Pin Ejector Definition . The most frequently used component of a mold’s ejection system is the ejector pin, which includes variations such as sleeves and blades. Ejector pins are designed to push or eject the molded parts out of the mold cavity, ensuring that they are released without damage and with precision. These pins, typically made of hardened steel, are responsible for forcefully ejecting the molded part from the mold cavity once the cooling process is complete. An ejector pin is an ejector system that pushes the molded part out of the mold cavity after injection. Part size, draft angle, shape complexity,. Alongside ejector systems such as ejector blades and blocks, ejector allows efficient parts removal after molding. There are several types of ejector pins. Ejector pins are vital in creating parts. An ejector pin is a specialized tool used in injection molding to help eject the molded part from the mold cavity after it has solidified. Think of them as the bouncers of the injection molding world, ensuring a smooth exit for the finished product. Ejector pins are slender rods that apply force to eject the part from the mold, ensuring that it is released without damage. Ejector pins are typically cylindrical in shape with a rounded tip and are mounted in the ejector plate or in the movable half of the mold (known as the ejector half). When it comes to injection molding, ejector pins are the unsung heroes. They are an essential part of the mold’s design, contributing to the efficiency and effectiveness of the injection molding process. They are an integral component of the ejection system in mold, which determines the outcome of products in an injection.

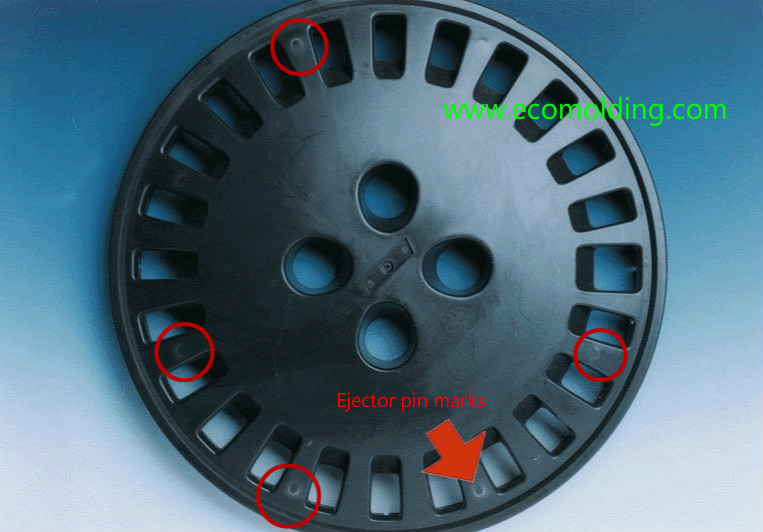

from www.ecomolding.com

The most frequently used component of a mold’s ejection system is the ejector pin, which includes variations such as sleeves and blades. They are an essential part of the mold’s design, contributing to the efficiency and effectiveness of the injection molding process. Ejector pins are designed to push or eject the molded parts out of the mold cavity, ensuring that they are released without damage and with precision. These pins, typically made of hardened steel, are responsible for forcefully ejecting the molded part from the mold cavity once the cooling process is complete. Think of them as the bouncers of the injection molding world, ensuring a smooth exit for the finished product. Ejector pins are vital in creating parts. They are an integral component of the ejection system in mold, which determines the outcome of products in an injection. Part size, draft angle, shape complexity,. Ejector pins are slender rods that apply force to eject the part from the mold, ensuring that it is released without damage. An ejector pin is an ejector system that pushes the molded part out of the mold cavity after injection.

What causes ejector pin marks in injection molded parts?

