Arc Of Contact In Belt Drives . The web page does not answer the query directly, but it explains the basic belt drive. 0 and therefore the pulleys should be selected accordingly. The maximum amount of torque which the drive. The amount of preload required in a belt drive depends on a number of factors, including: Learn about belt drives, contact angle geometry, and drive kinematics from a mechanical engineering course at mit. The pdf document explains the friction, wedging, speed ratio and lateral travel of. • properly designed belt drives should have an arc of contact greater than 120. It is determined by the width and arc of contact. Learn about the types, characteristics, and design of belt and chain drives for power transmission. The operation of the belt and its ability to transmit power depend on the size of the friction force and the arc of contact of the belt.

from www.youtube.com

• properly designed belt drives should have an arc of contact greater than 120. The pdf document explains the friction, wedging, speed ratio and lateral travel of. The web page does not answer the query directly, but it explains the basic belt drive. Learn about belt drives, contact angle geometry, and drive kinematics from a mechanical engineering course at mit. 0 and therefore the pulleys should be selected accordingly. It is determined by the width and arc of contact. Learn about the types, characteristics, and design of belt and chain drives for power transmission. The amount of preload required in a belt drive depends on a number of factors, including: The maximum amount of torque which the drive. The operation of the belt and its ability to transmit power depend on the size of the friction force and the arc of contact of the belt.

