Bubble Point Test Graph . It is important that integrity testing be conducted after filtration to detect any filter leaks or perforations that might have occurred during. This pressure level, known as the bubble point, is signaled by the first appearance of a steady stream of bubbles observed from a. Why is the bubble point limit provided different than the one on the certificate of test? The bubble point test is a method used to evaluate the integrity of sterilizing grade filters in pharmaceutical manufacturing. It determines the pore diameter by observing the. The “bubble point” test measures the force in gas pressure required to overcome the capillary forces, and therefore provide an assessment of. The tangent method is used to determine a filter bubble point from a series of pressure decays performed at increasing. What is a bubble point (bp) integrity test? Recommended bubble point ratio value for the durapore® 0.1 µm hydrophilic membrane wetted with 60/40 ipa and 70/30 ipa. K is the shape correction factor, σ the surface tension of the wetting medium, θ the contact angle and d the.

from www.youtube.com

Why is the bubble point limit provided different than the one on the certificate of test? The bubble point test is a method used to evaluate the integrity of sterilizing grade filters in pharmaceutical manufacturing. This pressure level, known as the bubble point, is signaled by the first appearance of a steady stream of bubbles observed from a. The tangent method is used to determine a filter bubble point from a series of pressure decays performed at increasing. Recommended bubble point ratio value for the durapore® 0.1 µm hydrophilic membrane wetted with 60/40 ipa and 70/30 ipa. What is a bubble point (bp) integrity test? The “bubble point” test measures the force in gas pressure required to overcome the capillary forces, and therefore provide an assessment of. It determines the pore diameter by observing the. K is the shape correction factor, σ the surface tension of the wetting medium, θ the contact angle and d the. It is important that integrity testing be conducted after filtration to detect any filter leaks or perforations that might have occurred during.

