Slip Casting Applications . This section will showcase the vast range of applications of slip casting, from functional pottery to sculptural art. This combination allows the slip to flow easily into molds, forming intricate ceramic shapes when dried. This technology is revolutionizing how pottery molds are created, making the process more efficient and accessible. A method used to make complex shaped ceramics without having to melt them. The process stops only when the required length of casting is. A liquid suspension of ceramic particles in. The slipform helps to conduct continuous pouring of the concrete to the moving formwork. Slip in the slip casting process is a liquid mixture of finely ground clay (like kaolin or porcelain), water, and deflocculants such as sodium silicate to reduce viscosity.

from www.open.edu

Slip in the slip casting process is a liquid mixture of finely ground clay (like kaolin or porcelain), water, and deflocculants such as sodium silicate to reduce viscosity. The slipform helps to conduct continuous pouring of the concrete to the moving formwork. A method used to make complex shaped ceramics without having to melt them. This technology is revolutionizing how pottery molds are created, making the process more efficient and accessible. The process stops only when the required length of casting is. This section will showcase the vast range of applications of slip casting, from functional pottery to sculptural art. This combination allows the slip to flow easily into molds, forming intricate ceramic shapes when dried. A liquid suspension of ceramic particles in.

Slipcasting OpenLearn Open University

Slip Casting Applications A method used to make complex shaped ceramics without having to melt them. This technology is revolutionizing how pottery molds are created, making the process more efficient and accessible. This section will showcase the vast range of applications of slip casting, from functional pottery to sculptural art. A method used to make complex shaped ceramics without having to melt them. A liquid suspension of ceramic particles in. Slip in the slip casting process is a liquid mixture of finely ground clay (like kaolin or porcelain), water, and deflocculants such as sodium silicate to reduce viscosity. The process stops only when the required length of casting is. This combination allows the slip to flow easily into molds, forming intricate ceramic shapes when dried. The slipform helps to conduct continuous pouring of the concrete to the moving formwork.

From www.youtube.com

Slip casting a cup from a one part plaster mold YouTube Slip Casting Applications The process stops only when the required length of casting is. A method used to make complex shaped ceramics without having to melt them. This technology is revolutionizing how pottery molds are created, making the process more efficient and accessible. This combination allows the slip to flow easily into molds, forming intricate ceramic shapes when dried. The slipform helps to. Slip Casting Applications.

From robertcomptonpottery.com

Slip Casting Robert Compton Pottery Slip Casting Applications This section will showcase the vast range of applications of slip casting, from functional pottery to sculptural art. The slipform helps to conduct continuous pouring of the concrete to the moving formwork. This combination allows the slip to flow easily into molds, forming intricate ceramic shapes when dried. A method used to make complex shaped ceramics without having to melt. Slip Casting Applications.

From mkmra2.blogspot.com

Digital Fabrication for Designers Slip Casting 3D Printed Forms Slip Casting Applications This section will showcase the vast range of applications of slip casting, from functional pottery to sculptural art. The process stops only when the required length of casting is. The slipform helps to conduct continuous pouring of the concrete to the moving formwork. This technology is revolutionizing how pottery molds are created, making the process more efficient and accessible. This. Slip Casting Applications.

