Wire Rope Minimum Sheave Diameter . Ratio a = sheave diameter rope diameter example to determine. For example, the minimum sheave pitch diameter for a 1/2″ (nominal diameter) x 30 (minimum ratio) or 15″. To find any pitch diameter from this table, the diameter for the rope construction to be used is multiplied by its nominal diameter (d). Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. Minimum 0.53 to 0.535 x d maximum 0.55 x d recommended: 35 rc, better is 40. Example asme b 30.5 allows minimum hoist rope d/d ratio of 18 and boom hoist rope d/d ratio of 15. ≈ 1% over the actual wire rope. Sheave diameter on wire rope fatigue life can be determined as shown below: The following are recommended values: The working life of the individual wire strands is greatly reduced as the pulley or sheave diameter is diminished. The chart below shows minimum tread diameters over which various sizes and. To calculate the recommended or minimum. We recommend only sheaves made of steel or cast steel.

from suncorstainless.com

≈ 1% over the actual wire rope. The following are recommended values: Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. Example asme b 30.5 allows minimum hoist rope d/d ratio of 18 and boom hoist rope d/d ratio of 15. To find any pitch diameter from this table, the diameter for the rope construction to be used is multiplied by its nominal diameter (d). The working life of the individual wire strands is greatly reduced as the pulley or sheave diameter is diminished. Sheave diameter on wire rope fatigue life can be determined as shown below: For example, the minimum sheave pitch diameter for a 1/2″ (nominal diameter) x 30 (minimum ratio) or 15″. Ratio a = sheave diameter rope diameter example to determine. To calculate the recommended or minimum.

Stainless Steel Sheaves Selection and Use Suncor Stainless

Wire Rope Minimum Sheave Diameter Ratio a = sheave diameter rope diameter example to determine. The following are recommended values: Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. 35 rc, better is 40. ≈ 1% over the actual wire rope. Minimum 0.53 to 0.535 x d maximum 0.55 x d recommended: Ratio a = sheave diameter rope diameter example to determine. The working life of the individual wire strands is greatly reduced as the pulley or sheave diameter is diminished. To find any pitch diameter from this table, the diameter for the rope construction to be used is multiplied by its nominal diameter (d). Example asme b 30.5 allows minimum hoist rope d/d ratio of 18 and boom hoist rope d/d ratio of 15. We recommend only sheaves made of steel or cast steel. To calculate the recommended or minimum. For example, the minimum sheave pitch diameter for a 1/2″ (nominal diameter) x 30 (minimum ratio) or 15″. Sheave diameter on wire rope fatigue life can be determined as shown below: The chart below shows minimum tread diameters over which various sizes and.

