What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim . Different types of grinding wheels include straight grinding wheels, large diameter grinding wheels, grinding cup wheels, grinding. There are many types of grinding wheels, each suited to specific applications. The workpiece is fed through the machine, and the grinding wheel removes material from the outer diameter. The cylindrical workpiece is mounted on the wheel, and its outer rim. The grinding wheel contacts the workpiece, removing material in a controlled manner to achieve the desired shape and surface finish. Grinding is a process that uses a grinding wheel to cut a workpiece. Enken, or cylindrical grinding, is frequently performed on a universal or cylinder grinding machine. Apply coolant to reduce heat buildup, preventing thermal damage and ensuring workpiece integrity. Great for tools like chisels.

from www.mdpi.com

There are many types of grinding wheels, each suited to specific applications. Grinding is a process that uses a grinding wheel to cut a workpiece. Different types of grinding wheels include straight grinding wheels, large diameter grinding wheels, grinding cup wheels, grinding. Great for tools like chisels. The cylindrical workpiece is mounted on the wheel, and its outer rim. Apply coolant to reduce heat buildup, preventing thermal damage and ensuring workpiece integrity. The workpiece is fed through the machine, and the grinding wheel removes material from the outer diameter. Enken, or cylindrical grinding, is frequently performed on a universal or cylinder grinding machine. The grinding wheel contacts the workpiece, removing material in a controlled manner to achieve the desired shape and surface finish.