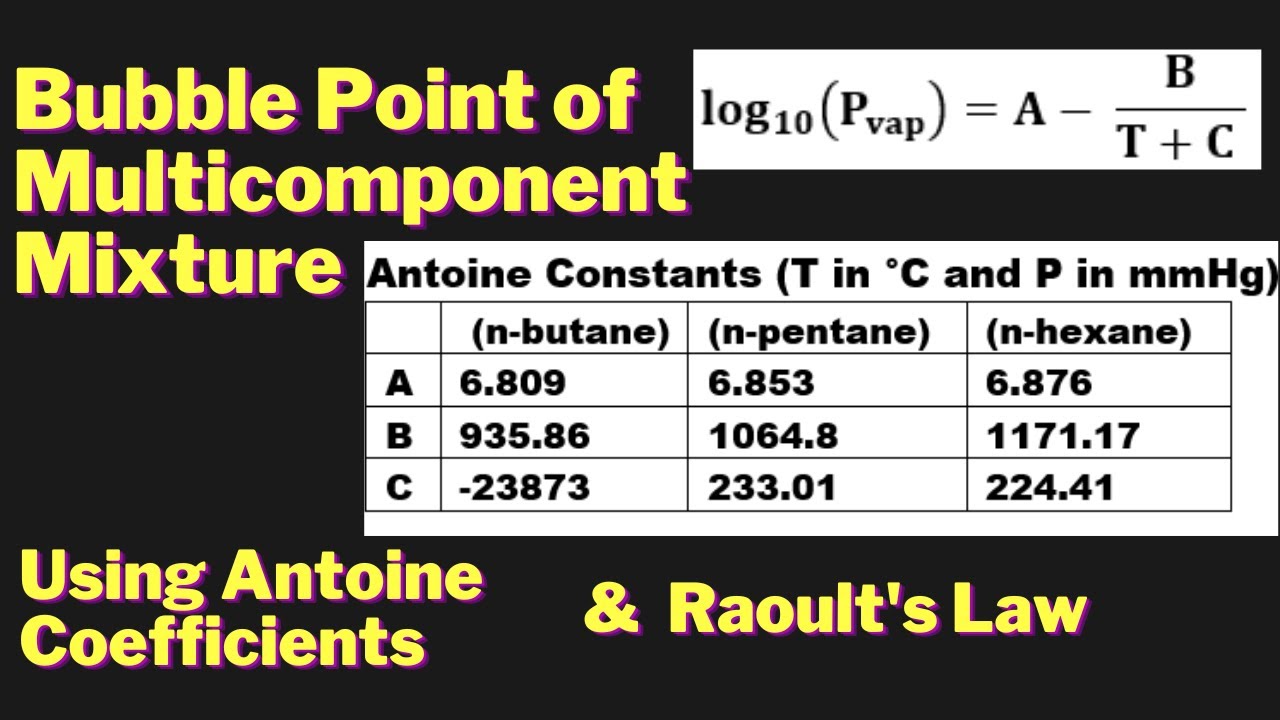

Bubble point calculation using Antoine coefficients & Raoult's Law

Bubble Point Test Graph It determines the pore diameter by observing the. This pressure level, known as the bubble point, is signaled by the first appearance of a steady stream of bubbles observed from a. The tangent method is used to determine a filter bubble point from a series of pressure decays performed at increasing. K is the shape correction factor, σ the surface tension of the wetting medium, θ the contact angle and d the. Recommended bubble point ratio value for the durapore® 0.1 µm hydrophilic membrane wetted with 60/40 ipa and 70/30 ipa. The bubble point test is a method used to evaluate the integrity of sterilizing grade filters in pharmaceutical manufacturing. It determines the pore diameter by observing the. The “bubble point” test measures the force in gas pressure required to overcome the capillary forces, and therefore provide an assessment of. What is a bubble point (bp) integrity test? Why is the bubble point limit provided different than the one on the certificate of test? It is important that integrity testing be conducted after filtration to detect any filter leaks or perforations that might have occurred during.

From petrofaq.org

Bubble point petrofaq Bubble Point Test Graph Recommended bubble point ratio value for the durapore® 0.1 µm hydrophilic membrane wetted with 60/40 ipa and 70/30 ipa. This pressure level, known as the bubble point, is signaled by the first appearance of a steady stream of bubbles observed from a. It is important that integrity testing be conducted after filtration to detect any filter leaks or perforations that. Bubble Point Test Graph.

From www.mdpi.com

Membranes Free FullText Defect Detection Sensitivity of Bubble Bubble Point Test Graph The tangent method is used to determine a filter bubble point from a series of pressure decays performed at increasing. It is important that integrity testing be conducted after filtration to detect any filter leaks or perforations that might have occurred during. It determines the pore diameter by observing the. Why is the bubble point limit provided different than the. Bubble Point Test Graph.

From www.researchgate.net

Bubble point and dew point temperature Download Scientific Diagram Bubble Point Test Graph K is the shape correction factor, σ the surface tension of the wetting medium, θ the contact angle and d the. The “bubble point” test measures the force in gas pressure required to overcome the capillary forces, and therefore provide an assessment of. Why is the bubble point limit provided different than the one on the certificate of test? The. Bubble Point Test Graph.

From www.researchgate.net

Bubble point pressure data for numerous correlation versus actual pb Bubble Point Test Graph This pressure level, known as the bubble point, is signaled by the first appearance of a steady stream of bubbles observed from a. K is the shape correction factor, σ the surface tension of the wetting medium, θ the contact angle and d the. The tangent method is used to determine a filter bubble point from a series of pressure. Bubble Point Test Graph.

From www.youtube.com

Bubble point calculation using Antoine coefficients & Raoult's Law Bubble Point Test Graph What is a bubble point (bp) integrity test? The “bubble point” test measures the force in gas pressure required to overcome the capillary forces, and therefore provide an assessment of. Why is the bubble point limit provided different than the one on the certificate of test? Recommended bubble point ratio value for the durapore® 0.1 µm hydrophilic membrane wetted with. Bubble Point Test Graph.

From jp.brotherfiltration.com

バブルポイント試験 何を使用し、何を使用しますか? Brother Filtration Bubble Point Test Graph It is important that integrity testing be conducted after filtration to detect any filter leaks or perforations that might have occurred during. The “bubble point” test measures the force in gas pressure required to overcome the capillary forces, and therefore provide an assessment of. This pressure level, known as the bubble point, is signaled by the first appearance of a. Bubble Point Test Graph.