From ubicaciondepersonas.cdmx.gob.mx

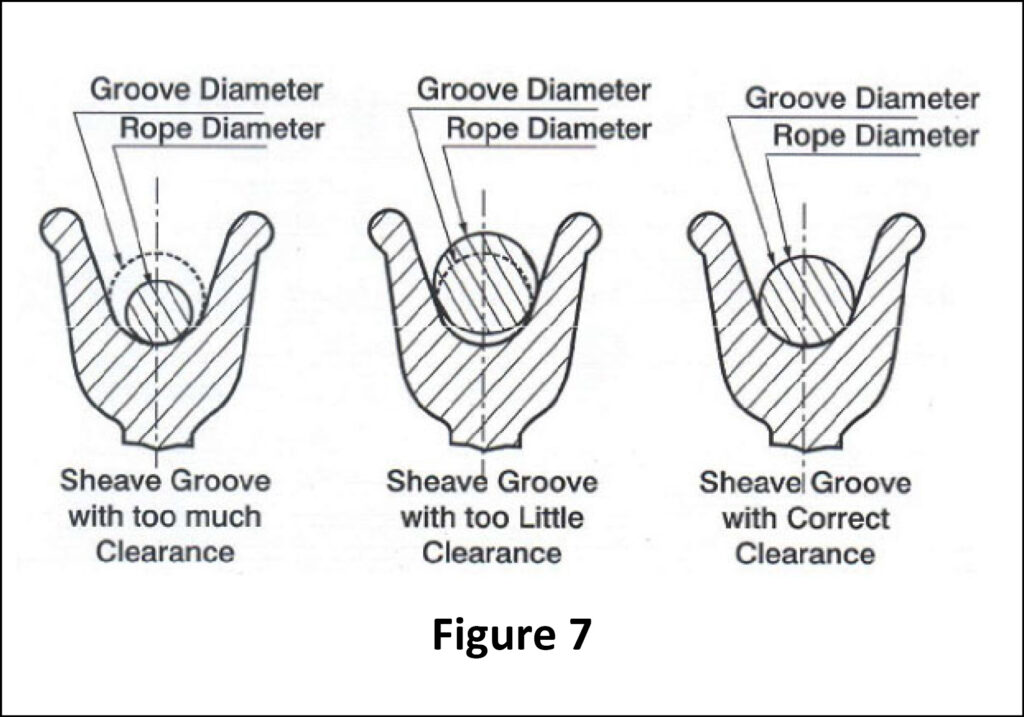

Wire Rope Sheave Groove Dimensions ubicaciondepersonas.cdmx.gob.mx Wire Rope Minimum Sheave Diameter To find any pitch diameter from this table, the diameter for the rope construction to be used is multiplied by its nominal diameter (d). Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. The chart below shows minimum tread diameters over which various sizes and. Minimum 0.53 to 0.535 x d maximum 0.55 x d. Wire Rope Minimum Sheave Diameter.

From www.mazzellacompanies.com

Why Sheave Design is Critical to Wire Rope Service Life Wire Rope Minimum Sheave Diameter Example asme b 30.5 allows minimum hoist rope d/d ratio of 18 and boom hoist rope d/d ratio of 15. Ratio a = sheave diameter rope diameter example to determine. The following are recommended values: To find any pitch diameter from this table, the diameter for the rope construction to be used is multiplied by its nominal diameter (d). For. Wire Rope Minimum Sheave Diameter.

From ceovmitf.blob.core.windows.net

Wire Rope Dimensions at Christopher Robinson blog Wire Rope Minimum Sheave Diameter Minimum 0.53 to 0.535 x d maximum 0.55 x d recommended: For example, the minimum sheave pitch diameter for a 1/2″ (nominal diameter) x 30 (minimum ratio) or 15″. The chart below shows minimum tread diameters over which various sizes and. We recommend only sheaves made of steel or cast steel. To find any pitch diameter from this table, the. Wire Rope Minimum Sheave Diameter.

From exypoylsr.blob.core.windows.net

Wire Rope Sheave Efficiency at Howard Valente blog Wire Rope Minimum Sheave Diameter 35 rc, better is 40. The chart below shows minimum tread diameters over which various sizes and. The following are recommended values: The working life of the individual wire strands is greatly reduced as the pulley or sheave diameter is diminished. For example, the minimum sheave pitch diameter for a 1/2″ (nominal diameter) x 30 (minimum ratio) or 15″. Ratio. Wire Rope Minimum Sheave Diameter.

From exypoylsr.blob.core.windows.net

Wire Rope Sheave Efficiency at Howard Valente blog Wire Rope Minimum Sheave Diameter The following are recommended values: For example, the minimum sheave pitch diameter for a 1/2″ (nominal diameter) x 30 (minimum ratio) or 15″. Sheave diameter on wire rope fatigue life can be determined as shown below: Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. The working life of the individual wire strands is greatly. Wire Rope Minimum Sheave Diameter.

From www.assemblyspecialty.com

Wire Rope Handling and Installation Assembly Specialty Products Wire Rope Minimum Sheave Diameter To find any pitch diameter from this table, the diameter for the rope construction to be used is multiplied by its nominal diameter (d). The following are recommended values: Ratio a = sheave diameter rope diameter example to determine. Sheave diameter on wire rope fatigue life can be determined as shown below: Example asme b 30.5 allows minimum hoist rope. Wire Rope Minimum Sheave Diameter.

From www.alibaba.com

Snatch Block Harbor Freight Wire Rope Minimum Sheave Diameter Buy Wire Rope Minimum Sheave Diameter For example, the minimum sheave pitch diameter for a 1/2″ (nominal diameter) x 30 (minimum ratio) or 15″. To calculate the recommended or minimum. Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. To find any pitch diameter from this table, the diameter for the rope construction to be used is multiplied by its nominal. Wire Rope Minimum Sheave Diameter.

From mungfali.com

Wire Rope Specs Chart Wire Rope Minimum Sheave Diameter The working life of the individual wire strands is greatly reduced as the pulley or sheave diameter is diminished. Sheave diameter on wire rope fatigue life can be determined as shown below: We recommend only sheaves made of steel or cast steel. The following are recommended values: To calculate the recommended or minimum. To find any pitch diameter from this. Wire Rope Minimum Sheave Diameter.

