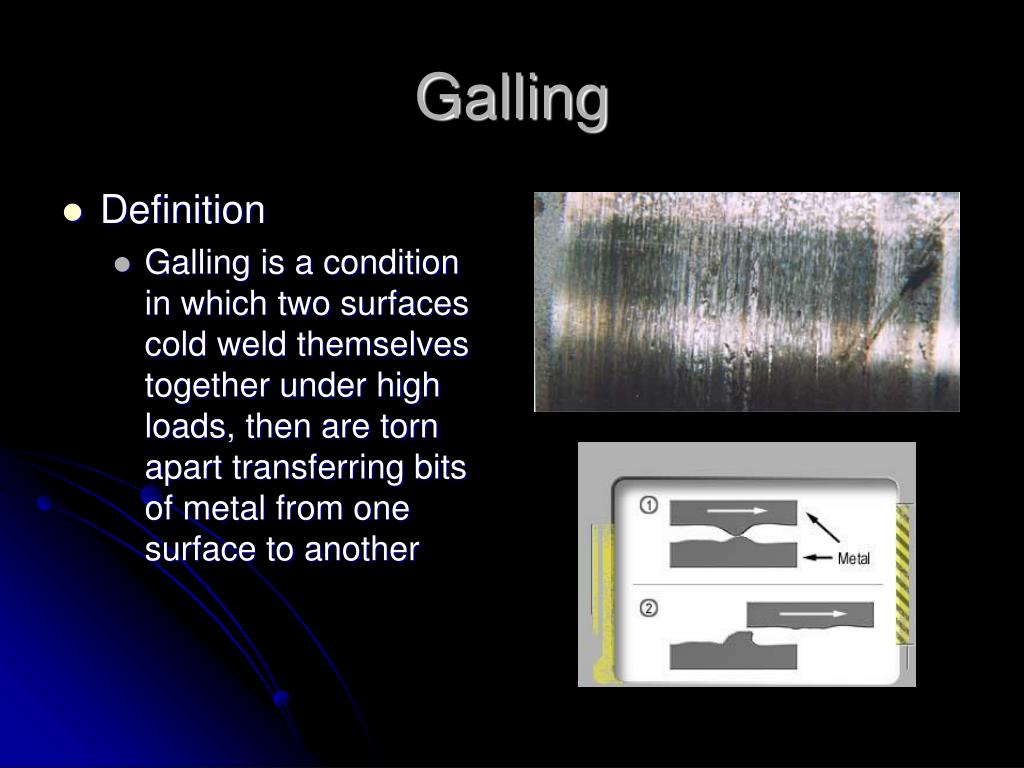

Aluminum Galling Definition . Galling can result separation of metal pieces from the original. Aluminum alloys are commonly used in various industries. Your team starts break out, and suddenly a nut won’t budge. Metal surfaces make direct contact. Galling is a type of wear that occurs when materials that are compressed against one another are put into motion that causes friction. High pressure exists between surfaces. It’s more than just friction or debris. Galling occurs when two surfaces in relative motion start sticking to each other through molecular forces, eventually resulting in accidental cold welding. Stuck nuts and seized bolts. Adhesive wear leads to metal galling when: However, they have a tendency to gall, especially when subjected to high loads and friction. Metal galling is a type of surface wear that causes a metal unintentionally engage with another metal in contact. Virtually everyone in industrial settings has encountered galling at some point, and you know the routine. It’s something that happens every day in every plant:

from www.slideserve.com

Stuck nuts and seized bolts. Metal galling is a type of surface wear that causes a metal unintentionally engage with another metal in contact. Your team starts break out, and suddenly a nut won’t budge. Virtually everyone in industrial settings has encountered galling at some point, and you know the routine. It’s something that happens every day in every plant: Metal surfaces make direct contact. Aluminum alloys are commonly used in various industries. Adhesive wear leads to metal galling when: It’s more than just friction or debris. However, they have a tendency to gall, especially when subjected to high loads and friction.

