Shrink Fit Gear To Shaft . I am currently working on analyzing the capability of using shrink fit (most likely with induction shrink fitting) to heat up a steel hub. The most common practical example of this type of fit is the mounting gear on a shaft. Current research applications for shrink fitting. Normally, if the fit is way down on a shaft, you'd like to have the length before it fits as a reduced area, so it doesn't touch until it gets. Shrink fitting is one of the common. Shrink fitting refers broadly to techniques in which thermal expansion and contraction effects are used to achieve an interference fit. In this method, you use an induction heater to warm the gear nearest to the bore and then you slide. Usually it's easiest if the shaft has shoulders to axially locate the gear or other elements on it (or you can use sleeves as well). This process is ideal for most components that require a precise and reliable interference fit, such as bearings, sockets and shafts.

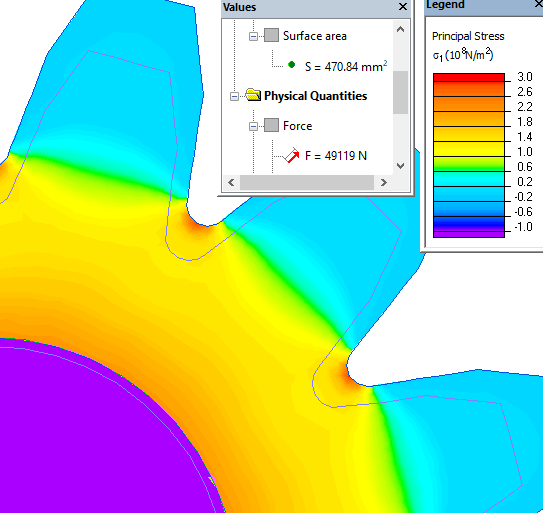

from quickfield.com

In this method, you use an induction heater to warm the gear nearest to the bore and then you slide. Usually it's easiest if the shaft has shoulders to axially locate the gear or other elements on it (or you can use sleeves as well). Shrink fitting refers broadly to techniques in which thermal expansion and contraction effects are used to achieve an interference fit. The most common practical example of this type of fit is the mounting gear on a shaft. This process is ideal for most components that require a precise and reliable interference fit, such as bearings, sockets and shafts. Shrink fitting is one of the common. Current research applications for shrink fitting. Normally, if the fit is way down on a shaft, you'd like to have the length before it fits as a reduced area, so it doesn't touch until it gets. I am currently working on analyzing the capability of using shrink fit (most likely with induction shrink fitting) to heat up a steel hub.

Gear wheel shrink fitting QuickField FEA Software

Shrink Fit Gear To Shaft Current research applications for shrink fitting. Normally, if the fit is way down on a shaft, you'd like to have the length before it fits as a reduced area, so it doesn't touch until it gets. This process is ideal for most components that require a precise and reliable interference fit, such as bearings, sockets and shafts. In this method, you use an induction heater to warm the gear nearest to the bore and then you slide. Current research applications for shrink fitting. I am currently working on analyzing the capability of using shrink fit (most likely with induction shrink fitting) to heat up a steel hub. Shrink fitting refers broadly to techniques in which thermal expansion and contraction effects are used to achieve an interference fit. The most common practical example of this type of fit is the mounting gear on a shaft. Usually it's easiest if the shaft has shoulders to axially locate the gear or other elements on it (or you can use sleeves as well). Shrink fitting is one of the common.

From www.youtube.com

Induction Shrink Fitting of Steel Gear Wheel YouTube Shrink Fit Gear To Shaft Shrink fitting is one of the common. This process is ideal for most components that require a precise and reliable interference fit, such as bearings, sockets and shafts. Normally, if the fit is way down on a shaft, you'd like to have the length before it fits as a reduced area, so it doesn't touch until it gets. Current research. Shrink Fit Gear To Shaft.

From www.slideserve.com

PPT Methods of Attaching Components to a Shaft PowerPoint Shrink Fit Gear To Shaft Shrink fitting refers broadly to techniques in which thermal expansion and contraction effects are used to achieve an interference fit. Current research applications for shrink fitting. Shrink fitting is one of the common. Usually it's easiest if the shaft has shoulders to axially locate the gear or other elements on it (or you can use sleeves as well). This process. Shrink Fit Gear To Shaft.

From www.hermann-bilz.de

Shrink Fit Shrink Fit Gear To Shaft Shrink fitting is one of the common. I am currently working on analyzing the capability of using shrink fit (most likely with induction shrink fitting) to heat up a steel hub. Usually it's easiest if the shaft has shoulders to axially locate the gear or other elements on it (or you can use sleeves as well). Normally, if the fit. Shrink Fit Gear To Shaft.

