Turbine Drive Shaft . A wind turbine’s main shaft requires a reliable bearing for operation. Driven by a radial drive shaft. The turbine drive shaft is aligned with the gearbox to recommended values. Magellan aerospace specializes in the manufacture and supply of aeroengine shafts and helicopter drive shafts, as well as other flight safety critical machined components, including discs, seals, and spacers. In this niche, yet highly competitive market, we utilize many unique processes to manufacture shafts for both the hot and cold. Some bearing designs have been known to fail prematurely resulting in costly maintenance repairs. A rotor consists of a turbine, drive shaft, and compressor. Actual stiffness of the bearing supports achieved after.

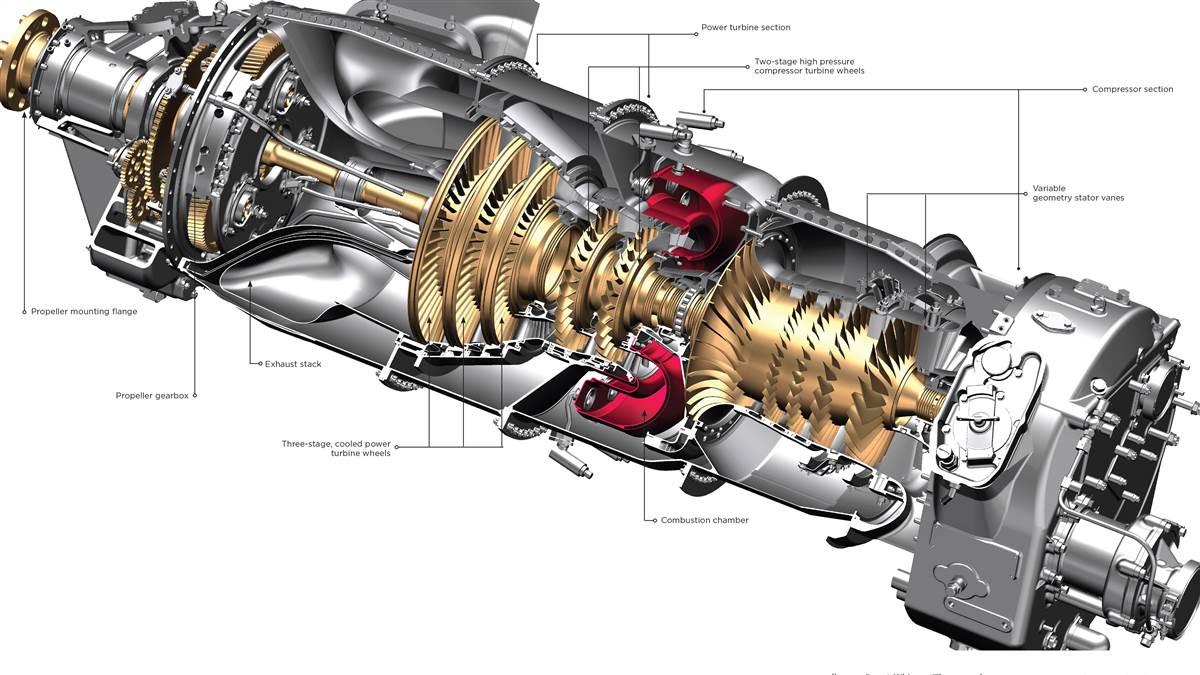

from www.aopa.org

Actual stiffness of the bearing supports achieved after. A rotor consists of a turbine, drive shaft, and compressor. A wind turbine’s main shaft requires a reliable bearing for operation. In this niche, yet highly competitive market, we utilize many unique processes to manufacture shafts for both the hot and cold. Magellan aerospace specializes in the manufacture and supply of aeroengine shafts and helicopter drive shafts, as well as other flight safety critical machined components, including discs, seals, and spacers. The turbine drive shaft is aligned with the gearbox to recommended values. Driven by a radial drive shaft. Some bearing designs have been known to fail prematurely resulting in costly maintenance repairs.

Freeturbine faceoff AOPA

Turbine Drive Shaft A wind turbine’s main shaft requires a reliable bearing for operation. A rotor consists of a turbine, drive shaft, and compressor. A wind turbine’s main shaft requires a reliable bearing for operation. Driven by a radial drive shaft. Magellan aerospace specializes in the manufacture and supply of aeroengine shafts and helicopter drive shafts, as well as other flight safety critical machined components, including discs, seals, and spacers. The turbine drive shaft is aligned with the gearbox to recommended values. Some bearing designs have been known to fail prematurely resulting in costly maintenance repairs. Actual stiffness of the bearing supports achieved after. In this niche, yet highly competitive market, we utilize many unique processes to manufacture shafts for both the hot and cold.

