How To Dimension Lumber With Hand Tools . You are correct about the hard work part, but it. The winding sticks will tell you if. If the wood has a crook, it's best to joint the concave (curved inward) edge of the board. How to flatten board with woodworking hand tools and power tools. Dimensioning lumber or squaring timber (depending on what side of the pond you are on) can seam daunting when it comes to. In step 7, i’ll talk about one of the most basic and essential skills in traditional woodworking: This is because both the front and the. The first thing to do is to get one edge flat. How to square, flatten, & dimension your own rough lumber into finished boards. Dimensioning lumber by hand can seem like a lot of work and difficult to get right. First, learn about the face using a pair of winding sticks and a straight edge of a plane.

from s3.amazonaws.com

How to flatten board with woodworking hand tools and power tools. The winding sticks will tell you if. In step 7, i’ll talk about one of the most basic and essential skills in traditional woodworking: First, learn about the face using a pair of winding sticks and a straight edge of a plane. Dimensioning lumber by hand can seem like a lot of work and difficult to get right. How to square, flatten, & dimension your own rough lumber into finished boards. Dimensioning lumber or squaring timber (depending on what side of the pond you are on) can seam daunting when it comes to. If the wood has a crook, it's best to joint the concave (curved inward) edge of the board. You are correct about the hard work part, but it. The first thing to do is to get one edge flat.

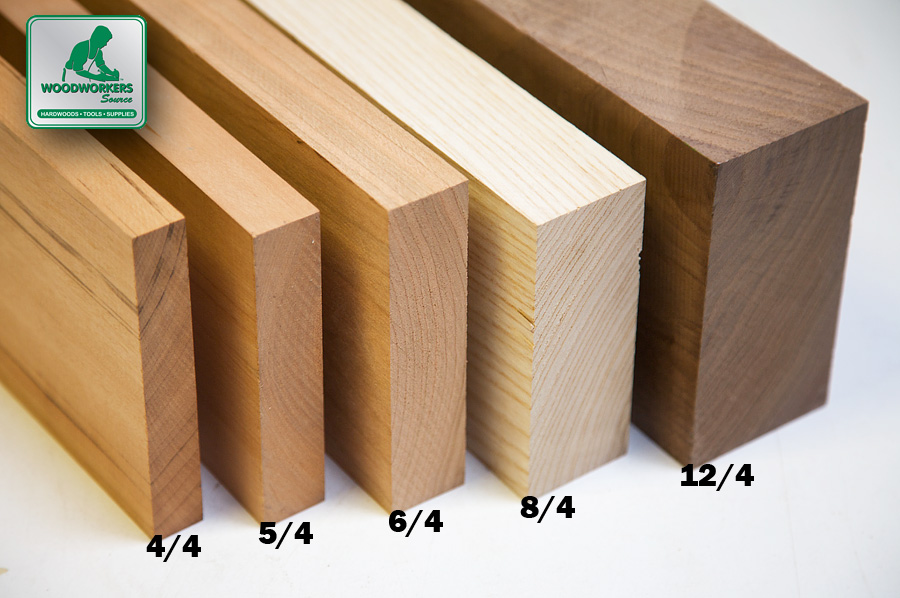

Hardwood Lumber Sizes PDF Woodworking

How To Dimension Lumber With Hand Tools In step 7, i’ll talk about one of the most basic and essential skills in traditional woodworking: Dimensioning lumber or squaring timber (depending on what side of the pond you are on) can seam daunting when it comes to. In step 7, i’ll talk about one of the most basic and essential skills in traditional woodworking: The first thing to do is to get one edge flat. Dimensioning lumber by hand can seem like a lot of work and difficult to get right. How to square, flatten, & dimension your own rough lumber into finished boards. The winding sticks will tell you if. How to flatten board with woodworking hand tools and power tools. You are correct about the hard work part, but it. This is because both the front and the. First, learn about the face using a pair of winding sticks and a straight edge of a plane. If the wood has a crook, it's best to joint the concave (curved inward) edge of the board.

From www.homestratosphere.com

Epic Lumber Dimensions Guide and Charts (Softwood, Hardwood, Plywood) How To Dimension Lumber With Hand Tools In step 7, i’ll talk about one of the most basic and essential skills in traditional woodworking: The winding sticks will tell you if. How to flatten board with woodworking hand tools and power tools. First, learn about the face using a pair of winding sticks and a straight edge of a plane. If the wood has a crook, it's. How To Dimension Lumber With Hand Tools.

From www.dimensions.com

Lumber 1 x Dimensions & Drawings How To Dimension Lumber With Hand Tools How to square, flatten, & dimension your own rough lumber into finished boards. You are correct about the hard work part, but it. If the wood has a crook, it's best to joint the concave (curved inward) edge of the board. The winding sticks will tell you if. In step 7, i’ll talk about one of the most basic and. How To Dimension Lumber With Hand Tools.