From www.youtube.com

Shrink Fitting a Shaft PINERIDGE LISCO EDWARDS LTD. YouTube Shrink Fit Gear To Shaft I am currently working on analyzing the capability of using shrink fit (most likely with induction shrink fitting) to heat up a steel hub. Usually it's easiest if the shaft has shoulders to axially locate the gear or other elements on it (or you can use sleeves as well). Shrink fitting is one of the common. Normally, if the fit. Shrink Fit Gear To Shaft.

From www.scribd.com

Analysis of a ShrinkFit Failure on a Gear Hub/Shaft Assembly Shrink Fit Gear To Shaft Normally, if the fit is way down on a shaft, you'd like to have the length before it fits as a reduced area, so it doesn't touch until it gets. In this method, you use an induction heater to warm the gear nearest to the bore and then you slide. Shrink fitting refers broadly to techniques in which thermal expansion. Shrink Fit Gear To Shaft.

From www.youtube.com

Fretting Testing on Deep Rolled ShrinkFitted Shaft Specimens YouTube Shrink Fit Gear To Shaft Usually it's easiest if the shaft has shoulders to axially locate the gear or other elements on it (or you can use sleeves as well). Shrink fitting is one of the common. Current research applications for shrink fitting. I am currently working on analyzing the capability of using shrink fit (most likely with induction shrink fitting) to heat up a. Shrink Fit Gear To Shaft.

From www.kwsmfg.com

Shrink Fit Shafts with Stronger Connection Features & Benefits Shrink Fit Gear To Shaft In this method, you use an induction heater to warm the gear nearest to the bore and then you slide. Normally, if the fit is way down on a shaft, you'd like to have the length before it fits as a reduced area, so it doesn't touch until it gets. Shrink fitting refers broadly to techniques in which thermal expansion. Shrink Fit Gear To Shaft.

From www.youtube.com

Mechanical Engineering Shrink fitting wheel shaft assembly YouTube Shrink Fit Gear To Shaft Usually it's easiest if the shaft has shoulders to axially locate the gear or other elements on it (or you can use sleeves as well). Shrink fitting refers broadly to techniques in which thermal expansion and contraction effects are used to achieve an interference fit. The most common practical example of this type of fit is the mounting gear on. Shrink Fit Gear To Shaft.

From www.ambrell.com

Shrink Fitting a Steel Gear Shrink Fit Gear To Shaft Shrink fitting is one of the common. Shrink fitting refers broadly to techniques in which thermal expansion and contraction effects are used to achieve an interference fit. The most common practical example of this type of fit is the mounting gear on a shaft. Usually it's easiest if the shaft has shoulders to axially locate the gear or other elements. Shrink Fit Gear To Shaft.

From www.chegg.com

Consider the shrink fit of a solid shaft with a Shrink Fit Gear To Shaft Shrink fitting is one of the common. I am currently working on analyzing the capability of using shrink fit (most likely with induction shrink fitting) to heat up a steel hub. The most common practical example of this type of fit is the mounting gear on a shaft. Usually it's easiest if the shaft has shoulders to axially locate the. Shrink Fit Gear To Shaft.

From www.youtube.com

Heating a Gear for Shrink Fitting.wmv YouTube Shrink Fit Gear To Shaft I am currently working on analyzing the capability of using shrink fit (most likely with induction shrink fitting) to heat up a steel hub. Current research applications for shrink fitting. Shrink fitting is one of the common. The most common practical example of this type of fit is the mounting gear on a shaft. Normally, if the fit is way. Shrink Fit Gear To Shaft.

From dw-inductionheater.com

Induction Shrink Fit Aluminum ShaftDAWEI Heater Shrink Fit Gear To Shaft In this method, you use an induction heater to warm the gear nearest to the bore and then you slide. This process is ideal for most components that require a precise and reliable interference fit, such as bearings, sockets and shafts. Usually it's easiest if the shaft has shoulders to axially locate the gear or other elements on it (or. Shrink Fit Gear To Shaft.

From www.chegg.com

Solved A solid steel shaft has a gear with ASTM grade 20 Shrink Fit Gear To Shaft Shrink fitting refers broadly to techniques in which thermal expansion and contraction effects are used to achieve an interference fit. I am currently working on analyzing the capability of using shrink fit (most likely with induction shrink fitting) to heat up a steel hub. Normally, if the fit is way down on a shaft, you'd like to have the length. Shrink Fit Gear To Shaft.