From pharmaguidances.com

BUBBLE POINT TEST Pharmaceutical Guidance Bubble Point Test Graph It is important that integrity testing be conducted after filtration to detect any filter leaks or perforations that might have occurred during. The tangent method is used to determine a filter bubble point from a series of pressure decays performed at increasing. The “bubble point” test measures the force in gas pressure required to overcome the capillary forces, and therefore. Bubble Point Test Graph.

From www.researchgate.net

8 Typical PSDs Obtained from Bubble Point Tests (after Fisher, 1994 Bubble Point Test Graph The “bubble point” test measures the force in gas pressure required to overcome the capillary forces, and therefore provide an assessment of. The bubble point test is a method used to evaluate the integrity of sterilizing grade filters in pharmaceutical manufacturing. Recommended bubble point ratio value for the durapore® 0.1 µm hydrophilic membrane wetted with 60/40 ipa and 70/30 ipa.. Bubble Point Test Graph.

From mungfali.com

What Is Bubble Point Bubble Point Test Graph Recommended bubble point ratio value for the durapore® 0.1 µm hydrophilic membrane wetted with 60/40 ipa and 70/30 ipa. It is important that integrity testing be conducted after filtration to detect any filter leaks or perforations that might have occurred during. What is a bubble point (bp) integrity test? Why is the bubble point limit provided different than the one. Bubble Point Test Graph.

From mungfali.com

What Is Bubble Point Bubble Point Test Graph The bubble point test is a method used to evaluate the integrity of sterilizing grade filters in pharmaceutical manufacturing. The “bubble point” test measures the force in gas pressure required to overcome the capillary forces, and therefore provide an assessment of. K is the shape correction factor, σ the surface tension of the wetting medium, θ the contact angle and. Bubble Point Test Graph.

From slideplayer.com

Bubble Point and dew point Calculations ppt video online download Bubble Point Test Graph This pressure level, known as the bubble point, is signaled by the first appearance of a steady stream of bubbles observed from a. The tangent method is used to determine a filter bubble point from a series of pressure decays performed at increasing. Recommended bubble point ratio value for the durapore® 0.1 µm hydrophilic membrane wetted with 60/40 ipa and. Bubble Point Test Graph.

From www.semanticscholar.org

Figure 1 from Analysis of Screen Channel LAD Bubble Point Tests in Bubble Point Test Graph Recommended bubble point ratio value for the durapore® 0.1 µm hydrophilic membrane wetted with 60/40 ipa and 70/30 ipa. It is important that integrity testing be conducted after filtration to detect any filter leaks or perforations that might have occurred during. The bubble point test is a method used to evaluate the integrity of sterilizing grade filters in pharmaceutical manufacturing.. Bubble Point Test Graph.

From www.researchgate.net

Principle of the bubblepoint test. Download Scientific Diagram Bubble Point Test Graph K is the shape correction factor, σ the surface tension of the wetting medium, θ the contact angle and d the. It is important that integrity testing be conducted after filtration to detect any filter leaks or perforations that might have occurred during. The tangent method is used to determine a filter bubble point from a series of pressure decays. Bubble Point Test Graph.

From www.researchgate.net

Principle of the bubblepoint test. Download Scientific Diagram Bubble Point Test Graph It determines the pore diameter by observing the. Recommended bubble point ratio value for the durapore® 0.1 µm hydrophilic membrane wetted with 60/40 ipa and 70/30 ipa. The tangent method is used to determine a filter bubble point from a series of pressure decays performed at increasing. Why is the bubble point limit provided different than the one on the. Bubble Point Test Graph.

From www.researchgate.net

Predicted (lines) bubble point (P * 0 ) values vs inverse temperature Bubble Point Test Graph The “bubble point” test measures the force in gas pressure required to overcome the capillary forces, and therefore provide an assessment of. Recommended bubble point ratio value for the durapore® 0.1 µm hydrophilic membrane wetted with 60/40 ipa and 70/30 ipa. K is the shape correction factor, σ the surface tension of the wetting medium, θ the contact angle and. Bubble Point Test Graph.

From www.semanticscholar.org

[PDF] Filter integrity testing in liquid applications, revisited. Part Bubble Point Test Graph Recommended bubble point ratio value for the durapore® 0.1 µm hydrophilic membrane wetted with 60/40 ipa and 70/30 ipa. This pressure level, known as the bubble point, is signaled by the first appearance of a steady stream of bubbles observed from a. The “bubble point” test measures the force in gas pressure required to overcome the capillary forces, and therefore. Bubble Point Test Graph.