From www.researchgate.net

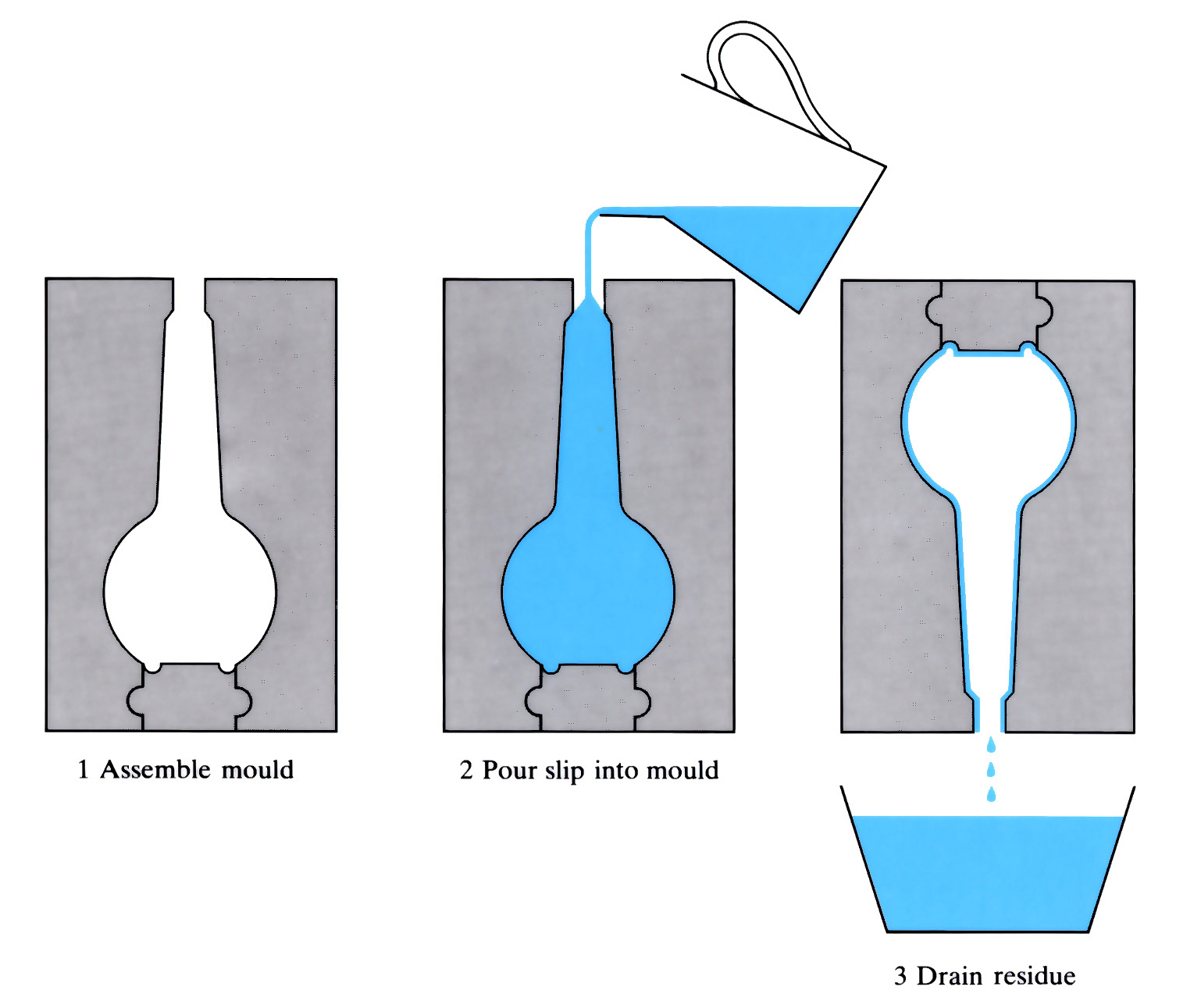

Slip casting steps [28] Download Scientific Diagram Slip Casting Applications The slipform helps to conduct continuous pouring of the concrete to the moving formwork. This technology is revolutionizing how pottery molds are created, making the process more efficient and accessible. The process stops only when the required length of casting is. This combination allows the slip to flow easily into molds, forming intricate ceramic shapes when dried. Slip in the. Slip Casting Applications.

From robertcomptonpottery.com

Slip Casting Robert Compton Pottery Slip Casting Applications Slip in the slip casting process is a liquid mixture of finely ground clay (like kaolin or porcelain), water, and deflocculants such as sodium silicate to reduce viscosity. This section will showcase the vast range of applications of slip casting, from functional pottery to sculptural art. A method used to make complex shaped ceramics without having to melt them. A. Slip Casting Applications.

From www.youtube.com

Slip Casting How to do it StepbyStep YouTube Slip Casting Applications The process stops only when the required length of casting is. A liquid suspension of ceramic particles in. A method used to make complex shaped ceramics without having to melt them. This technology is revolutionizing how pottery molds are created, making the process more efficient and accessible. This combination allows the slip to flow easily into molds, forming intricate ceramic. Slip Casting Applications.

