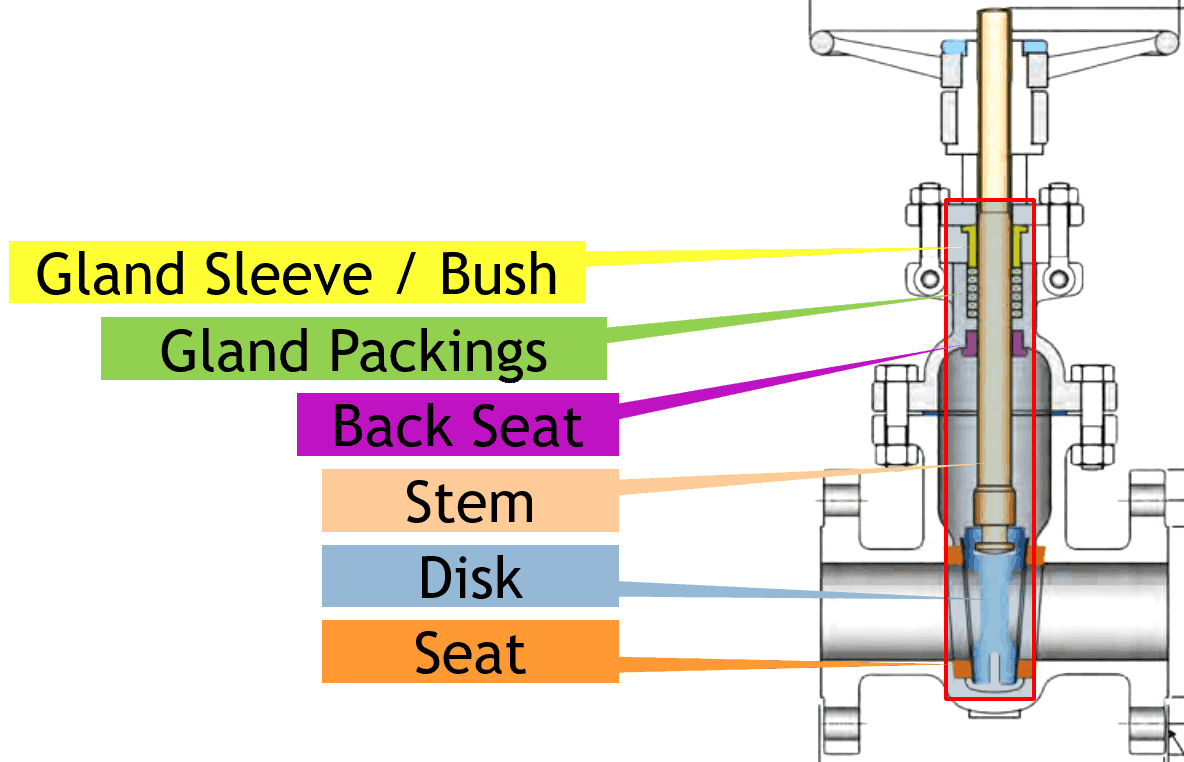

Valve Back Seat Design . Valve trim components will change with the types of valves. Disc, valve seat, and stem are common for all the valves. Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. Most apv valves are designed with stem ‘backseats’. However, valve manufactures in general including apv do not recommend the. The valve backseat test is performed in the valve with backseat feature and it is similar to the valve shell test and the valve shall be fully opened and packing gland shall be loose. Before specifying and selecting isolation valves, for the seating mechanism, the different seating styles must. Design valves are provided with a 1/8” hole drilled in the stem tang slot. This feature is critical for steam service since it prevents excessive.

from stvvalve.com

Disc, valve seat, and stem are common for all the valves. However, valve manufactures in general including apv do not recommend the. Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. Design valves are provided with a 1/8” hole drilled in the stem tang slot. Valve trim components will change with the types of valves. Most apv valves are designed with stem ‘backseats’. Before specifying and selecting isolation valves, for the seating mechanism, the different seating styles must. The valve backseat test is performed in the valve with backseat feature and it is similar to the valve shell test and the valve shall be fully opened and packing gland shall be loose. This feature is critical for steam service since it prevents excessive.

Valve Trim and Parts Including API Trim Charts China Industry Valves

Valve Back Seat Design This feature is critical for steam service since it prevents excessive. This feature is critical for steam service since it prevents excessive. However, valve manufactures in general including apv do not recommend the. Before specifying and selecting isolation valves, for the seating mechanism, the different seating styles must. Most apv valves are designed with stem ‘backseats’. Valve trim components will change with the types of valves. Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. Disc, valve seat, and stem are common for all the valves. The valve backseat test is performed in the valve with backseat feature and it is similar to the valve shell test and the valve shall be fully opened and packing gland shall be loose. Design valves are provided with a 1/8” hole drilled in the stem tang slot.