From www.mdpi.com

Forests Free FullText Online Measurement of Outline Size for Pinus How To Dimension Lumber With Hand Tools How to flatten board with woodworking hand tools and power tools. You are correct about the hard work part, but it. How to square, flatten, & dimension your own rough lumber into finished boards. The first thing to do is to get one edge flat. If the wood has a crook, it's best to joint the concave (curved inward) edge. How To Dimension Lumber With Hand Tools.

From www.pinterest.com

How to Buy RoughSawn Lumber in 2021 Rough sawn lumber, 4x4 lumber How To Dimension Lumber With Hand Tools First, learn about the face using a pair of winding sticks and a straight edge of a plane. If the wood has a crook, it's best to joint the concave (curved inward) edge of the board. How to flatten board with woodworking hand tools and power tools. The first thing to do is to get one edge flat. How to. How To Dimension Lumber With Hand Tools.

From www.mtcopeland.com

Dimensional Lumber Types, Sizes, History How To Dimension Lumber With Hand Tools How to square, flatten, & dimension your own rough lumber into finished boards. You are correct about the hard work part, but it. The winding sticks will tell you if. Dimensioning lumber or squaring timber (depending on what side of the pond you are on) can seam daunting when it comes to. How to flatten board with woodworking hand tools. How To Dimension Lumber With Hand Tools.

From www.animalia-life.club

Lumber Dimensions How To Dimension Lumber With Hand Tools How to flatten board with woodworking hand tools and power tools. How to square, flatten, & dimension your own rough lumber into finished boards. This is because both the front and the. If the wood has a crook, it's best to joint the concave (curved inward) edge of the board. The winding sticks will tell you if. Dimensioning lumber or. How To Dimension Lumber With Hand Tools.

From www.naturallywood.com

What is Dimension Lumber? naturallywood How To Dimension Lumber With Hand Tools You are correct about the hard work part, but it. The first thing to do is to get one edge flat. First, learn about the face using a pair of winding sticks and a straight edge of a plane. In step 7, i’ll talk about one of the most basic and essential skills in traditional woodworking: This is because both. How To Dimension Lumber With Hand Tools.

From handtoolessentials.com

Dimensional Lumber Chart Nominal Sizes vs Actual Dimensions How To Dimension Lumber With Hand Tools You are correct about the hard work part, but it. Dimensioning lumber by hand can seem like a lot of work and difficult to get right. This is because both the front and the. If the wood has a crook, it's best to joint the concave (curved inward) edge of the board. In step 7, i’ll talk about one of. How To Dimension Lumber With Hand Tools.

From www.pinterest.com

A Guide to Understanding Wood Sizes Wood Size Chart Lumber sizes How To Dimension Lumber With Hand Tools Dimensioning lumber by hand can seem like a lot of work and difficult to get right. If the wood has a crook, it's best to joint the concave (curved inward) edge of the board. You are correct about the hard work part, but it. First, learn about the face using a pair of winding sticks and a straight edge of. How To Dimension Lumber With Hand Tools.

From www.animalia-life.club

Lumber Dimensions How To Dimension Lumber With Hand Tools You are correct about the hard work part, but it. How to square, flatten, & dimension your own rough lumber into finished boards. Dimensioning lumber by hand can seem like a lot of work and difficult to get right. The winding sticks will tell you if. How to flatten board with woodworking hand tools and power tools. First, learn about. How To Dimension Lumber With Hand Tools.

From www.dimensions.com

Lumber 4 x Dimensions & Drawings How To Dimension Lumber With Hand Tools How to square, flatten, & dimension your own rough lumber into finished boards. Dimensioning lumber or squaring timber (depending on what side of the pond you are on) can seam daunting when it comes to. First, learn about the face using a pair of winding sticks and a straight edge of a plane. The first thing to do is to. How To Dimension Lumber With Hand Tools.

From www.pinterest.fr

Pin on Sawmilling How To Dimension Lumber With Hand Tools This is because both the front and the. In step 7, i’ll talk about one of the most basic and essential skills in traditional woodworking: You are correct about the hard work part, but it. First, learn about the face using a pair of winding sticks and a straight edge of a plane. Dimensioning lumber or squaring timber (depending on. How To Dimension Lumber With Hand Tools.

From www.instructables.com

How to Sharpen Your Woodworking Tools With Sandpaper 9 Steps How To Dimension Lumber With Hand Tools Dimensioning lumber or squaring timber (depending on what side of the pond you are on) can seam daunting when it comes to. If the wood has a crook, it's best to joint the concave (curved inward) edge of the board. The winding sticks will tell you if. You are correct about the hard work part, but it. First, learn about. How To Dimension Lumber With Hand Tools.