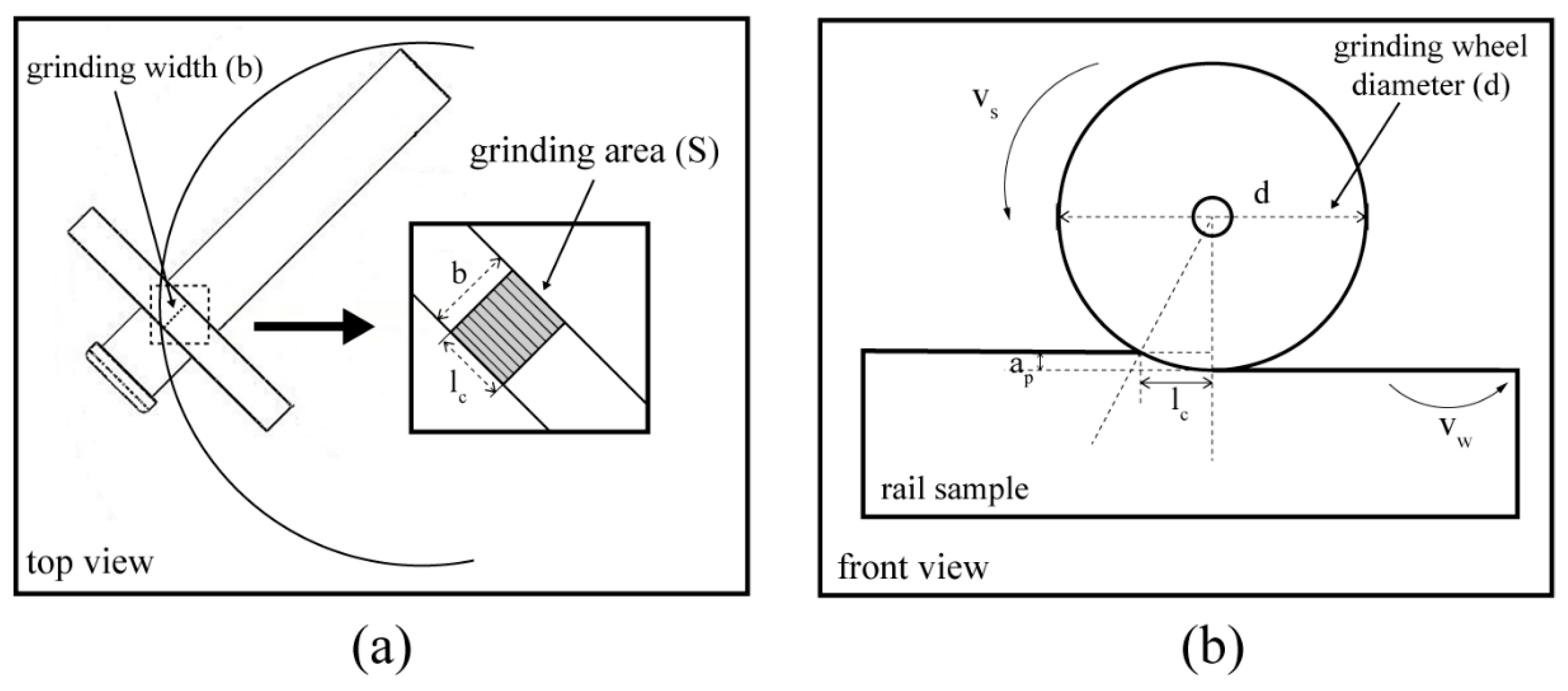

Processes Free FullText Designed a Passive Grinding Test Machine

What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim Apply coolant to reduce heat buildup, preventing thermal damage and ensuring workpiece integrity. There are many types of grinding wheels, each suited to specific applications. Great for tools like chisels. Apply coolant to reduce heat buildup, preventing thermal damage and ensuring workpiece integrity. Different types of grinding wheels include straight grinding wheels, large diameter grinding wheels, grinding cup wheels, grinding. Grinding is a process that uses a grinding wheel to cut a workpiece. The grinding wheel contacts the workpiece, removing material in a controlled manner to achieve the desired shape and surface finish. The workpiece is fed through the machine, and the grinding wheel removes material from the outer diameter. Enken, or cylindrical grinding, is frequently performed on a universal or cylinder grinding machine. The cylindrical workpiece is mounted on the wheel, and its outer rim.

From finemetalworking.com

Surface Grinding Wheels Types and Specification What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim Enken, or cylindrical grinding, is frequently performed on a universal or cylinder grinding machine. The cylindrical workpiece is mounted on the wheel, and its outer rim. Great for tools like chisels. The grinding wheel contacts the workpiece, removing material in a controlled manner to achieve the desired shape and surface finish. The workpiece is fed through the machine, and the. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From www.youtube.com

grinding wheel Standard Marking System grinding wheel types What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim Apply coolant to reduce heat buildup, preventing thermal damage and ensuring workpiece integrity. Different types of grinding wheels include straight grinding wheels, large diameter grinding wheels, grinding cup wheels, grinding. Grinding is a process that uses a grinding wheel to cut a workpiece. There are many types of grinding wheels, each suited to specific applications. Enken, or cylindrical grinding, is. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From www.researchgate.net

Workpiece and grinding wheel details and geometry Download Scientific What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim The grinding wheel contacts the workpiece, removing material in a controlled manner to achieve the desired shape and surface finish. There are many types of grinding wheels, each suited to specific applications. Apply coolant to reduce heat buildup, preventing thermal damage and ensuring workpiece integrity. The cylindrical workpiece is mounted on the wheel, and its outer rim. Grinding is a. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From www.researchgate.net

Schematic diagram of contact length between workpiece and grinding What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim The cylindrical workpiece is mounted on the wheel, and its outer rim. There are many types of grinding wheels, each suited to specific applications. Enken, or cylindrical grinding, is frequently performed on a universal or cylinder grinding machine. Different types of grinding wheels include straight grinding wheels, large diameter grinding wheels, grinding cup wheels, grinding. Great for tools like chisels.. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From www.mmsonline.com

7 Key Factors in Choosing a Grinding Wheel Modern Machine Shop What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim The workpiece is fed through the machine, and the grinding wheel removes material from the outer diameter. The grinding wheel contacts the workpiece, removing material in a controlled manner to achieve the desired shape and surface finish. Grinding is a process that uses a grinding wheel to cut a workpiece. The cylindrical workpiece is mounted on the wheel, and its. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From www.residencestyle.com

How to Choose From the Different Types of Grinding Wheels? » Residence What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim Great for tools like chisels. There are many types of grinding wheels, each suited to specific applications. Enken, or cylindrical grinding, is frequently performed on a universal or cylinder grinding machine. Different types of grinding wheels include straight grinding wheels, large diameter grinding wheels, grinding cup wheels, grinding. The cylindrical workpiece is mounted on the wheel, and its outer rim.. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From www.shakedeal.com

