Wire Rope Sheave Groove Hardness . We recommend only sheaves made of steel or cast steel. The following are recommended values: The mckissick sheave groove is flame. groove hardness the hardness of sheaves and drums is often overlooked. We recommend only sheaves made of steel or cast steel. The following are recommended values: A properly sized sheave groove radius should measure 0.53 to 0.54 times the nominal. the mckissick sheave groove is flame hardened to a minimum 35 rockwell c for a 140° contact area with the wire rope (upon. dimensions and inspection of sheaves. the groove hardness of a sheave, which is the hardness of the surface where the wire rope makes contact, is an important factor to consider in ensuring the. Wire rope is a very hard product having a.

from suncorstainless.com

A properly sized sheave groove radius should measure 0.53 to 0.54 times the nominal. groove hardness the hardness of sheaves and drums is often overlooked. The mckissick sheave groove is flame. Wire rope is a very hard product having a. We recommend only sheaves made of steel or cast steel. the groove hardness of a sheave, which is the hardness of the surface where the wire rope makes contact, is an important factor to consider in ensuring the. dimensions and inspection of sheaves. We recommend only sheaves made of steel or cast steel. the mckissick sheave groove is flame hardened to a minimum 35 rockwell c for a 140° contact area with the wire rope (upon. The following are recommended values:

PULLPRO® HiLOAD Wire Rope Sheave, Bearing Suncor Stainless

Wire Rope Sheave Groove Hardness dimensions and inspection of sheaves. the mckissick sheave groove is flame hardened to a minimum 35 rockwell c for a 140° contact area with the wire rope (upon. A properly sized sheave groove radius should measure 0.53 to 0.54 times the nominal. the groove hardness of a sheave, which is the hardness of the surface where the wire rope makes contact, is an important factor to consider in ensuring the. We recommend only sheaves made of steel or cast steel. The following are recommended values: Wire rope is a very hard product having a. dimensions and inspection of sheaves. groove hardness the hardness of sheaves and drums is often overlooked. We recommend only sheaves made of steel or cast steel. The following are recommended values: The mckissick sheave groove is flame.

From www.dgcranewheel.com

Main Hoist Wire Rope Sheave Wheels Supplier DGCRANE WHEEL Wire Rope Sheave Groove Hardness The following are recommended values: We recommend only sheaves made of steel or cast steel. The following are recommended values: dimensions and inspection of sheaves. the mckissick sheave groove is flame hardened to a minimum 35 rockwell c for a 140° contact area with the wire rope (upon. Wire rope is a very hard product having a. The. Wire Rope Sheave Groove Hardness.

From suncorstainless.com

PULLPRO® HiLOAD Wire Rope Sheave, Bearing Suncor Stainless Wire Rope Sheave Groove Hardness A properly sized sheave groove radius should measure 0.53 to 0.54 times the nominal. dimensions and inspection of sheaves. The following are recommended values: the groove hardness of a sheave, which is the hardness of the surface where the wire rope makes contact, is an important factor to consider in ensuring the. groove hardness the hardness of. Wire Rope Sheave Groove Hardness.

From www.alamy.com

wire rope in the sheave groove for lifting equipment Stock Photo Alamy Wire Rope Sheave Groove Hardness The following are recommended values: the groove hardness of a sheave, which is the hardness of the surface where the wire rope makes contact, is an important factor to consider in ensuring the. The following are recommended values: dimensions and inspection of sheaves. A properly sized sheave groove radius should measure 0.53 to 0.54 times the nominal. . Wire Rope Sheave Groove Hardness.

From www.dreamstime.com

Wire Rope In The Sheave Groove For Lifting Equipment Stock Image Wire Rope Sheave Groove Hardness groove hardness the hardness of sheaves and drums is often overlooked. The following are recommended values: the mckissick sheave groove is flame hardened to a minimum 35 rockwell c for a 140° contact area with the wire rope (upon. A properly sized sheave groove radius should measure 0.53 to 0.54 times the nominal. the groove hardness of. Wire Rope Sheave Groove Hardness.

