Worm Center Distance . for a pair of gears in mesh, the distance between the centers of the two gears (the minimum distance) is the center distance. the calculations for the geometry of a worm gear pair are dependent on several key parameters. This results in no crowning. worm gear formula table. l = lead of a worm which is the distance any one thread advances in a single revolution. There are fifteen standard lead angles: As shown below with the equation. Then the worm gear is finished. the size of the worm gearset is generally based on the centre distance between the worm and the wormwheel. Gear engineering and design data. the first step is to cut the worm gear at standard center distance. bearing distance from worm centre (see the figure) has a direct impact on worm deflection and thus on worm deflection.

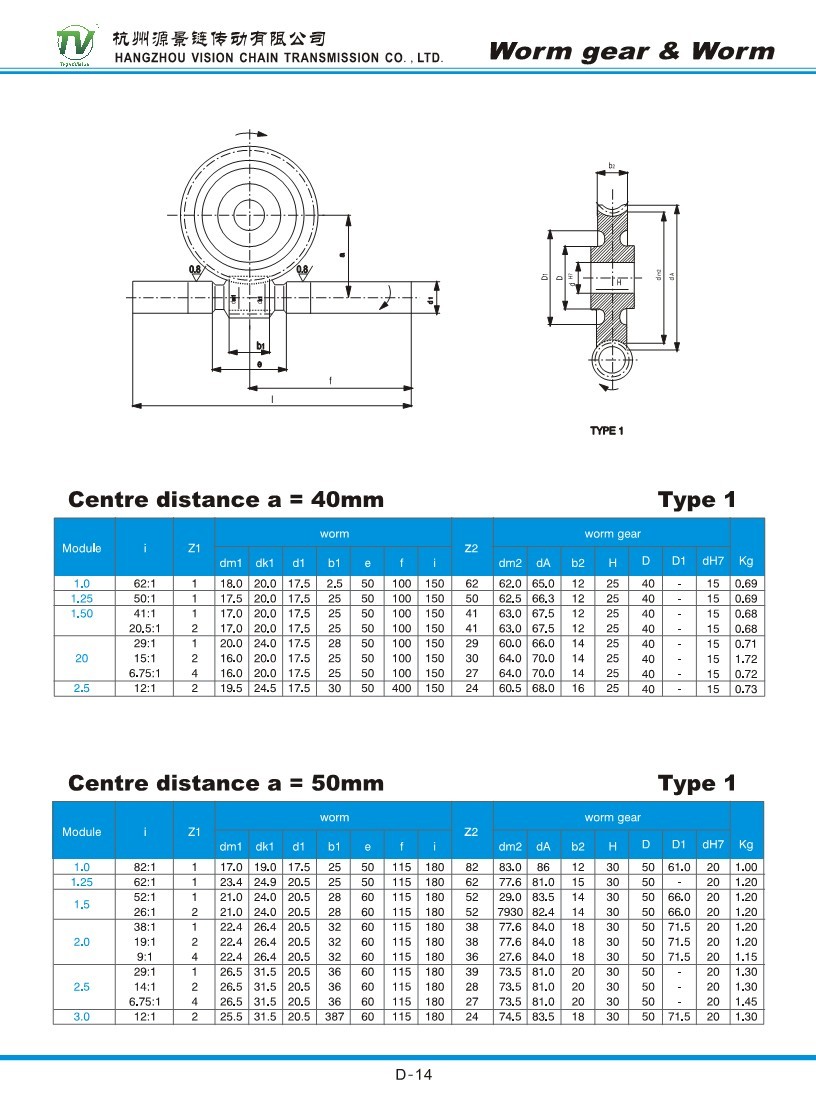

from www.tvchain.cn

This results in no crowning. Gear engineering and design data. the calculations for the geometry of a worm gear pair are dependent on several key parameters. worm gear formula table. bearing distance from worm centre (see the figure) has a direct impact on worm deflection and thus on worm deflection. Then the worm gear is finished. for a pair of gears in mesh, the distance between the centers of the two gears (the minimum distance) is the center distance. There are fifteen standard lead angles: the size of the worm gearset is generally based on the centre distance between the worm and the wormwheel. l = lead of a worm which is the distance any one thread advances in a single revolution.