PPT Manual Transmission Repair PowerPoint Presentation, free download

Aluminum Galling Definition Your team starts break out, and suddenly a nut won’t budge. It’s something that happens every day in every plant: Galling can result separation of metal pieces from the original. Stuck nuts and seized bolts. High pressure exists between surfaces. Aluminum alloys are commonly used in various industries. Metal galling is a type of surface wear that causes a metal unintentionally engage with another metal in contact. Galling occurs when two surfaces in relative motion start sticking to each other through molecular forces, eventually resulting in accidental cold welding. Virtually everyone in industrial settings has encountered galling at some point, and you know the routine. Metal surfaces make direct contact. Your team starts break out, and suddenly a nut won’t budge. However, they have a tendency to gall, especially when subjected to high loads and friction. It’s more than just friction or debris. Galling is a type of wear that occurs when materials that are compressed against one another are put into motion that causes friction. Adhesive wear leads to metal galling when:

From www.hextechnology.com

How to Prevent Galling and Avoid ‘Fake Galling’ Hex Technology Aluminum Galling Definition Aluminum alloys are commonly used in various industries. Virtually everyone in industrial settings has encountered galling at some point, and you know the routine. Galling is a type of wear that occurs when materials that are compressed against one another are put into motion that causes friction. However, they have a tendency to gall, especially when subjected to high loads. Aluminum Galling Definition.

From pipinginsider.com

What is Metal Galling? Its Causes, Mechanism, Susceptible Metals Aluminum Galling Definition It’s more than just friction or debris. Virtually everyone in industrial settings has encountered galling at some point, and you know the routine. Aluminum alloys are commonly used in various industries. Galling can result separation of metal pieces from the original. Galling occurs when two surfaces in relative motion start sticking to each other through molecular forces, eventually resulting in. Aluminum Galling Definition.

From www.thefabricator.com

Detecting galling onset in aluminum alloy stamping, Part III Aluminum Galling Definition Metal galling is a type of surface wear that causes a metal unintentionally engage with another metal in contact. High pressure exists between surfaces. Galling is a type of wear that occurs when materials that are compressed against one another are put into motion that causes friction. However, they have a tendency to gall, especially when subjected to high loads. Aluminum Galling Definition.

From www.thefabricator.com

Engineering Angle Detecting the onset of galling in aluminum sheet Aluminum Galling Definition Galling is a type of wear that occurs when materials that are compressed against one another are put into motion that causes friction. Galling occurs when two surfaces in relative motion start sticking to each other through molecular forces, eventually resulting in accidental cold welding. However, they have a tendency to gall, especially when subjected to high loads and friction.. Aluminum Galling Definition.

From www.youtube.com

What is Galling? Principles of Joint Integrity Ep. 1 YouTube Aluminum Galling Definition Metal galling is a type of surface wear that causes a metal unintentionally engage with another metal in contact. High pressure exists between surfaces. Stuck nuts and seized bolts. Metal surfaces make direct contact. Aluminum alloys are commonly used in various industries. Galling can result separation of metal pieces from the original. Adhesive wear leads to metal galling when: Your. Aluminum Galling Definition.

From www.langleyalloys.com

Comparative Galling Resistance of Super Duplex Stainless Steel Alloys Aluminum Galling Definition However, they have a tendency to gall, especially when subjected to high loads and friction. Adhesive wear leads to metal galling when: Virtually everyone in industrial settings has encountered galling at some point, and you know the routine. Your team starts break out, and suddenly a nut won’t budge. It’s something that happens every day in every plant: High pressure. Aluminum Galling Definition.

From www.slideserve.com

PPT Manual Transmission Repair PowerPoint Presentation, free download Aluminum Galling Definition Metal galling is a type of surface wear that causes a metal unintentionally engage with another metal in contact. Galling is a type of wear that occurs when materials that are compressed against one another are put into motion that causes friction. Metal surfaces make direct contact. High pressure exists between surfaces. Virtually everyone in industrial settings has encountered galling. Aluminum Galling Definition.