From www.animalia-life.club

Lumber Dimensions How To Dimension Lumber With Hand Tools How to flatten board with woodworking hand tools and power tools. The winding sticks will tell you if. In step 7, i’ll talk about one of the most basic and essential skills in traditional woodworking: Dimensioning lumber by hand can seem like a lot of work and difficult to get right. Dimensioning lumber or squaring timber (depending on what side. How To Dimension Lumber With Hand Tools.

From www.homestratosphere.com

Epic Lumber Dimensions Guide and Charts (Softwood, Hardwood, Plywood) How To Dimension Lumber With Hand Tools The winding sticks will tell you if. How to square, flatten, & dimension your own rough lumber into finished boards. How to flatten board with woodworking hand tools and power tools. If the wood has a crook, it's best to joint the concave (curved inward) edge of the board. This is because both the front and the. Dimensioning lumber by. How To Dimension Lumber With Hand Tools.

From s3.amazonaws.com

Hardwood Lumber Sizes PDF Woodworking How To Dimension Lumber With Hand Tools How to flatten board with woodworking hand tools and power tools. If the wood has a crook, it's best to joint the concave (curved inward) edge of the board. You are correct about the hard work part, but it. The first thing to do is to get one edge flat. The winding sticks will tell you if. In step 7,. How To Dimension Lumber With Hand Tools.

From ceojggfp.blob.core.windows.net

How To Make Scale Model Lumber at Angie Casarez blog How To Dimension Lumber With Hand Tools The winding sticks will tell you if. How to square, flatten, & dimension your own rough lumber into finished boards. Dimensioning lumber or squaring timber (depending on what side of the pond you are on) can seam daunting when it comes to. How to flatten board with woodworking hand tools and power tools. The first thing to do is to. How To Dimension Lumber With Hand Tools.

From joifiylon.blob.core.windows.net

What Is Dimension Lumber Used For at Joanne Wetherington blog How To Dimension Lumber With Hand Tools In step 7, i’ll talk about one of the most basic and essential skills in traditional woodworking: Dimensioning lumber or squaring timber (depending on what side of the pond you are on) can seam daunting when it comes to. Dimensioning lumber by hand can seem like a lot of work and difficult to get right. You are correct about the. How To Dimension Lumber With Hand Tools.

From architectwisdom.com

Nominal vs Actual Lumber Sizes (with charts) How To Dimension Lumber With Hand Tools Dimensioning lumber by hand can seem like a lot of work and difficult to get right. If the wood has a crook, it's best to joint the concave (curved inward) edge of the board. The winding sticks will tell you if. This is because both the front and the. The first thing to do is to get one edge flat.. How To Dimension Lumber With Hand Tools.

From www.oldworldtimber.com

How To Prevent Your Lumber From Warping Blog How To Dimension Lumber With Hand Tools How to square, flatten, & dimension your own rough lumber into finished boards. If the wood has a crook, it's best to joint the concave (curved inward) edge of the board. How to flatten board with woodworking hand tools and power tools. Dimensioning lumber by hand can seem like a lot of work and difficult to get right. The first. How To Dimension Lumber With Hand Tools.

From www.nrcan.gc.ca

Dimension lumber How To Dimension Lumber With Hand Tools How to square, flatten, & dimension your own rough lumber into finished boards. This is because both the front and the. Dimensioning lumber or squaring timber (depending on what side of the pond you are on) can seam daunting when it comes to. You are correct about the hard work part, but it. Dimensioning lumber by hand can seem like. How To Dimension Lumber With Hand Tools.

From www.pinterest.com

square_dimension_boards_DSC8962 By Plane, Woodworking Hand Tools, Fa How To Dimension Lumber With Hand Tools If the wood has a crook, it's best to joint the concave (curved inward) edge of the board. How to square, flatten, & dimension your own rough lumber into finished boards. The winding sticks will tell you if. How to flatten board with woodworking hand tools and power tools. Dimensioning lumber by hand can seem like a lot of work. How To Dimension Lumber With Hand Tools.

From mavink.com

Standard Lumber Dimension Chart How To Dimension Lumber With Hand Tools You are correct about the hard work part, but it. The winding sticks will tell you if. If the wood has a crook, it's best to joint the concave (curved inward) edge of the board. The first thing to do is to get one edge flat. How to flatten board with woodworking hand tools and power tools. First, learn about. How To Dimension Lumber With Hand Tools.

From jeffsdiy.com

Dimensional Lumber Cheat Sheet Jeff's DIY Projects How To Dimension Lumber With Hand Tools You are correct about the hard work part, but it. How to square, flatten, & dimension your own rough lumber into finished boards. The first thing to do is to get one edge flat. The winding sticks will tell you if. How to flatten board with woodworking hand tools and power tools. This is because both the front and the.. How To Dimension Lumber With Hand Tools.

