Tungsten Electrode For Tig Welding Aluminum . They have good arc stability, long. Zirconiated tungsten (white) is good for welding aluminum and magnesium alloys. 0.8% zirconiated (white) the 0.8% zirconiated (opens in a new window) electrodes are renowned for their extremely stable arc, high resistance to contamination, and resistance to tungsten. The various additions to the tungsten electrode serve two purposes. Which size and type of tungsten electrode should you use to gas tungsten arc weld (gtaw) aluminum? Thus, it is important that the tig tungsten size be selected carefully to add to the quality of the weld. From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. First, it makes the tungsten less likely to sag or droop at high temperatures.

from hogaki.com

They have good arc stability, long. First, it makes the tungsten less likely to sag or droop at high temperatures. From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. The various additions to the tungsten electrode serve two purposes. 0.8% zirconiated (white) the 0.8% zirconiated (opens in a new window) electrodes are renowned for their extremely stable arc, high resistance to contamination, and resistance to tungsten. Which size and type of tungsten electrode should you use to gas tungsten arc weld (gtaw) aluminum? Zirconiated tungsten (white) is good for welding aluminum and magnesium alloys. Thus, it is important that the tig tungsten size be selected carefully to add to the quality of the weld.

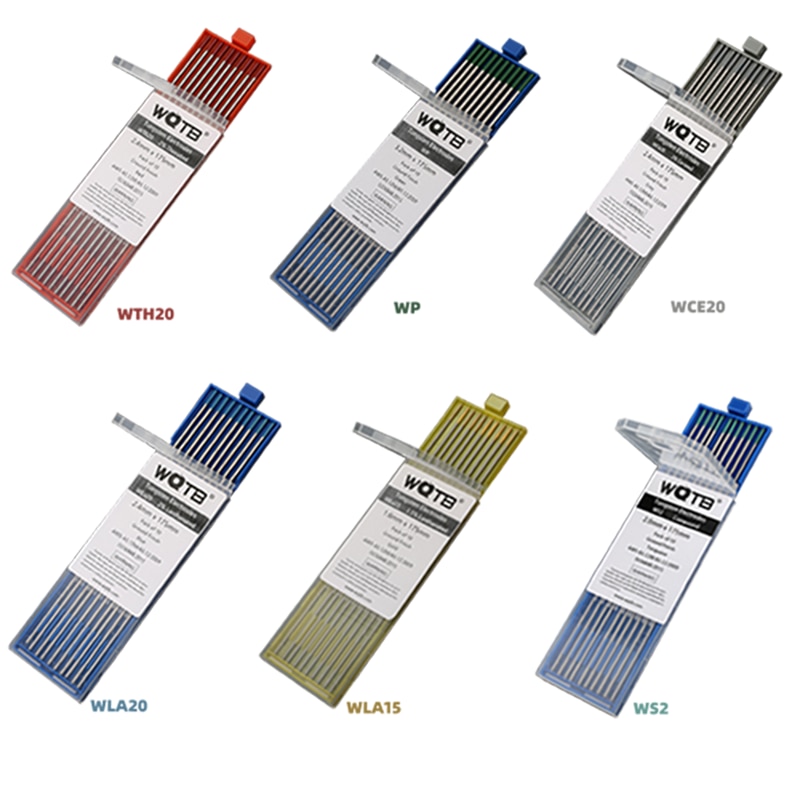

WQTB Tungsten Electrodes TIG Tungsten Rods WT20 Wl15 WL20 WC20 WZR8 WP

Tungsten Electrode For Tig Welding Aluminum Thus, it is important that the tig tungsten size be selected carefully to add to the quality of the weld. They have good arc stability, long. 0.8% zirconiated (white) the 0.8% zirconiated (opens in a new window) electrodes are renowned for their extremely stable arc, high resistance to contamination, and resistance to tungsten. Which size and type of tungsten electrode should you use to gas tungsten arc weld (gtaw) aluminum? First, it makes the tungsten less likely to sag or droop at high temperatures. From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. Zirconiated tungsten (white) is good for welding aluminum and magnesium alloys. The various additions to the tungsten electrode serve two purposes. Thus, it is important that the tig tungsten size be selected carefully to add to the quality of the weld.