From www.certex.ee

Wire Rope Sheave 8000 Certex Estonia Wire Rope Sheave Groove Hardness The following are recommended values: We recommend only sheaves made of steel or cast steel. The following are recommended values: the groove hardness of a sheave, which is the hardness of the surface where the wire rope makes contact, is an important factor to consider in ensuring the. dimensions and inspection of sheaves. A properly sized sheave groove. Wire Rope Sheave Groove Hardness.

From www.grainger.com

GRAINGER APPROVED Sheave, Designed For Wire Rope, 3/16 in Max. Cable Wire Rope Sheave Groove Hardness We recommend only sheaves made of steel or cast steel. A properly sized sheave groove radius should measure 0.53 to 0.54 times the nominal. The following are recommended values: the groove hardness of a sheave, which is the hardness of the surface where the wire rope makes contact, is an important factor to consider in ensuring the. groove. Wire Rope Sheave Groove Hardness.

From www.samselsupply.com

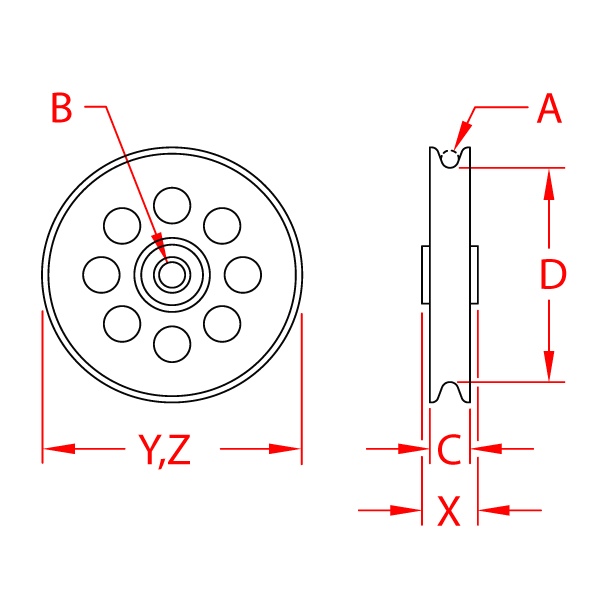

HOWTO Order Wire Rope Sheaves Wire Rope Sheave Groove Hardness The following are recommended values: the groove hardness of a sheave, which is the hardness of the surface where the wire rope makes contact, is an important factor to consider in ensuring the. A properly sized sheave groove radius should measure 0.53 to 0.54 times the nominal. The following are recommended values: dimensions and inspection of sheaves. Wire. Wire Rope Sheave Groove Hardness.

From www.mdpi.com

Materials Free FullText Sliding Friction and Wear Characteristics Wire Rope Sheave Groove Hardness We recommend only sheaves made of steel or cast steel. dimensions and inspection of sheaves. A properly sized sheave groove radius should measure 0.53 to 0.54 times the nominal. Wire rope is a very hard product having a. The following are recommended values: groove hardness the hardness of sheaves and drums is often overlooked. the groove hardness. Wire Rope Sheave Groove Hardness.

From www.certex.dk

Wire Rope Sheave, type SR CERTEX Denmark Wire Rope Sheave Groove Hardness The mckissick sheave groove is flame. A properly sized sheave groove radius should measure 0.53 to 0.54 times the nominal. the mckissick sheave groove is flame hardened to a minimum 35 rockwell c for a 140° contact area with the wire rope (upon. groove hardness the hardness of sheaves and drums is often overlooked. the groove hardness. Wire Rope Sheave Groove Hardness.

From www.researchgate.net

Rope guide mechanism and the sheaves along with their degrees of Wire Rope Sheave Groove Hardness We recommend only sheaves made of steel or cast steel. the groove hardness of a sheave, which is the hardness of the surface where the wire rope makes contact, is an important factor to consider in ensuring the. The following are recommended values: Wire rope is a very hard product having a. We recommend only sheaves made of steel. Wire Rope Sheave Groove Hardness.

