Lubrication In Bearing . The benefits of lubricating a rolling bearing can be. Five actionable steps to choosing the proper lubricant and lubrication method for your bearings. Oil lubrication methods vary widely, but many are equipped with flingers, dams and splash systems that help circulate the oil regularly, extending the bearing’s life without direct maintenance. Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. Lubrication is essential to prevent premature ball bearing failure. The main purpose of lubrication in bearings is to separate metal surfaces, support loads, and eliminate or minimize wear. Bearing lubrication is the factor that has the largest impact on bearing life, with up to 80% of bearing failures attributable to lubrication and. By developing a layer of oil between the rollers and raceways, oil actually can separate the moving components, fully supporting the bearing loads and preventing wear. Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to prevent wear and tear and friction. Probably the most critical factor in maintaining operating conditions, the lubricant. Read the expert guide by eriks:

from precisionlubrication.com

The benefits of lubricating a rolling bearing can be. The main purpose of lubrication in bearings is to separate metal surfaces, support loads, and eliminate or minimize wear. Bearing lubrication is the factor that has the largest impact on bearing life, with up to 80% of bearing failures attributable to lubrication and. Read the expert guide by eriks: Oil lubrication methods vary widely, but many are equipped with flingers, dams and splash systems that help circulate the oil regularly, extending the bearing’s life without direct maintenance. Lubrication is essential to prevent premature ball bearing failure. Five actionable steps to choosing the proper lubricant and lubrication method for your bearings. Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to prevent wear and tear and friction. By developing a layer of oil between the rollers and raceways, oil actually can separate the moving components, fully supporting the bearing loads and preventing wear. Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings.

Bearing Lubrication Boost Bearing Useful Life by Mastering Lubrication Management

Lubrication In Bearing The main purpose of lubrication in bearings is to separate metal surfaces, support loads, and eliminate or minimize wear. Bearing lubrication is the factor that has the largest impact on bearing life, with up to 80% of bearing failures attributable to lubrication and. Read the expert guide by eriks: Lubrication is essential to prevent premature ball bearing failure. The main purpose of lubrication in bearings is to separate metal surfaces, support loads, and eliminate or minimize wear. Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to prevent wear and tear and friction. Probably the most critical factor in maintaining operating conditions, the lubricant. Oil lubrication methods vary widely, but many are equipped with flingers, dams and splash systems that help circulate the oil regularly, extending the bearing’s life without direct maintenance. By developing a layer of oil between the rollers and raceways, oil actually can separate the moving components, fully supporting the bearing loads and preventing wear. The benefits of lubricating a rolling bearing can be. Five actionable steps to choosing the proper lubricant and lubrication method for your bearings.

From www.machinerylubrication.com

Rolling Bearing Lubrication for Critical Running Conditions Lubrication In Bearing The benefits of lubricating a rolling bearing can be. Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to prevent wear and tear and friction. Bearing lubrication is the factor that has the largest impact on bearing life, with up to 80% of bearing failures attributable to lubrication and. Bearing lubrication is vital. Lubrication In Bearing.

From studylib.net

Lubrication of rolling bearing Tips and advice Lubrication In Bearing By developing a layer of oil between the rollers and raceways, oil actually can separate the moving components, fully supporting the bearing loads and preventing wear. The benefits of lubricating a rolling bearing can be. Bearing lubrication is the factor that has the largest impact on bearing life, with up to 80% of bearing failures attributable to lubrication and. Oil. Lubrication In Bearing.

From www.ien.eu

Bearing lubrication is essential Lubrication In Bearing Read the expert guide by eriks: By developing a layer of oil between the rollers and raceways, oil actually can separate the moving components, fully supporting the bearing loads and preventing wear. Lubrication is essential to prevent premature ball bearing failure. The benefits of lubricating a rolling bearing can be. Oil lubrication methods vary widely, but many are equipped with. Lubrication In Bearing.