From www.alibaba.com

snatch block harbor freight wire rope minimum sheave diameter Wire Rope Minimum Sheave Diameter We recommend only sheaves made of steel or cast steel. The chart below shows minimum tread diameters over which various sizes and. Ratio a = sheave diameter rope diameter example to determine. To calculate the recommended or minimum. Sheave diameter on wire rope fatigue life can be determined as shown below: Minimum 0.53 to 0.535 x d maximum 0.55 x. Wire Rope Minimum Sheave Diameter.

From e-rigging.com

5/16" Cable x 3" Diameter Sheave Wire Rope Minimum Sheave Diameter Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. ≈ 1% over the actual wire rope. To calculate the recommended or minimum. Example asme b 30.5 allows minimum hoist rope d/d ratio of 18 and boom hoist rope d/d ratio of 15. Minimum 0.53 to 0.535 x d maximum 0.55 x d recommended: Sheave diameter. Wire Rope Minimum Sheave Diameter.

From suncorstainless.com

Stainless Steel Sheaves Selection and Use Suncor Stainless Wire Rope Minimum Sheave Diameter For example, the minimum sheave pitch diameter for a 1/2″ (nominal diameter) x 30 (minimum ratio) or 15″. To find any pitch diameter from this table, the diameter for the rope construction to be used is multiplied by its nominal diameter (d). Minimum 0.53 to 0.535 x d maximum 0.55 x d recommended: To calculate the recommended or minimum. The. Wire Rope Minimum Sheave Diameter.

From suncorstainless.com

Stainless Steel Sheaves Selection and Use Suncor Stainless Wire Rope Minimum Sheave Diameter Ratio a = sheave diameter rope diameter example to determine. The working life of the individual wire strands is greatly reduced as the pulley or sheave diameter is diminished. To find any pitch diameter from this table, the diameter for the rope construction to be used is multiplied by its nominal diameter (d). The following are recommended values: ≈ 1%. Wire Rope Minimum Sheave Diameter.

From www.mdpi.com

Materials Free FullText Sliding Friction and Wear Characteristics Wire Rope Minimum Sheave Diameter Minimum 0.53 to 0.535 x d maximum 0.55 x d recommended: Example asme b 30.5 allows minimum hoist rope d/d ratio of 18 and boom hoist rope d/d ratio of 15. The working life of the individual wire strands is greatly reduced as the pulley or sheave diameter is diminished. Ratio a = sheave diameter rope diameter example to determine.. Wire Rope Minimum Sheave Diameter.

From suncorstainless.com

PULLPRO® HiLOAD Wire Rope Sheave, Bearing Suncor Stainless Wire Rope Minimum Sheave Diameter Example asme b 30.5 allows minimum hoist rope d/d ratio of 18 and boom hoist rope d/d ratio of 15. We recommend only sheaves made of steel or cast steel. ≈ 1% over the actual wire rope. Sheave diameter on wire rope fatigue life can be determined as shown below: For example, the minimum sheave pitch diameter for a 1/2″. Wire Rope Minimum Sheave Diameter.

From exypoylsr.blob.core.windows.net

Wire Rope Sheave Efficiency at Howard Valente blog Wire Rope Minimum Sheave Diameter Minimum 0.53 to 0.535 x d maximum 0.55 x d recommended: To find any pitch diameter from this table, the diameter for the rope construction to be used is multiplied by its nominal diameter (d). The chart below shows minimum tread diameters over which various sizes and. Ratio a = sheave diameter rope diameter example to determine. Learn how optimizing. Wire Rope Minimum Sheave Diameter.

From suncorstainless.com

Stainless Steel Sheaves Selection and Use Suncor Stainless Wire Rope Minimum Sheave Diameter To calculate the recommended or minimum. The chart below shows minimum tread diameters over which various sizes and. Sheave diameter on wire rope fatigue life can be determined as shown below: 35 rc, better is 40. For example, the minimum sheave pitch diameter for a 1/2″ (nominal diameter) x 30 (minimum ratio) or 15″. Example asme b 30.5 allows minimum. Wire Rope Minimum Sheave Diameter.

From www.scribd.com

IWRC Wire Rope™ Standard Specification Ropes Php Manufactured Goods Wire Rope Minimum Sheave Diameter To calculate the recommended or minimum. Sheave diameter on wire rope fatigue life can be determined as shown below: For example, the minimum sheave pitch diameter for a 1/2″ (nominal diameter) x 30 (minimum ratio) or 15″. ≈ 1% over the actual wire rope. The chart below shows minimum tread diameters over which various sizes and. 35 rc, better is. Wire Rope Minimum Sheave Diameter.