From ar.inspiredpencil.com

Tungsten Electrodes For Tig Welding Tungsten Electrode For Tig Welding Aluminum 0.8% zirconiated (white) the 0.8% zirconiated (opens in a new window) electrodes are renowned for their extremely stable arc, high resistance to contamination, and resistance to tungsten. Which size and type of tungsten electrode should you use to gas tungsten arc weld (gtaw) aluminum? The various additions to the tungsten electrode serve two purposes. Thus, it is important that the. Tungsten Electrode For Tig Welding Aluminum.

From alexnld.com

10Pcs 3/32inch x 7inch (2.4x175mm) RED WT20 2 Thoriated Tungsten Tungsten Electrode For Tig Welding Aluminum Thus, it is important that the tig tungsten size be selected carefully to add to the quality of the weld. Which size and type of tungsten electrode should you use to gas tungsten arc weld (gtaw) aluminum? 0.8% zirconiated (white) the 0.8% zirconiated (opens in a new window) electrodes are renowned for their extremely stable arc, high resistance to contamination,. Tungsten Electrode For Tig Welding Aluminum.

From yeswelder.com

How To Shape Tungsten Electrode For TIG Welding YesWelder Tungsten Electrode For Tig Welding Aluminum Zirconiated tungsten (white) is good for welding aluminum and magnesium alloys. From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. Thus, it is important that the tig tungsten size be selected carefully to add to the quality of the weld. Which size and type of tungsten electrode should. Tungsten Electrode For Tig Welding Aluminum.

From weldsmartly.com

10 Best Tungsten For Aluminum Welding [Extensive Guide] Tungsten Electrode For Tig Welding Aluminum Which size and type of tungsten electrode should you use to gas tungsten arc weld (gtaw) aluminum? 0.8% zirconiated (white) the 0.8% zirconiated (opens in a new window) electrodes are renowned for their extremely stable arc, high resistance to contamination, and resistance to tungsten. They have good arc stability, long. Thus, it is important that the tig tungsten size be. Tungsten Electrode For Tig Welding Aluminum.

From www.amazon.ca

3mirrors ALUMINUM Tungsten Electrode Sharpener Grinder Head TIG Welding Tungsten Electrode For Tig Welding Aluminum Thus, it is important that the tig tungsten size be selected carefully to add to the quality of the weld. 0.8% zirconiated (white) the 0.8% zirconiated (opens in a new window) electrodes are renowned for their extremely stable arc, high resistance to contamination, and resistance to tungsten. First, it makes the tungsten less likely to sag or droop at high. Tungsten Electrode For Tig Welding Aluminum.

From www.aliexpress.com

10Pcs TIG Welding Tungsten Electrodes Rod Mayitr 2 Thoriated Tungsten Tungsten Electrode For Tig Welding Aluminum They have good arc stability, long. First, it makes the tungsten less likely to sag or droop at high temperatures. Zirconiated tungsten (white) is good for welding aluminum and magnesium alloys. The various additions to the tungsten electrode serve two purposes. Thus, it is important that the tig tungsten size be selected carefully to add to the quality of the. Tungsten Electrode For Tig Welding Aluminum.

From shop.tungsten.com

Sharpened Tungsten TIG Welding Electrodes Midwest Tungsten Service Tungsten Electrode For Tig Welding Aluminum First, it makes the tungsten less likely to sag or droop at high temperatures. 0.8% zirconiated (white) the 0.8% zirconiated (opens in a new window) electrodes are renowned for their extremely stable arc, high resistance to contamination, and resistance to tungsten. Which size and type of tungsten electrode should you use to gas tungsten arc weld (gtaw) aluminum? From providing. Tungsten Electrode For Tig Welding Aluminum.

From www.weldfabworld.com

Tungsten Electrodes For TIG (with Color Chart) Welding Fabrication World Tungsten Electrode For Tig Welding Aluminum First, it makes the tungsten less likely to sag or droop at high temperatures. They have good arc stability, long. The various additions to the tungsten electrode serve two purposes. Which size and type of tungsten electrode should you use to gas tungsten arc weld (gtaw) aluminum? From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes. Tungsten Electrode For Tig Welding Aluminum.

From hogaki.com

WQTB Tungsten Electrodes TIG Tungsten Rods WT20 Wl15 WL20 WC20 WZR8 WP Tungsten Electrode For Tig Welding Aluminum They have good arc stability, long. The various additions to the tungsten electrode serve two purposes. From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. 0.8% zirconiated (white) the 0.8% zirconiated (opens in a new window) electrodes are renowned for their extremely stable arc, high resistance to contamination,. Tungsten Electrode For Tig Welding Aluminum.