From dw-inductionheater.com

Induction Shrink Fit Aluminum ShaftDAWEI Heater Shrink Fit Gear To Shaft Shrink fitting refers broadly to techniques in which thermal expansion and contraction effects are used to achieve an interference fit. Usually it's easiest if the shaft has shoulders to axially locate the gear or other elements on it (or you can use sleeves as well). This process is ideal for most components that require a precise and reliable interference fit,. Shrink Fit Gear To Shaft.

From hlqinductionheating.wordpress.com

Shrink Fit Steel Gear onto Shaft HLQ INDUCTION EQUIPMENT CO.,LTD Shrink Fit Gear To Shaft Current research applications for shrink fitting. Shrink fitting refers broadly to techniques in which thermal expansion and contraction effects are used to achieve an interference fit. In this method, you use an induction heater to warm the gear nearest to the bore and then you slide. Normally, if the fit is way down on a shaft, you'd like to have. Shrink Fit Gear To Shaft.

From www.youtube.com

Shrink Fitting Video Gear and Shaft Application YouTube Shrink Fit Gear To Shaft Normally, if the fit is way down on a shaft, you'd like to have the length before it fits as a reduced area, so it doesn't touch until it gets. Current research applications for shrink fitting. Shrink fitting is one of the common. Usually it's easiest if the shaft has shoulders to axially locate the gear or other elements on. Shrink Fit Gear To Shaft.

From www.youtube.com

How to shrink fit two pieces of steel YouTube Shrink Fit Gear To Shaft This process is ideal for most components that require a precise and reliable interference fit, such as bearings, sockets and shafts. I am currently working on analyzing the capability of using shrink fit (most likely with induction shrink fitting) to heat up a steel hub. Current research applications for shrink fitting. In this method, you use an induction heater to. Shrink Fit Gear To Shaft.

From inductionheattreatment.com

How to do large workpieces induction shrink fitting? KETCHAN Induction Shrink Fit Gear To Shaft Shrink fitting refers broadly to techniques in which thermal expansion and contraction effects are used to achieve an interference fit. In this method, you use an induction heater to warm the gear nearest to the bore and then you slide. I am currently working on analyzing the capability of using shrink fit (most likely with induction shrink fitting) to heat. Shrink Fit Gear To Shaft.

From www.assemblymag.com

HeatShrink Assembly 20150505 Assembly Magazine Shrink Fit Gear To Shaft Shrink fitting is one of the common. This process is ideal for most components that require a precise and reliable interference fit, such as bearings, sockets and shafts. The most common practical example of this type of fit is the mounting gear on a shaft. Normally, if the fit is way down on a shaft, you'd like to have the. Shrink Fit Gear To Shaft.

From quickfield.com

Gear wheel shrink fitting QuickField FEA Software Shrink Fit Gear To Shaft The most common practical example of this type of fit is the mounting gear on a shaft. I am currently working on analyzing the capability of using shrink fit (most likely with induction shrink fitting) to heat up a steel hub. Normally, if the fit is way down on a shaft, you'd like to have the length before it fits. Shrink Fit Gear To Shaft.

From baartgroup.com

How to Determine Bearing Shaft and Housing Fit Baart Group Shrink Fit Gear To Shaft Normally, if the fit is way down on a shaft, you'd like to have the length before it fits as a reduced area, so it doesn't touch until it gets. In this method, you use an induction heater to warm the gear nearest to the bore and then you slide. I am currently working on analyzing the capability of using. Shrink Fit Gear To Shaft.

From www.mdpi.com

Materials Free FullText Precise Shrink Fitting Design of the High Shrink Fit Gear To Shaft In this method, you use an induction heater to warm the gear nearest to the bore and then you slide. I am currently working on analyzing the capability of using shrink fit (most likely with induction shrink fitting) to heat up a steel hub. Usually it's easiest if the shaft has shoulders to axially locate the gear or other elements. Shrink Fit Gear To Shaft.

From www.ctemag.com

Gear shop modernizes with shrinkfit technology Cutting Tool Engineering Shrink Fit Gear To Shaft Normally, if the fit is way down on a shaft, you'd like to have the length before it fits as a reduced area, so it doesn't touch until it gets. The most common practical example of this type of fit is the mounting gear on a shaft. Usually it's easiest if the shaft has shoulders to axially locate the gear. Shrink Fit Gear To Shaft.

From www.researchgate.net

Shaft displacement due to shrink fitting and bending load (a Shrink Fit Gear To Shaft Normally, if the fit is way down on a shaft, you'd like to have the length before it fits as a reduced area, so it doesn't touch until it gets. In this method, you use an induction heater to warm the gear nearest to the bore and then you slide. I am currently working on analyzing the capability of using. Shrink Fit Gear To Shaft.