Pin Ejector Definition There are several types of ejector pins. These pins, typically made of hardened steel, are responsible for forcefully ejecting the molded part from the mold cavity once the cooling process is complete. Part size, draft angle, shape complexity,. Ejector pins are designed to push or eject the molded parts out of the mold cavity, ensuring that they are released without damage and with precision. They are an essential part of the mold’s design, contributing to the efficiency and effectiveness of the injection molding process. Ejector pins are slender rods that apply force to eject the part from the mold, ensuring that it is released without damage. They are an integral component of the ejection system in mold, which determines the outcome of products in an injection. Alongside ejector systems such as ejector blades and blocks, ejector allows efficient parts removal after molding. An ejector pin is a specialized tool used in injection molding to help eject the molded part from the mold cavity after it has solidified. There are several types of ejector pins. The most frequently used component of a mold’s ejection system is the ejector pin, which includes variations such as sleeves and blades. Ejector pins are vital in creating parts. An ejector pin is an ejector system that pushes the molded part out of the mold cavity after injection. Ejector pins are typically cylindrical in shape with a rounded tip and are mounted in the ejector plate or in the movable half of the mold (known as the ejector half). When it comes to injection molding, ejector pins are the unsung heroes. Think of them as the bouncers of the injection molding world, ensuring a smooth exit for the finished product.

From www.egwhiter.co.nz

Ejector Pins Pin Ejector Definition They are an integral component of the ejection system in mold, which determines the outcome of products in an injection. They are an essential part of the mold’s design, contributing to the efficiency and effectiveness of the injection molding process. Ejector pins are slender rods that apply force to eject the part from the mold, ensuring that it is released. Pin Ejector Definition.

From www.indiamart.com

Ejector Pin, Material Grade EN31,H13 at Rs 20/piece in Manesar ID Pin Ejector Definition Part size, draft angle, shape complexity,. Alongside ejector systems such as ejector blades and blocks, ejector allows efficient parts removal after molding. There are several types of ejector pins. An ejector pin is a specialized tool used in injection molding to help eject the molded part from the mold cavity after it has solidified. Think of them as the bouncers. Pin Ejector Definition.

From www.bukalapak.com

Jual Ejektor Pin D.x200mm SKD61 Straight Ejector Pin Injection Mold Pin Ejector Definition Ejector pins are typically cylindrical in shape with a rounded tip and are mounted in the ejector plate or in the movable half of the mold (known as the ejector half). Ejector pins are slender rods that apply force to eject the part from the mold, ensuring that it is released without damage. Ejector pins are designed to push or. Pin Ejector Definition.

From www.xiamenhuaye.com

The layout principle of Ejector Pin HUAYE Pin Ejector Definition When it comes to injection molding, ejector pins are the unsung heroes. These pins, typically made of hardened steel, are responsible for forcefully ejecting the molded part from the mold cavity once the cooling process is complete. They are an essential part of the mold’s design, contributing to the efficiency and effectiveness of the injection molding process. They are an. Pin Ejector Definition.

From www.ecomolding.com

What causes ejector pin marks in injection molded parts? Pin Ejector Definition They are an integral component of the ejection system in mold, which determines the outcome of products in an injection. These pins, typically made of hardened steel, are responsible for forcefully ejecting the molded part from the mold cavity once the cooling process is complete. Part size, draft angle, shape complexity,. Think of them as the bouncers of the injection. Pin Ejector Definition.

From www.researchgate.net

Graphic template of ejector pin. a Section of the ejector pin. b The Pin Ejector Definition An ejector pin is an ejector system that pushes the molded part out of the mold cavity after injection. Part size, draft angle, shape complexity,. These pins, typically made of hardened steel, are responsible for forcefully ejecting the molded part from the mold cavity once the cooling process is complete. When it comes to injection molding, ejector pins are the. Pin Ejector Definition.

From www.indiamart.com

Vardhman Steel Flat Ejector Pins, Packaging Type Standard at Rs 25 Pin Ejector Definition They are an integral component of the ejection system in mold, which determines the outcome of products in an injection. These pins, typically made of hardened steel, are responsible for forcefully ejecting the molded part from the mold cavity once the cooling process is complete. They are an essential part of the mold’s design, contributing to the efficiency and effectiveness. Pin Ejector Definition.

From www.hadaseikou.co.jp

ストレートエジェクタピン(全長決め)|秦精工株式会社 Pin Ejector Definition Think of them as the bouncers of the injection molding world, ensuring a smooth exit for the finished product. There are several types of ejector pins. Ejector pins are vital in creating parts. These pins, typically made of hardened steel, are responsible for forcefully ejecting the molded part from the mold cavity once the cooling process is complete. An ejector. Pin Ejector Definition.