From www.researchgate.net

The schematic diagram of slip casting technique. Download Scientific Slip Casting Applications This combination allows the slip to flow easily into molds, forming intricate ceramic shapes when dried. This section will showcase the vast range of applications of slip casting, from functional pottery to sculptural art. The slipform helps to conduct continuous pouring of the concrete to the moving formwork. A method used to make complex shaped ceramics without having to melt. Slip Casting Applications.

From www.thecrucible.org

You Will Be Slip Casting Ceramics With These 5 Easy Steps The Crucible Slip Casting Applications Slip in the slip casting process is a liquid mixture of finely ground clay (like kaolin or porcelain), water, and deflocculants such as sodium silicate to reduce viscosity. This combination allows the slip to flow easily into molds, forming intricate ceramic shapes when dried. This section will showcase the vast range of applications of slip casting, from functional pottery to. Slip Casting Applications.

From www.researchgate.net

A schematic sketch summarizing the principle of slip casting method Slip Casting Applications A method used to make complex shaped ceramics without having to melt them. The slipform helps to conduct continuous pouring of the concrete to the moving formwork. A liquid suspension of ceramic particles in. Slip in the slip casting process is a liquid mixture of finely ground clay (like kaolin or porcelain), water, and deflocculants such as sodium silicate to. Slip Casting Applications.

From www.thecrucible.org

You Will Be Slip Casting Ceramics With These 5 Easy Steps The Crucible Slip Casting Applications A method used to make complex shaped ceramics without having to melt them. Slip in the slip casting process is a liquid mixture of finely ground clay (like kaolin or porcelain), water, and deflocculants such as sodium silicate to reduce viscosity. The process stops only when the required length of casting is. The slipform helps to conduct continuous pouring of. Slip Casting Applications.

From slabceramics.ae

Slip Casting Slab Ceramics Studio Slip Casting Applications A liquid suspension of ceramic particles in. The process stops only when the required length of casting is. This technology is revolutionizing how pottery molds are created, making the process more efficient and accessible. A method used to make complex shaped ceramics without having to melt them. The slipform helps to conduct continuous pouring of the concrete to the moving. Slip Casting Applications.

From www.youtube.com

Slip Casting with Plaster Molds In Six Steps YouTube Slip Casting Applications A liquid suspension of ceramic particles in. This combination allows the slip to flow easily into molds, forming intricate ceramic shapes when dried. Slip in the slip casting process is a liquid mixture of finely ground clay (like kaolin or porcelain), water, and deflocculants such as sodium silicate to reduce viscosity. A method used to make complex shaped ceramics without. Slip Casting Applications.

From robertcomptonpottery.com

Slip Casting Robert Compton Pottery Slip Casting Applications This combination allows the slip to flow easily into molds, forming intricate ceramic shapes when dried. This technology is revolutionizing how pottery molds are created, making the process more efficient and accessible. A liquid suspension of ceramic particles in. The slipform helps to conduct continuous pouring of the concrete to the moving formwork. This section will showcase the vast range. Slip Casting Applications.

From ceramics.org

Forming methods influence the microstructure of flashsintered ceramics Slip Casting Applications Slip in the slip casting process is a liquid mixture of finely ground clay (like kaolin or porcelain), water, and deflocculants such as sodium silicate to reduce viscosity. This technology is revolutionizing how pottery molds are created, making the process more efficient and accessible. The slipform helps to conduct continuous pouring of the concrete to the moving formwork. This combination. Slip Casting Applications.

From www.thecrucible.org

You Will Be Slip Casting Ceramics With These 5 Easy Steps The Crucible Slip Casting Applications The process stops only when the required length of casting is. A method used to make complex shaped ceramics without having to melt them. This section will showcase the vast range of applications of slip casting, from functional pottery to sculptural art. This technology is revolutionizing how pottery molds are created, making the process more efficient and accessible. The slipform. Slip Casting Applications.

From www.thecrucible.org

Industrial Art Classes in Oakland Slip Casting with Plaster Molds Slip Casting Applications The process stops only when the required length of casting is. This section will showcase the vast range of applications of slip casting, from functional pottery to sculptural art. Slip in the slip casting process is a liquid mixture of finely ground clay (like kaolin or porcelain), water, and deflocculants such as sodium silicate to reduce viscosity. The slipform helps. Slip Casting Applications.