From www.weldingcity.com

TIG Welding 10pk 2 Ceriated (Grey) Tungsten Electrode 5/32" (4.0mm) Tungsten Electrode For Tig Welding Aluminum Zirconiated tungsten (white) is good for welding aluminum and magnesium alloys. They have good arc stability, long. Thus, it is important that the tig tungsten size be selected carefully to add to the quality of the weld. 0.8% zirconiated (white) the 0.8% zirconiated (opens in a new window) electrodes are renowned for their extremely stable arc, high resistance to contamination,. Tungsten Electrode For Tig Welding Aluminum.

From www.intibangunan.com

Tig Welding Tungsten Electrodes PT. INTI BANGUNAN PERKASA Tungsten Electrode For Tig Welding Aluminum 0.8% zirconiated (white) the 0.8% zirconiated (opens in a new window) electrodes are renowned for their extremely stable arc, high resistance to contamination, and resistance to tungsten. From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. They have good arc stability, long. Zirconiated tungsten (white) is good for. Tungsten Electrode For Tig Welding Aluminum.

From hogaki.com

WQTB Tungsten Electrodes TIG Tungsten Rods WT20 Wl15 WL20 WC20 WZR8 WP Tungsten Electrode For Tig Welding Aluminum From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. They have good arc stability, long. First, it makes the tungsten less likely to sag or droop at high temperatures. 0.8% zirconiated (white) the 0.8% zirconiated (opens in a new window) electrodes are renowned for their extremely stable arc,. Tungsten Electrode For Tig Welding Aluminum.

From www.aliexpress.com

Wqtb Tungsten Electrodes Tig Tungsten Rods Wt20 Wl15 Wl20 Wc20 Wzr8 Wp Tungsten Electrode For Tig Welding Aluminum Which size and type of tungsten electrode should you use to gas tungsten arc weld (gtaw) aluminum? Thus, it is important that the tig tungsten size be selected carefully to add to the quality of the weld. They have good arc stability, long. 0.8% zirconiated (white) the 0.8% zirconiated (opens in a new window) electrodes are renowned for their extremely. Tungsten Electrode For Tig Welding Aluminum.

From www.topwellwelders.com

TIG Welding Tungsten Electrode 2 Thoriated (Red, WT20/ EWTh2) 10pk Tungsten Electrode For Tig Welding Aluminum They have good arc stability, long. The various additions to the tungsten electrode serve two purposes. Zirconiated tungsten (white) is good for welding aluminum and magnesium alloys. First, it makes the tungsten less likely to sag or droop at high temperatures. Thus, it is important that the tig tungsten size be selected carefully to add to the quality of the. Tungsten Electrode For Tig Welding Aluminum.

From www.weldingtipsandtricks.com

How to TIG Weld Aluminum Tungsten Electrode For Tig Welding Aluminum 0.8% zirconiated (white) the 0.8% zirconiated (opens in a new window) electrodes are renowned for their extremely stable arc, high resistance to contamination, and resistance to tungsten. Zirconiated tungsten (white) is good for welding aluminum and magnesium alloys. From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. The. Tungsten Electrode For Tig Welding Aluminum.

From www.ebay.com

TIG Welding Tungsten Electrodes 2 Thoriated 3/32” x 7” (Red, WT20) 10 Tungsten Electrode For Tig Welding Aluminum Zirconiated tungsten (white) is good for welding aluminum and magnesium alloys. From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. Which size and type of tungsten electrode should you use to gas tungsten arc weld (gtaw) aluminum? The various additions to the tungsten electrode serve two purposes. Thus,. Tungsten Electrode For Tig Welding Aluminum.

From www.alibaba.com

Wl20 Lanthanated Tungsten Electrodes Tungsten Tig Welding Electrodes Tungsten Electrode For Tig Welding Aluminum From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. 0.8% zirconiated (white) the 0.8% zirconiated (opens in a new window) electrodes are renowned for their extremely stable arc, high resistance to contamination, and resistance to tungsten. First, it makes the tungsten less likely to sag or droop at. Tungsten Electrode For Tig Welding Aluminum.

From akita-mitsubishi.co.jp

x1 Piece TIG WELDING TUNGSTEN ELECTRODES GREEN PURE 1.6/2.4mm PARWELD Tungsten Electrode For Tig Welding Aluminum They have good arc stability, long. Thus, it is important that the tig tungsten size be selected carefully to add to the quality of the weld. Zirconiated tungsten (white) is good for welding aluminum and magnesium alloys. The various additions to the tungsten electrode serve two purposes. From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes. Tungsten Electrode For Tig Welding Aluminum.

