Stator Scraping Rotor . Dry ice blasting is by far the best method for cleaning a stator and rotor. There’s no scraping, scrubbing, or friction. I replaced the stator and now i'm getting a pretty nasty scraping shiiing shiiing noise when i crank it. Its limit state is uneven air gap , that is, the motor stator and. Bore scraping is a mechanical quality failure that motor products often encounter. Specifically designed for motors stator diameter under 150mm, this motor separating production line efficiently processes various motors sourced from household appliances, electric tools, etc. The motor stator recycling machine is designed to recover the copper from scrap electric motor stators. Increasing the airgap is a way to reduce armature reaction without having to increase the amount of permanent magnet. This is the only evidence. Rotor was scraping on stator because the stator was cracked. It provides numerous benefits, including: This significantly reduces the risk of damage to the system’s components.

from www.semanticscholar.org

Rotor was scraping on stator because the stator was cracked. Its limit state is uneven air gap , that is, the motor stator and. Bore scraping is a mechanical quality failure that motor products often encounter. It provides numerous benefits, including: Dry ice blasting is by far the best method for cleaning a stator and rotor. There’s no scraping, scrubbing, or friction. I replaced the stator and now i'm getting a pretty nasty scraping shiiing shiiing noise when i crank it. Specifically designed for motors stator diameter under 150mm, this motor separating production line efficiently processes various motors sourced from household appliances, electric tools, etc. This is the only evidence. This significantly reduces the risk of damage to the system’s components.