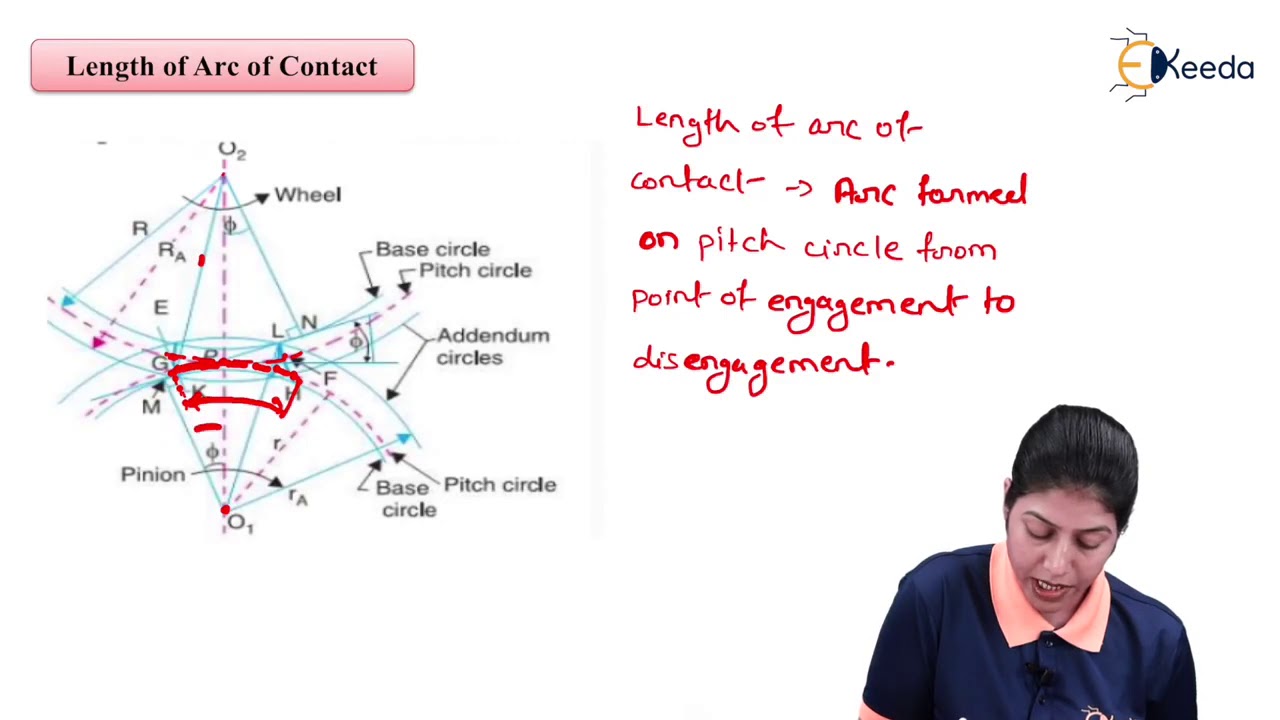

Description of Length of Arc of Contact Description of Gears

Arc Of Contact In Belt Drives • properly designed belt drives should have an arc of contact greater than 120. • properly designed belt drives should have an arc of contact greater than 120. The operation of the belt and its ability to transmit power depend on the size of the friction force and the arc of contact of the belt. 0 and therefore the pulleys should be selected accordingly. The maximum amount of torque which the drive. The amount of preload required in a belt drive depends on a number of factors, including: It is determined by the width and arc of contact. Learn about belt drives, contact angle geometry, and drive kinematics from a mechanical engineering course at mit. The pdf document explains the friction, wedging, speed ratio and lateral travel of. The web page does not answer the query directly, but it explains the basic belt drive. Learn about the types, characteristics, and design of belt and chain drives for power transmission.

From www.researchgate.net

Rounding mechanism of a novel doubledisc arccontact lapping for high Arc Of Contact In Belt Drives Learn about the types, characteristics, and design of belt and chain drives for power transmission. The pdf document explains the friction, wedging, speed ratio and lateral travel of. • properly designed belt drives should have an arc of contact greater than 120. 0 and therefore the pulleys should be selected accordingly. The web page does not answer the query directly,. Arc Of Contact In Belt Drives.

From atelier-yuwa.ciao.jp

Arc Of Contact In Belt Drives atelieryuwa.ciao.jp Arc Of Contact In Belt Drives Learn about the types, characteristics, and design of belt and chain drives for power transmission. Learn about belt drives, contact angle geometry, and drive kinematics from a mechanical engineering course at mit. 0 and therefore the pulleys should be selected accordingly. The web page does not answer the query directly, but it explains the basic belt drive. The pdf document. Arc Of Contact In Belt Drives.

From tgrbelt.en.made-in-china.com

China Manufacturer Good Quality Rubber Arc Toothed Drive and Pulleys Arc Of Contact In Belt Drives The pdf document explains the friction, wedging, speed ratio and lateral travel of. The web page does not answer the query directly, but it explains the basic belt drive. 0 and therefore the pulleys should be selected accordingly. Learn about the types, characteristics, and design of belt and chain drives for power transmission. The amount of preload required in a. Arc Of Contact In Belt Drives.

From atelier-yuwa.ciao.jp

Arc Of Contact In Belt Drives atelieryuwa.ciao.jp Arc Of Contact In Belt Drives Learn about belt drives, contact angle geometry, and drive kinematics from a mechanical engineering course at mit. The amount of preload required in a belt drive depends on a number of factors, including: • properly designed belt drives should have an arc of contact greater than 120. 0 and therefore the pulleys should be selected accordingly. The operation of the. Arc Of Contact In Belt Drives.

From www.chegg.com

Solved Problem 1 Design of Flatbelt Drives The figure Arc Of Contact In Belt Drives The maximum amount of torque which the drive. The operation of the belt and its ability to transmit power depend on the size of the friction force and the arc of contact of the belt. The web page does not answer the query directly, but it explains the basic belt drive. Learn about belt drives, contact angle geometry, and drive. Arc Of Contact In Belt Drives.

From www.tec-science.com

Slippage of the belt in belt drives tecscience Arc Of Contact In Belt Drives It is determined by the width and arc of contact. The operation of the belt and its ability to transmit power depend on the size of the friction force and the arc of contact of the belt. The amount of preload required in a belt drive depends on a number of factors, including: The pdf document explains the friction, wedging,. Arc Of Contact In Belt Drives.

From www.youtube.com

Description of Ratio of Driving Tension for Belt Drive Description of Arc Of Contact In Belt Drives The operation of the belt and its ability to transmit power depend on the size of the friction force and the arc of contact of the belt. The amount of preload required in a belt drive depends on a number of factors, including: Learn about the types, characteristics, and design of belt and chain drives for power transmission. Learn about. Arc Of Contact In Belt Drives.

