Welding At An Angle . A fillet weld joins together two pieces of metal that are perpendicular or at an angle. These angles differ depending on. This angle is an important factor in determining weld strength and quality. A groove weld is made in a groove between workpieces or between workpiece edges. We’ve outlined essential practices, common issues, and their solutions to. Electrode angles are the angles at which you should hold the stick electrode in relation to the workpiece while welding. For instance, when doing a lap weld (one piece of metal overlaps another) or a t. A steep, or “stickout,” angle can lead to excessive spatter and poor penetration, while a. The welding electrode angle refers to the angle between the welding electrode and the workpiece during a welding process. Mastering the technique of welding angle iron is crucial for both hobbyists and professionals. The angle of your welding electrode can have a significant impact on the quality of your weld. These angles differ depending on the type of weld you intend to make.

from www.wcwelding.com

A groove weld is made in a groove between workpieces or between workpiece edges. This angle is an important factor in determining weld strength and quality. Mastering the technique of welding angle iron is crucial for both hobbyists and professionals. A steep, or “stickout,” angle can lead to excessive spatter and poor penetration, while a. These angles differ depending on the type of weld you intend to make. A fillet weld joins together two pieces of metal that are perpendicular or at an angle. Electrode angles are the angles at which you should hold the stick electrode in relation to the workpiece while welding. The angle of your welding electrode can have a significant impact on the quality of your weld. We’ve outlined essential practices, common issues, and their solutions to. These angles differ depending on.

Arc Welding Rods Guide

Welding At An Angle A groove weld is made in a groove between workpieces or between workpiece edges. A steep, or “stickout,” angle can lead to excessive spatter and poor penetration, while a. For instance, when doing a lap weld (one piece of metal overlaps another) or a t. These angles differ depending on the type of weld you intend to make. Electrode angles are the angles at which you should hold the stick electrode in relation to the workpiece while welding. We’ve outlined essential practices, common issues, and their solutions to. These angles differ depending on. Mastering the technique of welding angle iron is crucial for both hobbyists and professionals. The welding electrode angle refers to the angle between the welding electrode and the workpiece during a welding process. This angle is an important factor in determining weld strength and quality. A groove weld is made in a groove between workpieces or between workpiece edges. A fillet weld joins together two pieces of metal that are perpendicular or at an angle. The angle of your welding electrode can have a significant impact on the quality of your weld.

From klakpzhrl.blob.core.windows.net

How To Weld 90 Degree Angles at Susan Rush blog Welding At An Angle The welding electrode angle refers to the angle between the welding electrode and the workpiece during a welding process. This angle is an important factor in determining weld strength and quality. These angles differ depending on the type of weld you intend to make. A fillet weld joins together two pieces of metal that are perpendicular or at an angle.. Welding At An Angle.

From www.youtube.com

welding angle iron.2 tricks on how to connect angle ironto make it Welding At An Angle These angles differ depending on. The angle of your welding electrode can have a significant impact on the quality of your weld. This angle is an important factor in determining weld strength and quality. A fillet weld joins together two pieces of metal that are perpendicular or at an angle. Mastering the technique of welding angle iron is crucial for. Welding At An Angle.

From eziil.com

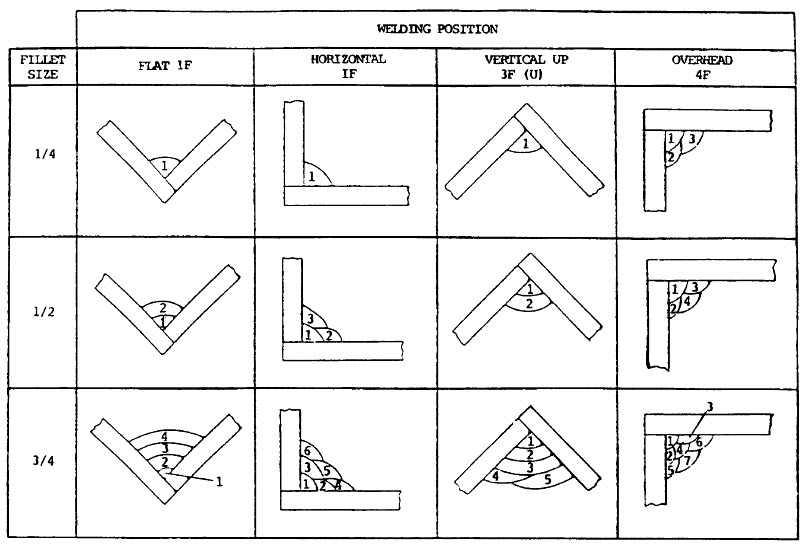

5 Types of Welding Positions 1g, 2f, 3g, 4g... Welding At An Angle We’ve outlined essential practices, common issues, and their solutions to. A steep, or “stickout,” angle can lead to excessive spatter and poor penetration, while a. A groove weld is made in a groove between workpieces or between workpiece edges. Mastering the technique of welding angle iron is crucial for both hobbyists and professionals. The angle of your welding electrode can. Welding At An Angle.