From www.alamy.com

wire rope in the sheave groove for lifting equipment Stock Photo Alamy Wire Rope Sheave Groove Hardness A properly sized sheave groove radius should measure 0.53 to 0.54 times the nominal. dimensions and inspection of sheaves. The following are recommended values: We recommend only sheaves made of steel or cast steel. The mckissick sheave groove is flame. the mckissick sheave groove is flame hardened to a minimum 35 rockwell c for a 140° contact area. Wire Rope Sheave Groove Hardness.

From www.fisheriessupply.com

Wire Rope Sheaves Wire Rope Sheave Groove Hardness The following are recommended values: Wire rope is a very hard product having a. We recommend only sheaves made of steel or cast steel. the groove hardness of a sheave, which is the hardness of the surface where the wire rope makes contact, is an important factor to consider in ensuring the. the mckissick sheave groove is flame. Wire Rope Sheave Groove Hardness.

From www.certex.co.uk

Steel Wire Rope Correct Use & Maintenance Certex UK Wire Rope Sheave Groove Hardness We recommend only sheaves made of steel or cast steel. groove hardness the hardness of sheaves and drums is often overlooked. We recommend only sheaves made of steel or cast steel. the groove hardness of a sheave, which is the hardness of the surface where the wire rope makes contact, is an important factor to consider in ensuring. Wire Rope Sheave Groove Hardness.

From www.bimat.com

Products Bimat Wire Rope Sheave Groove Hardness The following are recommended values: groove hardness the hardness of sheaves and drums is often overlooked. A properly sized sheave groove radius should measure 0.53 to 0.54 times the nominal. We recommend only sheaves made of steel or cast steel. the groove hardness of a sheave, which is the hardness of the surface where the wire rope makes. Wire Rope Sheave Groove Hardness.

From www.mazzellacompanies.com

How Sheave Size Affects Wire Rope Strength and Efficiency Wire Rope Sheave Groove Hardness the mckissick sheave groove is flame hardened to a minimum 35 rockwell c for a 140° contact area with the wire rope (upon. groove hardness the hardness of sheaves and drums is often overlooked. We recommend only sheaves made of steel or cast steel. We recommend only sheaves made of steel or cast steel. The following are recommended. Wire Rope Sheave Groove Hardness.

From www.youtube.com

Wire Rope Sling Explained with SWL Loading capacity formula Wirerope Wire Rope Sheave Groove Hardness We recommend only sheaves made of steel or cast steel. dimensions and inspection of sheaves. The mckissick sheave groove is flame. We recommend only sheaves made of steel or cast steel. The following are recommended values: groove hardness the hardness of sheaves and drums is often overlooked. A properly sized sheave groove radius should measure 0.53 to 0.54. Wire Rope Sheave Groove Hardness.

From suncorstainless.com

Stainless Steel Sheaves Selection and Use Suncor Stainless Wire Rope Sheave Groove Hardness The following are recommended values: Wire rope is a very hard product having a. The mckissick sheave groove is flame. the groove hardness of a sheave, which is the hardness of the surface where the wire rope makes contact, is an important factor to consider in ensuring the. the mckissick sheave groove is flame hardened to a minimum. Wire Rope Sheave Groove Hardness.

From suncorstainless.com

Stainless Steel Sheaves Selection and Use Suncor Stainless Wire Rope Sheave Groove Hardness We recommend only sheaves made of steel or cast steel. The mckissick sheave groove is flame. We recommend only sheaves made of steel or cast steel. The following are recommended values: the groove hardness of a sheave, which is the hardness of the surface where the wire rope makes contact, is an important factor to consider in ensuring the.. Wire Rope Sheave Groove Hardness.

From suncorstainless.com

Stainless Steel Sheaves Selection and Use Suncor Stainless Wire Rope Sheave Groove Hardness groove hardness the hardness of sheaves and drums is often overlooked. We recommend only sheaves made of steel or cast steel. The following are recommended values: the mckissick sheave groove is flame hardened to a minimum 35 rockwell c for a 140° contact area with the wire rope (upon. Wire rope is a very hard product having a.. Wire Rope Sheave Groove Hardness.