50mm Center Distance Worm Gear and Worm,10 years manufacturing roller chain, sprockets

Worm Center Distance l = lead of a worm which is the distance any one thread advances in a single revolution. l = lead of a worm which is the distance any one thread advances in a single revolution. This results in no crowning. the size of the worm gearset is generally based on the centre distance between the worm and the wormwheel. As shown below with the equation. Gear engineering and design data. the calculations for the geometry of a worm gear pair are dependent on several key parameters. the first step is to cut the worm gear at standard center distance. There are fifteen standard lead angles: for a pair of gears in mesh, the distance between the centers of the two gears (the minimum distance) is the center distance. bearing distance from worm centre (see the figure) has a direct impact on worm deflection and thus on worm deflection. worm gear formula table. Then the worm gear is finished.

From www.indiamart.com

Worm Gear Center Distance Tester at Rs 275000/piece गियर रोल टेस्टर in Rajkot ID 2228756873 Worm Center Distance bearing distance from worm centre (see the figure) has a direct impact on worm deflection and thus on worm deflection. This results in no crowning. worm gear formula table. for a pair of gears in mesh, the distance between the centers of the two gears (the minimum distance) is the center distance. As shown below with the. Worm Center Distance.

From engineering.stackexchange.com

mechanical engineering Fixing center distance of worm gear Engineering Stack Exchange Worm Center Distance the size of the worm gearset is generally based on the centre distance between the worm and the wormwheel. the first step is to cut the worm gear at standard center distance. Then the worm gear is finished. This results in no crowning. As shown below with the equation. the calculations for the geometry of a worm. Worm Center Distance.

From grabcad.com

How to Calculate the Centre to CentreDistance between Worm and Wrom Wheel in Worm Gear Setup Worm Center Distance bearing distance from worm centre (see the figure) has a direct impact on worm deflection and thus on worm deflection. worm gear formula table. the calculations for the geometry of a worm gear pair are dependent on several key parameters. l = lead of a worm which is the distance any one thread advances in a. Worm Center Distance.

From sgrgear.en.made-in-china.com

Worm Gear Double Enveloping Worm Gear Worm Gearbox 280mm Center Distance China Gearbox and Worm Center Distance the size of the worm gearset is generally based on the centre distance between the worm and the wormwheel. bearing distance from worm centre (see the figure) has a direct impact on worm deflection and thus on worm deflection. This results in no crowning. Gear engineering and design data. As shown below with the equation. worm gear. Worm Center Distance.

From www.aliexpress.com

1m50t Inner Hole812mm Center Distance33mm Reduction Copper Worm Gear Reducer Transmission Worm Center Distance As shown below with the equation. This results in no crowning. Gear engineering and design data. bearing distance from worm centre (see the figure) has a direct impact on worm deflection and thus on worm deflection. Then the worm gear is finished. There are fifteen standard lead angles: the calculations for the geometry of a worm gear pair. Worm Center Distance.

From zjgele.en.made-in-china.com

Center Distance 30150mm Worm Gear Reducer with IEC Input Flange China Gear Unit and Speed Reducer Worm Center Distance for a pair of gears in mesh, the distance between the centers of the two gears (the minimum distance) is the center distance. This results in no crowning. the size of the worm gearset is generally based on the centre distance between the worm and the wormwheel. As shown below with the equation. the first step is. Worm Center Distance.