From www.researchgate.net

Pore diameter vs. air pressure for ideal filter in bubblepoint test Bubble Point Test Graph The “bubble point” test measures the force in gas pressure required to overcome the capillary forces, and therefore provide an assessment of. The bubble point test is a method used to evaluate the integrity of sterilizing grade filters in pharmaceutical manufacturing. The tangent method is used to determine a filter bubble point from a series of pressure decays performed at. Bubble Point Test Graph.

From www.researchgate.net

Plot showing an example of bubble point determination from plot of Bubble Point Test Graph This pressure level, known as the bubble point, is signaled by the first appearance of a steady stream of bubbles observed from a. The bubble point test is a method used to evaluate the integrity of sterilizing grade filters in pharmaceutical manufacturing. It is important that integrity testing be conducted after filtration to detect any filter leaks or perforations that. Bubble Point Test Graph.

From pediaa.com

Difference Between Bubble Point and Dew Point Definition, Features Bubble Point Test Graph It determines the pore diameter by observing the. The bubble point test is a method used to evaluate the integrity of sterilizing grade filters in pharmaceutical manufacturing. It is important that integrity testing be conducted after filtration to detect any filter leaks or perforations that might have occurred during. K is the shape correction factor, σ the surface tension of. Bubble Point Test Graph.

From www.researchgate.net

Bubble point curve slope at different membrane configurations Bubble Point Test Graph Recommended bubble point ratio value for the durapore® 0.1 µm hydrophilic membrane wetted with 60/40 ipa and 70/30 ipa. This pressure level, known as the bubble point, is signaled by the first appearance of a steady stream of bubbles observed from a. K is the shape correction factor, σ the surface tension of the wetting medium, θ the contact angle. Bubble Point Test Graph.

From www.researchgate.net

Schematic diagram of (a) bubblepoint test apparatus and (b) permeated Bubble Point Test Graph Why is the bubble point limit provided different than the one on the certificate of test? What is a bubble point (bp) integrity test? K is the shape correction factor, σ the surface tension of the wetting medium, θ the contact angle and d the. It is important that integrity testing be conducted after filtration to detect any filter leaks. Bubble Point Test Graph.

From www.youtube.com

Define Bubble and Dew Points and Show on Graph YouTube Bubble Point Test Graph Why is the bubble point limit provided different than the one on the certificate of test? The bubble point test is a method used to evaluate the integrity of sterilizing grade filters in pharmaceutical manufacturing. What is a bubble point (bp) integrity test? It is important that integrity testing be conducted after filtration to detect any filter leaks or perforations. Bubble Point Test Graph.

From www.semanticscholar.org

Figure 3 from Numerical analyses of bubble point tests used for Bubble Point Test Graph It is important that integrity testing be conducted after filtration to detect any filter leaks or perforations that might have occurred during. Why is the bubble point limit provided different than the one on the certificate of test? This pressure level, known as the bubble point, is signaled by the first appearance of a steady stream of bubbles observed from. Bubble Point Test Graph.

From www.researchgate.net

Determination of bubble point from flow rate vs. pressure spectra (a Bubble Point Test Graph Recommended bubble point ratio value for the durapore® 0.1 µm hydrophilic membrane wetted with 60/40 ipa and 70/30 ipa. The bubble point test is a method used to evaluate the integrity of sterilizing grade filters in pharmaceutical manufacturing. What is a bubble point (bp) integrity test? The “bubble point” test measures the force in gas pressure required to overcome the. Bubble Point Test Graph.

From pediaa.com

Difference Between Bubble Point and Dew Point Definition, Features Bubble Point Test Graph This pressure level, known as the bubble point, is signaled by the first appearance of a steady stream of bubbles observed from a. Recommended bubble point ratio value for the durapore® 0.1 µm hydrophilic membrane wetted with 60/40 ipa and 70/30 ipa. It determines the pore diameter by observing the. What is a bubble point (bp) integrity test? Why is. Bubble Point Test Graph.