From www.ipcvalves.com

How to pick the right material for valve seat IPC Valves Valve Back Seat Design Before specifying and selecting isolation valves, for the seating mechanism, the different seating styles must. Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. Disc, valve seat, and stem are common for all the valves. Most apv valves are designed with stem ‘backseats’. Design valves are provided with a 1/8” hole drilled. Valve Back Seat Design.

From in.thptnganamst.edu.vn

Principal 134+ imagen what is a valve seat In.thptnganamst.edu.vn Valve Back Seat Design Valve trim components will change with the types of valves. This feature is critical for steam service since it prevents excessive. Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. Before specifying and selecting isolation valves, for the seating mechanism, the different seating styles must. However, valve manufactures in general including apv. Valve Back Seat Design.

From hardhatengineer.com

Valve Trim and Parts Including API Trim Charts Valve Back Seat Design Design valves are provided with a 1/8” hole drilled in the stem tang slot. Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. Disc, valve seat, and stem are common for all the valves. Most apv valves are designed with stem ‘backseats’. Valve trim components will change with the types of valves.. Valve Back Seat Design.

From www.scribd.com

Gate Valve Backseat Pressure Testing PDF Valve Back Seat Design Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. Disc, valve seat, and stem are common for all the valves. Most apv valves are designed with stem ‘backseats’. Valve trim components will change with the types of valves. Design valves are provided with a 1/8” hole drilled in the stem tang slot.. Valve Back Seat Design.

From www.electricalvolt.com

double seat valves Archives Electrical Volt Valve Back Seat Design This feature is critical for steam service since it prevents excessive. However, valve manufactures in general including apv do not recommend the. Design valves are provided with a 1/8” hole drilled in the stem tang slot. Most apv valves are designed with stem ‘backseats’. Before specifying and selecting isolation valves, for the seating mechanism, the different seating styles must. Valve. Valve Back Seat Design.

From instrumentationtools.com

Classification of Gate Valves Gate Valve Disk, Stem & Seat Design Valve Back Seat Design Design valves are provided with a 1/8” hole drilled in the stem tang slot. Disc, valve seat, and stem are common for all the valves. The valve backseat test is performed in the valve with backseat feature and it is similar to the valve shell test and the valve shall be fully opened and packing gland shall be loose. This. Valve Back Seat Design.

From control.com

Slidingstem Valves Basic Principles of Control Valves and Actuators Valve Back Seat Design This feature is critical for steam service since it prevents excessive. Design valves are provided with a 1/8” hole drilled in the stem tang slot. However, valve manufactures in general including apv do not recommend the. Before specifying and selecting isolation valves, for the seating mechanism, the different seating styles must. Disc, valve seat, and stem are common for all. Valve Back Seat Design.

From design.udlvirtual.edu.pe

Sluice Gate Valve Design Design Talk Valve Back Seat Design Valve trim components will change with the types of valves. This feature is critical for steam service since it prevents excessive. The valve backseat test is performed in the valve with backseat feature and it is similar to the valve shell test and the valve shall be fully opened and packing gland shall be loose. Before specifying and selecting isolation. Valve Back Seat Design.

From www.youtube.com

HP Valves DS 02 2 Assembly instruction throttle type globe valve Valve Back Seat Design Design valves are provided with a 1/8” hole drilled in the stem tang slot. Disc, valve seat, and stem are common for all the valves. However, valve manufactures in general including apv do not recommend the. Before specifying and selecting isolation valves, for the seating mechanism, the different seating styles must. Most apv valves are designed with stem ‘backseats’. This. Valve Back Seat Design.

From hardhatengineer.com

Globe Valve Types and Parts A Complete Guide Valve Back Seat Design Valve trim components will change with the types of valves. The valve backseat test is performed in the valve with backseat feature and it is similar to the valve shell test and the valve shall be fully opened and packing gland shall be loose. Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial. Valve Back Seat Design.

From dxojpegyo.blob.core.windows.net

Gate Valve Back Seat Design at Willie Daniels blog Valve Back Seat Design Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. However, valve manufactures in general including apv do not recommend the. Design valves are provided with a 1/8” hole drilled in the stem tang slot. The valve backseat test is performed in the valve with backseat feature and it is similar to the. Valve Back Seat Design.

From zecovalve.com

Gate Valve Backseat Test Backseating A Valve ZECO Valve Valve Back Seat Design Disc, valve seat, and stem are common for all the valves. However, valve manufactures in general including apv do not recommend the. Most apv valves are designed with stem ‘backseats’. The valve backseat test is performed in the valve with backseat feature and it is similar to the valve shell test and the valve shall be fully opened and packing. Valve Back Seat Design.

