Difference Between Hot Stamping And Cold Stamping . During cold forming, metal parts are shaped at room temperature. Understanding their differences, advantages, and. Although both can be holographic; When an application requires metal stamping, two approaches can be adopted, either hot metal stamping or cold metal stamping. The primary difference between cold and hot stamping lies in the temperature at which the process is carried out. The difference between cold stamping and hot stamping is their appearance. In the world of manufacturing, hot metal stamping and cold stamping serve as two of the most pivotal processes. Hot foil stamping requires a custom die, heat, and pressure to apply foil to your folding cartons and/or printed materials, while cold foil relies on uv light. It may be heated by a few degrees, but in general, the metal can. Selecting one or the other will depend on the kind of part that you are attempting to form and what the needs are for that particular part.

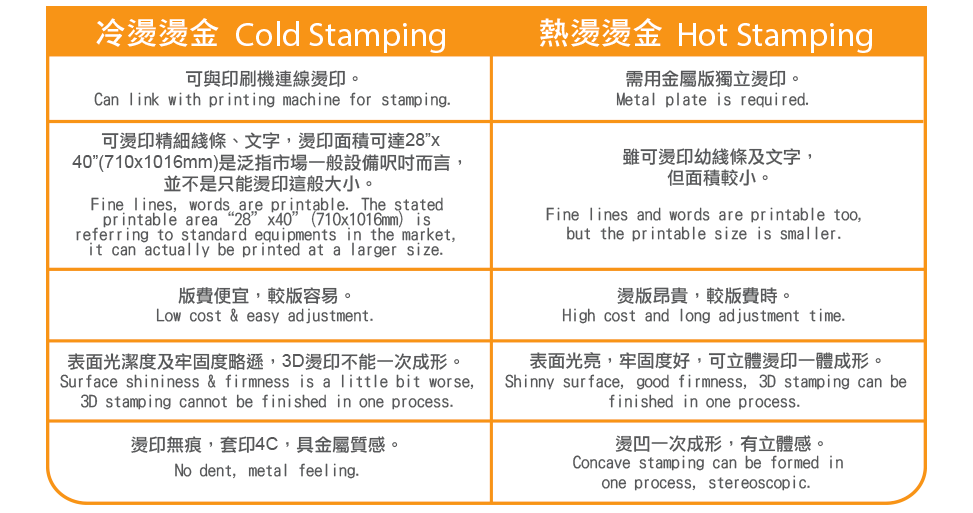

from www.levox.com.hk

Hot foil stamping requires a custom die, heat, and pressure to apply foil to your folding cartons and/or printed materials, while cold foil relies on uv light. When an application requires metal stamping, two approaches can be adopted, either hot metal stamping or cold metal stamping. Understanding their differences, advantages, and. Although both can be holographic; The difference between cold stamping and hot stamping is their appearance. Selecting one or the other will depend on the kind of part that you are attempting to form and what the needs are for that particular part. In the world of manufacturing, hot metal stamping and cold stamping serve as two of the most pivotal processes. The primary difference between cold and hot stamping lies in the temperature at which the process is carried out. It may be heated by a few degrees, but in general, the metal can. During cold forming, metal parts are shaped at room temperature.

Hot/Cold Stamping Processing 燙金加工服務 Levox Industrial Co. Ltd.

Difference Between Hot Stamping And Cold Stamping Although both can be holographic; It may be heated by a few degrees, but in general, the metal can. When an application requires metal stamping, two approaches can be adopted, either hot metal stamping or cold metal stamping. In the world of manufacturing, hot metal stamping and cold stamping serve as two of the most pivotal processes. Understanding their differences, advantages, and. The difference between cold stamping and hot stamping is their appearance. Although both can be holographic; During cold forming, metal parts are shaped at room temperature. The primary difference between cold and hot stamping lies in the temperature at which the process is carried out. Selecting one or the other will depend on the kind of part that you are attempting to form and what the needs are for that particular part. Hot foil stamping requires a custom die, heat, and pressure to apply foil to your folding cartons and/or printed materials, while cold foil relies on uv light.