From aroroi.com

リターンピンとエジェクタガイドピン【射出成形金型】スプリング あろろい Pin Ejector Definition Ejector pins are vital in creating parts. These pins, typically made of hardened steel, are responsible for forcefully ejecting the molded part from the mold cavity once the cooling process is complete. Alongside ejector systems such as ejector blades and blocks, ejector allows efficient parts removal after molding. They are an essential part of the mold’s design, contributing to the. Pin Ejector Definition.

From www.hadaseikou.co.jp

エジェクタピン(押出しピン)とコアピン(鋳抜きピン)の違いとは? エジェクタピンとコアピンの豆知識 Pin Ejector Definition There are several types of ejector pins. Think of them as the bouncers of the injection molding world, ensuring a smooth exit for the finished product. These pins, typically made of hardened steel, are responsible for forcefully ejecting the molded part from the mold cavity once the cooling process is complete. Ejector pins are typically cylindrical in shape with a. Pin Ejector Definition.

From www.vapsupplies.co.za

Stepped Ejector Pin VAP South Africa (Pty) Ltd Pin Ejector Definition They are an essential part of the mold’s design, contributing to the efficiency and effectiveness of the injection molding process. These pins, typically made of hardened steel, are responsible for forcefully ejecting the molded part from the mold cavity once the cooling process is complete. An ejector pin is an ejector system that pushes the molded part out of the. Pin Ejector Definition.

From www.diytrade.com

Ejector PIN Litian (China Manufacturer) Mold Machine Hardware Pin Ejector Definition Alongside ejector systems such as ejector blades and blocks, ejector allows efficient parts removal after molding. Ejector pins are vital in creating parts. They are an integral component of the ejection system in mold, which determines the outcome of products in an injection. These pins, typically made of hardened steel, are responsible for forcefully ejecting the molded part from the. Pin Ejector Definition.

From autoplasticsworld.com

Ejector Pins A Comprehensive Guide Pin Ejector Definition These pins, typically made of hardened steel, are responsible for forcefully ejecting the molded part from the mold cavity once the cooling process is complete. They are an essential part of the mold’s design, contributing to the efficiency and effectiveness of the injection molding process. There are several types of ejector pins. They are an integral component of the ejection. Pin Ejector Definition.

From www.mould-part.com

Cylindrical Head DIN1530A Ejector Pins And Sleeves Pin Ejector Definition There are several types of ejector pins. They are an essential part of the mold’s design, contributing to the efficiency and effectiveness of the injection molding process. Alongside ejector systems such as ejector blades and blocks, ejector allows efficient parts removal after molding. Ejector pins are slender rods that apply force to eject the part from the mold, ensuring that. Pin Ejector Definition.

From prototool.com

A Closer Look At The Ejector Pin in Injection Molding Pin Ejector Definition Think of them as the bouncers of the injection molding world, ensuring a smooth exit for the finished product. An ejector pin is a specialized tool used in injection molding to help eject the molded part from the mold cavity after it has solidified. They are an essential part of the mold’s design, contributing to the efficiency and effectiveness of. Pin Ejector Definition.

From www.nexpcb.com

One Picture to Understand the Structure of an Injection Mold Pin Ejector Definition Ejector pins are slender rods that apply force to eject the part from the mold, ensuring that it is released without damage. When it comes to injection molding, ejector pins are the unsung heroes. Alongside ejector systems such as ejector blades and blocks, ejector allows efficient parts removal after molding. They are an integral component of the ejection system in. Pin Ejector Definition.

From cgjmkj.en.made-in-china.com

High Precision Types Vijaydeep PCS Ejector Pins of Ejector Pin China Pin Ejector Definition Ejector pins are typically cylindrical in shape with a rounded tip and are mounted in the ejector plate or in the movable half of the mold (known as the ejector half). An ejector pin is a specialized tool used in injection molding to help eject the molded part from the mold cavity after it has solidified. They are an essential. Pin Ejector Definition.