From suncorstainless.com

Stainless Steel Sheaves Selection and Use Suncor Stainless Wire Rope Sheave Groove Hardness groove hardness the hardness of sheaves and drums is often overlooked. the groove hardness of a sheave, which is the hardness of the surface where the wire rope makes contact, is an important factor to consider in ensuring the. We recommend only sheaves made of steel or cast steel. dimensions and inspection of sheaves. The mckissick sheave. Wire Rope Sheave Groove Hardness.

From www.alllifting.com.au

Wire Rope Sheave All Lifting Australian Owned Wire Rope Sheave Groove Hardness the mckissick sheave groove is flame hardened to a minimum 35 rockwell c for a 140° contact area with the wire rope (upon. The mckissick sheave groove is flame. We recommend only sheaves made of steel or cast steel. A properly sized sheave groove radius should measure 0.53 to 0.54 times the nominal. dimensions and inspection of sheaves.. Wire Rope Sheave Groove Hardness.

From www.alamy.com

wire rope in the sheave groove for lifting equipment Stock Photo Alamy Wire Rope Sheave Groove Hardness groove hardness the hardness of sheaves and drums is often overlooked. The following are recommended values: We recommend only sheaves made of steel or cast steel. the groove hardness of a sheave, which is the hardness of the surface where the wire rope makes contact, is an important factor to consider in ensuring the. We recommend only sheaves. Wire Rope Sheave Groove Hardness.

From www.shutterstock.com

Wire Rope Sheave Groove Lifting Equipment Stock Photo 1380528035 Wire Rope Sheave Groove Hardness the groove hardness of a sheave, which is the hardness of the surface where the wire rope makes contact, is an important factor to consider in ensuring the. The following are recommended values: the mckissick sheave groove is flame hardened to a minimum 35 rockwell c for a 140° contact area with the wire rope (upon. The following. Wire Rope Sheave Groove Hardness.

From ubicaciondepersonas.cdmx.gob.mx

Wire Rope Sheave Groove Dimensions ubicaciondepersonas.cdmx.gob.mx Wire Rope Sheave Groove Hardness The following are recommended values: the mckissick sheave groove is flame hardened to a minimum 35 rockwell c for a 140° contact area with the wire rope (upon. dimensions and inspection of sheaves. We recommend only sheaves made of steel or cast steel. Wire rope is a very hard product having a. the groove hardness of a. Wire Rope Sheave Groove Hardness.

From mepsystems.com.sg

MORDEC WIRE ROPE SHEAVE GAUGE MEP Deck Solutions Wire Rope Sheave Groove Hardness We recommend only sheaves made of steel or cast steel. The following are recommended values: the mckissick sheave groove is flame hardened to a minimum 35 rockwell c for a 140° contact area with the wire rope (upon. dimensions and inspection of sheaves. the groove hardness of a sheave, which is the hardness of the surface where. Wire Rope Sheave Groove Hardness.

From www.liftsafer.com

Optimizing Sheave Groove Hardness for Wire Rope Performance and Longevity Wire Rope Sheave Groove Hardness dimensions and inspection of sheaves. The mckissick sheave groove is flame. The following are recommended values: The following are recommended values: groove hardness the hardness of sheaves and drums is often overlooked. the mckissick sheave groove is flame hardened to a minimum 35 rockwell c for a 140° contact area with the wire rope (upon. We recommend. Wire Rope Sheave Groove Hardness.

From www.liftsafer.com

Optimizing Sheave Groove Hardness for Wire Rope Performance and Longevity Wire Rope Sheave Groove Hardness dimensions and inspection of sheaves. The following are recommended values: We recommend only sheaves made of steel or cast steel. The mckissick sheave groove is flame. Wire rope is a very hard product having a. The following are recommended values: A properly sized sheave groove radius should measure 0.53 to 0.54 times the nominal. the groove hardness of. Wire Rope Sheave Groove Hardness.