From atelier-yuwa.ciao.jp

Arc Of Contact In Belt Drives atelieryuwa.ciao.jp Arc Of Contact In Belt Drives It is determined by the width and arc of contact. The operation of the belt and its ability to transmit power depend on the size of the friction force and the arc of contact of the belt. Learn about belt drives, contact angle geometry, and drive kinematics from a mechanical engineering course at mit. The amount of preload required in. Arc Of Contact In Belt Drives.

From www.powervbelt.com

HTD Arc Timing belts PU Arc Of Contact In Belt Drives Learn about belt drives, contact angle geometry, and drive kinematics from a mechanical engineering course at mit. • properly designed belt drives should have an arc of contact greater than 120. The pdf document explains the friction, wedging, speed ratio and lateral travel of. The operation of the belt and its ability to transmit power depend on the size of. Arc Of Contact In Belt Drives.

From atelier-yuwa.ciao.jp

Arc Of Contact In Belt Drives atelieryuwa.ciao.jp Arc Of Contact In Belt Drives The pdf document explains the friction, wedging, speed ratio and lateral travel of. Learn about belt drives, contact angle geometry, and drive kinematics from a mechanical engineering course at mit. The operation of the belt and its ability to transmit power depend on the size of the friction force and the arc of contact of the belt. Learn about the. Arc Of Contact In Belt Drives.

From www.tec-science.com

Calculation of the bearing force for belt drives tecscience Arc Of Contact In Belt Drives 0 and therefore the pulleys should be selected accordingly. It is determined by the width and arc of contact. • properly designed belt drives should have an arc of contact greater than 120. Learn about belt drives, contact angle geometry, and drive kinematics from a mechanical engineering course at mit. The pdf document explains the friction, wedging, speed ratio and. Arc Of Contact In Belt Drives.

From www.tec-science.com

Calculation of the belt length for belt drives tecscience Arc Of Contact In Belt Drives The maximum amount of torque which the drive. Learn about the types, characteristics, and design of belt and chain drives for power transmission. Learn about belt drives, contact angle geometry, and drive kinematics from a mechanical engineering course at mit. The amount of preload required in a belt drive depends on a number of factors, including: 0 and therefore the. Arc Of Contact In Belt Drives.

From www.aliexpress.com

Wide50mm HTD 20M 2100 105T Rubber Arc Tooth Synchronous Belt Drive Arc Of Contact In Belt Drives It is determined by the width and arc of contact. The web page does not answer the query directly, but it explains the basic belt drive. Learn about the types, characteristics, and design of belt and chain drives for power transmission. The amount of preload required in a belt drive depends on a number of factors, including: The pdf document. Arc Of Contact In Belt Drives.

From www.youtube.com

Video Lecture on Introduction to belt drives Power transmission YouTube Arc Of Contact In Belt Drives Learn about belt drives, contact angle geometry, and drive kinematics from a mechanical engineering course at mit. The maximum amount of torque which the drive. The web page does not answer the query directly, but it explains the basic belt drive. It is determined by the width and arc of contact. Learn about the types, characteristics, and design of belt. Arc Of Contact In Belt Drives.

From www.youtube.com

Calculating Power Transmitted Using Flat Belts and Vee Belts YouTube Arc Of Contact In Belt Drives The maximum amount of torque which the drive. • properly designed belt drives should have an arc of contact greater than 120. 0 and therefore the pulleys should be selected accordingly. The pdf document explains the friction, wedging, speed ratio and lateral travel of. Learn about the types, characteristics, and design of belt and chain drives for power transmission. The. Arc Of Contact In Belt Drives.

From atelier-yuwa.ciao.jp

Arc Of Contact In Belt Drives atelieryuwa.ciao.jp Arc Of Contact In Belt Drives Learn about belt drives, contact angle geometry, and drive kinematics from a mechanical engineering course at mit. Learn about the types, characteristics, and design of belt and chain drives for power transmission. 0 and therefore the pulleys should be selected accordingly. The web page does not answer the query directly, but it explains the basic belt drive. The amount of. Arc Of Contact In Belt Drives.