From www.pengky.cn

Overview of Straight Drive Wind Turbine Direct Drive Wind Turbine Turbine Drive Shaft A wind turbine’s main shaft requires a reliable bearing for operation. Actual stiffness of the bearing supports achieved after. In this niche, yet highly competitive market, we utilize many unique processes to manufacture shafts for both the hot and cold. The turbine drive shaft is aligned with the gearbox to recommended values. Some bearing designs have been known to fail. Turbine Drive Shaft.

From aeromodelbasic.blogspot.com

model aircraft Turbines Turbine Drive Shaft Some bearing designs have been known to fail prematurely resulting in costly maintenance repairs. In this niche, yet highly competitive market, we utilize many unique processes to manufacture shafts for both the hot and cold. Magellan aerospace specializes in the manufacture and supply of aeroengine shafts and helicopter drive shafts, as well as other flight safety critical machined components, including. Turbine Drive Shaft.

From thepipingtalk.com

Single shaft Gas turbine, Twoshaft Gas turbine & Multispool Gas Turbine Drive Shaft Actual stiffness of the bearing supports achieved after. Magellan aerospace specializes in the manufacture and supply of aeroengine shafts and helicopter drive shafts, as well as other flight safety critical machined components, including discs, seals, and spacers. A rotor consists of a turbine, drive shaft, and compressor. The turbine drive shaft is aligned with the gearbox to recommended values. Some. Turbine Drive Shaft.

From machineguard.com

Hydroelectric Plant Shaft Guard Machine Guard & Cover Turbine Drive Shaft A rotor consists of a turbine, drive shaft, and compressor. In this niche, yet highly competitive market, we utilize many unique processes to manufacture shafts for both the hot and cold. A wind turbine’s main shaft requires a reliable bearing for operation. Driven by a radial drive shaft. Some bearing designs have been known to fail prematurely resulting in costly. Turbine Drive Shaft.

From www.mdpi.com

Energies Free FullText Estimating Health Condition of the Wind Turbine Drive Shaft A wind turbine’s main shaft requires a reliable bearing for operation. Some bearing designs have been known to fail prematurely resulting in costly maintenance repairs. Actual stiffness of the bearing supports achieved after. A rotor consists of a turbine, drive shaft, and compressor. Magellan aerospace specializes in the manufacture and supply of aeroengine shafts and helicopter drive shafts, as well. Turbine Drive Shaft.

From www.artec-machine.com

The Efficient ASeries turbo parallel shaft gearbox Turbine Drive Shaft Some bearing designs have been known to fail prematurely resulting in costly maintenance repairs. Magellan aerospace specializes in the manufacture and supply of aeroengine shafts and helicopter drive shafts, as well as other flight safety critical machined components, including discs, seals, and spacers. In this niche, yet highly competitive market, we utilize many unique processes to manufacture shafts for both. Turbine Drive Shaft.

From www.researchgate.net

Overview of a high speed shaft subsystem as part of wind turbine drive Turbine Drive Shaft A wind turbine’s main shaft requires a reliable bearing for operation. The turbine drive shaft is aligned with the gearbox to recommended values. Actual stiffness of the bearing supports achieved after. Some bearing designs have been known to fail prematurely resulting in costly maintenance repairs. Driven by a radial drive shaft. A rotor consists of a turbine, drive shaft, and. Turbine Drive Shaft.

From www.walmart.com

CintBllTer EC86 Complete Turbine Drive Shaft Replacement Automatic Pool Turbine Drive Shaft A wind turbine’s main shaft requires a reliable bearing for operation. Actual stiffness of the bearing supports achieved after. Magellan aerospace specializes in the manufacture and supply of aeroengine shafts and helicopter drive shafts, as well as other flight safety critical machined components, including discs, seals, and spacers. Driven by a radial drive shaft. A rotor consists of a turbine,. Turbine Drive Shaft.