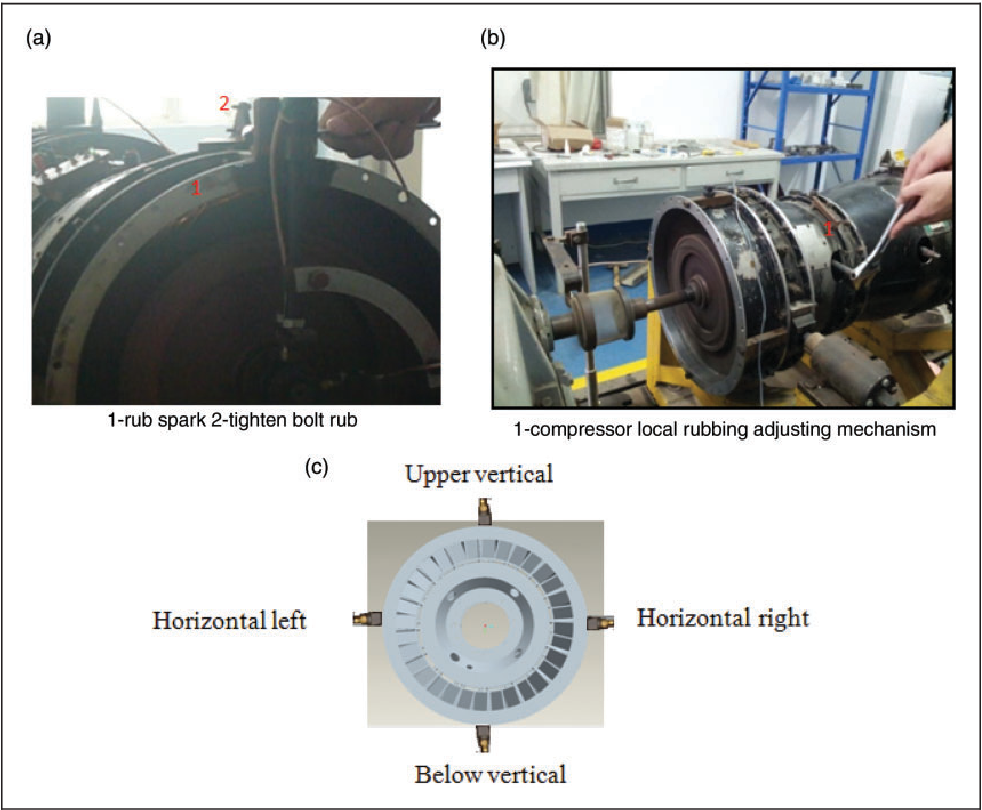

Figure 3 from A new characteristic analysis method for aeroengine

Stator Scraping Rotor I replaced the stator and now i'm getting a pretty nasty scraping shiiing shiiing noise when i crank it. Dry ice blasting is by far the best method for cleaning a stator and rotor. There’s no scraping, scrubbing, or friction. This significantly reduces the risk of damage to the system’s components. Rotor was scraping on stator because the stator was cracked. Bore scraping is a mechanical quality failure that motor products often encounter. It provides numerous benefits, including: Increasing the airgap is a way to reduce armature reaction without having to increase the amount of permanent magnet. Specifically designed for motors stator diameter under 150mm, this motor separating production line efficiently processes various motors sourced from household appliances, electric tools, etc. I replaced the stator and now i'm getting a pretty nasty scraping shiiing shiiing noise when i crank it. The motor stator recycling machine is designed to recover the copper from scrap electric motor stators. This is the only evidence. Its limit state is uneven air gap , that is, the motor stator and.

From www.youtube.com

Suppression of Rubbing in a RotorStator Assembly by Circular Bearing Stator Scraping Rotor It provides numerous benefits, including: Rotor was scraping on stator because the stator was cracked. This is the only evidence. Bore scraping is a mechanical quality failure that motor products often encounter. Increasing the airgap is a way to reduce armature reaction without having to increase the amount of permanent magnet. There’s no scraping, scrubbing, or friction. Its limit state. Stator Scraping Rotor.

From www.researchgate.net

Stator topologies of single stator‐double rotor AFPMs (a) Slotless core Stator Scraping Rotor There’s no scraping, scrubbing, or friction. This significantly reduces the risk of damage to the system’s components. Bore scraping is a mechanical quality failure that motor products often encounter. This is the only evidence. It provides numerous benefits, including: I replaced the stator and now i'm getting a pretty nasty scraping shiiing shiiing noise when i crank it. Increasing the. Stator Scraping Rotor.

From meghamotors.com

Stator and Rotor Sets Megha RotoTech Pvt. Ltd. Stator Scraping Rotor Increasing the airgap is a way to reduce armature reaction without having to increase the amount of permanent magnet. There’s no scraping, scrubbing, or friction. Specifically designed for motors stator diameter under 150mm, this motor separating production line efficiently processes various motors sourced from household appliances, electric tools, etc. This significantly reduces the risk of damage to the system’s components.. Stator Scraping Rotor.

From www.researchgate.net

1 Schematic representation of a single rotorstator cavity. It Stator Scraping Rotor Rotor was scraping on stator because the stator was cracked. I replaced the stator and now i'm getting a pretty nasty scraping shiiing shiiing noise when i crank it. The motor stator recycling machine is designed to recover the copper from scrap electric motor stators. Bore scraping is a mechanical quality failure that motor products often encounter. Dry ice blasting. Stator Scraping Rotor.

From advrotors.com

Stator Repair Advanced Rotors Stator Scraping Rotor Its limit state is uneven air gap , that is, the motor stator and. It provides numerous benefits, including: This significantly reduces the risk of damage to the system’s components. Increasing the airgap is a way to reduce armature reaction without having to increase the amount of permanent magnet. Specifically designed for motors stator diameter under 150mm, this motor separating. Stator Scraping Rotor.

From travelknowledge.org

The Basics of Stator Core Lamination in Your Equipment Travel Knowledge Stator Scraping Rotor Increasing the airgap is a way to reduce armature reaction without having to increase the amount of permanent magnet. Specifically designed for motors stator diameter under 150mm, this motor separating production line efficiently processes various motors sourced from household appliances, electric tools, etc. It provides numerous benefits, including: Rotor was scraping on stator because the stator was cracked. Its limit. Stator Scraping Rotor.

From www.semanticscholar.org

Figure 3 from Dynamic characteristics analysis of a rotorstator system Stator Scraping Rotor The motor stator recycling machine is designed to recover the copper from scrap electric motor stators. This is the only evidence. This significantly reduces the risk of damage to the system’s components. I replaced the stator and now i'm getting a pretty nasty scraping shiiing shiiing noise when i crank it. It provides numerous benefits, including: Rotor was scraping on. Stator Scraping Rotor.

