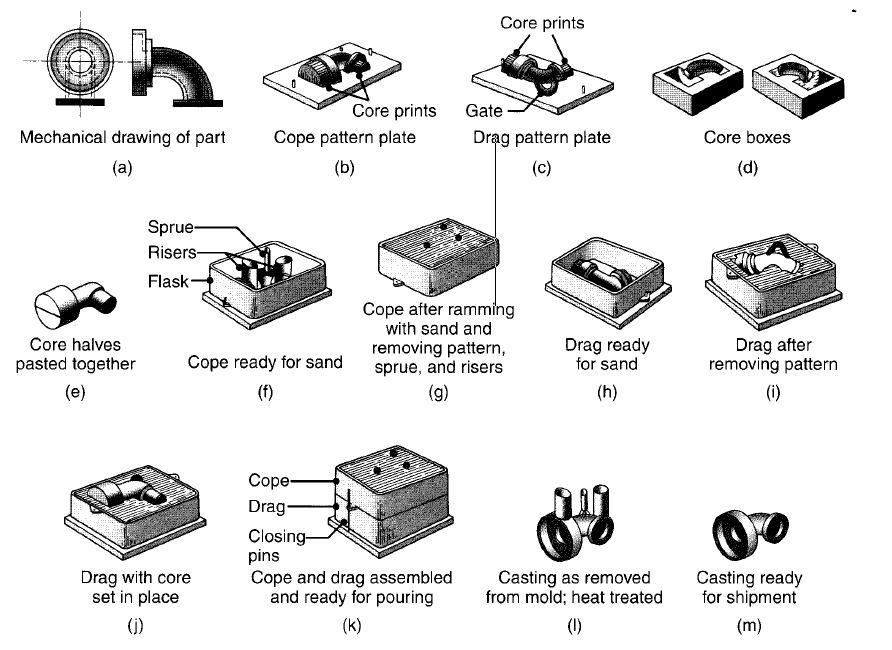

Sand Casting Mould Diagram . The process involves pouring of the molten metal in to the mold. Melted metal is poured into a sand mold that has a cavity in it, where it. The six steps of the sand casting process are; Sand cores form internal features like holes. Wooden, plastic, or metal patterns create the mold cavity. How does sand casting works? Green sand moulding is a traditional and widely used foundry process that forms the backbone of metal casting operations. Placing the mold in patern in sand, setting up the gating system, removing the mold pattern, pour molten metal into mold cavity, wait for the metal to cool, the final step is to break There are 6 steps involved in the sand casting process, which includes making pattern and core → making sand mould. It involves the creation of moulds using a mixture of silica sand, water, and a clay binder, giving it a In sand casting which is also known as sand molded casting, an object is produced by sand mold.

from engineeringproductdesign.com

Green sand moulding is a traditional and widely used foundry process that forms the backbone of metal casting operations. It involves the creation of moulds using a mixture of silica sand, water, and a clay binder, giving it a Sand cores form internal features like holes. The six steps of the sand casting process are; How does sand casting works? There are 6 steps involved in the sand casting process, which includes making pattern and core → making sand mould. Wooden, plastic, or metal patterns create the mold cavity. In sand casting which is also known as sand molded casting, an object is produced by sand mold. The process involves pouring of the molten metal in to the mold. Placing the mold in patern in sand, setting up the gating system, removing the mold pattern, pour molten metal into mold cavity, wait for the metal to cool, the final step is to break

What is Sand casting & How does it work? Pros & Cons casting

Sand Casting Mould Diagram Sand cores form internal features like holes. There are 6 steps involved in the sand casting process, which includes making pattern and core → making sand mould. How does sand casting works? Melted metal is poured into a sand mold that has a cavity in it, where it. Sand cores form internal features like holes. In sand casting which is also known as sand molded casting, an object is produced by sand mold. The six steps of the sand casting process are; Wooden, plastic, or metal patterns create the mold cavity. Placing the mold in patern in sand, setting up the gating system, removing the mold pattern, pour molten metal into mold cavity, wait for the metal to cool, the final step is to break It involves the creation of moulds using a mixture of silica sand, water, and a clay binder, giving it a The process involves pouring of the molten metal in to the mold. Green sand moulding is a traditional and widely used foundry process that forms the backbone of metal casting operations.

From www.andersonglobal.com

Sand Casting Patterns Anderson Global Sand Casting Mould Diagram The six steps of the sand casting process are; It involves the creation of moulds using a mixture of silica sand, water, and a clay binder, giving it a Wooden, plastic, or metal patterns create the mold cavity. How does sand casting works? Sand cores form internal features like holes. Melted metal is poured into a sand mold that has. Sand Casting Mould Diagram.