From www.arccaptain.com

The Best Tungsten Electrode for TIG Welding Aluminum Tungsten Electrode For Tig Welding Aluminum Which size and type of tungsten electrode should you use to gas tungsten arc weld (gtaw) aluminum? The various additions to the tungsten electrode serve two purposes. First, it makes the tungsten less likely to sag or droop at high temperatures. From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of. Tungsten Electrode For Tig Welding Aluminum.

From hogaki.com

WQTB Tungsten Electrodes TIG Tungsten Rods WT20 Wl15 WL20 WC20 WZR8 WP Tungsten Electrode For Tig Welding Aluminum 0.8% zirconiated (white) the 0.8% zirconiated (opens in a new window) electrodes are renowned for their extremely stable arc, high resistance to contamination, and resistance to tungsten. They have good arc stability, long. From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. Thus, it is important that the. Tungsten Electrode For Tig Welding Aluminum.

From www.dhgate.com

2020 TIG Welding Tungsten Electrode Pure Tungsten 1/16 X 7 Green, EWP Tungsten Electrode For Tig Welding Aluminum The various additions to the tungsten electrode serve two purposes. 0.8% zirconiated (white) the 0.8% zirconiated (opens in a new window) electrodes are renowned for their extremely stable arc, high resistance to contamination, and resistance to tungsten. Thus, it is important that the tig tungsten size be selected carefully to add to the quality of the weld. Zirconiated tungsten (white). Tungsten Electrode For Tig Welding Aluminum.

From www.ebay.com

10Pcs 1mm x 175mm Green Tip Pure Tungsten Electrode For TIG Welding Tungsten Electrode For Tig Welding Aluminum Which size and type of tungsten electrode should you use to gas tungsten arc weld (gtaw) aluminum? First, it makes the tungsten less likely to sag or droop at high temperatures. From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. 0.8% zirconiated (white) the 0.8% zirconiated (opens in. Tungsten Electrode For Tig Welding Aluminum.

From www.dhgate.com

TIG Welding Tungsten Electrode Pure Tungsten 1/16 X 7 Green, EWP 10 Pk Tungsten Electrode For Tig Welding Aluminum Thus, it is important that the tig tungsten size be selected carefully to add to the quality of the weld. Which size and type of tungsten electrode should you use to gas tungsten arc weld (gtaw) aluminum? From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. Zirconiated tungsten. Tungsten Electrode For Tig Welding Aluminum.

From kowelding.com.au

2 Thoriated [WT20] Tungsten Electrodes 1.6mm/2.4mm/3.2mm RED KO Tungsten Electrode For Tig Welding Aluminum From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. Thus, it is important that the tig tungsten size be selected carefully to add to the quality of the weld. They have good arc stability, long. 0.8% zirconiated (white) the 0.8% zirconiated (opens in a new window) electrodes are. Tungsten Electrode For Tig Welding Aluminum.

From www.ebay.com

TIG Welding Tungsten Rod Electrodes 2 Lanthanated 3/32” x 7”(Blue Tungsten Electrode For Tig Welding Aluminum From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. First, it makes the tungsten less likely to sag or droop at high temperatures. 0.8% zirconiated (white) the 0.8% zirconiated (opens in a new window) electrodes are renowned for their extremely stable arc, high resistance to contamination, and resistance. Tungsten Electrode For Tig Welding Aluminum.

From www.amazon.ca

Pure Tungsten Electrodes for Aluminum TIG/GTAW Welding, Green (1/16 Tungsten Electrode For Tig Welding Aluminum 0.8% zirconiated (white) the 0.8% zirconiated (opens in a new window) electrodes are renowned for their extremely stable arc, high resistance to contamination, and resistance to tungsten. The various additions to the tungsten electrode serve two purposes. From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. Which size. Tungsten Electrode For Tig Welding Aluminum.

From hogaki.com

WQTB Tungsten Electrodes TIG Tungsten Rods WT20 Wl15 WL20 WC20 WZR8 WP Tungsten Electrode For Tig Welding Aluminum From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. Zirconiated tungsten (white) is good for welding aluminum and magnesium alloys. 0.8% zirconiated (white) the 0.8% zirconiated (opens in a new window) electrodes are renowned for their extremely stable arc, high resistance to contamination, and resistance to tungsten. Thus,. Tungsten Electrode For Tig Welding Aluminum.