From packagengo.com

Cold vs Hot Foil Stamping Difference Between Hot Stamping And Cold Stamping During cold forming, metal parts are shaped at room temperature. Understanding their differences, advantages, and. Selecting one or the other will depend on the kind of part that you are attempting to form and what the needs are for that particular part. The primary difference between cold and hot stamping lies in the temperature at which the process is carried. Difference Between Hot Stamping And Cold Stamping.

From worldsteel.org

ArcelorMittal Carbon footprint of cold stamping and hot stamping Difference Between Hot Stamping And Cold Stamping Selecting one or the other will depend on the kind of part that you are attempting to form and what the needs are for that particular part. Understanding their differences, advantages, and. Hot foil stamping requires a custom die, heat, and pressure to apply foil to your folding cartons and/or printed materials, while cold foil relies on uv light. It. Difference Between Hot Stamping And Cold Stamping.

From www.qmc-emi.com

Hot Stamping QMCEMI Difference Between Hot Stamping And Cold Stamping In the world of manufacturing, hot metal stamping and cold stamping serve as two of the most pivotal processes. When an application requires metal stamping, two approaches can be adopted, either hot metal stamping or cold metal stamping. Although both can be holographic; During cold forming, metal parts are shaped at room temperature. Hot foil stamping requires a custom die,. Difference Between Hot Stamping And Cold Stamping.

From es.linkedin.com

Diferencias entre Hot Stamping y Cold Foil Difference Between Hot Stamping And Cold Stamping Hot foil stamping requires a custom die, heat, and pressure to apply foil to your folding cartons and/or printed materials, while cold foil relies on uv light. The difference between cold stamping and hot stamping is their appearance. When an application requires metal stamping, two approaches can be adopted, either hot metal stamping or cold metal stamping. Although both can. Difference Between Hot Stamping And Cold Stamping.

From www.youtube.com

PLI What is the difference between Hot Foil Stamping and Cold Foil Difference Between Hot Stamping And Cold Stamping In the world of manufacturing, hot metal stamping and cold stamping serve as two of the most pivotal processes. During cold forming, metal parts are shaped at room temperature. Selecting one or the other will depend on the kind of part that you are attempting to form and what the needs are for that particular part. When an application requires. Difference Between Hot Stamping And Cold Stamping.

From www.johnsbyrne.com

Helpful Facts on Hot Foil Stamping and Cold Foil Printing JohnsByrne Difference Between Hot Stamping And Cold Stamping Hot foil stamping requires a custom die, heat, and pressure to apply foil to your folding cartons and/or printed materials, while cold foil relies on uv light. The difference between cold stamping and hot stamping is their appearance. Understanding their differences, advantages, and. The primary difference between cold and hot stamping lies in the temperature at which the process is. Difference Between Hot Stamping And Cold Stamping.

From www.dragonfoils.com

China Holographic Cold Foil Stamping Foil Manufacturer Dragon Foils Difference Between Hot Stamping And Cold Stamping Understanding their differences, advantages, and. Selecting one or the other will depend on the kind of part that you are attempting to form and what the needs are for that particular part. Although both can be holographic; During cold forming, metal parts are shaped at room temperature. In the world of manufacturing, hot metal stamping and cold stamping serve as. Difference Between Hot Stamping And Cold Stamping.

From azcolor.pl

What is the difference between cold stamping and hot stamping Difference Between Hot Stamping And Cold Stamping Selecting one or the other will depend on the kind of part that you are attempting to form and what the needs are for that particular part. The difference between cold stamping and hot stamping is their appearance. When an application requires metal stamping, two approaches can be adopted, either hot metal stamping or cold metal stamping. Understanding their differences,. Difference Between Hot Stamping And Cold Stamping.

From printindooffset.com

Hot Stamping Vs Cold Foil Printing PT Printindo Utama Difference Between Hot Stamping And Cold Stamping Selecting one or the other will depend on the kind of part that you are attempting to form and what the needs are for that particular part. When an application requires metal stamping, two approaches can be adopted, either hot metal stamping or cold metal stamping. Understanding their differences, advantages, and. During cold forming, metal parts are shaped at room. Difference Between Hot Stamping And Cold Stamping.