From msvs-dei.vlabs.ac.in

Manufacturing ProcessesI Sand Casting Mould Diagram In sand casting which is also known as sand molded casting, an object is produced by sand mold. Placing the mold in patern in sand, setting up the gating system, removing the mold pattern, pour molten metal into mold cavity, wait for the metal to cool, the final step is to break Sand cores form internal features like holes. There. Sand Casting Mould Diagram.

From www.alucast.co.uk

Sand moulding full Alucast, aluminium casting, aluminium castings Sand Casting Mould Diagram In sand casting which is also known as sand molded casting, an object is produced by sand mold. There are 6 steps involved in the sand casting process, which includes making pattern and core → making sand mould. Wooden, plastic, or metal patterns create the mold cavity. Green sand moulding is a traditional and widely used foundry process that forms. Sand Casting Mould Diagram.

From www.zhycasting.com

Design and Working Process of Sand Core Mould for Complex Turbine Cover Sand Casting Mould Diagram The six steps of the sand casting process are; Placing the mold in patern in sand, setting up the gating system, removing the mold pattern, pour molten metal into mold cavity, wait for the metal to cool, the final step is to break There are 6 steps involved in the sand casting process, which includes making pattern and core →. Sand Casting Mould Diagram.

From www.open.edu

Sand casting OpenLearn Open University Sand Casting Mould Diagram It involves the creation of moulds using a mixture of silica sand, water, and a clay binder, giving it a In sand casting which is also known as sand molded casting, an object is produced by sand mold. Wooden, plastic, or metal patterns create the mold cavity. Placing the mold in patern in sand, setting up the gating system, removing. Sand Casting Mould Diagram.

From mechanicalinventions.blogspot.com

Diferent Parts of Sand Mold Features Mechanical Engineering Sand Casting Mould Diagram The process involves pouring of the molten metal in to the mold. Wooden, plastic, or metal patterns create the mold cavity. How does sand casting works? In sand casting which is also known as sand molded casting, an object is produced by sand mold. The six steps of the sand casting process are; Placing the mold in patern in sand,. Sand Casting Mould Diagram.

From www.vrogue.co

Types Of Pattern In Casting Process Explained In Deta vrogue.co Sand Casting Mould Diagram Green sand moulding is a traditional and widely used foundry process that forms the backbone of metal casting operations. It involves the creation of moulds using a mixture of silica sand, water, and a clay binder, giving it a Placing the mold in patern in sand, setting up the gating system, removing the mold pattern, pour molten metal into mold. Sand Casting Mould Diagram.

From www.iqsdirectory.com

Sand Casting Construction, Types, Applications, and Advantages Sand Casting Mould Diagram There are 6 steps involved in the sand casting process, which includes making pattern and core → making sand mould. Green sand moulding is a traditional and widely used foundry process that forms the backbone of metal casting operations. Wooden, plastic, or metal patterns create the mold cavity. It involves the creation of moulds using a mixture of silica sand,. Sand Casting Mould Diagram.

From www.zhycasting.com

Arrangement of teaching links of sand casting ZHY Casting Sand Casting Mould Diagram Green sand moulding is a traditional and widely used foundry process that forms the backbone of metal casting operations. The six steps of the sand casting process are; It involves the creation of moulds using a mixture of silica sand, water, and a clay binder, giving it a In sand casting which is also known as sand molded casting, an. Sand Casting Mould Diagram.

From coadengineering.com

The components of the sand casting process Coadengineering Sand Casting Mould Diagram Placing the mold in patern in sand, setting up the gating system, removing the mold pattern, pour molten metal into mold cavity, wait for the metal to cool, the final step is to break The process involves pouring of the molten metal in to the mold. Sand cores form internal features like holes. In sand casting which is also known. Sand Casting Mould Diagram.

From localrevive.com

Construction, Types, Applications, and Advantages (2022) Sand Casting Mould Diagram There are 6 steps involved in the sand casting process, which includes making pattern and core → making sand mould. How does sand casting works? Placing the mold in patern in sand, setting up the gating system, removing the mold pattern, pour molten metal into mold cavity, wait for the metal to cool, the final step is to break It. Sand Casting Mould Diagram.

From www.the-warren.org

Sand Casting Sand Casting Mould Diagram How does sand casting works? Green sand moulding is a traditional and widely used foundry process that forms the backbone of metal casting operations. In sand casting which is also known as sand molded casting, an object is produced by sand mold. Wooden, plastic, or metal patterns create the mold cavity. Melted metal is poured into a sand mold that. Sand Casting Mould Diagram.