How to choose the right grinding wheel? What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim Grinding is a process that uses a grinding wheel to cut a workpiece. Apply coolant to reduce heat buildup, preventing thermal damage and ensuring workpiece integrity. There are many types of grinding wheels, each suited to specific applications. The grinding wheel contacts the workpiece, removing material in a controlled manner to achieve the desired shape and surface finish. The cylindrical. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From www.youtube.com

Grinding Wheel Selection Grinding Methods Types of Grinding What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim Grinding is a process that uses a grinding wheel to cut a workpiece. Different types of grinding wheels include straight grinding wheels, large diameter grinding wheels, grinding cup wheels, grinding. There are many types of grinding wheels, each suited to specific applications. The workpiece is fed through the machine, and the grinding wheel removes material from the outer diameter. Apply. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From www.researchgate.net

Position of the contact between the grinding wheel and workpiece Slika What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim Apply coolant to reduce heat buildup, preventing thermal damage and ensuring workpiece integrity. The grinding wheel contacts the workpiece, removing material in a controlled manner to achieve the desired shape and surface finish. Grinding is a process that uses a grinding wheel to cut a workpiece. There are many types of grinding wheels, each suited to specific applications. Great for. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From www.researchgate.net

Contact zone between the workpiece and orderlymicrogrooved wheel The What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim Apply coolant to reduce heat buildup, preventing thermal damage and ensuring workpiece integrity. Great for tools like chisels. The grinding wheel contacts the workpiece, removing material in a controlled manner to achieve the desired shape and surface finish. Enken, or cylindrical grinding, is frequently performed on a universal or cylinder grinding machine. The cylindrical workpiece is mounted on the wheel,. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From www.researchgate.net

Contact line between grinding wheel surface and spiral groove surface What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim Enken, or cylindrical grinding, is frequently performed on a universal or cylinder grinding machine. The workpiece is fed through the machine, and the grinding wheel removes material from the outer diameter. Apply coolant to reduce heat buildup, preventing thermal damage and ensuring workpiece integrity. The cylindrical workpiece is mounted on the wheel, and its outer rim. There are many types. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From thors.com

Safety Directives for Handling Grinding Wheels What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim The grinding wheel contacts the workpiece, removing material in a controlled manner to achieve the desired shape and surface finish. There are many types of grinding wheels, each suited to specific applications. Enken, or cylindrical grinding, is frequently performed on a universal or cylinder grinding machine. The workpiece is fed through the machine, and the grinding wheel removes material from. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From www.youtube.com

grinding wheel specifications explained (English) YouTube What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim Great for tools like chisels. Apply coolant to reduce heat buildup, preventing thermal damage and ensuring workpiece integrity. The grinding wheel contacts the workpiece, removing material in a controlled manner to achieve the desired shape and surface finish. Different types of grinding wheels include straight grinding wheels, large diameter grinding wheels, grinding cup wheels, grinding. There are many types of. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From www.researchgate.net

Schematic diagram of grinding wheel contact conditions Download What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim The workpiece is fed through the machine, and the grinding wheel removes material from the outer diameter. The grinding wheel contacts the workpiece, removing material in a controlled manner to achieve the desired shape and surface finish. Grinding is a process that uses a grinding wheel to cut a workpiece. Apply coolant to reduce heat buildup, preventing thermal damage and. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From engineeringlearn.com

8 Types of Grinding Machine Parts, Working Principle & Grinding Wheel What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim Different types of grinding wheels include straight grinding wheels, large diameter grinding wheels, grinding cup wheels, grinding. The cylindrical workpiece is mounted on the wheel, and its outer rim. Great for tools like chisels. Apply coolant to reduce heat buildup, preventing thermal damage and ensuring workpiece integrity. Enken, or cylindrical grinding, is frequently performed on a universal or cylinder grinding. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From www.researchgate.net

Illustration of wheel and workpiece contact for vertical groove What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim The cylindrical workpiece is mounted on the wheel, and its outer rim. The grinding wheel contacts the workpiece, removing material in a controlled manner to achieve the desired shape and surface finish. Great for tools like chisels. Different types of grinding wheels include straight grinding wheels, large diameter grinding wheels, grinding cup wheels, grinding. Grinding is a process that uses. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From metrol-sensor.com