From hogaki.com

10 Pieces Tungsten Welding Electrodes Tig Argon Arc Welding Rods for Tungsten Electrode For Tig Welding Aluminum 0.8% zirconiated (white) the 0.8% zirconiated (opens in a new window) electrodes are renowned for their extremely stable arc, high resistance to contamination, and resistance to tungsten. Zirconiated tungsten (white) is good for welding aluminum and magnesium alloys. They have good arc stability, long. First, it makes the tungsten less likely to sag or droop at high temperatures. The various. Tungsten Electrode For Tig Welding Aluminum.

From bakersgas.com

The Best Tungsten for TIG Welding Aluminum Baker's Gas & Welding Tungsten Electrode For Tig Welding Aluminum From providing excellent thermal conductivity to ensuring precision arc control, using tungsten electrodes adds to the various benefits of tig welding. 0.8% zirconiated (white) the 0.8% zirconiated (opens in a new window) electrodes are renowned for their extremely stable arc, high resistance to contamination, and resistance to tungsten. The various additions to the tungsten electrode serve two purposes. First, it. Tungsten Electrode For Tig Welding Aluminum.

From hogaki.com

WQTB Tungsten Electrodes TIG Tungsten Rods WT20 Wl15 WL20 WC20 WZR8 WP Tungsten Electrode For Tig Welding Aluminum First, it makes the tungsten less likely to sag or droop at high temperatures. The various additions to the tungsten electrode serve two purposes. Which size and type of tungsten electrode should you use to gas tungsten arc weld (gtaw) aluminum? 0.8% zirconiated (white) the 0.8% zirconiated (opens in a new window) electrodes are renowned for their extremely stable arc,. Tungsten Electrode For Tig Welding Aluminum.

From hogaki.com

WQTB Tungsten Electrodes TIG Tungsten Rods WT20 Wl15 WL20 WC20 WZR8 WP Tungsten Electrode For Tig Welding Aluminum The various additions to the tungsten electrode serve two purposes. 0.8% zirconiated (white) the 0.8% zirconiated (opens in a new window) electrodes are renowned for their extremely stable arc, high resistance to contamination, and resistance to tungsten. They have good arc stability, long. First, it makes the tungsten less likely to sag or droop at high temperatures. Thus, it is. Tungsten Electrode For Tig Welding Aluminum.

From www.weldingcity.com

10pcs WeldingCity® TIG Welding Tungsten Electrode 1/16" and 3/32" x 7 Tungsten Electrode For Tig Welding Aluminum The various additions to the tungsten electrode serve two purposes. Thus, it is important that the tig tungsten size be selected carefully to add to the quality of the weld. They have good arc stability, long. Which size and type of tungsten electrode should you use to gas tungsten arc weld (gtaw) aluminum? Zirconiated tungsten (white) is good for welding. Tungsten Electrode For Tig Welding Aluminum.

From weldingpros.net

Tips For Selecting Tungsten Electrodes [TIG Welding] Tungsten Electrode For Tig Welding Aluminum Zirconiated tungsten (white) is good for welding aluminum and magnesium alloys. Thus, it is important that the tig tungsten size be selected carefully to add to the quality of the weld. Which size and type of tungsten electrode should you use to gas tungsten arc weld (gtaw) aluminum? 0.8% zirconiated (white) the 0.8% zirconiated (opens in a new window) electrodes. Tungsten Electrode For Tig Welding Aluminum.

From weldguru.com

TIG Tungsten Electrodes Explained (with Color Chart) Tungsten Electrode For Tig Welding Aluminum Zirconiated tungsten (white) is good for welding aluminum and magnesium alloys. They have good arc stability, long. Thus, it is important that the tig tungsten size be selected carefully to add to the quality of the weld. Which size and type of tungsten electrode should you use to gas tungsten arc weld (gtaw) aluminum? First, it makes the tungsten less. Tungsten Electrode For Tig Welding Aluminum.

From intejweld.en.made-in-china.com

Intej Weld Pure Tungsten Electrode for TIG Welding Wc/Wt/Wp20 China Tungsten Electrode For Tig Welding Aluminum 0.8% zirconiated (white) the 0.8% zirconiated (opens in a new window) electrodes are renowned for their extremely stable arc, high resistance to contamination, and resistance to tungsten. Zirconiated tungsten (white) is good for welding aluminum and magnesium alloys. Which size and type of tungsten electrode should you use to gas tungsten arc weld (gtaw) aluminum? First, it makes the tungsten. Tungsten Electrode For Tig Welding Aluminum.