From www.researchgate.net

Forces acting on the rotorstator rub with clearance. Download Stator Scraping Rotor Specifically designed for motors stator diameter under 150mm, this motor separating production line efficiently processes various motors sourced from household appliances, electric tools, etc. The motor stator recycling machine is designed to recover the copper from scrap electric motor stators. Its limit state is uneven air gap , that is, the motor stator and. This significantly reduces the risk of. Stator Scraping Rotor.

From forum.esk8.news

Stator and rotor scraping at one motor side only?? Esk8 Mechanics Stator Scraping Rotor I replaced the stator and now i'm getting a pretty nasty scraping shiiing shiiing noise when i crank it. It provides numerous benefits, including: Increasing the airgap is a way to reduce armature reaction without having to increase the amount of permanent magnet. Bore scraping is a mechanical quality failure that motor products often encounter. Specifically designed for motors stator. Stator Scraping Rotor.

From engrsci.com

Insight into the stickslip characteristics of dry friction backward Stator Scraping Rotor Rotor was scraping on stator because the stator was cracked. This significantly reduces the risk of damage to the system’s components. This is the only evidence. Dry ice blasting is by far the best method for cleaning a stator and rotor. I replaced the stator and now i'm getting a pretty nasty scraping shiiing shiiing noise when i crank it.. Stator Scraping Rotor.

From www.semanticscholar.org

Figure 1 from Identifying rotorstator rubbing positions based on Stator Scraping Rotor Dry ice blasting is by far the best method for cleaning a stator and rotor. This significantly reduces the risk of damage to the system’s components. It provides numerous benefits, including: This is the only evidence. Bore scraping is a mechanical quality failure that motor products often encounter. The motor stator recycling machine is designed to recover the copper from. Stator Scraping Rotor.

From forum.esk8.news

Stator and rotor scraping at one motor side only?? Esk8 Mechanics Stator Scraping Rotor The motor stator recycling machine is designed to recover the copper from scrap electric motor stators. This is the only evidence. Specifically designed for motors stator diameter under 150mm, this motor separating production line efficiently processes various motors sourced from household appliances, electric tools, etc. This significantly reduces the risk of damage to the system’s components. Rotor was scraping on. Stator Scraping Rotor.

From www.sotek.com

Stator and Rotor Assembly Lamination Replacement Sotek, inc. Stator Scraping Rotor It provides numerous benefits, including: This is the only evidence. Dry ice blasting is by far the best method for cleaning a stator and rotor. Specifically designed for motors stator diameter under 150mm, this motor separating production line efficiently processes various motors sourced from household appliances, electric tools, etc. There’s no scraping, scrubbing, or friction. The motor stator recycling machine. Stator Scraping Rotor.

From www.semanticscholar.org

Figure 3 from A novel intrinsic timescale signal Stator Scraping Rotor Specifically designed for motors stator diameter under 150mm, this motor separating production line efficiently processes various motors sourced from household appliances, electric tools, etc. Dry ice blasting is by far the best method for cleaning a stator and rotor. Rotor was scraping on stator because the stator was cracked. The motor stator recycling machine is designed to recover the copper. Stator Scraping Rotor.

From hockmeyer.com

The Rotor Stator Principles Guide Everything You Need to Know Blog Stator Scraping Rotor This significantly reduces the risk of damage to the system’s components. There’s no scraping, scrubbing, or friction. It provides numerous benefits, including: Dry ice blasting is by far the best method for cleaning a stator and rotor. Its limit state is uneven air gap , that is, the motor stator and. Increasing the airgap is a way to reduce armature. Stator Scraping Rotor.

From forum.esk8.news

Stator and rotor scraping at one motor side only?? Esk8 Mechanics Stator Scraping Rotor The motor stator recycling machine is designed to recover the copper from scrap electric motor stators. Dry ice blasting is by far the best method for cleaning a stator and rotor. It provides numerous benefits, including: This significantly reduces the risk of damage to the system’s components. There’s no scraping, scrubbing, or friction. This is the only evidence. Rotor was. Stator Scraping Rotor.

From www.researchgate.net

Vertical rotor deflection response with unbalance and rotortostator Stator Scraping Rotor I replaced the stator and now i'm getting a pretty nasty scraping shiiing shiiing noise when i crank it. Increasing the airgap is a way to reduce armature reaction without having to increase the amount of permanent magnet. Its limit state is uneven air gap , that is, the motor stator and. There’s no scraping, scrubbing, or friction. Bore scraping. Stator Scraping Rotor.