From engineeringproductdesign.com

What is Sand casting & How does it work? Pros & Cons casting Sand Casting Mould Diagram There are 6 steps involved in the sand casting process, which includes making pattern and core → making sand mould. In sand casting which is also known as sand molded casting, an object is produced by sand mold. The six steps of the sand casting process are; Placing the mold in patern in sand, setting up the gating system, removing. Sand Casting Mould Diagram.

From www.zhycasting.com

Introduce sand casting parts ZHY Casting Sand Casting Mould Diagram The process involves pouring of the molten metal in to the mold. Melted metal is poured into a sand mold that has a cavity in it, where it. Placing the mold in patern in sand, setting up the gating system, removing the mold pattern, pour molten metal into mold cavity, wait for the metal to cool, the final step is. Sand Casting Mould Diagram.

From www.mechgrace.com

Core In Sand Casting Core Design Application Advantages Core In Sand Casting Mould Diagram Melted metal is poured into a sand mold that has a cavity in it, where it. It involves the creation of moulds using a mixture of silica sand, water, and a clay binder, giving it a There are 6 steps involved in the sand casting process, which includes making pattern and core → making sand mould. In sand casting which. Sand Casting Mould Diagram.

From www.youtube.com

How to make a sand mold for casting metal YouTube Sand Casting Mould Diagram Green sand moulding is a traditional and widely used foundry process that forms the backbone of metal casting operations. The six steps of the sand casting process are; Melted metal is poured into a sand mold that has a cavity in it, where it. Sand cores form internal features like holes. Wooden, plastic, or metal patterns create the mold cavity.. Sand Casting Mould Diagram.

From engineeringstuff.co.in

Sand mold casting Explained Engineeringstuff Sand Casting Mould Diagram There are 6 steps involved in the sand casting process, which includes making pattern and core → making sand mould. How does sand casting works? Melted metal is poured into a sand mold that has a cavity in it, where it. In sand casting which is also known as sand molded casting, an object is produced by sand mold. It. Sand Casting Mould Diagram.

From www.pinterest.com

Handbook The Ultimate Guide to Metal Casting It cast, Metal casting Sand Casting Mould Diagram The process involves pouring of the molten metal in to the mold. There are 6 steps involved in the sand casting process, which includes making pattern and core → making sand mould. The six steps of the sand casting process are; Sand cores form internal features like holes. Green sand moulding is a traditional and widely used foundry process that. Sand Casting Mould Diagram.

From mechanicalinventions.blogspot.com

Diferent Parts of Sand Mold Features Mechanical Engineering Sand Casting Mould Diagram Melted metal is poured into a sand mold that has a cavity in it, where it. Green sand moulding is a traditional and widely used foundry process that forms the backbone of metal casting operations. The process involves pouring of the molten metal in to the mold. In sand casting which is also known as sand molded casting, an object. Sand Casting Mould Diagram.

From toolnotes.com

Sand Casting ToolNotes Sand Casting Mould Diagram The process involves pouring of the molten metal in to the mold. There are 6 steps involved in the sand casting process, which includes making pattern and core → making sand mould. Green sand moulding is a traditional and widely used foundry process that forms the backbone of metal casting operations. The six steps of the sand casting process are;. Sand Casting Mould Diagram.

From alliedfortech.com

Sand casting ALLIED FOR TECH Sand Casting Mould Diagram It involves the creation of moulds using a mixture of silica sand, water, and a clay binder, giving it a Wooden, plastic, or metal patterns create the mold cavity. The six steps of the sand casting process are; Green sand moulding is a traditional and widely used foundry process that forms the backbone of metal casting operations. Melted metal is. Sand Casting Mould Diagram.

From strode.co

Sand Casting Mould Strode & Co Sand Casting Mould Diagram In sand casting which is also known as sand molded casting, an object is produced by sand mold. The six steps of the sand casting process are; The process involves pouring of the molten metal in to the mold. Green sand moulding is a traditional and widely used foundry process that forms the backbone of metal casting operations. There are. Sand Casting Mould Diagram.

From tacitceiyrs.blogspot.com

Sand Casting Process tacitceiyrs Sand Casting Mould Diagram Melted metal is poured into a sand mold that has a cavity in it, where it. Sand cores form internal features like holes. In sand casting which is also known as sand molded casting, an object is produced by sand mold. There are 6 steps involved in the sand casting process, which includes making pattern and core → making sand. Sand Casting Mould Diagram.

From www.pinterest.com

Advantages and disadvantages of Sand casting It cast, Sand casting, Sand Sand Casting Mould Diagram How does sand casting works? In sand casting which is also known as sand molded casting, an object is produced by sand mold. There are 6 steps involved in the sand casting process, which includes making pattern and core → making sand mould. Wooden, plastic, or metal patterns create the mold cavity. Placing the mold in patern in sand, setting. Sand Casting Mould Diagram.

