What Is A Manifold In Injection Molding . In addition, it comes in different shapes and sizes depending on the number. The hot runner injection molding system is an injection molding where plastic is injected through a heated manifold system to deliver plastic directly into each. A hot runner mold consists of two heated plates with a manifold system (ie, containing heating components, manifolds, and nozzles). The manifolds are the channels that distribute molten plastic from the nozzle to the different mold cavities. Flow control refers to the use of valve gate technology to control the plastic melt flow. Manifolds are normally used where multiple cavities are. The main task of the hot runner manifold is to distribute the plastic material into different nozzles.

from www.directindustry.com

Flow control refers to the use of valve gate technology to control the plastic melt flow. In addition, it comes in different shapes and sizes depending on the number. A hot runner mold consists of two heated plates with a manifold system (ie, containing heating components, manifolds, and nozzles). The hot runner injection molding system is an injection molding where plastic is injected through a heated manifold system to deliver plastic directly into each. Manifolds are normally used where multiple cavities are. The manifolds are the channels that distribute molten plastic from the nozzle to the different mold cavities. The main task of the hot runner manifold is to distribute the plastic material into different nozzles.

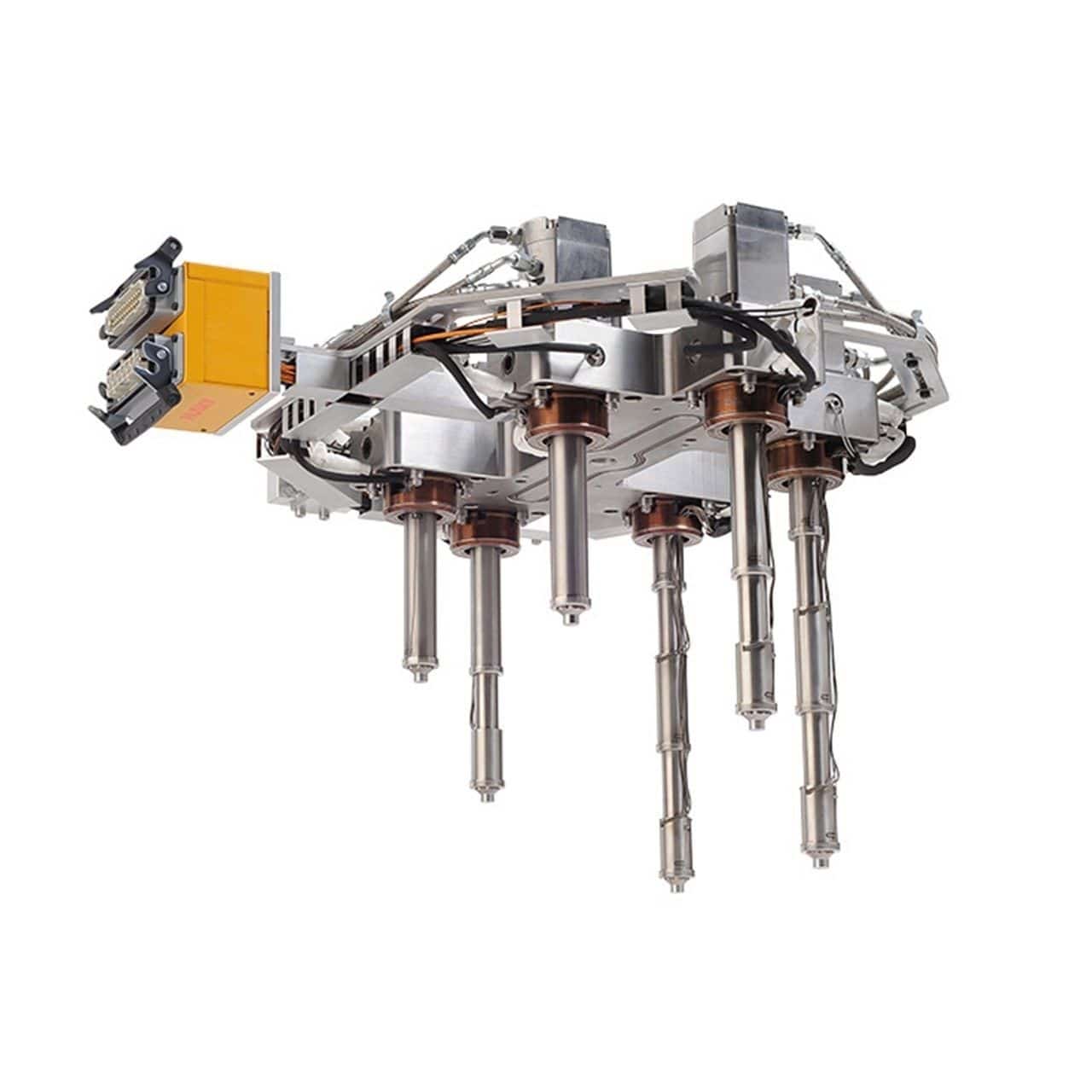

Hot runner manifold UNIFY™ HUSKY INJECTION MOLDING SYSTEMS

What Is A Manifold In Injection Molding A hot runner mold consists of two heated plates with a manifold system (ie, containing heating components, manifolds, and nozzles). The main task of the hot runner manifold is to distribute the plastic material into different nozzles. A hot runner mold consists of two heated plates with a manifold system (ie, containing heating components, manifolds, and nozzles). In addition, it comes in different shapes and sizes depending on the number. The manifolds are the channels that distribute molten plastic from the nozzle to the different mold cavities. Flow control refers to the use of valve gate technology to control the plastic melt flow. Manifolds are normally used where multiple cavities are. The hot runner injection molding system is an injection molding where plastic is injected through a heated manifold system to deliver plastic directly into each.

From darrow.en.made-in-china.com

Injection Mold for Air Intake Manifold Injection Molding and Plastic What Is A Manifold In Injection Molding In addition, it comes in different shapes and sizes depending on the number. Flow control refers to the use of valve gate technology to control the plastic melt flow. The hot runner injection molding system is an injection molding where plastic is injected through a heated manifold system to deliver plastic directly into each. The main task of the hot. What Is A Manifold In Injection Molding.

From china-plastic-injection-molding.com