From xecogioinhapkhau.com

How Do You Keep Aluminum Threads From Galling Proven Tips And Techniques Aluminum Galling Definition It’s more than just friction or debris. Galling can result separation of metal pieces from the original. Metal galling is a type of surface wear that causes a metal unintentionally engage with another metal in contact. It’s something that happens every day in every plant: Galling is a type of wear that occurs when materials that are compressed against one. Aluminum Galling Definition.

From southaustinmetals.com

What Is Galling and How to Fix It South Austin Metals Aluminum Galling Definition Your team starts break out, and suddenly a nut won’t budge. Adhesive wear leads to metal galling when: However, they have a tendency to gall, especially when subjected to high loads and friction. Galling can result separation of metal pieces from the original. High pressure exists between surfaces. Metal surfaces make direct contact. Galling is a type of wear that. Aluminum Galling Definition.

From www.youtube.com

Gallium Induced Structural Failure of an Aluminum Sheet YouTube Aluminum Galling Definition It’s more than just friction or debris. Your team starts break out, and suddenly a nut won’t budge. Adhesive wear leads to metal galling when: Galling occurs when two surfaces in relative motion start sticking to each other through molecular forces, eventually resulting in accidental cold welding. Stuck nuts and seized bolts. Virtually everyone in industrial settings has encountered galling. Aluminum Galling Definition.

From www.mdpi.com

Lubricants Free FullText Friction and Wear in Stages of Galling Aluminum Galling Definition Adhesive wear leads to metal galling when: Metal galling is a type of surface wear that causes a metal unintentionally engage with another metal in contact. It’s something that happens every day in every plant: Galling can result separation of metal pieces from the original. Stuck nuts and seized bolts. Metal surfaces make direct contact. High pressure exists between surfaces.. Aluminum Galling Definition.

From www.uccomponents.com

Simply Galling and the Fasteners it Ruins UC Components, Inc. Aluminum Galling Definition Galling is a type of wear that occurs when materials that are compressed against one another are put into motion that causes friction. Galling occurs when two surfaces in relative motion start sticking to each other through molecular forces, eventually resulting in accidental cold welding. Metal galling is a type of surface wear that causes a metal unintentionally engage with. Aluminum Galling Definition.

From www.linkedin.com

Galling and Seizing of StainlessSteel Bolts Aluminum Galling Definition Metal surfaces make direct contact. Virtually everyone in industrial settings has encountered galling at some point, and you know the routine. Stuck nuts and seized bolts. Metal galling is a type of surface wear that causes a metal unintentionally engage with another metal in contact. However, they have a tendency to gall, especially when subjected to high loads and friction.. Aluminum Galling Definition.

From www.semanticscholar.org

[PDF] Galling in aluminum alloys and Duralcan aluminum matrix Aluminum Galling Definition It’s more than just friction or debris. Galling occurs when two surfaces in relative motion start sticking to each other through molecular forces, eventually resulting in accidental cold welding. Virtually everyone in industrial settings has encountered galling at some point, and you know the routine. It’s something that happens every day in every plant: Your team starts break out, and. Aluminum Galling Definition.

From www.marketsmartb2b.com

What is Metal Galling and How It Caused? Aluminum Galling Definition However, they have a tendency to gall, especially when subjected to high loads and friction. Metal surfaces make direct contact. Your team starts break out, and suddenly a nut won’t budge. High pressure exists between surfaces. Galling can result separation of metal pieces from the original. Galling is a type of wear that occurs when materials that are compressed against. Aluminum Galling Definition.

From www.fluoramics.com

Fastener Failure Caused by Galling Aluminum Galling Definition It’s something that happens every day in every plant: Metal galling is a type of surface wear that causes a metal unintentionally engage with another metal in contact. Virtually everyone in industrial settings has encountered galling at some point, and you know the routine. Aluminum alloys are commonly used in various industries. However, they have a tendency to gall, especially. Aluminum Galling Definition.

From www.slideshare.net

1 Basic Punching Tt 2010 Aluminum Galling Definition Your team starts break out, and suddenly a nut won’t budge. Stuck nuts and seized bolts. Galling occurs when two surfaces in relative motion start sticking to each other through molecular forces, eventually resulting in accidental cold welding. Virtually everyone in industrial settings has encountered galling at some point, and you know the routine. Galling can result separation of metal. Aluminum Galling Definition.

