Tube Stuck In Centrifuge Rotor . Wait for the centrifuge to cool down before opening it. The main cause of an imbalanced centrifuge is usually because the rotor is unevenly loaded. If the centrifuge is not receiving power, check the circuit breaker or fuse. This tool will remove a stuck centrifuge rotor and these maintenance tips that help prevent it from happening. Glass tubes can break during centrifugation, due either to improper loading or inherent defects. Buckets must be loaded symetrically and the tubes or containers should be distributed evenly on all rotor positions. The tubes or bottles should loosen or soften enough to slide out. Inspect the centrifuge assembly for. Examine the rotor area for any visible obstructions, such as debris, broken parts or tubes. Centrifugal force may cause improperly filled or sealed tubes to collapse. Any glass fragments must be. Position and align the rotor properly. Your centrifuge must contain a balanced load to work properly. Apply a small amount of lubricant near the rotor axis to help loosen it. Spinning balanced loads will extend the life of the centrifuge and produce better.

from www.beckman.com

Inspect the centrifuge assembly for. Wait for the centrifuge to cool down before opening it. Centrifugal force may cause improperly filled or sealed tubes to collapse. Examine the rotor area for any visible obstructions, such as debris, broken parts or tubes. Your centrifuge must contain a balanced load to work properly. Apply a small amount of lubricant near the rotor axis to help loosen it. Position and align the rotor properly. The main cause of an imbalanced centrifuge is usually because the rotor is unevenly loaded. Spinning balanced loads will extend the life of the centrifuge and produce better. Buckets must be loaded symetrically and the tubes or containers should be distributed evenly on all rotor positions.

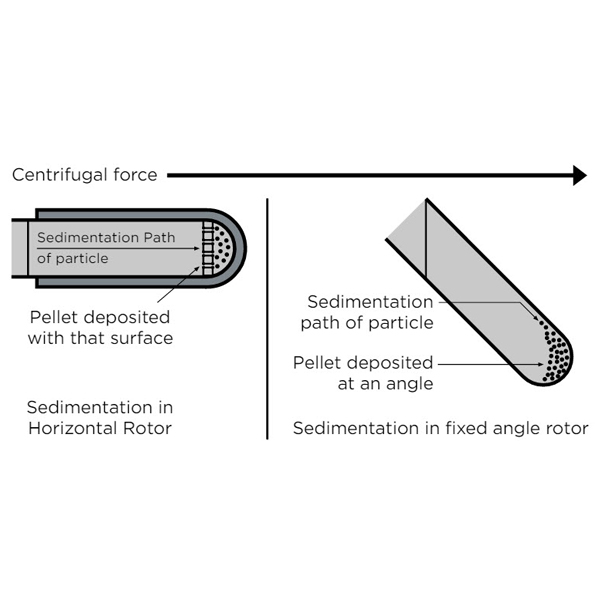

Centrifuge Rotor Types

Tube Stuck In Centrifuge Rotor Spinning balanced loads will extend the life of the centrifuge and produce better. Apply a small amount of lubricant near the rotor axis to help loosen it. Inspect the centrifuge assembly for. Wait for the centrifuge to cool down before opening it. Your centrifuge must contain a balanced load to work properly. Buckets must be loaded symetrically and the tubes or containers should be distributed evenly on all rotor positions. Examine the rotor area for any visible obstructions, such as debris, broken parts or tubes. Centrifugal force may cause improperly filled or sealed tubes to collapse. Spinning balanced loads will extend the life of the centrifuge and produce better. Glass tubes can break during centrifugation, due either to improper loading or inherent defects. If the centrifuge is not receiving power, check the circuit breaker or fuse. This tool will remove a stuck centrifuge rotor and these maintenance tips that help prevent it from happening. The tubes or bottles should loosen or soften enough to slide out. The main cause of an imbalanced centrifuge is usually because the rotor is unevenly loaded. Any glass fragments must be. Position and align the rotor properly.

From www.researchgate.net

Schematic representations of a centrifuge rotor (left) and gas Tube Stuck In Centrifuge Rotor Glass tubes can break during centrifugation, due either to improper loading or inherent defects. Your centrifuge must contain a balanced load to work properly. Wait for the centrifuge to cool down before opening it. Examine the rotor area for any visible obstructions, such as debris, broken parts or tubes. Any glass fragments must be. The tubes or bottles should loosen. Tube Stuck In Centrifuge Rotor.

From www.linquip.com

centrifuge rotor types an insight to the types, uses and the history Tube Stuck In Centrifuge Rotor Centrifugal force may cause improperly filled or sealed tubes to collapse. The main cause of an imbalanced centrifuge is usually because the rotor is unevenly loaded. Spinning balanced loads will extend the life of the centrifuge and produce better. Inspect the centrifuge assembly for. Your centrifuge must contain a balanced load to work properly. If the centrifuge is not receiving. Tube Stuck In Centrifuge Rotor.

From www.researchgate.net

Setting of the centrifuge tubes in rotors and the appearance of the Tube Stuck In Centrifuge Rotor Position and align the rotor properly. If the centrifuge is not receiving power, check the circuit breaker or fuse. This tool will remove a stuck centrifuge rotor and these maintenance tips that help prevent it from happening. The main cause of an imbalanced centrifuge is usually because the rotor is unevenly loaded. The tubes or bottles should loosen or soften. Tube Stuck In Centrifuge Rotor.