From www.youtube.com

WELD PERFECT CORNERS ON ANGLE IRON WITH THIS SIMPLE TIP NOTCHING WITH Welding At An Angle A steep, or “stickout,” angle can lead to excessive spatter and poor penetration, while a. These angles differ depending on the type of weld you intend to make. These angles differ depending on. A groove weld is made in a groove between workpieces or between workpiece edges. The welding electrode angle refers to the angle between the welding electrode and. Welding At An Angle.

From www.wcwelding.com

Arc Welding Rods Guide Welding At An Angle A fillet weld joins together two pieces of metal that are perpendicular or at an angle. These angles differ depending on the type of weld you intend to make. Electrode angles are the angles at which you should hold the stick electrode in relation to the workpiece while welding. This angle is an important factor in determining weld strength and. Welding At An Angle.

From stevenling-ilpks.blogspot.com

WELDING TECHNOLOGY Perform Straight Bead Welding At An Angle A steep, or “stickout,” angle can lead to excessive spatter and poor penetration, while a. Mastering the technique of welding angle iron is crucial for both hobbyists and professionals. Electrode angles are the angles at which you should hold the stick electrode in relation to the workpiece while welding. For instance, when doing a lap weld (one piece of metal. Welding At An Angle.

From www.fleetmaintenance.com

Welding Types and Positions poster Fleet Maintenance Welding At An Angle The welding electrode angle refers to the angle between the welding electrode and the workpiece during a welding process. A steep, or “stickout,” angle can lead to excessive spatter and poor penetration, while a. Electrode angles are the angles at which you should hold the stick electrode in relation to the workpiece while welding. Mastering the technique of welding angle. Welding At An Angle.

From gowelding.org

Stick Welding Learn Basic Electrode Selection, Welding Techniques and Welding At An Angle A steep, or “stickout,” angle can lead to excessive spatter and poor penetration, while a. This angle is an important factor in determining weld strength and quality. For instance, when doing a lap weld (one piece of metal overlaps another) or a t. The welding electrode angle refers to the angle between the welding electrode and the workpiece during a. Welding At An Angle.

From www.ideastatica.com

Fillet weld in angle plate joint IDEA StatiCa Welding At An Angle The angle of your welding electrode can have a significant impact on the quality of your weld. These angles differ depending on the type of weld you intend to make. These angles differ depending on. A groove weld is made in a groove between workpieces or between workpiece edges. A steep, or “stickout,” angle can lead to excessive spatter and. Welding At An Angle.

From www.slideserve.com

PPT Intro to SMAW Welding PowerPoint Presentation, free download ID Welding At An Angle These angles differ depending on the type of weld you intend to make. Electrode angles are the angles at which you should hold the stick electrode in relation to the workpiece while welding. A groove weld is made in a groove between workpieces or between workpiece edges. The angle of your welding electrode can have a significant impact on the. Welding At An Angle.

From www.hgg-group.com

Welding basics; terminology HGG 3D Profiling Specialists Welding At An Angle A fillet weld joins together two pieces of metal that are perpendicular or at an angle. The welding electrode angle refers to the angle between the welding electrode and the workpiece during a welding process. Electrode angles are the angles at which you should hold the stick electrode in relation to the workpiece while welding. A steep, or “stickout,” angle. Welding At An Angle.

From www.researchgate.net

Welding speed, torch angles, and orbital angle (adapted from [10 Welding At An Angle A groove weld is made in a groove between workpieces or between workpiece edges. These angles differ depending on the type of weld you intend to make. Mastering the technique of welding angle iron is crucial for both hobbyists and professionals. Electrode angles are the angles at which you should hold the stick electrode in relation to the workpiece while. Welding At An Angle.

From www.youtube.com

Tig welding of angle iron to steel plate / How to weld a corner joint Welding At An Angle This angle is an important factor in determining weld strength and quality. Electrode angles are the angles at which you should hold the stick electrode in relation to the workpiece while welding. Mastering the technique of welding angle iron is crucial for both hobbyists and professionals. We’ve outlined essential practices, common issues, and their solutions to. The angle of your. Welding At An Angle.