From holomex.com.mx

Cold Foil vs. Hot Stamping ¿Cuál es mejor? Holomex Difference Between Hot Stamping And Cold Stamping Hot foil stamping requires a custom die, heat, and pressure to apply foil to your folding cartons and/or printed materials, while cold foil relies on uv light. Although both can be holographic; It may be heated by a few degrees, but in general, the metal can. During cold forming, metal parts are shaped at room temperature. In the world of. Difference Between Hot Stamping And Cold Stamping.

From www.levox.com.hk

Hot/Cold Stamping Processing 燙金加工服務 Levox Industrial Co. Ltd. Difference Between Hot Stamping And Cold Stamping Understanding their differences, advantages, and. Although both can be holographic; Selecting one or the other will depend on the kind of part that you are attempting to form and what the needs are for that particular part. It may be heated by a few degrees, but in general, the metal can. Hot foil stamping requires a custom die, heat, and. Difference Between Hot Stamping And Cold Stamping.

From www.oliverinc.com

Hot Foil Stamping vs. Cold Foil Difference Between Hot Stamping And Cold Stamping The difference between cold stamping and hot stamping is their appearance. Understanding their differences, advantages, and. When an application requires metal stamping, two approaches can be adopted, either hot metal stamping or cold metal stamping. In the world of manufacturing, hot metal stamping and cold stamping serve as two of the most pivotal processes. The primary difference between cold and. Difference Between Hot Stamping And Cold Stamping.

From www.ulbrich.com

What Is the Difference Between Drawing and Stamping? Ulbrich Difference Between Hot Stamping And Cold Stamping Understanding their differences, advantages, and. Although both can be holographic; During cold forming, metal parts are shaped at room temperature. The primary difference between cold and hot stamping lies in the temperature at which the process is carried out. Selecting one or the other will depend on the kind of part that you are attempting to form and what the. Difference Between Hot Stamping And Cold Stamping.

From greatlakeslabel.com

All About Mirafoil, Cold Foil & Hot Stamp Great Lakes Label Difference Between Hot Stamping And Cold Stamping The primary difference between cold and hot stamping lies in the temperature at which the process is carried out. Although both can be holographic; Selecting one or the other will depend on the kind of part that you are attempting to form and what the needs are for that particular part. It may be heated by a few degrees, but. Difference Between Hot Stamping And Cold Stamping.

From packagengo.com

Foil Stamping Difference Between Hot Stamping And Cold Stamping It may be heated by a few degrees, but in general, the metal can. Although both can be holographic; The primary difference between cold and hot stamping lies in the temperature at which the process is carried out. Selecting one or the other will depend on the kind of part that you are attempting to form and what the needs. Difference Between Hot Stamping And Cold Stamping.

From blog.thepipingmart.com

Stamping vs Forming of Metal What's the Difference Difference Between Hot Stamping And Cold Stamping The primary difference between cold and hot stamping lies in the temperature at which the process is carried out. Understanding their differences, advantages, and. Selecting one or the other will depend on the kind of part that you are attempting to form and what the needs are for that particular part. Although both can be holographic; When an application requires. Difference Between Hot Stamping And Cold Stamping.

From printindooffset.com

Hot Stamping Vs Cold Foil Printing PT Printindo Utama Difference Between Hot Stamping And Cold Stamping The difference between cold stamping and hot stamping is their appearance. In the world of manufacturing, hot metal stamping and cold stamping serve as two of the most pivotal processes. Hot foil stamping requires a custom die, heat, and pressure to apply foil to your folding cartons and/or printed materials, while cold foil relies on uv light. Selecting one or. Difference Between Hot Stamping And Cold Stamping.

From packagengo.com

Cold vs Hot Foil Stamping Difference Between Hot Stamping And Cold Stamping The primary difference between cold and hot stamping lies in the temperature at which the process is carried out. In the world of manufacturing, hot metal stamping and cold stamping serve as two of the most pivotal processes. When an application requires metal stamping, two approaches can be adopted, either hot metal stamping or cold metal stamping. Understanding their differences,. Difference Between Hot Stamping And Cold Stamping.