From www.youtube.com

Types of Belt drives Classification of belt drives Different Arc Of Contact In Belt Drives The amount of preload required in a belt drive depends on a number of factors, including: Learn about the types, characteristics, and design of belt and chain drives for power transmission. The maximum amount of torque which the drive. It is determined by the width and arc of contact. The web page does not answer the query directly, but it. Arc Of Contact In Belt Drives.

From www.mech4study.com

Belt Drive and its Types mech4study Arc Of Contact In Belt Drives The web page does not answer the query directly, but it explains the basic belt drive. It is determined by the width and arc of contact. Learn about the types, characteristics, and design of belt and chain drives for power transmission. The maximum amount of torque which the drive. 0 and therefore the pulleys should be selected accordingly. Learn about. Arc Of Contact In Belt Drives.

From www.pinnaxis.com

How Does A Belt Drive Work? Tecscience, 51 OFF Arc Of Contact In Belt Drives The amount of preload required in a belt drive depends on a number of factors, including: The operation of the belt and its ability to transmit power depend on the size of the friction force and the arc of contact of the belt. • properly designed belt drives should have an arc of contact greater than 120. It is determined. Arc Of Contact In Belt Drives.

From eng-resources.charlotte.edu

Belts & Chains UNC Charlotte Engineering Tool Kit Arc Of Contact In Belt Drives • properly designed belt drives should have an arc of contact greater than 120. The pdf document explains the friction, wedging, speed ratio and lateral travel of. The web page does not answer the query directly, but it explains the basic belt drive. 0 and therefore the pulleys should be selected accordingly. Learn about belt drives, contact angle geometry, and. Arc Of Contact In Belt Drives.

From atelier-yuwa.ciao.jp

Arc Of Contact In Belt Drives atelieryuwa.ciao.jp Arc Of Contact In Belt Drives The pdf document explains the friction, wedging, speed ratio and lateral travel of. • properly designed belt drives should have an arc of contact greater than 120. The maximum amount of torque which the drive. Learn about the types, characteristics, and design of belt and chain drives for power transmission. The web page does not answer the query directly, but. Arc Of Contact In Belt Drives.

From www.iqsdirectory.com

VBelt What Is It? How Does It Work? Types Of, Uses Arc Of Contact In Belt Drives Learn about the types, characteristics, and design of belt and chain drives for power transmission. The operation of the belt and its ability to transmit power depend on the size of the friction force and the arc of contact of the belt. The web page does not answer the query directly, but it explains the basic belt drive. The maximum. Arc Of Contact In Belt Drives.

From atelier-yuwa.ciao.jp

Arc Of Contact In Belt Drives atelieryuwa.ciao.jp Arc Of Contact In Belt Drives The web page does not answer the query directly, but it explains the basic belt drive. 0 and therefore the pulleys should be selected accordingly. The amount of preload required in a belt drive depends on a number of factors, including: • properly designed belt drives should have an arc of contact greater than 120. Learn about belt drives, contact. Arc Of Contact In Belt Drives.

From www.len.com.ng

Belt and Pulley Drives Types of belt in belt drives Arc Of Contact In Belt Drives The web page does not answer the query directly, but it explains the basic belt drive. 0 and therefore the pulleys should be selected accordingly. It is determined by the width and arc of contact. The operation of the belt and its ability to transmit power depend on the size of the friction force and the arc of contact of. Arc Of Contact In Belt Drives.

From www.conveyorbelting.net

Drive Belt Manufacturers Drive Belt Suppliers Arc Of Contact In Belt Drives The web page does not answer the query directly, but it explains the basic belt drive. The operation of the belt and its ability to transmit power depend on the size of the friction force and the arc of contact of the belt. 0 and therefore the pulleys should be selected accordingly. Learn about the types, characteristics, and design of. Arc Of Contact In Belt Drives.

From www.slideshare.net

MET 304 Belt drives Arc Of Contact In Belt Drives Learn about belt drives, contact angle geometry, and drive kinematics from a mechanical engineering course at mit. 0 and therefore the pulleys should be selected accordingly. The web page does not answer the query directly, but it explains the basic belt drive. The pdf document explains the friction, wedging, speed ratio and lateral travel of. The maximum amount of torque. Arc Of Contact In Belt Drives.