From www.chevyhardcore.com

Video TIG Welding Tips And Tricks From Miller Welding Welding At An Angle We’ve outlined essential practices, common issues, and their solutions to. These angles differ depending on the type of weld you intend to make. The angle of your welding electrode can have a significant impact on the quality of your weld. Mastering the technique of welding angle iron is crucial for both hobbyists and professionals. This angle is an important factor. Welding At An Angle.

From www.youtube.com

Easy learning in welding angle bar YouTube Welding At An Angle A fillet weld joins together two pieces of metal that are perpendicular or at an angle. The welding electrode angle refers to the angle between the welding electrode and the workpiece during a welding process. For instance, when doing a lap weld (one piece of metal overlaps another) or a t. A groove weld is made in a groove between. Welding At An Angle.

From weldingtorchapes.com

Tig welding torch angle and arc centering position 2/2 APES Welding At An Angle The angle of your welding electrode can have a significant impact on the quality of your weld. Electrode angles are the angles at which you should hold the stick electrode in relation to the workpiece while welding. We’ve outlined essential practices, common issues, and their solutions to. The welding electrode angle refers to the angle between the welding electrode and. Welding At An Angle.

From www.youtube.com

Manual Metal Arc Tfillet Weld Slope Angle Tutorial YouTube Welding At An Angle Mastering the technique of welding angle iron is crucial for both hobbyists and professionals. The welding electrode angle refers to the angle between the welding electrode and the workpiece during a welding process. A fillet weld joins together two pieces of metal that are perpendicular or at an angle. This angle is an important factor in determining weld strength and. Welding At An Angle.

From www.hgg-group.com

Welding basics; terminology HGG 3D Profiling Specialists Welding At An Angle A steep, or “stickout,” angle can lead to excessive spatter and poor penetration, while a. We’ve outlined essential practices, common issues, and their solutions to. Mastering the technique of welding angle iron is crucial for both hobbyists and professionals. These angles differ depending on the type of weld you intend to make. This angle is an important factor in determining. Welding At An Angle.

From www.youtube.com

How to Weld Mitered Corners YouTube Welding At An Angle These angles differ depending on. The welding electrode angle refers to the angle between the welding electrode and the workpiece during a welding process. We’ve outlined essential practices, common issues, and their solutions to. Mastering the technique of welding angle iron is crucial for both hobbyists and professionals. A steep, or “stickout,” angle can lead to excessive spatter and poor. Welding At An Angle.

From www.youtube.com

Joining angle iron at 90 degrees using 3 easy joint methods cope Welding At An Angle We’ve outlined essential practices, common issues, and their solutions to. Electrode angles are the angles at which you should hold the stick electrode in relation to the workpiece while welding. This angle is an important factor in determining weld strength and quality. Mastering the technique of welding angle iron is crucial for both hobbyists and professionals. A fillet weld joins. Welding At An Angle.

From weldguru.com

Welding Rod Sizes How To Choose the Right Electrode Weld Guru Welding At An Angle The angle of your welding electrode can have a significant impact on the quality of your weld. These angles differ depending on the type of weld you intend to make. The welding electrode angle refers to the angle between the welding electrode and the workpiece during a welding process. Electrode angles are the angles at which you should hold the. Welding At An Angle.

From www.youtube.com

few know the secret tricks of welding and cutting angle iron welding Welding At An Angle For instance, when doing a lap weld (one piece of metal overlaps another) or a t. The angle of your welding electrode can have a significant impact on the quality of your weld. These angles differ depending on. The welding electrode angle refers to the angle between the welding electrode and the workpiece during a welding process. A groove weld. Welding At An Angle.

From www.vecteezy.com

Fillet weld. 2f position. electrode angel type. 3 layers 2 pass fillet Welding At An Angle These angles differ depending on the type of weld you intend to make. These angles differ depending on. A fillet weld joins together two pieces of metal that are perpendicular or at an angle. Mastering the technique of welding angle iron is crucial for both hobbyists and professionals. For instance, when doing a lap weld (one piece of metal overlaps. Welding At An Angle.

From www.grainews.ca

How to weld corner joints Grainews Welding At An Angle A groove weld is made in a groove between workpieces or between workpiece edges. Mastering the technique of welding angle iron is crucial for both hobbyists and professionals. A fillet weld joins together two pieces of metal that are perpendicular or at an angle. The welding electrode angle refers to the angle between the welding electrode and the workpiece during. Welding At An Angle.