From www.mdpi.com

Symmetry Free FullText A Review on Hot Stamping of Advanced High Difference Between Hot Stamping And Cold Stamping When an application requires metal stamping, two approaches can be adopted, either hot metal stamping or cold metal stamping. Although both can be holographic; Hot foil stamping requires a custom die, heat, and pressure to apply foil to your folding cartons and/or printed materials, while cold foil relies on uv light. Selecting one or the other will depend on the. Difference Between Hot Stamping And Cold Stamping.

From boppbusch.com

The difference between hot metal and cold metal stamping BoppBusch Difference Between Hot Stamping And Cold Stamping The difference between cold stamping and hot stamping is their appearance. Understanding their differences, advantages, and. When an application requires metal stamping, two approaches can be adopted, either hot metal stamping or cold metal stamping. Selecting one or the other will depend on the kind of part that you are attempting to form and what the needs are for that. Difference Between Hot Stamping And Cold Stamping.

From www.researchgate.net

Schematic of the processes, a) Hot stamping and b) cold stamping plus Difference Between Hot Stamping And Cold Stamping It may be heated by a few degrees, but in general, the metal can. The primary difference between cold and hot stamping lies in the temperature at which the process is carried out. During cold forming, metal parts are shaped at room temperature. In the world of manufacturing, hot metal stamping and cold stamping serve as two of the most. Difference Between Hot Stamping And Cold Stamping.

From macrodynepress.com

Hot Stamping 101 Macrodyne Difference Between Hot Stamping And Cold Stamping Although both can be holographic; It may be heated by a few degrees, but in general, the metal can. Hot foil stamping requires a custom die, heat, and pressure to apply foil to your folding cartons and/or printed materials, while cold foil relies on uv light. Understanding their differences, advantages, and. When an application requires metal stamping, two approaches can. Difference Between Hot Stamping And Cold Stamping.

From www.researchgate.net

Comparison of a laser trimming, b cold press trimming, and c hot Difference Between Hot Stamping And Cold Stamping The primary difference between cold and hot stamping lies in the temperature at which the process is carried out. It may be heated by a few degrees, but in general, the metal can. When an application requires metal stamping, two approaches can be adopted, either hot metal stamping or cold metal stamping. Although both can be holographic; The difference between. Difference Between Hot Stamping And Cold Stamping.

From www.guojuntex.com

Introduction to hot stamping the difference between hot stamping and Difference Between Hot Stamping And Cold Stamping The difference between cold stamping and hot stamping is their appearance. The primary difference between cold and hot stamping lies in the temperature at which the process is carried out. Hot foil stamping requires a custom die, heat, and pressure to apply foil to your folding cartons and/or printed materials, while cold foil relies on uv light. Although both can. Difference Between Hot Stamping And Cold Stamping.

From greatlakeslabel.com

All About Mirafoil, Cold Foil & Hot Stamp Great Lakes Label Difference Between Hot Stamping And Cold Stamping Understanding their differences, advantages, and. The difference between cold stamping and hot stamping is their appearance. It may be heated by a few degrees, but in general, the metal can. During cold forming, metal parts are shaped at room temperature. When an application requires metal stamping, two approaches can be adopted, either hot metal stamping or cold metal stamping. The. Difference Between Hot Stamping And Cold Stamping.

From www.myxxgirl.com

Cold Foil Vs Hot Stamping Principales Diferencias Que Debes Saber My Difference Between Hot Stamping And Cold Stamping Hot foil stamping requires a custom die, heat, and pressure to apply foil to your folding cartons and/or printed materials, while cold foil relies on uv light. The primary difference between cold and hot stamping lies in the temperature at which the process is carried out. Understanding their differences, advantages, and. It may be heated by a few degrees, but. Difference Between Hot Stamping And Cold Stamping.