From www.sintef.no

GAlf Galling in Aluminium Forming SINTEF Aluminum Galling Definition Metal surfaces make direct contact. Aluminum alloys are commonly used in various industries. High pressure exists between surfaces. Galling is a type of wear that occurs when materials that are compressed against one another are put into motion that causes friction. However, they have a tendency to gall, especially when subjected to high loads and friction. Your team starts break. Aluminum Galling Definition.

From dynamicdiesupply.com

Detecting galling onset in aluminum alloy stamping, Part I Dynamic Aluminum Galling Definition Galling occurs when two surfaces in relative motion start sticking to each other through molecular forces, eventually resulting in accidental cold welding. Your team starts break out, and suddenly a nut won’t budge. Metal surfaces make direct contact. Galling is a type of wear that occurs when materials that are compressed against one another are put into motion that causes. Aluminum Galling Definition.

From www.fluoramics.com

Galling Causes Performances Failures Aluminum Galling Definition It’s something that happens every day in every plant: Galling occurs when two surfaces in relative motion start sticking to each other through molecular forces, eventually resulting in accidental cold welding. Stuck nuts and seized bolts. However, they have a tendency to gall, especially when subjected to high loads and friction. Aluminum alloys are commonly used in various industries. Virtually. Aluminum Galling Definition.

From www.tribonet.org

Galling About Tribology Aluminum Galling Definition It’s something that happens every day in every plant: Virtually everyone in industrial settings has encountered galling at some point, and you know the routine. Aluminum alloys are commonly used in various industries. Galling can result separation of metal pieces from the original. Adhesive wear leads to metal galling when: However, they have a tendency to gall, especially when subjected. Aluminum Galling Definition.

From clintonaluminum.com

Galling of Aluminum and Stainless Steel Clinton Aluminum Aluminum Galling Definition Metal galling is a type of surface wear that causes a metal unintentionally engage with another metal in contact. Galling can result separation of metal pieces from the original. Virtually everyone in industrial settings has encountered galling at some point, and you know the routine. Stuck nuts and seized bolts. It’s more than just friction or debris. Adhesive wear leads. Aluminum Galling Definition.

From www.thefabricator.com

Detecting galling onset in aluminum alloy stamping, Part I Aluminum Galling Definition Galling occurs when two surfaces in relative motion start sticking to each other through molecular forces, eventually resulting in accidental cold welding. Aluminum alloys are commonly used in various industries. Your team starts break out, and suddenly a nut won’t budge. Adhesive wear leads to metal galling when: High pressure exists between surfaces. Galling can result separation of metal pieces. Aluminum Galling Definition.

From www.museoinclusivo.com

Exploring Aluminum Definition Properties, Uses, and Benefits Aluminum Galling Definition Galling can result separation of metal pieces from the original. However, they have a tendency to gall, especially when subjected to high loads and friction. Aluminum alloys are commonly used in various industries. High pressure exists between surfaces. Your team starts break out, and suddenly a nut won’t budge. Adhesive wear leads to metal galling when: Virtually everyone in industrial. Aluminum Galling Definition.

From www.researchgate.net

(PDF) Friction and Wear in Stages of Galling for Sheet Metal Forming Aluminum Galling Definition Metal surfaces make direct contact. Aluminum alloys are commonly used in various industries. Galling can result separation of metal pieces from the original. Stuck nuts and seized bolts. It’s more than just friction or debris. Galling occurs when two surfaces in relative motion start sticking to each other through molecular forces, eventually resulting in accidental cold welding. It’s something that. Aluminum Galling Definition.

From www.toolhustle.com

What is galling? And why your stainless steel bolts seize ToolHustle Aluminum Galling Definition Galling occurs when two surfaces in relative motion start sticking to each other through molecular forces, eventually resulting in accidental cold welding. Metal galling is a type of surface wear that causes a metal unintentionally engage with another metal in contact. Metal surfaces make direct contact. Your team starts break out, and suddenly a nut won’t budge. Galling is a. Aluminum Galling Definition.