How Does Plastic Injection Molding Work? What Is A Manifold In Injection Molding The hot runner injection molding system is an injection molding where plastic is injected through a heated manifold system to deliver plastic directly into each. A hot runner mold consists of two heated plates with a manifold system (ie, containing heating components, manifolds, and nozzles). The main task of the hot runner manifold is to distribute the plastic material into. What Is A Manifold In Injection Molding.

From polyshot.com

Hot Runner Manifold Advanced Injection Molding Solutions What Is A Manifold In Injection Molding The hot runner injection molding system is an injection molding where plastic is injected through a heated manifold system to deliver plastic directly into each. Manifolds are normally used where multiple cavities are. The manifolds are the channels that distribute molten plastic from the nozzle to the different mold cavities. The main task of the hot runner manifold is to. What Is A Manifold In Injection Molding.

From mungfali.com

Injection Molding Water Manifolds What Is A Manifold In Injection Molding Manifolds are normally used where multiple cavities are. In addition, it comes in different shapes and sizes depending on the number. The main task of the hot runner manifold is to distribute the plastic material into different nozzles. The manifolds are the channels that distribute molten plastic from the nozzle to the different mold cavities. A hot runner mold consists. What Is A Manifold In Injection Molding.

From www.youtube.com

What is a Manifold? YouTube What Is A Manifold In Injection Molding Manifolds are normally used where multiple cavities are. Flow control refers to the use of valve gate technology to control the plastic melt flow. In addition, it comes in different shapes and sizes depending on the number. A hot runner mold consists of two heated plates with a manifold system (ie, containing heating components, manifolds, and nozzles). The hot runner. What Is A Manifold In Injection Molding.

From www.dgmfmoldclamps.com

Aluminum Water Manifolds For Plastic Injection Molds Mold Components What Is A Manifold In Injection Molding Flow control refers to the use of valve gate technology to control the plastic melt flow. In addition, it comes in different shapes and sizes depending on the number. The main task of the hot runner manifold is to distribute the plastic material into different nozzles. The manifolds are the channels that distribute molten plastic from the nozzle to the. What Is A Manifold In Injection Molding.

From lhrtechserv.com

Hot Runner Tooling Injection Molding LHR Technical Service What Is A Manifold In Injection Molding Manifolds are normally used where multiple cavities are. The main task of the hot runner manifold is to distribute the plastic material into different nozzles. In addition, it comes in different shapes and sizes depending on the number. A hot runner mold consists of two heated plates with a manifold system (ie, containing heating components, manifolds, and nozzles). The hot. What Is A Manifold In Injection Molding.