From www.indiamart.com

Step Ejector Pin at Rs 10/piece Step Ejector Pin in Mumbai ID Pin Ejector Definition Ejector pins are typically cylindrical in shape with a rounded tip and are mounted in the ejector plate or in the movable half of the mold (known as the ejector half). They are an integral component of the ejection system in mold, which determines the outcome of products in an injection. The most frequently used component of a mold’s ejection. Pin Ejector Definition.

From www.indiamart.com

Mild Steel Polished CE Ejector Pin, Packaging Type Carton Box at Rs 20 Pin Ejector Definition Think of them as the bouncers of the injection molding world, ensuring a smooth exit for the finished product. Alongside ejector systems such as ejector blades and blocks, ejector allows efficient parts removal after molding. They are an integral component of the ejection system in mold, which determines the outcome of products in an injection. These pins, typically made of. Pin Ejector Definition.

From www.nationalpune.com

Ejector Pin Wholesale Trader from Pune Pin Ejector Definition When it comes to injection molding, ejector pins are the unsung heroes. There are several types of ejector pins. These pins, typically made of hardened steel, are responsible for forcefully ejecting the molded part from the mold cavity once the cooling process is complete. Part size, draft angle, shape complexity,. Think of them as the bouncers of the injection molding. Pin Ejector Definition.

From www.hasonindustry.com

Ejector pins with D head Ejector Pins Sleeves Ejector Pins Sleeves Pin Ejector Definition These pins, typically made of hardened steel, are responsible for forcefully ejecting the molded part from the mold cavity once the cooling process is complete. Ejector pins are vital in creating parts. Ejector pins are typically cylindrical in shape with a rounded tip and are mounted in the ejector plate or in the movable half of the mold (known as. Pin Ejector Definition.

From www.mqmold.com

Ejection_MQ Mold Co.,Ltd. Pin Ejector Definition Ejector pins are designed to push or eject the molded parts out of the mold cavity, ensuring that they are released without damage and with precision. Part size, draft angle, shape complexity,. An ejector pin is a specialized tool used in injection molding to help eject the molded part from the mold cavity after it has solidified. They are an. Pin Ejector Definition.

From www.hadaseikou.co.jp

エジェクタピン(押出しピン)とコアピン(鋳抜きピン)の違いとは? エジェクタピンとコアピンの豆知識 Pin Ejector Definition Ejector pins are vital in creating parts. Alongside ejector systems such as ejector blades and blocks, ejector allows efficient parts removal after molding. The most frequently used component of a mold’s ejection system is the ejector pin, which includes variations such as sleeves and blades. They are an integral component of the ejection system in mold, which determines the outcome. Pin Ejector Definition.

From dmscomponents.com

DHead Ejector Pins Nitrided Parallel 1/8 6" DPIN12L06 Pin Ejector Definition Alongside ejector systems such as ejector blades and blocks, ejector allows efficient parts removal after molding. These pins, typically made of hardened steel, are responsible for forcefully ejecting the molded part from the mold cavity once the cooling process is complete. There are several types of ejector pins. Ejector pins are slender rods that apply force to eject the part. Pin Ejector Definition.

From yizhengpart.en.made-in-china.com

Mould Component Ejector Pins/Core Pins/Shoulder Ejector Pin for Plastic Pin Ejector Definition There are several types of ejector pins. When it comes to injection molding, ejector pins are the unsung heroes. Alongside ejector systems such as ejector blades and blocks, ejector allows efficient parts removal after molding. These pins, typically made of hardened steel, are responsible for forcefully ejecting the molded part from the mold cavity once the cooling process is complete.. Pin Ejector Definition.

From www.researchgate.net

Compliant 2DOF ejector pin mechanism for the mass transfer of robotic Pin Ejector Definition An ejector pin is an ejector system that pushes the molded part out of the mold cavity after injection. They are an essential part of the mold’s design, contributing to the efficiency and effectiveness of the injection molding process. Ejector pins are vital in creating parts. The most frequently used component of a mold’s ejection system is the ejector pin,. Pin Ejector Definition.