From rooneyirving.ca

Sheave grooves worn with rope pattern Rooney Irving & Associates Wire Rope Sheave Groove Hardness the mckissick sheave groove is flame hardened to a minimum 35 rockwell c for a 140° contact area with the wire rope (upon. dimensions and inspection of sheaves. The mckissick sheave groove is flame. groove hardness the hardness of sheaves and drums is often overlooked. The following are recommended values: We recommend only sheaves made of steel. Wire Rope Sheave Groove Hardness.

From www.mazzellacompanies.com

Why Sheave Design is Critical to Wire Rope Service Life Wire Rope Sheave Groove Hardness groove hardness the hardness of sheaves and drums is often overlooked. The following are recommended values: the mckissick sheave groove is flame hardened to a minimum 35 rockwell c for a 140° contact area with the wire rope (upon. We recommend only sheaves made of steel or cast steel. the groove hardness of a sheave, which is. Wire Rope Sheave Groove Hardness.

From www.mazzellacompanies.com

Crosby McKissick Wire Rope Sheaves Mazzella Companies Wire Rope Sheave Groove Hardness The following are recommended values: dimensions and inspection of sheaves. Wire rope is a very hard product having a. We recommend only sheaves made of steel or cast steel. groove hardness the hardness of sheaves and drums is often overlooked. A properly sized sheave groove radius should measure 0.53 to 0.54 times the nominal. The following are recommended. Wire Rope Sheave Groove Hardness.

From www.alamy.com

wire rope in the sheave groove for lifting equipment Stock Photo Alamy Wire Rope Sheave Groove Hardness groove hardness the hardness of sheaves and drums is often overlooked. We recommend only sheaves made of steel or cast steel. the mckissick sheave groove is flame hardened to a minimum 35 rockwell c for a 140° contact area with the wire rope (upon. The following are recommended values: The mckissick sheave groove is flame. A properly sized. Wire Rope Sheave Groove Hardness.

From www.alatas.com

ROPE SHEAVE ASSEMBLY, FABRICATION, & REPAIRS Alatas Wire Rope Sheave Groove Hardness the mckissick sheave groove is flame hardened to a minimum 35 rockwell c for a 140° contact area with the wire rope (upon. A properly sized sheave groove radius should measure 0.53 to 0.54 times the nominal. The following are recommended values: dimensions and inspection of sheaves. The following are recommended values: groove hardness the hardness of. Wire Rope Sheave Groove Hardness.

From www.semanticscholar.org

Figure 1 from Frictional performance of wire and fibre ropes bent over Wire Rope Sheave Groove Hardness We recommend only sheaves made of steel or cast steel. the mckissick sheave groove is flame hardened to a minimum 35 rockwell c for a 140° contact area with the wire rope (upon. A properly sized sheave groove radius should measure 0.53 to 0.54 times the nominal. Wire rope is a very hard product having a. The following are. Wire Rope Sheave Groove Hardness.

From www.traclev.com

Wire rope Sheaves McKissick For Lifting Traction Levage Wire Rope Sheave Groove Hardness groove hardness the hardness of sheaves and drums is often overlooked. We recommend only sheaves made of steel or cast steel. We recommend only sheaves made of steel or cast steel. The following are recommended values: A properly sized sheave groove radius should measure 0.53 to 0.54 times the nominal. the groove hardness of a sheave, which is. Wire Rope Sheave Groove Hardness.

From www.mdpi.com

Machines Free FullText Laboratory Device Detecting Tensile Forces Wire Rope Sheave Groove Hardness We recommend only sheaves made of steel or cast steel. The following are recommended values: the mckissick sheave groove is flame hardened to a minimum 35 rockwell c for a 140° contact area with the wire rope (upon. groove hardness the hardness of sheaves and drums is often overlooked. the groove hardness of a sheave, which is. Wire Rope Sheave Groove Hardness.