From www.numerade.com

SOLVED Casting defects The main reasons for casting defects are Sand Casting Mould Diagram In sand casting which is also known as sand molded casting, an object is produced by sand mold. The six steps of the sand casting process are; The process involves pouring of the molten metal in to the mold. How does sand casting works? Sand cores form internal features like holes. Melted metal is poured into a sand mold that. Sand Casting Mould Diagram.

From www.weld2cast.com

Sand Casting Weld2Cast Sand Casting Mould Diagram Melted metal is poured into a sand mold that has a cavity in it, where it. Wooden, plastic, or metal patterns create the mold cavity. There are 6 steps involved in the sand casting process, which includes making pattern and core → making sand mould. The six steps of the sand casting process are; In sand casting which is also. Sand Casting Mould Diagram.

From alchetron.com

Sand casting Alchetron, The Free Social Encyclopedia Sand Casting Mould Diagram Green sand moulding is a traditional and widely used foundry process that forms the backbone of metal casting operations. The six steps of the sand casting process are; How does sand casting works? It involves the creation of moulds using a mixture of silica sand, water, and a clay binder, giving it a There are 6 steps involved in the. Sand Casting Mould Diagram.

From design.udlvirtual.edu.pe

What Is Mold In Manufacturing Process Design Talk Sand Casting Mould Diagram Placing the mold in patern in sand, setting up the gating system, removing the mold pattern, pour molten metal into mold cavity, wait for the metal to cool, the final step is to break Melted metal is poured into a sand mold that has a cavity in it, where it. Wooden, plastic, or metal patterns create the mold cavity. Sand. Sand Casting Mould Diagram.

From www.youtube.com

Sand mould making procedure Mould for sand casting Mould making Sand Casting Mould Diagram The process involves pouring of the molten metal in to the mold. Wooden, plastic, or metal patterns create the mold cavity. In sand casting which is also known as sand molded casting, an object is produced by sand mold. Green sand moulding is a traditional and widely used foundry process that forms the backbone of metal casting operations. How does. Sand Casting Mould Diagram.

From tacitceiyrs.blogspot.com

Sand Casting Process tacitceiyrs Sand Casting Mould Diagram Green sand moulding is a traditional and widely used foundry process that forms the backbone of metal casting operations. Placing the mold in patern in sand, setting up the gating system, removing the mold pattern, pour molten metal into mold cavity, wait for the metal to cool, the final step is to break In sand casting which is also known. Sand Casting Mould Diagram.

From www.reliance-foundry.com

Sand Casting Metal Casting Resources Sand Casting Mould Diagram Melted metal is poured into a sand mold that has a cavity in it, where it. It involves the creation of moulds using a mixture of silica sand, water, and a clay binder, giving it a There are 6 steps involved in the sand casting process, which includes making pattern and core → making sand mould. The process involves pouring. Sand Casting Mould Diagram.

From learnmech.com

Types of Moulding Machines Squeezers , Jolt Machines , Sand Slingers Sand Casting Mould Diagram Melted metal is poured into a sand mold that has a cavity in it, where it. Sand cores form internal features like holes. Green sand moulding is a traditional and widely used foundry process that forms the backbone of metal casting operations. How does sand casting works? In sand casting which is also known as sand molded casting, an object. Sand Casting Mould Diagram.

From www.compass-anvil.com

Die Casting versus Sand Casting Compass & Anvil Sand Casting Mould Diagram Placing the mold in patern in sand, setting up the gating system, removing the mold pattern, pour molten metal into mold cavity, wait for the metal to cool, the final step is to break Melted metal is poured into a sand mold that has a cavity in it, where it. The process involves pouring of the molten metal in to. Sand Casting Mould Diagram.

From www.researchgate.net

Detail drawing of proposed sand casting mould design Download Sand Casting Mould Diagram It involves the creation of moulds using a mixture of silica sand, water, and a clay binder, giving it a Placing the mold in patern in sand, setting up the gating system, removing the mold pattern, pour molten metal into mold cavity, wait for the metal to cool, the final step is to break The six steps of the sand. Sand Casting Mould Diagram.

From vietnamcastiron.com

Instructions for Making Sand Casting Molds in detail Step by Step Sand Casting Mould Diagram Green sand moulding is a traditional and widely used foundry process that forms the backbone of metal casting operations. The process involves pouring of the molten metal in to the mold. Sand cores form internal features like holes. In sand casting which is also known as sand molded casting, an object is produced by sand mold. Placing the mold in. Sand Casting Mould Diagram.