From www.researchgate.net

Stator and rotor lamination Download Scientific Diagram Stator Scraping Rotor Increasing the airgap is a way to reduce armature reaction without having to increase the amount of permanent magnet. The motor stator recycling machine is designed to recover the copper from scrap electric motor stators. There’s no scraping, scrubbing, or friction. It provides numerous benefits, including: Bore scraping is a mechanical quality failure that motor products often encounter. This significantly. Stator Scraping Rotor.

From www.semanticscholar.org

Figure 3 from A new characteristic analysis method for aeroengine Stator Scraping Rotor This is the only evidence. This significantly reduces the risk of damage to the system’s components. Specifically designed for motors stator diameter under 150mm, this motor separating production line efficiently processes various motors sourced from household appliances, electric tools, etc. Dry ice blasting is by far the best method for cleaning a stator and rotor. Increasing the airgap is a. Stator Scraping Rotor.

From www.scribd.com

RotorStator Rubbing Contact in An Overhung Rotordynamic System PDF Stator Scraping Rotor Its limit state is uneven air gap , that is, the motor stator and. Rotor was scraping on stator because the stator was cracked. Increasing the airgap is a way to reduce armature reaction without having to increase the amount of permanent magnet. It provides numerous benefits, including: This significantly reduces the risk of damage to the system’s components. Dry. Stator Scraping Rotor.

From www.semanticscholar.org

Figure 1 from Determining the Global Response Characteristics of Stator Scraping Rotor Specifically designed for motors stator diameter under 150mm, this motor separating production line efficiently processes various motors sourced from household appliances, electric tools, etc. The motor stator recycling machine is designed to recover the copper from scrap electric motor stators. This significantly reduces the risk of damage to the system’s components. Its limit state is uneven air gap , that. Stator Scraping Rotor.

From askanydifference.com

Rotor vs Stator Difference and Comparison Stator Scraping Rotor Increasing the airgap is a way to reduce armature reaction without having to increase the amount of permanent magnet. Bore scraping is a mechanical quality failure that motor products often encounter. Dry ice blasting is by far the best method for cleaning a stator and rotor. Specifically designed for motors stator diameter under 150mm, this motor separating production line efficiently. Stator Scraping Rotor.

From www.researchgate.net

8 Schematic representation of the 3stage rotorstator spinning disc Stator Scraping Rotor There’s no scraping, scrubbing, or friction. This significantly reduces the risk of damage to the system’s components. The motor stator recycling machine is designed to recover the copper from scrap electric motor stators. This is the only evidence. Increasing the airgap is a way to reduce armature reaction without having to increase the amount of permanent magnet. Rotor was scraping. Stator Scraping Rotor.

From journals.sagepub.com

Finite Element Analysis Design of a Split Rotor Bracket for a Bulb Stator Scraping Rotor Specifically designed for motors stator diameter under 150mm, this motor separating production line efficiently processes various motors sourced from household appliances, electric tools, etc. The motor stator recycling machine is designed to recover the copper from scrap electric motor stators. Dry ice blasting is by far the best method for cleaning a stator and rotor. I replaced the stator and. Stator Scraping Rotor.

From www.dreamstime.com

Stator and Rotor Exploded View Presentation Used in Asynchronous Stator Scraping Rotor I replaced the stator and now i'm getting a pretty nasty scraping shiiing shiiing noise when i crank it. Rotor was scraping on stator because the stator was cracked. Specifically designed for motors stator diameter under 150mm, this motor separating production line efficiently processes various motors sourced from household appliances, electric tools, etc. This is the only evidence. Increasing the. Stator Scraping Rotor.

From www.researchgate.net

Effect of rubbing between the rotor and stator. Download Scientific Stator Scraping Rotor Increasing the airgap is a way to reduce armature reaction without having to increase the amount of permanent magnet. Bore scraping is a mechanical quality failure that motor products often encounter. The motor stator recycling machine is designed to recover the copper from scrap electric motor stators. This is the only evidence. There’s no scraping, scrubbing, or friction. This significantly. Stator Scraping Rotor.