From www.youtube.com

Pump bearing housing lubrication YouTube Lubrication In Bearing By developing a layer of oil between the rollers and raceways, oil actually can separate the moving components, fully supporting the bearing loads and preventing wear. Lubrication is essential to prevent premature ball bearing failure. Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to prevent wear and tear and friction. The benefits. Lubrication In Bearing.

From www.bearingtips.com

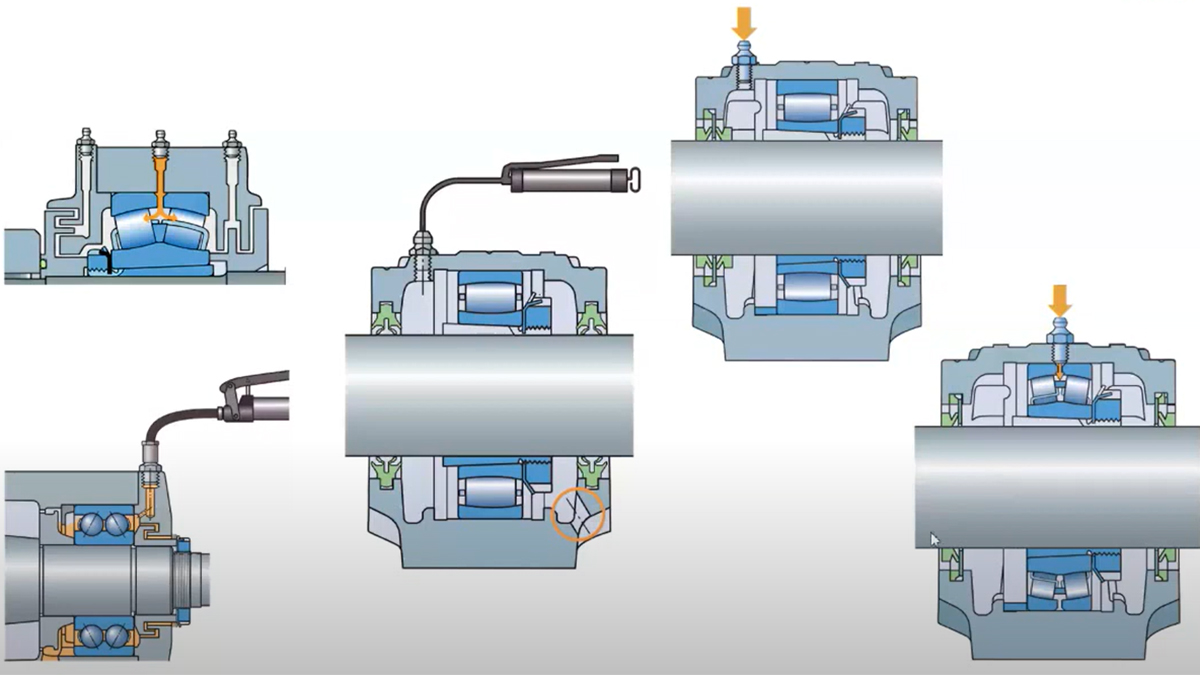

Bearing Lubrication Methods Bearing Tips Lubrication In Bearing By developing a layer of oil between the rollers and raceways, oil actually can separate the moving components, fully supporting the bearing loads and preventing wear. Lubrication is essential to prevent premature ball bearing failure. Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to prevent wear and tear and friction. The main. Lubrication In Bearing.

From www.linkedin.com

Different Methods of Lubrication Used in Rotating Equipment Bearing Lubrication In Bearing Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to prevent wear and tear and friction. Oil lubrication methods vary widely, but many are equipped with flingers, dams and splash systems that help circulate the oil regularly, extending the bearing’s life without direct maintenance. Read the expert guide by eriks: The benefits of. Lubrication In Bearing.