From www.youtube.com

Slip Casting 101 Working with larger scale molds YouTube Slip Casting Applications This combination allows the slip to flow easily into molds, forming intricate ceramic shapes when dried. A liquid suspension of ceramic particles in. This section will showcase the vast range of applications of slip casting, from functional pottery to sculptural art. The slipform helps to conduct continuous pouring of the concrete to the moving formwork. This technology is revolutionizing how. Slip Casting Applications.

From castimo.de

High Pressure Slip Casting System (HPSC or HPC) Castimo Slip Casting Applications The process stops only when the required length of casting is. A liquid suspension of ceramic particles in. This section will showcase the vast range of applications of slip casting, from functional pottery to sculptural art. Slip in the slip casting process is a liquid mixture of finely ground clay (like kaolin or porcelain), water, and deflocculants such as sodium. Slip Casting Applications.

From jackygao.com

Ceramic slip casting method Yongchuan Ceramics Co.,Ltd Slip Casting Applications The process stops only when the required length of casting is. A liquid suspension of ceramic particles in. The slipform helps to conduct continuous pouring of the concrete to the moving formwork. This technology is revolutionizing how pottery molds are created, making the process more efficient and accessible. This combination allows the slip to flow easily into molds, forming intricate. Slip Casting Applications.

From ceramicartsnetwork.org

Inlaid Slip Casting Slip Casting Applications This technology is revolutionizing how pottery molds are created, making the process more efficient and accessible. A method used to make complex shaped ceramics without having to melt them. This combination allows the slip to flow easily into molds, forming intricate ceramic shapes when dried. A liquid suspension of ceramic particles in. The slipform helps to conduct continuous pouring of. Slip Casting Applications.

From everson.org

SlipCasting Patterns & Colored Porcelain Everson Museum of Art Slip Casting Applications The process stops only when the required length of casting is. Slip in the slip casting process is a liquid mixture of finely ground clay (like kaolin or porcelain), water, and deflocculants such as sodium silicate to reduce viscosity. This combination allows the slip to flow easily into molds, forming intricate ceramic shapes when dried. A method used to make. Slip Casting Applications.

From www.thesprucecrafts.com

How to Slip Cast Ceramics Slip Casting Applications This combination allows the slip to flow easily into molds, forming intricate ceramic shapes when dried. This technology is revolutionizing how pottery molds are created, making the process more efficient and accessible. This section will showcase the vast range of applications of slip casting, from functional pottery to sculptural art. The slipform helps to conduct continuous pouring of the concrete. Slip Casting Applications.

From www.lomceramics.com

What Is Slip Casting? — Lōm Ceramics Slip Casting Applications Slip in the slip casting process is a liquid mixture of finely ground clay (like kaolin or porcelain), water, and deflocculants such as sodium silicate to reduce viscosity. A method used to make complex shaped ceramics without having to melt them. A liquid suspension of ceramic particles in. This section will showcase the vast range of applications of slip casting,. Slip Casting Applications.

From www.youtube.com

How it's made Ceramic Slip Casting YouTube Slip Casting Applications This technology is revolutionizing how pottery molds are created, making the process more efficient and accessible. Slip in the slip casting process is a liquid mixture of finely ground clay (like kaolin or porcelain), water, and deflocculants such as sodium silicate to reduce viscosity. This section will showcase the vast range of applications of slip casting, from functional pottery to. Slip Casting Applications.

From www.open.edu

Slipcasting OpenLearn Open University Slip Casting Applications The process stops only when the required length of casting is. This combination allows the slip to flow easily into molds, forming intricate ceramic shapes when dried. This technology is revolutionizing how pottery molds are created, making the process more efficient and accessible. This section will showcase the vast range of applications of slip casting, from functional pottery to sculptural. Slip Casting Applications.