From www.yogiemachinery.com

Cheap Shrink Fitting Support Roller Shaft Manufacturers & Supplier Shrink Fit Gear To Shaft Shrink fitting is one of the common. I am currently working on analyzing the capability of using shrink fit (most likely with induction shrink fitting) to heat up a steel hub. The most common practical example of this type of fit is the mounting gear on a shaft. Normally, if the fit is way down on a shaft, you'd like. Shrink Fit Gear To Shaft.

From ultraflexpower.com

Induction Shrink Fitting of Steel Gear Wheel UltraFlex Shrink Fit Gear To Shaft Usually it's easiest if the shaft has shoulders to axially locate the gear or other elements on it (or you can use sleeves as well). In this method, you use an induction heater to warm the gear nearest to the bore and then you slide. Current research applications for shrink fitting. I am currently working on analyzing the capability of. Shrink Fit Gear To Shaft.

From www.youtube.com

How to Shrink fit shaft YouTube Shrink Fit Gear To Shaft The most common practical example of this type of fit is the mounting gear on a shaft. Shrink fitting is one of the common. Usually it's easiest if the shaft has shoulders to axially locate the gear or other elements on it (or you can use sleeves as well). This process is ideal for most components that require a precise. Shrink Fit Gear To Shaft.

From www.inductionheatingexperts.com

ShrinkFit Connections Simplify Assembly eldec LLC Shrink Fit Gear To Shaft Current research applications for shrink fitting. Shrink fitting refers broadly to techniques in which thermal expansion and contraction effects are used to achieve an interference fit. This process is ideal for most components that require a precise and reliable interference fit, such as bearings, sockets and shafts. Normally, if the fit is way down on a shaft, you'd like to. Shrink Fit Gear To Shaft.

From www.researchgate.net

Shaft shrinkfitted into a grooved hub oscillating torsionally Shrink Fit Gear To Shaft Normally, if the fit is way down on a shaft, you'd like to have the length before it fits as a reduced area, so it doesn't touch until it gets. Shrink fitting refers broadly to techniques in which thermal expansion and contraction effects are used to achieve an interference fit. Shrink fitting is one of the common. This process is. Shrink Fit Gear To Shaft.

From www.practicalmachinist.com

shrink/interference fits Shrink Fit Gear To Shaft In this method, you use an induction heater to warm the gear nearest to the bore and then you slide. Shrink fitting is one of the common. This process is ideal for most components that require a precise and reliable interference fit, such as bearings, sockets and shafts. Current research applications for shrink fitting. The most common practical example of. Shrink Fit Gear To Shaft.

From www.howoautopart.com

Aluminium Motor Housing Induction Heating Machine Motor Enclosure Motor Shrink Fit Gear To Shaft This process is ideal for most components that require a precise and reliable interference fit, such as bearings, sockets and shafts. Usually it's easiest if the shaft has shoulders to axially locate the gear or other elements on it (or you can use sleeves as well). In this method, you use an induction heater to warm the gear nearest to. Shrink Fit Gear To Shaft.

From www.tradeindia.com

Induction Based Gear Shaft Shrink Fitting Machine at Best Price in Shrink Fit Gear To Shaft Shrink fitting is one of the common. Usually it's easiest if the shaft has shoulders to axially locate the gear or other elements on it (or you can use sleeves as well). In this method, you use an induction heater to warm the gear nearest to the bore and then you slide. Normally, if the fit is way down on. Shrink Fit Gear To Shaft.

From www.directindustry.com

Rigid coupling BLOC SD 14010 Fenner Drives shrink disc / gear Shrink Fit Gear To Shaft Shrink fitting is one of the common. This process is ideal for most components that require a precise and reliable interference fit, such as bearings, sockets and shafts. The most common practical example of this type of fit is the mounting gear on a shaft. In this method, you use an induction heater to warm the gear nearest to the. Shrink Fit Gear To Shaft.

From engineeringlearn.com

3 Types of Fits Clearance Fit, Interference Fit, Transition Fit Shrink Fit Gear To Shaft Usually it's easiest if the shaft has shoulders to axially locate the gear or other elements on it (or you can use sleeves as well). The most common practical example of this type of fit is the mounting gear on a shaft. Shrink fitting is one of the common. Normally, if the fit is way down on a shaft, you'd. Shrink Fit Gear To Shaft.

From www.kwsmfg.com

Shrink Fit Shafts with Stronger Connection Features & Benefits Shrink Fit Gear To Shaft Current research applications for shrink fitting. In this method, you use an induction heater to warm the gear nearest to the bore and then you slide. Shrink fitting is one of the common. Shrink fitting refers broadly to techniques in which thermal expansion and contraction effects are used to achieve an interference fit. Usually it's easiest if the shaft has. Shrink Fit Gear To Shaft.