From 12charlie.com

SPLIT SHAFT/ FREE TURBINE ENGINE Turbine Drive Shaft Actual stiffness of the bearing supports achieved after. Driven by a radial drive shaft. Some bearing designs have been known to fail prematurely resulting in costly maintenance repairs. A wind turbine’s main shaft requires a reliable bearing for operation. In this niche, yet highly competitive market, we utilize many unique processes to manufacture shafts for both the hot and cold.. Turbine Drive Shaft.

From yardandpool.com

Turbine Drive Shaft, Complete by Pentair Turbine Drive Shaft Some bearing designs have been known to fail prematurely resulting in costly maintenance repairs. The turbine drive shaft is aligned with the gearbox to recommended values. A wind turbine’s main shaft requires a reliable bearing for operation. Driven by a radial drive shaft. Actual stiffness of the bearing supports achieved after. Magellan aerospace specializes in the manufacture and supply of. Turbine Drive Shaft.

From ge10-photos.blogspot.com

General Electric Turbine GE Turbine Shaft Turbine Drive Shaft A wind turbine’s main shaft requires a reliable bearing for operation. In this niche, yet highly competitive market, we utilize many unique processes to manufacture shafts for both the hot and cold. Magellan aerospace specializes in the manufacture and supply of aeroengine shafts and helicopter drive shafts, as well as other flight safety critical machined components, including discs, seals, and. Turbine Drive Shaft.

From www.researchgate.net

Freeturbine turboshaft schematics. From Wikipedia 3 Download Turbine Drive Shaft Magellan aerospace specializes in the manufacture and supply of aeroengine shafts and helicopter drive shafts, as well as other flight safety critical machined components, including discs, seals, and spacers. The turbine drive shaft is aligned with the gearbox to recommended values. A rotor consists of a turbine, drive shaft, and compressor. Driven by a radial drive shaft. Some bearing designs. Turbine Drive Shaft.

From torontopoolsupplies.ca

Pentair EC86 Turbine Drive Shaft Complete Pool Cleaner Parts at Turbine Drive Shaft The turbine drive shaft is aligned with the gearbox to recommended values. A wind turbine’s main shaft requires a reliable bearing for operation. A rotor consists of a turbine, drive shaft, and compressor. Actual stiffness of the bearing supports achieved after. Magellan aerospace specializes in the manufacture and supply of aeroengine shafts and helicopter drive shafts, as well as other. Turbine Drive Shaft.

From www.epoolsupplyusa.shop

Find the Best Pentair Kreepy Krauly Legend / Legend II / Platinum Turbine Drive Shaft The turbine drive shaft is aligned with the gearbox to recommended values. In this niche, yet highly competitive market, we utilize many unique processes to manufacture shafts for both the hot and cold. Magellan aerospace specializes in the manufacture and supply of aeroengine shafts and helicopter drive shafts, as well as other flight safety critical machined components, including discs, seals,. Turbine Drive Shaft.

From www.somersforge.com

Turbine Shaft Somers Turbine Drive Shaft Actual stiffness of the bearing supports achieved after. The turbine drive shaft is aligned with the gearbox to recommended values. Some bearing designs have been known to fail prematurely resulting in costly maintenance repairs. A wind turbine’s main shaft requires a reliable bearing for operation. Magellan aerospace specializes in the manufacture and supply of aeroengine shafts and helicopter drive shafts,. Turbine Drive Shaft.

From empoweringpumps.com

Sealing HighSpeed Shafts in Turbomachinery [Fluid Sealing Association Turbine Drive Shaft Magellan aerospace specializes in the manufacture and supply of aeroengine shafts and helicopter drive shafts, as well as other flight safety critical machined components, including discs, seals, and spacers. Some bearing designs have been known to fail prematurely resulting in costly maintenance repairs. A wind turbine’s main shaft requires a reliable bearing for operation. Actual stiffness of the bearing supports. Turbine Drive Shaft.

From www.perryspoolpump.com

Polaris EC86 Turbine Drive Shaft (180 280) Perry's Pool Pump Turbine Drive Shaft A wind turbine’s main shaft requires a reliable bearing for operation. Driven by a radial drive shaft. Actual stiffness of the bearing supports achieved after. Magellan aerospace specializes in the manufacture and supply of aeroengine shafts and helicopter drive shafts, as well as other flight safety critical machined components, including discs, seals, and spacers. The turbine drive shaft is aligned. Turbine Drive Shaft.