From www.certex.ee

Wire Rope Sheave 8000 Certex Estonia Wire Rope Minimum Sheave Diameter 35 rc, better is 40. ≈ 1% over the actual wire rope. For example, the minimum sheave pitch diameter for a 1/2″ (nominal diameter) x 30 (minimum ratio) or 15″. Example asme b 30.5 allows minimum hoist rope d/d ratio of 18 and boom hoist rope d/d ratio of 15. We recommend only sheaves made of steel or cast steel.. Wire Rope Minimum Sheave Diameter.

From www.mazzellacompanies.com

How Sheave Size Affects Wire Rope Strength and Efficiency Wire Rope Minimum Sheave Diameter Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. 35 rc, better is 40. We recommend only sheaves made of steel or cast steel. ≈ 1% over the actual wire rope. To calculate the recommended or minimum. Sheave diameter on wire rope fatigue life can be determined as shown below: The following are recommended values:. Wire Rope Minimum Sheave Diameter.

From ebonmachine.en.made-in-china.com

Custom Casting Welded Wire Rope Guide Pulley Crane Wire Rope Minimum Sheave Diameter ≈ 1% over the actual wire rope. For example, the minimum sheave pitch diameter for a 1/2″ (nominal diameter) x 30 (minimum ratio) or 15″. The following are recommended values: Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. We recommend only sheaves made of steel or cast steel. Ratio a = sheave diameter rope. Wire Rope Minimum Sheave Diameter.

From www.scribd.com

Wire Rope Chart Rope Equipment Wire Rope Minimum Sheave Diameter Sheave diameter on wire rope fatigue life can be determined as shown below: Ratio a = sheave diameter rope diameter example to determine. Example asme b 30.5 allows minimum hoist rope d/d ratio of 18 and boom hoist rope d/d ratio of 15. 35 rc, better is 40. The chart below shows minimum tread diameters over which various sizes and.. Wire Rope Minimum Sheave Diameter.

From www.samselsupply.com

HOWTO Order Wire Rope Sheaves Wire Rope Minimum Sheave Diameter Ratio a = sheave diameter rope diameter example to determine. Example asme b 30.5 allows minimum hoist rope d/d ratio of 18 and boom hoist rope d/d ratio of 15. We recommend only sheaves made of steel or cast steel. To find any pitch diameter from this table, the diameter for the rope construction to be used is multiplied by. Wire Rope Minimum Sheave Diameter.

From www.ropemarine.com

Wire Rope (7 x 19) Wire Rope Minimum Sheave Diameter 35 rc, better is 40. The following are recommended values: Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. To find any pitch diameter from this table, the diameter for the rope construction to be used is multiplied by its nominal diameter (d). Example asme b 30.5 allows minimum hoist rope d/d ratio of 18. Wire Rope Minimum Sheave Diameter.

From www.youtube.com

Lecture on Wire Rope (Method of Diameter and Pitch) YouTube Wire Rope Minimum Sheave Diameter ≈ 1% over the actual wire rope. 35 rc, better is 40. For example, the minimum sheave pitch diameter for a 1/2″ (nominal diameter) x 30 (minimum ratio) or 15″. We recommend only sheaves made of steel or cast steel. The following are recommended values: Example asme b 30.5 allows minimum hoist rope d/d ratio of 18 and boom hoist. Wire Rope Minimum Sheave Diameter.

From materiallibbeckenbauer.z19.web.core.windows.net

Wire Rope Diameter Chart Wire Rope Minimum Sheave Diameter To calculate the recommended or minimum. We recommend only sheaves made of steel or cast steel. 35 rc, better is 40. Ratio a = sheave diameter rope diameter example to determine. The following are recommended values: Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. ≈ 1% over the actual wire rope. Sheave diameter on. Wire Rope Minimum Sheave Diameter.

From studylib.net

STANDARD WIRE ROPES Wire Rope Minimum Sheave Diameter ≈ 1% over the actual wire rope. The working life of the individual wire strands is greatly reduced as the pulley or sheave diameter is diminished. 35 rc, better is 40. The chart below shows minimum tread diameters over which various sizes and. Sheave diameter on wire rope fatigue life can be determined as shown below: To calculate the recommended. Wire Rope Minimum Sheave Diameter.