From greatlakeslabel.com

All About Mirafoil, Cold Foil & Hot Stamp Great Lakes Label Difference Between Hot Stamping And Cold Stamping It may be heated by a few degrees, but in general, the metal can. In the world of manufacturing, hot metal stamping and cold stamping serve as two of the most pivotal processes. Understanding their differences, advantages, and. The primary difference between cold and hot stamping lies in the temperature at which the process is carried out. Selecting one or. Difference Between Hot Stamping And Cold Stamping.

From packagengo.com

Difference between Cold vs Hot Foil Stamping Package N'Go Difference Between Hot Stamping And Cold Stamping Understanding their differences, advantages, and. The difference between cold stamping and hot stamping is their appearance. It may be heated by a few degrees, but in general, the metal can. The primary difference between cold and hot stamping lies in the temperature at which the process is carried out. In the world of manufacturing, hot metal stamping and cold stamping. Difference Between Hot Stamping And Cold Stamping.

From www.pinterest.com

How to Decide Between Hot Foil Stamping and Cold Foil Printing Difference Between Hot Stamping And Cold Stamping When an application requires metal stamping, two approaches can be adopted, either hot metal stamping or cold metal stamping. Selecting one or the other will depend on the kind of part that you are attempting to form and what the needs are for that particular part. Although both can be holographic; It may be heated by a few degrees, but. Difference Between Hot Stamping And Cold Stamping.

From www.bonanomi.it

Differences between Hot Cold and Stamping Bonanomi Difference Between Hot Stamping And Cold Stamping Understanding their differences, advantages, and. The difference between cold stamping and hot stamping is their appearance. The primary difference between cold and hot stamping lies in the temperature at which the process is carried out. Hot foil stamping requires a custom die, heat, and pressure to apply foil to your folding cartons and/or printed materials, while cold foil relies on. Difference Between Hot Stamping And Cold Stamping.

From sybridge.com

Everything You Need to Know About Hot Stamping SyBridge Technologies Difference Between Hot Stamping And Cold Stamping In the world of manufacturing, hot metal stamping and cold stamping serve as two of the most pivotal processes. Although both can be holographic; During cold forming, metal parts are shaped at room temperature. When an application requires metal stamping, two approaches can be adopted, either hot metal stamping or cold metal stamping. Understanding their differences, advantages, and. Selecting one. Difference Between Hot Stamping And Cold Stamping.

From packagengo.com

Cold vs Hot Foil Stamping Difference Between Hot Stamping And Cold Stamping The primary difference between cold and hot stamping lies in the temperature at which the process is carried out. Selecting one or the other will depend on the kind of part that you are attempting to form and what the needs are for that particular part. Although both can be holographic; Understanding their differences, advantages, and. In the world of. Difference Between Hot Stamping And Cold Stamping.

From printindooffset.com

Hot Stamping Vs Cold Foil Printing PT Printindo Utama Difference Between Hot Stamping And Cold Stamping The difference between cold stamping and hot stamping is their appearance. When an application requires metal stamping, two approaches can be adopted, either hot metal stamping or cold metal stamping. Hot foil stamping requires a custom die, heat, and pressure to apply foil to your folding cartons and/or printed materials, while cold foil relies on uv light. It may be. Difference Between Hot Stamping And Cold Stamping.

From www.hopinc.com

Cold Foil Printing vs. Hot Foil Stamping Difference Between Hot Stamping And Cold Stamping It may be heated by a few degrees, but in general, the metal can. In the world of manufacturing, hot metal stamping and cold stamping serve as two of the most pivotal processes. The primary difference between cold and hot stamping lies in the temperature at which the process is carried out. During cold forming, metal parts are shaped at. Difference Between Hot Stamping And Cold Stamping.

From www.mdpi.com

Study on the Effect of the PreForming of 22MnB5 Steel in Indirect Hot Difference Between Hot Stamping And Cold Stamping The primary difference between cold and hot stamping lies in the temperature at which the process is carried out. It may be heated by a few degrees, but in general, the metal can. Hot foil stamping requires a custom die, heat, and pressure to apply foil to your folding cartons and/or printed materials, while cold foil relies on uv light.. Difference Between Hot Stamping And Cold Stamping.