From www.researchgate.net

Describing the shapes of worms. (A) Raw image in the tracking... Download Scientific Diagram Worm Center Distance l = lead of a worm which is the distance any one thread advances in a single revolution. As shown below with the equation. the first step is to cut the worm gear at standard center distance. This results in no crowning. bearing distance from worm centre (see the figure) has a direct impact on worm deflection. Worm Center Distance.

From www.grainger.com

DAYTON, For 3.25 in Worm Center Distance, 182TC/184TC, Flange Coupling Kit 3A7103A710 Grainger Worm Center Distance There are fifteen standard lead angles: the size of the worm gearset is generally based on the centre distance between the worm and the wormwheel. the calculations for the geometry of a worm gear pair are dependent on several key parameters. This results in no crowning. Then the worm gear is finished. the first step is to. Worm Center Distance.

From www.indiamart.com

Worm Gear Center Distance Tester at Rs 275000/piece गियर रोल टेस्टर in Rajkot ID 2228756873 Worm Center Distance the size of the worm gearset is generally based on the centre distance between the worm and the wormwheel. There are fifteen standard lead angles: for a pair of gears in mesh, the distance between the centers of the two gears (the minimum distance) is the center distance. the first step is to cut the worm gear. Worm Center Distance.

From www.grainger.com

DAYTON Speed Reducer Mounting Base 2.37 in Worm Center Distance, Horizontal 4RN664RN66 Worm Center Distance for a pair of gears in mesh, the distance between the centers of the two gears (the minimum distance) is the center distance. Gear engineering and design data. the size of the worm gearset is generally based on the centre distance between the worm and the wormwheel. As shown below with the equation. This results in no crowning.. Worm Center Distance.

From www.researchgate.net

A. The distribution of 262 earthworms (black dots) that emerged from a... Download Scientific Worm Center Distance Gear engineering and design data. bearing distance from worm centre (see the figure) has a direct impact on worm deflection and thus on worm deflection. Then the worm gear is finished. This results in no crowning. for a pair of gears in mesh, the distance between the centers of the two gears (the minimum distance) is the center. Worm Center Distance.

From www.degruyter.com

Mathematical description of tooth flank surface of globoidal worm gear with straight axial tooth Worm Center Distance bearing distance from worm centre (see the figure) has a direct impact on worm deflection and thus on worm deflection. There are fifteen standard lead angles: Then the worm gear is finished. the size of the worm gearset is generally based on the centre distance between the worm and the wormwheel. l = lead of a worm. Worm Center Distance.

From www.researchgate.net

Chemotaxis vs. random capture a Schematic of breaking down a worm’s... Download Scientific Diagram Worm Center Distance This results in no crowning. Gear engineering and design data. the size of the worm gearset is generally based on the centre distance between the worm and the wormwheel. worm gear formula table. for a pair of gears in mesh, the distance between the centers of the two gears (the minimum distance) is the center distance. As. Worm Center Distance.

From www.chegg.com

Solved 5. Figure 5 shows that a 2tooth lefthand worm Worm Center Distance the calculations for the geometry of a worm gear pair are dependent on several key parameters. This results in no crowning. worm gear formula table. There are fifteen standard lead angles: As shown below with the equation. Gear engineering and design data. Then the worm gear is finished. the first step is to cut the worm gear. Worm Center Distance.

From sgrgear.en.made-in-china.com

Cast Iron Reducer Double Enveloping Worm Gearbox Transmission 225mm Center Distance China Worm Worm Center Distance As shown below with the equation. the calculations for the geometry of a worm gear pair are dependent on several key parameters. the size of the worm gearset is generally based on the centre distance between the worm and the wormwheel. Gear engineering and design data. worm gear formula table. bearing distance from worm centre (see. Worm Center Distance.

From www.researchgate.net

Worm gear test rig center distance a = 100 mm Download Scientific Diagram Worm Center Distance Gear engineering and design data. the first step is to cut the worm gear at standard center distance. This results in no crowning. l = lead of a worm which is the distance any one thread advances in a single revolution. There are fifteen standard lead angles: bearing distance from worm centre (see the figure) has a. Worm Center Distance.