From precisionlubrication.com

Bearing Lubrication Boost Bearing Useful Life by Mastering Lubrication Management Lubrication In Bearing Oil lubrication methods vary widely, but many are equipped with flingers, dams and splash systems that help circulate the oil regularly, extending the bearing’s life without direct maintenance. Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. Read the expert guide by eriks: By developing a layer of oil between the rollers and raceways, oil. Lubrication In Bearing.

From www.machinerylubrication.com

Lubrication’s Effects on Rolling Bearing Reliability Lubrication In Bearing By developing a layer of oil between the rollers and raceways, oil actually can separate the moving components, fully supporting the bearing loads and preventing wear. Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to prevent wear and tear and friction. Oil lubrication methods vary widely, but many are equipped with flingers,. Lubrication In Bearing.

From justicebearing.com

Lubrication & Relube Justice Bearings Lubrication In Bearing Five actionable steps to choosing the proper lubricant and lubrication method for your bearings. By developing a layer of oil between the rollers and raceways, oil actually can separate the moving components, fully supporting the bearing loads and preventing wear. The benefits of lubricating a rolling bearing can be. Bearing lubrication is vital for preserving the performance and lifespan of. Lubrication In Bearing.

From www.mdpi.com

Applied Sciences Free FullText Experimental and Simulated Investigation of Lubrication Lubrication In Bearing Probably the most critical factor in maintaining operating conditions, the lubricant. Bearing lubrication is the factor that has the largest impact on bearing life, with up to 80% of bearing failures attributable to lubrication and. Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to prevent wear and tear and friction. Bearing lubrication. Lubrication In Bearing.

From eriks.com

Bearing grease select the right lubrication method Lubrication In Bearing By developing a layer of oil between the rollers and raceways, oil actually can separate the moving components, fully supporting the bearing loads and preventing wear. Bearing lubrication is the factor that has the largest impact on bearing life, with up to 80% of bearing failures attributable to lubrication and. Oil lubrication methods vary widely, but many are equipped with. Lubrication In Bearing.

From baartgroup.com

Lubricate a Mounted Bearing A Howto Guide Baart Group Lubrication In Bearing Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. Read the expert guide by eriks: By developing a layer of oil between the rollers and raceways, oil actually can separate the moving components, fully supporting the bearing loads and preventing wear. Lubrication helps separate moving parts relative to one another, such as rollers and raceways. Lubrication In Bearing.

From www.ibtinc.com

Bearing and Lubrication Maintenance IBT Training Lubrication In Bearing Oil lubrication methods vary widely, but many are equipped with flingers, dams and splash systems that help circulate the oil regularly, extending the bearing’s life without direct maintenance. The main purpose of lubrication in bearings is to separate metal surfaces, support loads, and eliminate or minimize wear. Lubrication is essential to prevent premature ball bearing failure. Five actionable steps to. Lubrication In Bearing.

From www.mckeownbiofuels.com

How to Lubricate Your Bearings Mckeown Biofuels Lubrication In Bearing Oil lubrication methods vary widely, but many are equipped with flingers, dams and splash systems that help circulate the oil regularly, extending the bearing’s life without direct maintenance. Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. Read the expert guide by eriks: Five actionable steps to choosing the proper lubricant and lubrication method for. Lubrication In Bearing.

From baartgroup.com

What is Solid Lubrication? Baart Industrial Group Lubrication In Bearing Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to prevent wear and tear and friction. Oil lubrication methods vary widely, but many are equipped with flingers, dams and splash systems that help circulate the oil regularly, extending the bearing’s life without direct maintenance. Probably the most critical factor in maintaining operating conditions,. Lubrication In Bearing.

From www.alamy.com

Ball bearing stainless with grease lithium machinery lubrication for automotive and industrial Lubrication In Bearing Oil lubrication methods vary widely, but many are equipped with flingers, dams and splash systems that help circulate the oil regularly, extending the bearing’s life without direct maintenance. By developing a layer of oil between the rollers and raceways, oil actually can separate the moving components, fully supporting the bearing loads and preventing wear. Bearing lubrication is the factor that. Lubrication In Bearing.