From www.youtube.com

Belt drive / type of belt drives / type of pulley /v belt drive / cross Arc Of Contact In Belt Drives The maximum amount of torque which the drive. Learn about belt drives, contact angle geometry, and drive kinematics from a mechanical engineering course at mit. The amount of preload required in a belt drive depends on a number of factors, including: The web page does not answer the query directly, but it explains the basic belt drive. • properly designed. Arc Of Contact In Belt Drives.

From www.slideserve.com

PPT Flat Belt Drives PowerPoint Presentation, free download ID2343821 Arc Of Contact In Belt Drives The pdf document explains the friction, wedging, speed ratio and lateral travel of. Learn about belt drives, contact angle geometry, and drive kinematics from a mechanical engineering course at mit. It is determined by the width and arc of contact. The web page does not answer the query directly, but it explains the basic belt drive. • properly designed belt. Arc Of Contact In Belt Drives.

From www.youtube.com

Belt Drive Angle of contact calculation Open Belt Drive Cross Belt Arc Of Contact In Belt Drives • properly designed belt drives should have an arc of contact greater than 120. 0 and therefore the pulleys should be selected accordingly. The maximum amount of torque which the drive. Learn about the types, characteristics, and design of belt and chain drives for power transmission. The web page does not answer the query directly, but it explains the basic. Arc Of Contact In Belt Drives.

From www.youtube.com

Description of Length of Arc of Contact Description of Gears Arc Of Contact In Belt Drives The web page does not answer the query directly, but it explains the basic belt drive. The operation of the belt and its ability to transmit power depend on the size of the friction force and the arc of contact of the belt. It is determined by the width and arc of contact. The pdf document explains the friction, wedging,. Arc Of Contact In Belt Drives.

From www.youtube.com

Belts and BeltDrives YouTube Arc Of Contact In Belt Drives Learn about the types, characteristics, and design of belt and chain drives for power transmission. The pdf document explains the friction, wedging, speed ratio and lateral travel of. • properly designed belt drives should have an arc of contact greater than 120. The web page does not answer the query directly, but it explains the basic belt drive. 0 and. Arc Of Contact In Belt Drives.

From sinoconve02.en.made-in-china.com

Best Coated Rubber Arc Toothed Timing Drive Belt China Drive Belt and Arc Of Contact In Belt Drives The pdf document explains the friction, wedging, speed ratio and lateral travel of. Learn about belt drives, contact angle geometry, and drive kinematics from a mechanical engineering course at mit. 0 and therefore the pulleys should be selected accordingly. The maximum amount of torque which the drive. It is determined by the width and arc of contact. The amount of. Arc Of Contact In Belt Drives.

From innovationdiscoveries.space

Belt Drive and its Types Arc Of Contact In Belt Drives The web page does not answer the query directly, but it explains the basic belt drive. Learn about the types, characteristics, and design of belt and chain drives for power transmission. 0 and therefore the pulleys should be selected accordingly. It is determined by the width and arc of contact. • properly designed belt drives should have an arc of. Arc Of Contact In Belt Drives.

From eng-resources.charlotte.edu

Belts & Chains UNC Charlotte Engineering Tool Kit Arc Of Contact In Belt Drives The maximum amount of torque which the drive. The pdf document explains the friction, wedging, speed ratio and lateral travel of. Learn about belt drives, contact angle geometry, and drive kinematics from a mechanical engineering course at mit. The operation of the belt and its ability to transmit power depend on the size of the friction force and the arc. Arc Of Contact In Belt Drives.

From mectips.com

Belt Drive and its Types Mechanical Engineering Arc Of Contact In Belt Drives 0 and therefore the pulleys should be selected accordingly. The operation of the belt and its ability to transmit power depend on the size of the friction force and the arc of contact of the belt. Learn about the types, characteristics, and design of belt and chain drives for power transmission. The pdf document explains the friction, wedging, speed ratio. Arc Of Contact In Belt Drives.