From maedler.in

Precision worm centre distance 40mm i=50 SKU 32245000 Maedler India Worm Center Distance As shown below with the equation. the first step is to cut the worm gear at standard center distance. the size of the worm gearset is generally based on the centre distance between the worm and the wormwheel. This results in no crowning. bearing distance from worm centre (see the figure) has a direct impact on worm. Worm Center Distance.

From maedler.in

Precision worm centre distance 33mm i=14 SKU 32141400 Maedler India Worm Center Distance l = lead of a worm which is the distance any one thread advances in a single revolution. the size of the worm gearset is generally based on the centre distance between the worm and the wormwheel. for a pair of gears in mesh, the distance between the centers of the two gears (the minimum distance) is. Worm Center Distance.

From www.researchgate.net

Mean stiffness of single worms measured via AFM force spectroscopy.... Download Scientific Diagram Worm Center Distance As shown below with the equation. the first step is to cut the worm gear at standard center distance. There are fifteen standard lead angles: bearing distance from worm centre (see the figure) has a direct impact on worm deflection and thus on worm deflection. worm gear formula table. Gear engineering and design data. This results in. Worm Center Distance.

From sgrgear.en.made-in-china.com

Worm Gear Series Double Enveloping Worm Gear Worm Gearbox 225mm Center Distance China Gearbox Worm Center Distance This results in no crowning. There are fifteen standard lead angles: the first step is to cut the worm gear at standard center distance. worm gear formula table. l = lead of a worm which is the distance any one thread advances in a single revolution. the size of the worm gearset is generally based on. Worm Center Distance.

From www.youtube.com

Worm Gear terminology/Nomenclature and velocity ratio YouTube Worm Center Distance This results in no crowning. l = lead of a worm which is the distance any one thread advances in a single revolution. As shown below with the equation. the calculations for the geometry of a worm gear pair are dependent on several key parameters. There are fifteen standard lead angles: worm gear formula table. Then the. Worm Center Distance.

From ptbestaribiology.blogspot.com

Biology Movement of Earthworm Worm Center Distance the size of the worm gearset is generally based on the centre distance between the worm and the wormwheel. Then the worm gear is finished. bearing distance from worm centre (see the figure) has a direct impact on worm deflection and thus on worm deflection. for a pair of gears in mesh, the distance between the centers. Worm Center Distance.

From maedlernorthamerica.com

Precision worm centre distance 17mm i=7 SKU 32010700 Maedler North America Worm Center Distance the calculations for the geometry of a worm gear pair are dependent on several key parameters. bearing distance from worm centre (see the figure) has a direct impact on worm deflection and thus on worm deflection. This results in no crowning. worm gear formula table. There are fifteen standard lead angles: Gear engineering and design data. . Worm Center Distance.

From unimaterna.com.br

Precision worm wheel centre distance 31mm i=7 28 teeth Industrial & Scientific Worm Center Distance bearing distance from worm centre (see the figure) has a direct impact on worm deflection and thus on worm deflection. l = lead of a worm which is the distance any one thread advances in a single revolution. There are fifteen standard lead angles: for a pair of gears in mesh, the distance between the centers of. Worm Center Distance.

From dxosymfpt.blob.core.windows.net

Worm Wheel Gear Ratio Calculation at Lucille Behan blog Worm Center Distance l = lead of a worm which is the distance any one thread advances in a single revolution. This results in no crowning. bearing distance from worm centre (see the figure) has a direct impact on worm deflection and thus on worm deflection. the size of the worm gearset is generally based on the centre distance between. Worm Center Distance.