From savree.com

Bearing Lubrication Explained saVRee Lubrication In Bearing Read the expert guide by eriks: Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. Oil lubrication methods vary widely, but many are equipped with flingers, dams and splash systems that help circulate the oil regularly, extending the bearing’s life without direct maintenance. Lubrication is essential to prevent premature ball bearing failure. The benefits of. Lubrication In Bearing.

From www.bearingtips.com

When should I use solid film lubricants? Bearing Tips Lubrication In Bearing Read the expert guide by eriks: Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. Bearing lubrication is the factor that has the largest impact on bearing life, with up to 80% of bearing failures attributable to lubrication and. Lubrication is essential to prevent premature ball bearing failure. Oil lubrication methods vary widely, but many. Lubrication In Bearing.

From blog.slsbearings.com

The Importance of Lubrication in Bearings and Other Components Lubrication In Bearing Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to prevent wear and tear and friction. Probably the most critical factor in maintaining operating conditions, the lubricant. Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. By developing a layer of oil between the rollers and raceways, oil. Lubrication In Bearing.

From nmbtc.com

Ball Bearings Lubrication Selection NMB Technologies Lubrication In Bearing Lubrication is essential to prevent premature ball bearing failure. By developing a layer of oil between the rollers and raceways, oil actually can separate the moving components, fully supporting the bearing loads and preventing wear. Oil lubrication methods vary widely, but many are equipped with flingers, dams and splash systems that help circulate the oil regularly, extending the bearing’s life. Lubrication In Bearing.

From www.youtube.com

How to Properly Lubricate a Plain Linear Bearing YouTube Lubrication In Bearing Probably the most critical factor in maintaining operating conditions, the lubricant. Read the expert guide by eriks: By developing a layer of oil between the rollers and raceways, oil actually can separate the moving components, fully supporting the bearing loads and preventing wear. Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to. Lubrication In Bearing.

From baartgroup.com

What Is Solid Lubrication? Baart Group Lubrication In Bearing Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. Lubrication is essential to prevent premature ball bearing failure. Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to prevent wear and tear and friction. The benefits of lubricating a rolling bearing can be. Five actionable steps to choosing. Lubrication In Bearing.

From www.plantengineering.com

Plant Engineering Understanding lubrication from the bearing’s perspective Lubrication In Bearing Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. Read the expert guide by eriks: By developing a layer of oil between the rollers and raceways, oil actually can separate the moving components, fully supporting the bearing loads and preventing wear. Lubrication is essential to prevent premature ball bearing failure. The main purpose of lubrication. Lubrication In Bearing.

From belgo-bearings.com

Bearing Lubrication Belgo Bearings Lubrication In Bearing Read the expert guide by eriks: The benefits of lubricating a rolling bearing can be. Bearing lubrication is the factor that has the largest impact on bearing life, with up to 80% of bearing failures attributable to lubrication and. By developing a layer of oil between the rollers and raceways, oil actually can separate the moving components, fully supporting the. Lubrication In Bearing.

From www.bosch-presse.de

Conductive lubricants will protect the electric motors of the future Bosch Media Service Lubrication In Bearing The main purpose of lubrication in bearings is to separate metal surfaces, support loads, and eliminate or minimize wear. Read the expert guide by eriks: Bearing lubrication is the factor that has the largest impact on bearing life, with up to 80% of bearing failures attributable to lubrication and. By developing a layer of oil between the rollers and raceways,. Lubrication In Bearing.

From precisionlubrication.com

How to Properly Lubricate a Rolling Element Bearing Lubrication In Bearing Lubrication is essential to prevent premature ball bearing failure. By developing a layer of oil between the rollers and raceways, oil actually can separate the moving components, fully supporting the bearing loads and preventing wear. Bearing lubrication is the factor that has the largest impact on bearing life, with up to 80% of bearing failures attributable to lubrication and. Bearing. Lubrication In Bearing.