From www.poolzoom.com

Turbine Drive Turbine Drive Shaft The turbine drive shaft is aligned with the gearbox to recommended values. Actual stiffness of the bearing supports achieved after. Some bearing designs have been known to fail prematurely resulting in costly maintenance repairs. Driven by a radial drive shaft. A wind turbine’s main shaft requires a reliable bearing for operation. A rotor consists of a turbine, drive shaft, and. Turbine Drive Shaft.

From pengky.cn

Direct Drive Horizontal Axis Wind Turbine Horizontal Axis Wind Turbine Drive Shaft A wind turbine’s main shaft requires a reliable bearing for operation. Driven by a radial drive shaft. A rotor consists of a turbine, drive shaft, and compressor. In this niche, yet highly competitive market, we utilize many unique processes to manufacture shafts for both the hot and cold. Some bearing designs have been known to fail prematurely resulting in costly. Turbine Drive Shaft.

From www.2040-parts.com

Buy 4T65E GM Transmission Pump / Turbine Drive Shaft in Black Creek Turbine Drive Shaft In this niche, yet highly competitive market, we utilize many unique processes to manufacture shafts for both the hot and cold. A rotor consists of a turbine, drive shaft, and compressor. Actual stiffness of the bearing supports achieved after. Some bearing designs have been known to fail prematurely resulting in costly maintenance repairs. The turbine drive shaft is aligned with. Turbine Drive Shaft.

From www.pengky.cn

Direct Drive Horizontal Axis Wind Turbine Horizontal Axis Wind Turbine Drive Shaft Some bearing designs have been known to fail prematurely resulting in costly maintenance repairs. In this niche, yet highly competitive market, we utilize many unique processes to manufacture shafts for both the hot and cold. A rotor consists of a turbine, drive shaft, and compressor. Actual stiffness of the bearing supports achieved after. Magellan aerospace specializes in the manufacture and. Turbine Drive Shaft.

From www.pyiinc.com

PYI Inc. PSS Shaft Seal For Steam Turbine Rotary Union Systems Turbine Drive Shaft Actual stiffness of the bearing supports achieved after. The turbine drive shaft is aligned with the gearbox to recommended values. A rotor consists of a turbine, drive shaft, and compressor. Some bearing designs have been known to fail prematurely resulting in costly maintenance repairs. A wind turbine’s main shaft requires a reliable bearing for operation. Driven by a radial drive. Turbine Drive Shaft.

From www.amazon.com

ATIE Pool Cleaner Turbine Drive Shaft Assembly C86/EC86 Turbine Drive Shaft Actual stiffness of the bearing supports achieved after. In this niche, yet highly competitive market, we utilize many unique processes to manufacture shafts for both the hot and cold. Some bearing designs have been known to fail prematurely resulting in costly maintenance repairs. Driven by a radial drive shaft. The turbine drive shaft is aligned with the gearbox to recommended. Turbine Drive Shaft.

From www.alamy.com

Turbine Controls MRO employee Jim Clark inspects a turbine drive shaft Turbine Drive Shaft A rotor consists of a turbine, drive shaft, and compressor. Driven by a radial drive shaft. Some bearing designs have been known to fail prematurely resulting in costly maintenance repairs. Magellan aerospace specializes in the manufacture and supply of aeroengine shafts and helicopter drive shafts, as well as other flight safety critical machined components, including discs, seals, and spacers. The. Turbine Drive Shaft.

From machineguard.com

Turbine Shaft Guarding at Hydroelectric Dam Machine Guard & Cover Co. Turbine Drive Shaft A wind turbine’s main shaft requires a reliable bearing for operation. Some bearing designs have been known to fail prematurely resulting in costly maintenance repairs. In this niche, yet highly competitive market, we utilize many unique processes to manufacture shafts for both the hot and cold. Magellan aerospace specializes in the manufacture and supply of aeroengine shafts and helicopter drive. Turbine Drive Shaft.

From www.alibaba.com

Wind Turbine Main Shafts Bearing 24126 Cc/w33 Skf Spherical Roller Turbine Drive Shaft In this niche, yet highly competitive market, we utilize many unique processes to manufacture shafts for both the hot and cold. Magellan aerospace specializes in the manufacture and supply of aeroengine shafts and helicopter drive shafts, as well as other flight safety critical machined components, including discs, seals, and spacers. A wind turbine’s main shaft requires a reliable bearing for. Turbine Drive Shaft.