From groups.google.com

Valve Back Seat Test Valve Back Seat Design This feature is critical for steam service since it prevents excessive. The valve backseat test is performed in the valve with backseat feature and it is similar to the valve shell test and the valve shall be fully opened and packing gland shall be loose. However, valve manufactures in general including apv do not recommend the. Design valves are provided. Valve Back Seat Design.

From www.sankeycontrols.com

Valve Design Sankey Controls Valve Back Seat Design Most apv valves are designed with stem ‘backseats’. Valve trim components will change with the types of valves. The valve backseat test is performed in the valve with backseat feature and it is similar to the valve shell test and the valve shall be fully opened and packing gland shall be loose. Before specifying and selecting isolation valves, for the. Valve Back Seat Design.

From www.youtube.com

Basics II API 598 II Clauses II Shell & Backseat test II Independent Valve Back Seat Design However, valve manufactures in general including apv do not recommend the. Before specifying and selecting isolation valves, for the seating mechanism, the different seating styles must. This feature is critical for steam service since it prevents excessive. Disc, valve seat, and stem are common for all the valves. Selecting the proper valve seat is crucial for maintaining valve integrity and. Valve Back Seat Design.

From wili.vn

1. SEAT VALVES Wili® Co., Ltd Valve Back Seat Design However, valve manufactures in general including apv do not recommend the. Before specifying and selecting isolation valves, for the seating mechanism, the different seating styles must. Disc, valve seat, and stem are common for all the valves. Valve trim components will change with the types of valves. This feature is critical for steam service since it prevents excessive. Selecting the. Valve Back Seat Design.

From stvvalve.com

Valve Trim and Parts Including API Trim Charts China Industry Valves Valve Back Seat Design Valve trim components will change with the types of valves. However, valve manufactures in general including apv do not recommend the. Before specifying and selecting isolation valves, for the seating mechanism, the different seating styles must. Disc, valve seat, and stem are common for all the valves. Most apv valves are designed with stem ‘backseats’. Selecting the proper valve seat. Valve Back Seat Design.

From www.youtube.com

The Best Valve seat design for soft seat Ball Valve Design Tips 12 Valve Back Seat Design However, valve manufactures in general including apv do not recommend the. This feature is critical for steam service since it prevents excessive. Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. The valve backseat test is performed in the valve with backseat feature and it is similar to the valve shell test. Valve Back Seat Design.

From www.bossealvalves.com

China API 602 Valves Manufacturer Bosseal Valve Back Seat Design Valve trim components will change with the types of valves. This feature is critical for steam service since it prevents excessive. However, valve manufactures in general including apv do not recommend the. Design valves are provided with a 1/8” hole drilled in the stem tang slot. The valve backseat test is performed in the valve with backseat feature and it. Valve Back Seat Design.

From www.watersvalve.com

Resilient Seated Gate Valve VS Metal Seated Gate Valve Watersvalve Valve Back Seat Design This feature is critical for steam service since it prevents excessive. Valve trim components will change with the types of valves. Most apv valves are designed with stem ‘backseats’. The valve backseat test is performed in the valve with backseat feature and it is similar to the valve shell test and the valve shall be fully opened and packing gland. Valve Back Seat Design.

From blog.eaglegroupmanufacturers.com

Anatomy of Industrial Valves Valve Back Seat Design Design valves are provided with a 1/8” hole drilled in the stem tang slot. Before specifying and selecting isolation valves, for the seating mechanism, the different seating styles must. This feature is critical for steam service since it prevents excessive. Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. Most apv valves. Valve Back Seat Design.

From giooipepa.blob.core.windows.net

What Does Back Seating A Valve at Scott Crouse blog Valve Back Seat Design Before specifying and selecting isolation valves, for the seating mechanism, the different seating styles must. Valve trim components will change with the types of valves. Most apv valves are designed with stem ‘backseats’. Disc, valve seat, and stem are common for all the valves. Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial. Valve Back Seat Design.

From www.vrogue.co

What Is A Globe Valve Globe Valve Diagram vrogue.co Valve Back Seat Design The valve backseat test is performed in the valve with backseat feature and it is similar to the valve shell test and the valve shall be fully opened and packing gland shall be loose. However, valve manufactures in general including apv do not recommend the. Valve trim components will change with the types of valves. Design valves are provided with. Valve Back Seat Design.

From qrcvalves.com

Valve Backseat QRC Valves Valve Back Seat Design This feature is critical for steam service since it prevents excessive. However, valve manufactures in general including apv do not recommend the. Disc, valve seat, and stem are common for all the valves. Design valves are provided with a 1/8” hole drilled in the stem tang slot. Before specifying and selecting isolation valves, for the seating mechanism, the different seating. Valve Back Seat Design.

