique that uses a filler metal and is performed at a lower temperature than welding. Examples include arc brazing and resistance spot welding. We’ve said that a brazed joint. Brazing is one of the most reliable processes for the aerospace. Brazing Dissimilar Metals.

From www.mechero.my

What is Brazing Process? Brazing Types & Applications Brazing Dissimilar Metals Furnace or vacuum brazing is the most popular method for automated joining of similar or dissimilar materials under a. The peak temperature exceeds the melting point of both materials. Examples include arc brazing and resistance spot welding. We’ve said that a brazed joint. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. Between. Brazing Dissimilar Metals.

From www.mdpi.com

Metals Free FullText Recent Advances in Brazing Fillers for Brazing Dissimilar Metals Brazing is a joining technique that uses a filler metal and is performed at a lower temperature than welding. Between dissimilar metals, however, suffer from significant intermetallic formation which causes them to fail in a brittle manner. We’ve said that a brazed joint. The peak temperature exceeds the melting point of both materials. Examples include arc brazing and resistance spot. Brazing Dissimilar Metals.

From www.mdpi.com

Metals Free FullText Vacuum Brazing of Dissimilar Al 7075 and Al Brazing Dissimilar Metals Brazing is a joining technique that uses a filler metal and is performed at a lower temperature than welding. Furnace or vacuum brazing is the most popular method for automated joining of similar or dissimilar materials under a. We’ve said that a brazed joint. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature.. Brazing Dissimilar Metals.

From eureka.patsnap.com

Dissimilar metal semisolid friction brazing method based on high Brazing Dissimilar Metals Examples include arc brazing and resistance spot welding. Furnace or vacuum brazing is the most popular method for automated joining of similar or dissimilar materials under a. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. The peak temperature exceeds the melting point of both materials. Between dissimilar metals, however, suffer from significant. Brazing Dissimilar Metals.

From www.mdpi.com

Metals Free FullText Microstructural Control of the Interface Brazing Dissimilar Metals The peak temperature exceeds the melting point of both materials. Brazing is one of the most reliable processes for the aerospace industry to obtain sound joints between dissimilar materials. Examples include arc brazing and resistance spot welding. Brazing is a joining technique that uses a filler metal and is performed at a lower temperature than welding. We’ve said that a. Brazing Dissimilar Metals.

From www.mdpi.com

Metals Free FullText Microstructural Control of the Interface Brazing Dissimilar Metals Examples include arc brazing and resistance spot welding. Brazing is one of the most reliable processes for the aerospace industry to obtain sound joints between dissimilar materials. Between dissimilar metals, however, suffer from significant intermetallic formation which causes them to fail in a brittle manner. We’ve said that a brazed joint. Furnace or vacuum brazing is the most popular method. Brazing Dissimilar Metals.

From www.slideshare.net

Brazing Brazing Dissimilar Metals Brazing is a joining technique that uses a filler metal and is performed at a lower temperature than welding. Between dissimilar metals, however, suffer from significant intermetallic formation which causes them to fail in a brittle manner. The peak temperature exceeds the melting point of both materials. Brazing is ideally suited for joining of dissimilar metals and is performed at. Brazing Dissimilar Metals.

From www.mdpi.com

Metals Free FullText Effect of Brazing Filler Metals and Welding Brazing Dissimilar Metals Furnace or vacuum brazing is the most popular method for automated joining of similar or dissimilar materials under a. Brazing is one of the most reliable processes for the aerospace industry to obtain sound joints between dissimilar materials. Brazing is ideally suited for joining of dissimilar metals and is performed at relatively low temperature. The peak temperature exceeds the melting. Brazing Dissimilar Metals.