From www.semanticscholar.org

Figure 2 from Numerical analyses of bubble point tests used for Bubble Point Test Graph K is the shape correction factor, σ the surface tension of the wetting medium, θ the contact angle and d the. The “bubble point” test measures the force in gas pressure required to overcome the capillary forces, and therefore provide an assessment of. This pressure level, known as the bubble point, is signaled by the first appearance of a steady. Bubble Point Test Graph.

From www.researchgate.net

Visual graphical analysis to obtain the first estimate of bubble point Bubble Point Test Graph The bubble point test is a method used to evaluate the integrity of sterilizing grade filters in pharmaceutical manufacturing. It determines the pore diameter by observing the. What is a bubble point (bp) integrity test? The “bubble point” test measures the force in gas pressure required to overcome the capillary forces, and therefore provide an assessment of. Recommended bubble point. Bubble Point Test Graph.

From www2.mdpi.com

Membranes Free FullText Defect Detection Sensitivity of Bubble Bubble Point Test Graph Why is the bubble point limit provided different than the one on the certificate of test? The “bubble point” test measures the force in gas pressure required to overcome the capillary forces, and therefore provide an assessment of. This pressure level, known as the bubble point, is signaled by the first appearance of a steady stream of bubbles observed from. Bubble Point Test Graph.

From www.slideshare.net

bubble point calculations (MATLAB) Bubble Point Test Graph The bubble point test is a method used to evaluate the integrity of sterilizing grade filters in pharmaceutical manufacturing. The “bubble point” test measures the force in gas pressure required to overcome the capillary forces, and therefore provide an assessment of. It determines the pore diameter by observing the. Recommended bubble point ratio value for the durapore® 0.1 µm hydrophilic. Bubble Point Test Graph.

From mpl.loesungsfabrik.de

How is the filter’s bacterial retention capability connected with its Bubble Point Test Graph The tangent method is used to determine a filter bubble point from a series of pressure decays performed at increasing. It determines the pore diameter by observing the. K is the shape correction factor, σ the surface tension of the wetting medium, θ the contact angle and d the. The bubble point test is a method used to evaluate the. Bubble Point Test Graph.

From www.scribd.com

How To Do A Reverse Bubble Point Test PDF Bubble Point Test Graph What is a bubble point (bp) integrity test? Recommended bubble point ratio value for the durapore® 0.1 µm hydrophilic membrane wetted with 60/40 ipa and 70/30 ipa. The bubble point test is a method used to evaluate the integrity of sterilizing grade filters in pharmaceutical manufacturing. Why is the bubble point limit provided different than the one on the certificate. Bubble Point Test Graph.

From www.researchgate.net

Predicted versus measured bubble point pressure for the testing subset Bubble Point Test Graph It determines the pore diameter by observing the. Why is the bubble point limit provided different than the one on the certificate of test? It is important that integrity testing be conducted after filtration to detect any filter leaks or perforations that might have occurred during. This pressure level, known as the bubble point, is signaled by the first appearance. Bubble Point Test Graph.

From www.researchgate.net

Effect of Bubble Point Pressure on the dimensionless IPR curve Bubble Point Test Graph The “bubble point” test measures the force in gas pressure required to overcome the capillary forces, and therefore provide an assessment of. What is a bubble point (bp) integrity test? Why is the bubble point limit provided different than the one on the certificate of test? It is important that integrity testing be conducted after filtration to detect any filter. Bubble Point Test Graph.

From www.researchgate.net

The bubble point curves of the scenarios. Download Scientific Diagram Bubble Point Test Graph Recommended bubble point ratio value for the durapore® 0.1 µm hydrophilic membrane wetted with 60/40 ipa and 70/30 ipa. K is the shape correction factor, σ the surface tension of the wetting medium, θ the contact angle and d the. It determines the pore diameter by observing the. The bubble point test is a method used to evaluate the integrity. Bubble Point Test Graph.

From hvacrschool.com

bubble point HVAC School Bubble Point Test Graph It determines the pore diameter by observing the. What is a bubble point (bp) integrity test? K is the shape correction factor, σ the surface tension of the wetting medium, θ the contact angle and d the. Recommended bubble point ratio value for the durapore® 0.1 µm hydrophilic membrane wetted with 60/40 ipa and 70/30 ipa. It is important that. Bubble Point Test Graph.