Automation of NC Grinding Machines [Introduction] Ultra Precision What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim Different types of grinding wheels include straight grinding wheels, large diameter grinding wheels, grinding cup wheels, grinding. Grinding is a process that uses a grinding wheel to cut a workpiece. Enken, or cylindrical grinding, is frequently performed on a universal or cylinder grinding machine. The grinding wheel contacts the workpiece, removing material in a controlled manner to achieve the desired. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From www.utechrubberproducts.in

Ftype Grinding Wheel Manufacturer, Supplier from Chennai What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim The workpiece is fed through the machine, and the grinding wheel removes material from the outer diameter. Enken, or cylindrical grinding, is frequently performed on a universal or cylinder grinding machine. There are many types of grinding wheels, each suited to specific applications. Apply coolant to reduce heat buildup, preventing thermal damage and ensuring workpiece integrity. Grinding is a process. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From www.forturetools.com

How to read a grinding wheel's specification Forture Tools What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim Great for tools like chisels. The grinding wheel contacts the workpiece, removing material in a controlled manner to achieve the desired shape and surface finish. Apply coolant to reduce heat buildup, preventing thermal damage and ensuring workpiece integrity. The cylindrical workpiece is mounted on the wheel, and its outer rim. Enken, or cylindrical grinding, is frequently performed on a universal. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From www.dreamstime.com

Surface Grinding Wheel Machine Working with Metal Workpiece at Factory What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim Apply coolant to reduce heat buildup, preventing thermal damage and ensuring workpiece integrity. There are many types of grinding wheels, each suited to specific applications. Enken, or cylindrical grinding, is frequently performed on a universal or cylinder grinding machine. The grinding wheel contacts the workpiece, removing material in a controlled manner to achieve the desired shape and surface finish. The. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From www.mmsonline.com

Managing Grinding Forces and Abrasive Sharpness Modern Machine Shop What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim Great for tools like chisels. Apply coolant to reduce heat buildup, preventing thermal damage and ensuring workpiece integrity. Enken, or cylindrical grinding, is frequently performed on a universal or cylinder grinding machine. Grinding is a process that uses a grinding wheel to cut a workpiece. Different types of grinding wheels include straight grinding wheels, large diameter grinding wheels, grinding cup. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From www.superabrasivetools.com

2019 The Tips of Grinding Wheel Selection Diamond Grinding tools What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim Enken, or cylindrical grinding, is frequently performed on a universal or cylinder grinding machine. Grinding is a process that uses a grinding wheel to cut a workpiece. The cylindrical workpiece is mounted on the wheel, and its outer rim. Apply coolant to reduce heat buildup, preventing thermal damage and ensuring workpiece integrity. The grinding wheel contacts the workpiece, removing material. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From engineeringlearn.com

8 Types of Grinding Machine Parts, Working Principle & Grinding Wheel What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim The grinding wheel contacts the workpiece, removing material in a controlled manner to achieve the desired shape and surface finish. There are many types of grinding wheels, each suited to specific applications. Enken, or cylindrical grinding, is frequently performed on a universal or cylinder grinding machine. Great for tools like chisels. The cylindrical workpiece is mounted on the wheel, and. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From www.researchgate.net

Interaction between the grinding wheel and workpiece Download What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim Great for tools like chisels. Enken, or cylindrical grinding, is frequently performed on a universal or cylinder grinding machine. The grinding wheel contacts the workpiece, removing material in a controlled manner to achieve the desired shape and surface finish. The workpiece is fed through the machine, and the grinding wheel removes material from the outer diameter. Apply coolant to reduce. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From www.researchgate.net

Grinding geometric model. a Grinding wheelworkpiece contact mode What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim The grinding wheel contacts the workpiece, removing material in a controlled manner to achieve the desired shape and surface finish. Apply coolant to reduce heat buildup, preventing thermal damage and ensuring workpiece integrity. Different types of grinding wheels include straight grinding wheels, large diameter grinding wheels, grinding cup wheels, grinding. The cylindrical workpiece is mounted on the wheel, and its. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From www.researchgate.net