From www.windpowerengineering.com

How galled fasteners may affect windturbine O&M Aluminum Galling Definition Galling is a type of wear that occurs when materials that are compressed against one another are put into motion that causes friction. It’s more than just friction or debris. Aluminum alloys are commonly used in various industries. Virtually everyone in industrial settings has encountered galling at some point, and you know the routine. Adhesive wear leads to metal galling. Aluminum Galling Definition.

From provenproductivity.com

What is Galling and How do you Prevent it? Proven Productivity Aluminum Galling Definition However, they have a tendency to gall, especially when subjected to high loads and friction. Galling occurs when two surfaces in relative motion start sticking to each other through molecular forces, eventually resulting in accidental cold welding. High pressure exists between surfaces. Aluminum alloys are commonly used in various industries. Metal surfaces make direct contact. Metal galling is a type. Aluminum Galling Definition.

From blog.thepipingmart.com

What is Galling in Metals? Aluminum Galling Definition Stuck nuts and seized bolts. Adhesive wear leads to metal galling when: Metal surfaces make direct contact. High pressure exists between surfaces. However, they have a tendency to gall, especially when subjected to high loads and friction. Galling occurs when two surfaces in relative motion start sticking to each other through molecular forces, eventually resulting in accidental cold welding. Galling. Aluminum Galling Definition.

From www.thefabricator.com

Detecting galling onset in aluminum alloy stamping, Part II Aluminum Galling Definition Adhesive wear leads to metal galling when: Virtually everyone in industrial settings has encountered galling at some point, and you know the routine. It’s more than just friction or debris. Galling is a type of wear that occurs when materials that are compressed against one another are put into motion that causes friction. Galling occurs when two surfaces in relative. Aluminum Galling Definition.

From www.rg-group.com

Stainless Steel Galling and Its Causes RG Group Aluminum Galling Definition However, they have a tendency to gall, especially when subjected to high loads and friction. Virtually everyone in industrial settings has encountered galling at some point, and you know the routine. Metal surfaces make direct contact. Galling occurs when two surfaces in relative motion start sticking to each other through molecular forces, eventually resulting in accidental cold welding. Galling is. Aluminum Galling Definition.

From coatingtechnologiesllc.com

NP3 and Galling Prevention CT Aluminum Galling Definition It’s more than just friction or debris. Metal galling is a type of surface wear that causes a metal unintentionally engage with another metal in contact. Stuck nuts and seized bolts. High pressure exists between surfaces. Your team starts break out, and suddenly a nut won’t budge. Virtually everyone in industrial settings has encountered galling at some point, and you. Aluminum Galling Definition.

From www.thefabricator.com

Detecting galling onset in aluminum alloy stamping, Part I Aluminum Galling Definition It’s something that happens every day in every plant: Adhesive wear leads to metal galling when: Virtually everyone in industrial settings has encountered galling at some point, and you know the routine. Galling can result separation of metal pieces from the original. Your team starts break out, and suddenly a nut won’t budge. Aluminum alloys are commonly used in various. Aluminum Galling Definition.

From www.slideserve.com

PPT Tools PowerPoint Presentation, free download ID163798 Aluminum Galling Definition Your team starts break out, and suddenly a nut won’t budge. Galling is a type of wear that occurs when materials that are compressed against one another are put into motion that causes friction. Metal galling is a type of surface wear that causes a metal unintentionally engage with another metal in contact. High pressure exists between surfaces. Galling occurs. Aluminum Galling Definition.

From formingworld.com

Elimination of Galling on Tailgate Outer with Improved Bead Design Aluminum Galling Definition It’s something that happens every day in every plant: Galling is a type of wear that occurs when materials that are compressed against one another are put into motion that causes friction. High pressure exists between surfaces. Galling can result separation of metal pieces from the original. Adhesive wear leads to metal galling when: Aluminum alloys are commonly used in. Aluminum Galling Definition.