From www.semanticscholar.org

Figure 1 from A Method to Transit the RotortoStator Rubbing to Normal Stator Scraping Rotor There’s no scraping, scrubbing, or friction. Dry ice blasting is by far the best method for cleaning a stator and rotor. The motor stator recycling machine is designed to recover the copper from scrap electric motor stators. It provides numerous benefits, including: This is the only evidence. Specifically designed for motors stator diameter under 150mm, this motor separating production line. Stator Scraping Rotor.

From www.researchgate.net

Effects of rubbing between rotor and stator due to eccentricity (a Stator Scraping Rotor Bore scraping is a mechanical quality failure that motor products often encounter. Rotor was scraping on stator because the stator was cracked. The motor stator recycling machine is designed to recover the copper from scrap electric motor stators. Its limit state is uneven air gap , that is, the motor stator and. This is the only evidence. Dry ice blasting. Stator Scraping Rotor.

From www.pinterest.com

Rotor Stacks, Stator Stacks Diy cnc, Stepper motor, Motor Stator Scraping Rotor Bore scraping is a mechanical quality failure that motor products often encounter. Specifically designed for motors stator diameter under 150mm, this motor separating production line efficiently processes various motors sourced from household appliances, electric tools, etc. The motor stator recycling machine is designed to recover the copper from scrap electric motor stators. It provides numerous benefits, including: Rotor was scraping. Stator Scraping Rotor.

From www.pinterest.com

Insight into the stickslip characteristics of dry friction backward Stator Scraping Rotor Dry ice blasting is by far the best method for cleaning a stator and rotor. It provides numerous benefits, including: Rotor was scraping on stator because the stator was cracked. Specifically designed for motors stator diameter under 150mm, this motor separating production line efficiently processes various motors sourced from household appliances, electric tools, etc. Increasing the airgap is a way. Stator Scraping Rotor.

From www.youtube.com

What is a Rotor and Stator and How a Motor Works YouTube Stator Scraping Rotor Bore scraping is a mechanical quality failure that motor products often encounter. It provides numerous benefits, including: Specifically designed for motors stator diameter under 150mm, this motor separating production line efficiently processes various motors sourced from household appliances, electric tools, etc. Its limit state is uneven air gap , that is, the motor stator and. I replaced the stator and. Stator Scraping Rotor.

From electricalengineeringdesigns.blogspot.com

STATOR AND ROTOR CONSTRUCTION OF AC GENERATORS ELECTRICAL ENGINEERING Stator Scraping Rotor Increasing the airgap is a way to reduce armature reaction without having to increase the amount of permanent magnet. I replaced the stator and now i'm getting a pretty nasty scraping shiiing shiiing noise when i crank it. Dry ice blasting is by far the best method for cleaning a stator and rotor. The motor stator recycling machine is designed. Stator Scraping Rotor.

From www.applied-motion.com

What is Step Motor Stack Length? Applied Motion Stator Scraping Rotor Specifically designed for motors stator diameter under 150mm, this motor separating production line efficiently processes various motors sourced from household appliances, electric tools, etc. It provides numerous benefits, including: Its limit state is uneven air gap , that is, the motor stator and. Increasing the airgap is a way to reduce armature reaction without having to increase the amount of. Stator Scraping Rotor.

From www.semanticscholar.org

Figure 12 from Dynamic characteristics analysis of a rotorstator Stator Scraping Rotor Rotor was scraping on stator because the stator was cracked. This is the only evidence. Dry ice blasting is by far the best method for cleaning a stator and rotor. This significantly reduces the risk of damage to the system’s components. The motor stator recycling machine is designed to recover the copper from scrap electric motor stators. Bore scraping is. Stator Scraping Rotor.

From www.alamy.com

Stator sheet package and copper winding with rotor for motor Stock Stator Scraping Rotor Rotor was scraping on stator because the stator was cracked. The motor stator recycling machine is designed to recover the copper from scrap electric motor stators. It provides numerous benefits, including: Dry ice blasting is by far the best method for cleaning a stator and rotor. I replaced the stator and now i'm getting a pretty nasty scraping shiiing shiiing. Stator Scraping Rotor.