From www.youtube.com

Automotive Air Intake Manifold Injection molding / injection moulding What Is A Manifold In Injection Molding Manifolds are normally used where multiple cavities are. Flow control refers to the use of valve gate technology to control the plastic melt flow. The hot runner injection molding system is an injection molding where plastic is injected through a heated manifold system to deliver plastic directly into each. In addition, it comes in different shapes and sizes depending on. What Is A Manifold In Injection Molding.

From www.kydmold.com

Hot Manifold Plastic Multi Cavity Mold Die Medical Plastic Injection What Is A Manifold In Injection Molding The manifolds are the channels that distribute molten plastic from the nozzle to the different mold cavities. Flow control refers to the use of valve gate technology to control the plastic melt flow. The hot runner injection molding system is an injection molding where plastic is injected through a heated manifold system to deliver plastic directly into each. Manifolds are. What Is A Manifold In Injection Molding.

From www.dgmfmoldclamps.com

Aluminum Water Manifolds For Plastic Injection Molds Mold Components What Is A Manifold In Injection Molding A hot runner mold consists of two heated plates with a manifold system (ie, containing heating components, manifolds, and nozzles). The main task of the hot runner manifold is to distribute the plastic material into different nozzles. Flow control refers to the use of valve gate technology to control the plastic melt flow. The hot runner injection molding system is. What Is A Manifold In Injection Molding.

From www.nexpcb.com

One Picture to Understand the Structure of an Injection Mold What Is A Manifold In Injection Molding Manifolds are normally used where multiple cavities are. A hot runner mold consists of two heated plates with a manifold system (ie, containing heating components, manifolds, and nozzles). In addition, it comes in different shapes and sizes depending on the number. The hot runner injection molding system is an injection molding where plastic is injected through a heated manifold system. What Is A Manifold In Injection Molding.

From www.moldchina.com

Hot runner system types and their application in plastic injection mold What Is A Manifold In Injection Molding A hot runner mold consists of two heated plates with a manifold system (ie, containing heating components, manifolds, and nozzles). The manifolds are the channels that distribute molten plastic from the nozzle to the different mold cavities. The hot runner injection molding system is an injection molding where plastic is injected through a heated manifold system to deliver plastic directly. What Is A Manifold In Injection Molding.

From www.viewmold.com

CITO water manifold What Is A Manifold In Injection Molding Manifolds are normally used where multiple cavities are. A hot runner mold consists of two heated plates with a manifold system (ie, containing heating components, manifolds, and nozzles). Flow control refers to the use of valve gate technology to control the plastic melt flow. In addition, it comes in different shapes and sizes depending on the number. The main task. What Is A Manifold In Injection Molding.

From lhrtechserv.com

Hot Runner Tooling Injection Molding LHR Technical Service What Is A Manifold In Injection Molding Flow control refers to the use of valve gate technology to control the plastic melt flow. The main task of the hot runner manifold is to distribute the plastic material into different nozzles. A hot runner mold consists of two heated plates with a manifold system (ie, containing heating components, manifolds, and nozzles). In addition, it comes in different shapes. What Is A Manifold In Injection Molding.

From telonmould.en.made-in-china.com

Auto Air Intake Manifold Plastic Injection Molding China Injection What Is A Manifold In Injection Molding The manifolds are the channels that distribute molten plastic from the nozzle to the different mold cavities. The hot runner injection molding system is an injection molding where plastic is injected through a heated manifold system to deliver plastic directly into each. Flow control refers to the use of valve gate technology to control the plastic melt flow. Manifolds are. What Is A Manifold In Injection Molding.

From fazziosurplus.com

Plastixs 6Port Injection Molding Manifold 1/2" Valves, 13" Joseph What Is A Manifold In Injection Molding The manifolds are the channels that distribute molten plastic from the nozzle to the different mold cavities. The hot runner injection molding system is an injection molding where plastic is injected through a heated manifold system to deliver plastic directly into each. The main task of the hot runner manifold is to distribute the plastic material into different nozzles. In. What Is A Manifold In Injection Molding.