From www.youtube.com

Lead welding angles YouTube Welding At An Angle A fillet weld joins together two pieces of metal that are perpendicular or at an angle. The angle of your welding electrode can have a significant impact on the quality of your weld. These angles differ depending on. A groove weld is made in a groove between workpieces or between workpiece edges. We’ve outlined essential practices, common issues, and their. Welding At An Angle.

From www.youtube.com

Angle Iron Welding 3 Tricks for Beginners to Get Started YouTube Welding At An Angle The welding electrode angle refers to the angle between the welding electrode and the workpiece during a welding process. A fillet weld joins together two pieces of metal that are perpendicular or at an angle. A groove weld is made in a groove between workpieces or between workpiece edges. The angle of your welding electrode can have a significant impact. Welding At An Angle.

From weldingheadquarters.com

How to Weld Angle Iron Welding Headquarters Welding At An Angle These angles differ depending on the type of weld you intend to make. Mastering the technique of welding angle iron is crucial for both hobbyists and professionals. For instance, when doing a lap weld (one piece of metal overlaps another) or a t. The angle of your welding electrode can have a significant impact on the quality of your weld.. Welding At An Angle.

From www.youtube.com

Welding Basics Learning How To Use A Welding Square For Perfect Welding At An Angle The welding electrode angle refers to the angle between the welding electrode and the workpiece during a welding process. The angle of your welding electrode can have a significant impact on the quality of your weld. Mastering the technique of welding angle iron is crucial for both hobbyists and professionals. These angles differ depending on the type of weld you. Welding At An Angle.

From welderplanet.com

How To Read Welding Blueprints Welder Welding At An Angle A fillet weld joins together two pieces of metal that are perpendicular or at an angle. The welding electrode angle refers to the angle between the welding electrode and the workpiece during a welding process. These angles differ depending on. A groove weld is made in a groove between workpieces or between workpiece edges. These angles differ depending on the. Welding At An Angle.

From weldingclarity.com

How to Weld Angle Iron? Perfect Your Skill with These Tips Welding At An Angle This angle is an important factor in determining weld strength and quality. A fillet weld joins together two pieces of metal that are perpendicular or at an angle. The welding electrode angle refers to the angle between the welding electrode and the workpiece during a welding process. A steep, or “stickout,” angle can lead to excessive spatter and poor penetration,. Welding At An Angle.

From www.collisionblast.com

Auto Welding Lesson 6 Basic Auto Body and Paint Training Welding At An Angle A groove weld is made in a groove between workpieces or between workpiece edges. A steep, or “stickout,” angle can lead to excessive spatter and poor penetration, while a. Mastering the technique of welding angle iron is crucial for both hobbyists and professionals. These angles differ depending on the type of weld you intend to make. A fillet weld joins. Welding At An Angle.

From www.skillshack.co.uk

MIG Welding Masterclass Getting the Right Nozzle Angle Skill Shack Welding At An Angle The welding electrode angle refers to the angle between the welding electrode and the workpiece during a welding process. Electrode angles are the angles at which you should hold the stick electrode in relation to the workpiece while welding. These angles differ depending on. A fillet weld joins together two pieces of metal that are perpendicular or at an angle.. Welding At An Angle.

From www.youtube.com

easy waywelding 90 degree angle iron YouTube Welding At An Angle A steep, or “stickout,” angle can lead to excessive spatter and poor penetration, while a. The angle of your welding electrode can have a significant impact on the quality of your weld. We’ve outlined essential practices, common issues, and their solutions to. These angles differ depending on. This angle is an important factor in determining weld strength and quality. These. Welding At An Angle.

From weldguru.com

How To MIG Weld Stainless Steel A Beginners Guide Welding At An Angle Electrode angles are the angles at which you should hold the stick electrode in relation to the workpiece while welding. These angles differ depending on. A groove weld is made in a groove between workpieces or between workpiece edges. A fillet weld joins together two pieces of metal that are perpendicular or at an angle. We’ve outlined essential practices, common. Welding At An Angle.

From www.youtube.com

Inner angle welding YouTube Welding At An Angle Electrode angles are the angles at which you should hold the stick electrode in relation to the workpiece while welding. Mastering the technique of welding angle iron is crucial for both hobbyists and professionals. A groove weld is made in a groove between workpieces or between workpiece edges. The welding electrode angle refers to the angle between the welding electrode. Welding At An Angle.