From www.yubomold.com

High Precision ejector pin Yubo Mold Parts Pin Ejector Definition Think of them as the bouncers of the injection molding world, ensuring a smooth exit for the finished product. They are an essential part of the mold’s design, contributing to the efficiency and effectiveness of the injection molding process. Ejector pins are vital in creating parts. The most frequently used component of a mold’s ejection system is the ejector pin,. Pin Ejector Definition.

From www.hadaseikou.co.jp

エジェクタピン(押出しピン)・コアピン|秦精工株式会社 Pin Ejector Definition When it comes to injection molding, ejector pins are the unsung heroes. An ejector pin is an ejector system that pushes the molded part out of the mold cavity after injection. Alongside ejector systems such as ejector blades and blocks, ejector allows efficient parts removal after molding. An ejector pin is a specialized tool used in injection molding to help. Pin Ejector Definition.

From www.exportersindia.com

Ejector Pins, Nitrided Ejector Pins Buy Ejector Pins, Nitrided Ejector Pins Pin Ejector Definition Ejector pins are typically cylindrical in shape with a rounded tip and are mounted in the ejector plate or in the movable half of the mold (known as the ejector half). Part size, draft angle, shape complexity,. Think of them as the bouncers of the injection molding world, ensuring a smooth exit for the finished product. Ejector pins are slender. Pin Ejector Definition.

From autoplasticsworld.com

Ejector Pins A Comprehensive Guide Pin Ejector Definition Ejector pins are slender rods that apply force to eject the part from the mold, ensuring that it is released without damage. They are an essential part of the mold’s design, contributing to the efficiency and effectiveness of the injection molding process. The most frequently used component of a mold’s ejection system is the ejector pin, which includes variations such. Pin Ejector Definition.

From ja.boyiprototyping.com

射出成形におけるエジェクタピン:種類、用途、材質 BOYI Pin Ejector Definition Ejector pins are designed to push or eject the molded parts out of the mold cavity, ensuring that they are released without damage and with precision. There are several types of ejector pins. Think of them as the bouncers of the injection molding world, ensuring a smooth exit for the finished product. When it comes to injection molding, ejector pins. Pin Ejector Definition.

From dir.indiamart.com

Ejector Pins Injector Pin Latest Price, Manufacturers & Suppliers Pin Ejector Definition Ejector pins are designed to push or eject the molded parts out of the mold cavity, ensuring that they are released without damage and with precision. Ejector pins are typically cylindrical in shape with a rounded tip and are mounted in the ejector plate or in the movable half of the mold (known as the ejector half). An ejector pin. Pin Ejector Definition.

From www.moldmakingtechnology.com

Ejector Pin Selection Guide MoldMaking Technology Pin Ejector Definition They are an integral component of the ejection system in mold, which determines the outcome of products in an injection. Ejector pins are vital in creating parts. When it comes to injection molding, ejector pins are the unsung heroes. Alongside ejector systems such as ejector blades and blocks, ejector allows efficient parts removal after molding. An ejector pin is an. Pin Ejector Definition.

From www.indiamart.com

Stainless Steel Ejector Pin, Rs 45 /piece Shree Samarth Traders ID Pin Ejector Definition These pins, typically made of hardened steel, are responsible for forcefully ejecting the molded part from the mold cavity once the cooling process is complete. Ejector pins are designed to push or eject the molded parts out of the mold cavity, ensuring that they are released without damage and with precision. Alongside ejector systems such as ejector blades and blocks,. Pin Ejector Definition.

From plantecuador.com

Firearm signatures on a fired cartridge case include the firing, fired Pin Ejector Definition Ejector pins are designed to push or eject the molded parts out of the mold cavity, ensuring that they are released without damage and with precision. Ejector pins are vital in creating parts. Ejector pins are typically cylindrical in shape with a rounded tip and are mounted in the ejector plate or in the movable half of the mold (known. Pin Ejector Definition.