From blog.slsbearings.com

8 Tips For Bearing Maintenance Lubrication In Bearing Five actionable steps to choosing the proper lubricant and lubrication method for your bearings. Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. The main purpose of lubrication in bearings is to separate metal surfaces, support loads, and eliminate or minimize wear. Probably the most critical factor in maintaining operating conditions, the lubricant. Read the. Lubrication In Bearing.

From www.researchgate.net

Lubrication in roller bearing based on elastohydrodynamic theory Download Scientific Diagram Lubrication In Bearing By developing a layer of oil between the rollers and raceways, oil actually can separate the moving components, fully supporting the bearing loads and preventing wear. The benefits of lubricating a rolling bearing can be. Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. Oil lubrication methods vary widely, but many are equipped with flingers,. Lubrication In Bearing.

From www.maintworld.com

Bearing Lubrication Best Practices What to Know and Mistakes to Avoid Asset Management Lubrication In Bearing Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. The main purpose of lubrication in bearings is to separate metal surfaces, support loads, and eliminate or minimize wear. Lubrication is essential to prevent premature ball bearing failure. Probably the most critical factor in maintaining operating conditions, the lubricant. Read the expert guide by eriks: Bearing. Lubrication In Bearing.

From www.machinerylubrication.com

Rolling Bearing Lubrication for Critical Running Conditions Lubrication In Bearing Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. The benefits of lubricating a rolling bearing can be. Oil lubrication methods vary widely, but many are equipped with flingers, dams and splash systems that help circulate the oil regularly, extending the bearing’s life without direct maintenance. Lubrication helps separate moving parts relative to one another,. Lubrication In Bearing.

From www.machinerylubrication.com

Selecting the Correct Lubricant for Bearing Applications Lubrication In Bearing Five actionable steps to choosing the proper lubricant and lubrication method for your bearings. Lubrication is essential to prevent premature ball bearing failure. The benefits of lubricating a rolling bearing can be. Probably the most critical factor in maintaining operating conditions, the lubricant. The main purpose of lubrication in bearings is to separate metal surfaces, support loads, and eliminate or. Lubrication In Bearing.

From www.marineinsight.com

Ship's Main Engine Lubrication System Explained Lubrication In Bearing Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. The benefits of lubricating a rolling bearing can be. By developing a layer of oil between the rollers and raceways, oil actually can separate the moving components, fully supporting the bearing loads and preventing wear. Five actionable steps to choosing the proper lubricant and lubrication method. Lubrication In Bearing.

From smbbearings.blogspot.com

SMB Bearings Ltd Blog Bearing Lubrication the importance of lubricant selection for ball bearings Lubrication In Bearing Probably the most critical factor in maintaining operating conditions, the lubricant. The benefits of lubricating a rolling bearing can be. Five actionable steps to choosing the proper lubricant and lubrication method for your bearings. Bearing lubrication is the factor that has the largest impact on bearing life, with up to 80% of bearing failures attributable to lubrication and. Bearing lubrication. Lubrication In Bearing.

From lubchem.com

What is the Best Bearing Lubrication? Oil vs Grease Lubchem, Inc. Lubrication In Bearing Oil lubrication methods vary widely, but many are equipped with flingers, dams and splash systems that help circulate the oil regularly, extending the bearing’s life without direct maintenance. Probably the most critical factor in maintaining operating conditions, the lubricant. Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to prevent wear and tear. Lubrication In Bearing.

From www.youtube.com

How to lubricate your bearings YouTube Lubrication In Bearing Bearing lubrication is vital for preserving the performance and lifespan of rolling element bearings. Lubrication helps separate moving parts relative to one another, such as rollers and raceways or balls, to prevent wear and tear and friction. The main purpose of lubrication in bearings is to separate metal surfaces, support loads, and eliminate or minimize wear. Bearing lubrication is the. Lubrication In Bearing.