From www.thecrucible.org

You Will Be Slip Casting Ceramics With These 5 Easy Steps The Crucible Slip Casting Applications A method used to make complex shaped ceramics without having to melt them. This combination allows the slip to flow easily into molds, forming intricate ceramic shapes when dried. Slip in the slip casting process is a liquid mixture of finely ground clay (like kaolin or porcelain), water, and deflocculants such as sodium silicate to reduce viscosity. The process stops. Slip Casting Applications.

From www.thecrucible.org

You Will Be Slip Casting Ceramics With These 5 Easy Steps The Crucible Slip Casting Applications The process stops only when the required length of casting is. This section will showcase the vast range of applications of slip casting, from functional pottery to sculptural art. This combination allows the slip to flow easily into molds, forming intricate ceramic shapes when dried. A liquid suspension of ceramic particles in. Slip in the slip casting process is a. Slip Casting Applications.

From www.dsource.in

D'source Slip Casting Casting D'Source Digital Online Learning Slip Casting Applications Slip in the slip casting process is a liquid mixture of finely ground clay (like kaolin or porcelain), water, and deflocculants such as sodium silicate to reduce viscosity. The process stops only when the required length of casting is. This combination allows the slip to flow easily into molds, forming intricate ceramic shapes when dried. A method used to make. Slip Casting Applications.

From donkeymud.com

Slip Casting Dan’s Quick Glimpse HowTo Dan Pearce Pottery Slip Casting Applications This technology is revolutionizing how pottery molds are created, making the process more efficient and accessible. A liquid suspension of ceramic particles in. The slipform helps to conduct continuous pouring of the concrete to the moving formwork. This section will showcase the vast range of applications of slip casting, from functional pottery to sculptural art. The process stops only when. Slip Casting Applications.

From www.jennyrijke.com

Free Resources Slip Casting Applications This section will showcase the vast range of applications of slip casting, from functional pottery to sculptural art. A liquid suspension of ceramic particles in. The slipform helps to conduct continuous pouring of the concrete to the moving formwork. This combination allows the slip to flow easily into molds, forming intricate ceramic shapes when dried. A method used to make. Slip Casting Applications.

From robertcomptonpottery.com

Slip Casting Robert Compton Pottery Slip Casting Applications This combination allows the slip to flow easily into molds, forming intricate ceramic shapes when dried. This section will showcase the vast range of applications of slip casting, from functional pottery to sculptural art. A liquid suspension of ceramic particles in. The slipform helps to conduct continuous pouring of the concrete to the moving formwork. The process stops only when. Slip Casting Applications.

From www.thecrucible.org

You Will Be Slip Casting Ceramics With These 5 Easy Steps The Crucible Slip Casting Applications The slipform helps to conduct continuous pouring of the concrete to the moving formwork. This combination allows the slip to flow easily into molds, forming intricate ceramic shapes when dried. This section will showcase the vast range of applications of slip casting, from functional pottery to sculptural art. A method used to make complex shaped ceramics without having to melt. Slip Casting Applications.

From www.youtube.com

Slip Casting YouTube Slip Casting Applications A liquid suspension of ceramic particles in. Slip in the slip casting process is a liquid mixture of finely ground clay (like kaolin or porcelain), water, and deflocculants such as sodium silicate to reduce viscosity. The slipform helps to conduct continuous pouring of the concrete to the moving formwork. The process stops only when the required length of casting is.. Slip Casting Applications.

From eugenehon.blogspot.com

EUGENE HŐN CERAMIC ARTIST Slipcasting the decoyduck; stepbystep Slip Casting Applications This combination allows the slip to flow easily into molds, forming intricate ceramic shapes when dried. Slip in the slip casting process is a liquid mixture of finely ground clay (like kaolin or porcelain), water, and deflocculants such as sodium silicate to reduce viscosity. The slipform helps to conduct continuous pouring of the concrete to the moving formwork. A liquid. Slip Casting Applications.

From www.youtube.com

Ceramic automatic slip casting Sunny Group factory YouTube Slip Casting Applications A method used to make complex shaped ceramics without having to melt them. This combination allows the slip to flow easily into molds, forming intricate ceramic shapes when dried. This section will showcase the vast range of applications of slip casting, from functional pottery to sculptural art. The slipform helps to conduct continuous pouring of the concrete to the moving. Slip Casting Applications.