From fazziosurplus.com

Plastixs 6Port Injection Molding Manifold 1/2" Valves, 13" Joseph What Is A Manifold In Injection Molding In addition, it comes in different shapes and sizes depending on the number. Manifolds are normally used where multiple cavities are. Flow control refers to the use of valve gate technology to control the plastic melt flow. The hot runner injection molding system is an injection molding where plastic is injected through a heated manifold system to deliver plastic directly. What Is A Manifold In Injection Molding.

From www.linkedin.com

Water manifold at plastic injection mold What Is A Manifold In Injection Molding The manifolds are the channels that distribute molten plastic from the nozzle to the different mold cavities. In addition, it comes in different shapes and sizes depending on the number. Manifolds are normally used where multiple cavities are. The main task of the hot runner manifold is to distribute the plastic material into different nozzles. Flow control refers to the. What Is A Manifold In Injection Molding.

From www.industrialtoolingservices.com

Manifolds Manifold for Injection Molding Manufacturer from Chennai What Is A Manifold In Injection Molding In addition, it comes in different shapes and sizes depending on the number. A hot runner mold consists of two heated plates with a manifold system (ie, containing heating components, manifolds, and nozzles). The main task of the hot runner manifold is to distribute the plastic material into different nozzles. Flow control refers to the use of valve gate technology. What Is A Manifold In Injection Molding.

From www.emicorp.com

Bronze Water Manifolds for Plastic Injection Molding EMI Corp What Is A Manifold In Injection Molding In addition, it comes in different shapes and sizes depending on the number. The manifolds are the channels that distribute molten plastic from the nozzle to the different mold cavities. The hot runner injection molding system is an injection molding where plastic is injected through a heated manifold system to deliver plastic directly into each. Manifolds are normally used where. What Is A Manifold In Injection Molding.

From fazziosurplus.com

Plastixs 6Port Injection Molding Manifold 1/2" Valves, 13" Joseph What Is A Manifold In Injection Molding In addition, it comes in different shapes and sizes depending on the number. Flow control refers to the use of valve gate technology to control the plastic melt flow. A hot runner mold consists of two heated plates with a manifold system (ie, containing heating components, manifolds, and nozzles). The hot runner injection molding system is an injection molding where. What Is A Manifold In Injection Molding.

From fazziosurplus.com

Plastixs 6Port Injection Molding Manifold 1/2" Valves, 13" Joseph What Is A Manifold In Injection Molding Manifolds are normally used where multiple cavities are. The manifolds are the channels that distribute molten plastic from the nozzle to the different mold cavities. Flow control refers to the use of valve gate technology to control the plastic melt flow. A hot runner mold consists of two heated plates with a manifold system (ie, containing heating components, manifolds, and. What Is A Manifold In Injection Molding.

From www.dasformen.com

Plastic Injection Mold Components Overview DasFormen Shop What Is A Manifold In Injection Molding Manifolds are normally used where multiple cavities are. The main task of the hot runner manifold is to distribute the plastic material into different nozzles. In addition, it comes in different shapes and sizes depending on the number. A hot runner mold consists of two heated plates with a manifold system (ie, containing heating components, manifolds, and nozzles). The manifolds. What Is A Manifold In Injection Molding.

From www.moldmasters.com

What is a hot runner? Mold Masters What Is A Manifold In Injection Molding A hot runner mold consists of two heated plates with a manifold system (ie, containing heating components, manifolds, and nozzles). The hot runner injection molding system is an injection molding where plastic is injected through a heated manifold system to deliver plastic directly into each. The manifolds are the channels that distribute molten plastic from the nozzle to the different. What Is A Manifold In Injection Molding.

From www.ace-mold.com

3 Types of hot runner mold Injection Molding System What Is A Manifold In Injection Molding Manifolds are normally used where multiple cavities are. The manifolds are the channels that distribute molten plastic from the nozzle to the different mold cavities. The main task of the hot runner manifold is to distribute the plastic material into different nozzles. In addition, it comes in different shapes and sizes depending on the number. A hot runner mold consists. What Is A Manifold In Injection Molding.

From www.echosupply.com

Injection Molding Basics Hot Runner Systems Echo Supply What Is A Manifold In Injection Molding The manifolds are the channels that distribute molten plastic from the nozzle to the different mold cavities. The main task of the hot runner manifold is to distribute the plastic material into different nozzles. A hot runner mold consists of two heated plates with a manifold system (ie, containing heating components, manifolds, and nozzles). The hot runner injection molding system. What Is A Manifold In Injection Molding.