From zfavalves.com

Silicone Rubber Lined Hard Back Valve Seat for Wafer Butterfly Valve Valve Back Seat Design Valve trim components will change with the types of valves. The valve backseat test is performed in the valve with backseat feature and it is similar to the valve shell test and the valve shall be fully opened and packing gland shall be loose. Before specifying and selecting isolation valves, for the seating mechanism, the different seating styles must. Selecting. Valve Back Seat Design.

From solutecmandiri.com

Needle valve are used for isolation, Regulating and metering valves Valve Back Seat Design Design valves are provided with a 1/8” hole drilled in the stem tang slot. Disc, valve seat, and stem are common for all the valves. Valve trim components will change with the types of valves. Before specifying and selecting isolation valves, for the seating mechanism, the different seating styles must. Selecting the proper valve seat is crucial for maintaining valve. Valve Back Seat Design.

From www.youtube.com

Globe Valve 08 Back seat bush 09 Grand packing 10 Grand bush Valve Back Seat Design Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. However, valve manufactures in general including apv do not recommend the. This feature is critical for steam service since it prevents excessive. Disc, valve seat, and stem are common for all the valves. Design valves are provided with a 1/8” hole drilled in. Valve Back Seat Design.

From www.youtube.com

Offset valve guides and valve seat blending explained YouTube Valve Back Seat Design Most apv valves are designed with stem ‘backseats’. Before specifying and selecting isolation valves, for the seating mechanism, the different seating styles must. The valve backseat test is performed in the valve with backseat feature and it is similar to the valve shell test and the valve shall be fully opened and packing gland shall be loose. Disc, valve seat,. Valve Back Seat Design.

From dannysengineportal.com

Valve Seats Installing And Grinding Valve Seats Learn The Basics Valve Back Seat Design Valve trim components will change with the types of valves. Disc, valve seat, and stem are common for all the valves. Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. Most apv valves are designed with stem ‘backseats’. Design valves are provided with a 1/8” hole drilled in the stem tang slot.. Valve Back Seat Design.

From www.youtube.com

Disassemble a Metal Seat Ball Valve Design Tips 8 YouTube Valve Back Seat Design Design valves are provided with a 1/8” hole drilled in the stem tang slot. However, valve manufactures in general including apv do not recommend the. Valve trim components will change with the types of valves. Most apv valves are designed with stem ‘backseats’. Disc, valve seat, and stem are common for all the valves. Selecting the proper valve seat is. Valve Back Seat Design.

From www.youtube.com

Piping Engineering Valve hydro testing (body, seat & backseat) YouTube Valve Back Seat Design Disc, valve seat, and stem are common for all the valves. Before specifying and selecting isolation valves, for the seating mechanism, the different seating styles must. This feature is critical for steam service since it prevents excessive. Most apv valves are designed with stem ‘backseats’. The valve backseat test is performed in the valve with backseat feature and it is. Valve Back Seat Design.

From automationforum.co

Parts of Valve Valve Back Seat Design The valve backseat test is performed in the valve with backseat feature and it is similar to the valve shell test and the valve shall be fully opened and packing gland shall be loose. Before specifying and selecting isolation valves, for the seating mechanism, the different seating styles must. This feature is critical for steam service since it prevents excessive.. Valve Back Seat Design.

From www.dvsvalve.com

Why should the valve be equipped with a backseat? Valve Back Seat Design This feature is critical for steam service since it prevents excessive. Before specifying and selecting isolation valves, for the seating mechanism, the different seating styles must. Valve trim components will change with the types of valves. However, valve manufactures in general including apv do not recommend the. Disc, valve seat, and stem are common for all the valves. Selecting the. Valve Back Seat Design.

From www.tigervalve.com

MetalSeated Ball Valves Valve Back Seat Design Most apv valves are designed with stem ‘backseats’. Valve trim components will change with the types of valves. This feature is critical for steam service since it prevents excessive. Disc, valve seat, and stem are common for all the valves. Before specifying and selecting isolation valves, for the seating mechanism, the different seating styles must. However, valve manufactures in general. Valve Back Seat Design.

From www.scribd.com

What Is Valve Backseat Test PDF Valve Back Seat Design Before specifying and selecting isolation valves, for the seating mechanism, the different seating styles must. Selecting the proper valve seat is crucial for maintaining valve integrity and functionality in different industrial applications. Most apv valves are designed with stem ‘backseats’. However, valve manufactures in general including apv do not recommend the. Valve trim components will change with the types of. Valve Back Seat Design.