Grinding geometric model. a Grinding wheelworkpiece contact mode What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim The workpiece is fed through the machine, and the grinding wheel removes material from the outer diameter. The cylindrical workpiece is mounted on the wheel, and its outer rim. There are many types of grinding wheels, each suited to specific applications. Great for tools like chisels. Grinding is a process that uses a grinding wheel to cut a workpiece. The. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From engineeringlearn.com

8 Types of Grinding Machine Parts, Working Principle & Grinding Wheel What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim Enken, or cylindrical grinding, is frequently performed on a universal or cylinder grinding machine. Great for tools like chisels. The workpiece is fed through the machine, and the grinding wheel removes material from the outer diameter. The cylindrical workpiece is mounted on the wheel, and its outer rim. Grinding is a process that uses a grinding wheel to cut a. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From www.mdpi.com

Inventions Free FullText The Effect of Grinding Wheel Contact What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim There are many types of grinding wheels, each suited to specific applications. The cylindrical workpiece is mounted on the wheel, and its outer rim. Great for tools like chisels. Grinding is a process that uses a grinding wheel to cut a workpiece. Apply coolant to reduce heat buildup, preventing thermal damage and ensuring workpiece integrity. Different types of grinding wheels. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From www.researchgate.net

The schematic illustration of grinding wheel dressing Download What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim Grinding is a process that uses a grinding wheel to cut a workpiece. The cylindrical workpiece is mounted on the wheel, and its outer rim. The workpiece is fed through the machine, and the grinding wheel removes material from the outer diameter. There are many types of grinding wheels, each suited to specific applications. Great for tools like chisels. Enken,. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From www.researchgate.net

Position of the contact between the grinding wheel and workpiece Slika What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim The workpiece is fed through the machine, and the grinding wheel removes material from the outer diameter. The cylindrical workpiece is mounted on the wheel, and its outer rim. Great for tools like chisels. Grinding is a process that uses a grinding wheel to cut a workpiece. Enken, or cylindrical grinding, is frequently performed on a universal or cylinder grinding. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From www.researchgate.net

The grinding wheel and workpiece system model Download Scientific Diagram What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim The workpiece is fed through the machine, and the grinding wheel removes material from the outer diameter. The grinding wheel contacts the workpiece, removing material in a controlled manner to achieve the desired shape and surface finish. Great for tools like chisels. Grinding is a process that uses a grinding wheel to cut a workpiece. Apply coolant to reduce heat. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From www.youtube.com

Grinding Wheel Specification YouTube What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim Grinding is a process that uses a grinding wheel to cut a workpiece. The grinding wheel contacts the workpiece, removing material in a controlled manner to achieve the desired shape and surface finish. Great for tools like chisels. Apply coolant to reduce heat buildup, preventing thermal damage and ensuring workpiece integrity. The cylindrical workpiece is mounted on the wheel, and. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From www.youtube.com

MOUNTING OF GRINDING WHEEL Changing New Grinding Wheel YouTube What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim The workpiece is fed through the machine, and the grinding wheel removes material from the outer diameter. The cylindrical workpiece is mounted on the wheel, and its outer rim. The grinding wheel contacts the workpiece, removing material in a controlled manner to achieve the desired shape and surface finish. Apply coolant to reduce heat buildup, preventing thermal damage and ensuring. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From www.mdpi.com

Processes Free FullText Designed a Passive Grinding Test Machine What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim Grinding is a process that uses a grinding wheel to cut a workpiece. The grinding wheel contacts the workpiece, removing material in a controlled manner to achieve the desired shape and surface finish. Great for tools like chisels. Apply coolant to reduce heat buildup, preventing thermal damage and ensuring workpiece integrity. The cylindrical workpiece is mounted on the wheel, and. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.

From sinomagnesium.en.made-in-china.com

Diamond Grinding Wheel for Carbide Tools and High Speed Steels What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim The grinding wheel contacts the workpiece, removing material in a controlled manner to achieve the desired shape and surface finish. Enken, or cylindrical grinding, is frequently performed on a universal or cylinder grinding machine. Grinding is a process that uses a grinding wheel to cut a workpiece. Great for tools like chisels. There are many types of grinding wheels, each. What Type Of Grinding Wheel Contacts The Workpiece With Its Outer Rim.