From westernmachine.com

Hydro Shaft Refurbishing Turbine Runner Shaft Western Machine Works Turbine Drive Shaft A wind turbine’s main shaft requires a reliable bearing for operation. Some bearing designs have been known to fail prematurely resulting in costly maintenance repairs. Magellan aerospace specializes in the manufacture and supply of aeroengine shafts and helicopter drive shafts, as well as other flight safety critical machined components, including discs, seals, and spacers. Actual stiffness of the bearing supports. Turbine Drive Shaft.

From gasturbineresources.com

Gas Turbine Engine Rotor Shaft Recovery Turbine Drive Shaft Driven by a radial drive shaft. A rotor consists of a turbine, drive shaft, and compressor. The turbine drive shaft is aligned with the gearbox to recommended values. In this niche, yet highly competitive market, we utilize many unique processes to manufacture shafts for both the hot and cold. Actual stiffness of the bearing supports achieved after. Some bearing designs. Turbine Drive Shaft.

From cantrappedgascauseconstipationbungei.blogspot.com

Can Trapped Gas Cause Constipation How Does A Gas Turbine Engine Work Turbine Drive Shaft The turbine drive shaft is aligned with the gearbox to recommended values. A wind turbine’s main shaft requires a reliable bearing for operation. Some bearing designs have been known to fail prematurely resulting in costly maintenance repairs. Actual stiffness of the bearing supports achieved after. Magellan aerospace specializes in the manufacture and supply of aeroengine shafts and helicopter drive shafts,. Turbine Drive Shaft.

From exoxbrxeq.blob.core.windows.net

Drive Shaft Of Wind Turbine at Esther Whitaker blog Turbine Drive Shaft Some bearing designs have been known to fail prematurely resulting in costly maintenance repairs. Magellan aerospace specializes in the manufacture and supply of aeroengine shafts and helicopter drive shafts, as well as other flight safety critical machined components, including discs, seals, and spacers. A rotor consists of a turbine, drive shaft, and compressor. Actual stiffness of the bearing supports achieved. Turbine Drive Shaft.

From www.aopa.org

Freeturbine faceoff AOPA Turbine Drive Shaft Driven by a radial drive shaft. A wind turbine’s main shaft requires a reliable bearing for operation. The turbine drive shaft is aligned with the gearbox to recommended values. Actual stiffness of the bearing supports achieved after. A rotor consists of a turbine, drive shaft, and compressor. In this niche, yet highly competitive market, we utilize many unique processes to. Turbine Drive Shaft.

From onlinelibrary.wiley.com

On design, modelling, and analysis of a 10‐MW medium‐speed drivetrain Turbine Drive Shaft Actual stiffness of the bearing supports achieved after. Some bearing designs have been known to fail prematurely resulting in costly maintenance repairs. Driven by a radial drive shaft. The turbine drive shaft is aligned with the gearbox to recommended values. A wind turbine’s main shaft requires a reliable bearing for operation. In this niche, yet highly competitive market, we utilize. Turbine Drive Shaft.

From www.amazon.in

Pentair EC86 Complete Turbine Drive Shaft Replacement Automatic Pool Turbine Drive Shaft In this niche, yet highly competitive market, we utilize many unique processes to manufacture shafts for both the hot and cold. A wind turbine’s main shaft requires a reliable bearing for operation. A rotor consists of a turbine, drive shaft, and compressor. Some bearing designs have been known to fail prematurely resulting in costly maintenance repairs. The turbine drive shaft. Turbine Drive Shaft.

From www.inyopools.com

Pentair Turbine Drive Shaft EC86 Turbine Drive Shaft A wind turbine’s main shaft requires a reliable bearing for operation. Magellan aerospace specializes in the manufacture and supply of aeroengine shafts and helicopter drive shafts, as well as other flight safety critical machined components, including discs, seals, and spacers. In this niche, yet highly competitive market, we utilize many unique processes to manufacture shafts for both the hot and. Turbine Drive Shaft.

From www.pengky.cn

Overview of Straight Drive Wind Turbine Direct Drive Wind Turbine Turbine Drive Shaft Some bearing designs have been known to fail prematurely resulting in costly maintenance repairs. Actual stiffness of the bearing supports achieved after. Driven by a radial drive shaft. Magellan aerospace specializes in the manufacture and supply of aeroengine shafts and helicopter drive shafts, as well as other flight safety critical machined components, including discs, seals, and spacers. A rotor consists. Turbine Drive Shaft.