From www.indiamart.com

Worm Gear Center Distance Tester at Rs 275000/piece गियर रोल टेस्टर in Rajkot ID 2228756873 Worm Center Distance the calculations for the geometry of a worm gear pair are dependent on several key parameters. the size of the worm gearset is generally based on the centre distance between the worm and the wormwheel. This results in no crowning. Then the worm gear is finished. There are fifteen standard lead angles: worm gear formula table. . Worm Center Distance.

From www.raptorsupplies.com

Dayton 1A507 Speed Reducer Mounting Base, 2.62 Inch Worm Center Distance, Horizontal Worm Center Distance worm gear formula table. l = lead of a worm which is the distance any one thread advances in a single revolution. As shown below with the equation. This results in no crowning. for a pair of gears in mesh, the distance between the centers of the two gears (the minimum distance) is the center distance. . Worm Center Distance.

From www.chegg.com

Solved Problem 1 A wormgear has 50 teeth and a transverse Worm Center Distance This results in no crowning. the calculations for the geometry of a worm gear pair are dependent on several key parameters. the first step is to cut the worm gear at standard center distance. Gear engineering and design data. bearing distance from worm centre (see the figure) has a direct impact on worm deflection and thus on. Worm Center Distance.

From www.grainger.com

WINSMITH, For 2 in Worm Center Distance, 24 in Max Arm Lg, Torque Arm Kit 3XJF9E20MWSS Worm Center Distance the calculations for the geometry of a worm gear pair are dependent on several key parameters. There are fifteen standard lead angles: l = lead of a worm which is the distance any one thread advances in a single revolution. This results in no crowning. bearing distance from worm centre (see the figure) has a direct impact. Worm Center Distance.

From exoyqkhax.blob.core.windows.net

Worm Gear System Efficiency at Larry London blog Worm Center Distance for a pair of gears in mesh, the distance between the centers of the two gears (the minimum distance) is the center distance. There are fifteen standard lead angles: the size of the worm gearset is generally based on the centre distance between the worm and the wormwheel. Gear engineering and design data. Then the worm gear is. Worm Center Distance.

From heremup766.weebly.com

Worm Gear Design Calculation Pdf heremup Worm Center Distance the size of the worm gearset is generally based on the centre distance between the worm and the wormwheel. Then the worm gear is finished. bearing distance from worm centre (see the figure) has a direct impact on worm deflection and thus on worm deflection. the first step is to cut the worm gear at standard center. Worm Center Distance.

From www.youtube.com

Worm Gear Center Distance and Efficiency YouTube Worm Center Distance Then the worm gear is finished. worm gear formula table. There are fifteen standard lead angles: the first step is to cut the worm gear at standard center distance. This results in no crowning. l = lead of a worm which is the distance any one thread advances in a single revolution. for a pair of. Worm Center Distance.

From www.indiamart.com

Worm Gear Center Distance Tester at Rs 275000/piece गियर रोल टेस्टर in Rajkot ID 2228756873 Worm Center Distance the calculations for the geometry of a worm gear pair are dependent on several key parameters. worm gear formula table. As shown below with the equation. bearing distance from worm centre (see the figure) has a direct impact on worm deflection and thus on worm deflection. for a pair of gears in mesh, the distance between. Worm Center Distance.

From www.youtube.com

Worm and Worm Gear Design in SolidWorks 2022 Part 1 (Worm Gear) beginner’s guide to Worm Center Distance This results in no crowning. Then the worm gear is finished. As shown below with the equation. Gear engineering and design data. bearing distance from worm centre (see the figure) has a direct impact on worm deflection and thus on worm deflection. for a pair of gears in mesh, the distance between the centers of the two gears. Worm Center Distance.

From www.tvchain.cn

50mm Center Distance Worm Gear and Worm,10 years manufacturing roller chain, sprockets Worm Center Distance worm gear formula table. l = lead of a worm which is the distance any one thread advances in a single revolution. As shown below with the equation. There are fifteen standard lead angles: Then the worm gear is finished. This results in no crowning. the first step is to cut the worm gear at standard center. Worm Center Distance.