From suncorstainless.com

Stainless Steel Sheaves Selection and Use Suncor Stainless Wire Rope Minimum Sheave Diameter ≈ 1% over the actual wire rope. Minimum 0.53 to 0.535 x d maximum 0.55 x d recommended: Ratio a = sheave diameter rope diameter example to determine. To find any pitch diameter from this table, the diameter for the rope construction to be used is multiplied by its nominal diameter (d). 35 rc, better is 40. We recommend only. Wire Rope Minimum Sheave Diameter.

From liediaoweiye.en.alibaba.com

snatch block harbor freight wire rope minimum sheave diameter, View Wire Rope Minimum Sheave Diameter We recommend only sheaves made of steel or cast steel. To find any pitch diameter from this table, the diameter for the rope construction to be used is multiplied by its nominal diameter (d). 35 rc, better is 40. For example, the minimum sheave pitch diameter for a 1/2″ (nominal diameter) x 30 (minimum ratio) or 15″. The working life. Wire Rope Minimum Sheave Diameter.

From liediaoweiye.en.alibaba.com

snatch block harbor freight wire rope minimum sheave diameter, View Wire Rope Minimum Sheave Diameter Example asme b 30.5 allows minimum hoist rope d/d ratio of 18 and boom hoist rope d/d ratio of 15. The working life of the individual wire strands is greatly reduced as the pulley or sheave diameter is diminished. ≈ 1% over the actual wire rope. For example, the minimum sheave pitch diameter for a 1/2″ (nominal diameter) x 30. Wire Rope Minimum Sheave Diameter.

From mungfali.com

Wire Rope Rigging Chart Wire Rope Minimum Sheave Diameter ≈ 1% over the actual wire rope. Sheave diameter on wire rope fatigue life can be determined as shown below: For example, the minimum sheave pitch diameter for a 1/2″ (nominal diameter) x 30 (minimum ratio) or 15″. Minimum 0.53 to 0.535 x d maximum 0.55 x d recommended: The following are recommended values: To find any pitch diameter from. Wire Rope Minimum Sheave Diameter.

From liediaoweiye.en.alibaba.com

snatch block harbor freight wire rope minimum sheave diameter, View Wire Rope Minimum Sheave Diameter The chart below shows minimum tread diameters over which various sizes and. To calculate the recommended or minimum. Example asme b 30.5 allows minimum hoist rope d/d ratio of 18 and boom hoist rope d/d ratio of 15. Ratio a = sheave diameter rope diameter example to determine. ≈ 1% over the actual wire rope. Learn how optimizing cable diameter. Wire Rope Minimum Sheave Diameter.

From www.alibaba.com

Snatch Block Harbor Freight Wire Rope Minimum Sheave Diameter Buy Wire Rope Minimum Sheave Diameter The chart below shows minimum tread diameters over which various sizes and. ≈ 1% over the actual wire rope. The working life of the individual wire strands is greatly reduced as the pulley or sheave diameter is diminished. Example asme b 30.5 allows minimum hoist rope d/d ratio of 18 and boom hoist rope d/d ratio of 15. Sheave diameter. Wire Rope Minimum Sheave Diameter.

From mepsystems.com.sg

MORDEC WIRE ROPE SHEAVE GAUGE MEP Deck Solutions Wire Rope Minimum Sheave Diameter ≈ 1% over the actual wire rope. Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. To find any pitch diameter from this table, the diameter for the rope construction to be used is multiplied by its nominal diameter (d). Ratio a = sheave diameter rope diameter example to determine. To calculate the recommended or. Wire Rope Minimum Sheave Diameter.

From shaws.co.nz

General Products Wire Rope General Purpose Rope Wire Rope Minimum Sheave Diameter The following are recommended values: 35 rc, better is 40. Minimum 0.53 to 0.535 x d maximum 0.55 x d recommended: The chart below shows minimum tread diameters over which various sizes and. To find any pitch diameter from this table, the diameter for the rope construction to be used is multiplied by its nominal diameter (d). Sheave diameter on. Wire Rope Minimum Sheave Diameter.

From chinasteelwirerope.en.made-in-china.com

How to Transfer Sheave Diameter to Rope Diameter 8mm 10mm 12mm Steel Wire Rope Minimum Sheave Diameter ≈ 1% over the actual wire rope. The working life of the individual wire strands is greatly reduced as the pulley or sheave diameter is diminished. Learn how optimizing cable diameter to pulley/sheave diameter ratios increases service life and performance. Example asme b 30.5 allows minimum hoist rope d/d ratio of 18 and boom hoist rope d/d ratio of 15.. Wire Rope Minimum Sheave Diameter.