From www.pinterest.ca

Actual Size of Dimensional Lumber Nominal Sizes Explained How To Dimension Lumber With Hand Tools You are correct about the hard work part, but it. How to square, flatten, & dimension your own rough lumber into finished boards. Dimensioning lumber or squaring timber (depending on what side of the pond you are on) can seam daunting when it comes to. First, learn about the face using a pair of winding sticks and a straight edge. How To Dimension Lumber With Hand Tools.

From housefulofhandmade.com

Beginners Guide to Buying Lumber Houseful of Handmade How To Dimension Lumber With Hand Tools This is because both the front and the. First, learn about the face using a pair of winding sticks and a straight edge of a plane. Dimensioning lumber or squaring timber (depending on what side of the pond you are on) can seam daunting when it comes to. How to flatten board with woodworking hand tools and power tools. In. How To Dimension Lumber With Hand Tools.

From dylanbrowndesigns.com

Dimensional Lumber Guide Dylan Brown Designs How To Dimension Lumber With Hand Tools Dimensioning lumber or squaring timber (depending on what side of the pond you are on) can seam daunting when it comes to. The winding sticks will tell you if. In step 7, i’ll talk about one of the most basic and essential skills in traditional woodworking: If the wood has a crook, it's best to joint the concave (curved inward). How To Dimension Lumber With Hand Tools.

From wtrask.com

Bright Wood Dimension Lumber Warren Trask Company How To Dimension Lumber With Hand Tools First, learn about the face using a pair of winding sticks and a straight edge of a plane. This is because both the front and the. The winding sticks will tell you if. You are correct about the hard work part, but it. How to square, flatten, & dimension your own rough lumber into finished boards. If the wood has. How To Dimension Lumber With Hand Tools.

From www.pinterest.fr

When building projects with dimensional lumber, remember the size of How To Dimension Lumber With Hand Tools In step 7, i’ll talk about one of the most basic and essential skills in traditional woodworking: The first thing to do is to get one edge flat. If the wood has a crook, it's best to joint the concave (curved inward) edge of the board. Dimensioning lumber or squaring timber (depending on what side of the pond you are. How To Dimension Lumber With Hand Tools.

From www.pinterest.com

Lumber Sizes, Chainsaw Mill, Dimensional Lumber, Easy Woodworking How To Dimension Lumber With Hand Tools How to flatten board with woodworking hand tools and power tools. In step 7, i’ll talk about one of the most basic and essential skills in traditional woodworking: The winding sticks will tell you if. Dimensioning lumber or squaring timber (depending on what side of the pond you are on) can seam daunting when it comes to. The first thing. How To Dimension Lumber With Hand Tools.

From www.pinterest.com

lumber dimensions Converting Lumber Dimensions TM 7 Hardwood How To Dimension Lumber With Hand Tools You are correct about the hard work part, but it. Dimensioning lumber or squaring timber (depending on what side of the pond you are on) can seam daunting when it comes to. Dimensioning lumber by hand can seem like a lot of work and difficult to get right. How to square, flatten, & dimension your own rough lumber into finished. How To Dimension Lumber With Hand Tools.

From www.pinterest.com

Actual Sizes and Dimensions of Lumber Homesteady Plates on wall How To Dimension Lumber With Hand Tools This is because both the front and the. The winding sticks will tell you if. Dimensioning lumber or squaring timber (depending on what side of the pond you are on) can seam daunting when it comes to. The first thing to do is to get one edge flat. How to square, flatten, & dimension your own rough lumber into finished. How To Dimension Lumber With Hand Tools.

From www.familyhandyman.com

Making Sense of Lumber Dimensions Like 2x4 Dimensions How To Dimension Lumber With Hand Tools In step 7, i’ll talk about one of the most basic and essential skills in traditional woodworking: Dimensioning lumber by hand can seem like a lot of work and difficult to get right. This is because both the front and the. The first thing to do is to get one edge flat. The winding sticks will tell you if. Dimensioning. How To Dimension Lumber With Hand Tools.

From www.instructables.com

How to Dimension Lumber With Hand Tools 7 Steps (with Pictures How To Dimension Lumber With Hand Tools The winding sticks will tell you if. First, learn about the face using a pair of winding sticks and a straight edge of a plane. The first thing to do is to get one edge flat. If the wood has a crook, it's best to joint the concave (curved inward) edge of the board. Dimensioning lumber by hand can seem. How To Dimension Lumber With Hand Tools.

From www.animalia-life.club

Lumber Dimensions How To Dimension Lumber With Hand Tools In step 7, i’ll talk about one of the most basic and essential skills in traditional woodworking: First, learn about the face using a pair of winding sticks and a straight edge of a plane. How to square, flatten, & dimension your own rough lumber into finished boards. This is because both the front and the. The winding sticks will. How To Dimension Lumber With Hand Tools.