From www.directindustry.com

Hot runner manifold UNIFY™ HUSKY INJECTION MOLDING SYSTEMS What Is A Manifold In Injection Molding Flow control refers to the use of valve gate technology to control the plastic melt flow. A hot runner mold consists of two heated plates with a manifold system (ie, containing heating components, manifolds, and nozzles). In addition, it comes in different shapes and sizes depending on the number. The hot runner injection molding system is an injection molding where. What Is A Manifold In Injection Molding.

From www.controlledfluidics.com

Injection Molded Manifolds For Challenging Configurations What Is A Manifold In Injection Molding The main task of the hot runner manifold is to distribute the plastic material into different nozzles. Manifolds are normally used where multiple cavities are. Flow control refers to the use of valve gate technology to control the plastic melt flow. The hot runner injection molding system is an injection molding where plastic is injected through a heated manifold system. What Is A Manifold In Injection Molding.

From www.improve-your-injection-molding.com

Hot Runner Mold Benefits What Is A Manifold In Injection Molding The main task of the hot runner manifold is to distribute the plastic material into different nozzles. The hot runner injection molding system is an injection molding where plastic is injected through a heated manifold system to deliver plastic directly into each. In addition, it comes in different shapes and sizes depending on the number. Flow control refers to the. What Is A Manifold In Injection Molding.

From fazziosurplus.com

Plastixs 6Port Injection Molding Manifold 1/2" Valves, 13" Joseph What Is A Manifold In Injection Molding The main task of the hot runner manifold is to distribute the plastic material into different nozzles. The hot runner injection molding system is an injection molding where plastic is injected through a heated manifold system to deliver plastic directly into each. A hot runner mold consists of two heated plates with a manifold system (ie, containing heating components, manifolds,. What Is A Manifold In Injection Molding.

From fazziosurplus.com

Plastixs 6Port Injection Molding Manifold 1/2" Valves, 13" Joseph What Is A Manifold In Injection Molding The hot runner injection molding system is an injection molding where plastic is injected through a heated manifold system to deliver plastic directly into each. A hot runner mold consists of two heated plates with a manifold system (ie, containing heating components, manifolds, and nozzles). Flow control refers to the use of valve gate technology to control the plastic melt. What Is A Manifold In Injection Molding.

From techsavvy.co.in

Sole Guide about PLASTIC INJECTION MOLDS TechSavvy Engineers What Is A Manifold In Injection Molding The hot runner injection molding system is an injection molding where plastic is injected through a heated manifold system to deliver plastic directly into each. The manifolds are the channels that distribute molten plastic from the nozzle to the different mold cavities. In addition, it comes in different shapes and sizes depending on the number. A hot runner mold consists. What Is A Manifold In Injection Molding.

From www.youtube.com

HOT RUNNER SYSTEM AND ITS FUNCTION INJECTION MOLDING YouTube What Is A Manifold In Injection Molding A hot runner mold consists of two heated plates with a manifold system (ie, containing heating components, manifolds, and nozzles). The manifolds are the channels that distribute molten plastic from the nozzle to the different mold cavities. Flow control refers to the use of valve gate technology to control the plastic melt flow. The hot runner injection molding system is. What Is A Manifold In Injection Molding.

From www.arptech.com.au

Injection Moulding Process Explained ArpTechBlog What Is A Manifold In Injection Molding A hot runner mold consists of two heated plates with a manifold system (ie, containing heating components, manifolds, and nozzles). Manifolds are normally used where multiple cavities are. Flow control refers to the use of valve gate technology to control the plastic melt flow. In addition, it comes in different shapes and sizes depending on the number. The hot runner. What Is A Manifold In Injection Molding.

From themechanicalengineering.com

Injection Molding Definition, Construction, Working Process What Is A Manifold In Injection Molding The main task of the hot runner manifold is to distribute the plastic material into different nozzles. Manifolds are normally used where multiple cavities are. Flow control refers to the use of valve gate technology to control the plastic melt flow. A hot runner mold consists of two heated plates with a manifold system (ie, containing heating components, manifolds, and. What Is A Manifold In Injection Molding.