From exonsijki.blob.core.windows.net

Centrifuge Tube Mechanism at Minnie Gibbs blog Tube Stuck In Centrifuge Rotor Your centrifuge must contain a balanced load to work properly. Apply a small amount of lubricant near the rotor axis to help loosen it. Centrifugal force may cause improperly filled or sealed tubes to collapse. Spinning balanced loads will extend the life of the centrifuge and produce better. Glass tubes can break during centrifugation, due either to improper loading or. Tube Stuck In Centrifuge Rotor.

From www.prpcentrifuges.com

Fixed Angle Rotor 2.2ml Tubes Medical Centrifuge Machine Cenlee Tube Stuck In Centrifuge Rotor Inspect the centrifuge assembly for. Spinning balanced loads will extend the life of the centrifuge and produce better. If the centrifuge is not receiving power, check the circuit breaker or fuse. The tubes or bottles should loosen or soften enough to slide out. The main cause of an imbalanced centrifuge is usually because the rotor is unevenly loaded. Centrifugal force. Tube Stuck In Centrifuge Rotor.

From www.beckman.com

Centrifuge Rotor Types Tube Stuck In Centrifuge Rotor This tool will remove a stuck centrifuge rotor and these maintenance tips that help prevent it from happening. Spinning balanced loads will extend the life of the centrifuge and produce better. Inspect the centrifuge assembly for. Glass tubes can break during centrifugation, due either to improper loading or inherent defects. Wait for the centrifuge to cool down before opening it.. Tube Stuck In Centrifuge Rotor.

From www.degruyter.com

An important source of preanalytical error in medical laboratories Tube Stuck In Centrifuge Rotor Inspect the centrifuge assembly for. Any glass fragments must be. Spinning balanced loads will extend the life of the centrifuge and produce better. Examine the rotor area for any visible obstructions, such as debris, broken parts or tubes. Position and align the rotor properly. Buckets must be loaded symetrically and the tubes or containers should be distributed evenly on all. Tube Stuck In Centrifuge Rotor.

From community.osseonews.com

Why does it look like the tubes are at angle in the photo for the Tube Stuck In Centrifuge Rotor The main cause of an imbalanced centrifuge is usually because the rotor is unevenly loaded. Your centrifuge must contain a balanced load to work properly. Centrifugal force may cause improperly filled or sealed tubes to collapse. If the centrifuge is not receiving power, check the circuit breaker or fuse. This tool will remove a stuck centrifuge rotor and these maintenance. Tube Stuck In Centrifuge Rotor.

From klaptycna.blob.core.windows.net

Centrifuge Tube Machine at Ronald Sears blog Tube Stuck In Centrifuge Rotor Spinning balanced loads will extend the life of the centrifuge and produce better. Wait for the centrifuge to cool down before opening it. Buckets must be loaded symetrically and the tubes or containers should be distributed evenly on all rotor positions. Examine the rotor area for any visible obstructions, such as debris, broken parts or tubes. Glass tubes can break. Tube Stuck In Centrifuge Rotor.

From www.alamy.com

Centrifuge tubes hires stock photography and images Alamy Tube Stuck In Centrifuge Rotor Inspect the centrifuge assembly for. Centrifugal force may cause improperly filled or sealed tubes to collapse. Your centrifuge must contain a balanced load to work properly. Glass tubes can break during centrifugation, due either to improper loading or inherent defects. If the centrifuge is not receiving power, check the circuit breaker or fuse. Wait for the centrifuge to cool down. Tube Stuck In Centrifuge Rotor.

From www.richmondscientific.com

Centrifuge Top Tips Part 1 Types of Centrifuges and Rotors Richmond Tube Stuck In Centrifuge Rotor Buckets must be loaded symetrically and the tubes or containers should be distributed evenly on all rotor positions. Inspect the centrifuge assembly for. Wait for the centrifuge to cool down before opening it. Glass tubes can break during centrifugation, due either to improper loading or inherent defects. Examine the rotor area for any visible obstructions, such as debris, broken parts. Tube Stuck In Centrifuge Rotor.

From www.integra-biosciences.com

How to balance a centrifuge (and which tubes to use) INTEGRA Tube Stuck In Centrifuge Rotor Centrifugal force may cause improperly filled or sealed tubes to collapse. Inspect the centrifuge assembly for. If the centrifuge is not receiving power, check the circuit breaker or fuse. The tubes or bottles should loosen or soften enough to slide out. Your centrifuge must contain a balanced load to work properly. Spinning balanced loads will extend the life of the. Tube Stuck In Centrifuge Rotor.

From exokycsnc.blob.core.windows.net

Centrifuge Tube Rotator at Filomena Gilbert blog Tube Stuck In Centrifuge Rotor Centrifugal force may cause improperly filled or sealed tubes to collapse. Buckets must be loaded symetrically and the tubes or containers should be distributed evenly on all rotor positions. The main cause of an imbalanced centrifuge is usually because the rotor is unevenly loaded. Apply a small amount of lubricant near the rotor axis to help loosen it. This tool. Tube Stuck In Centrifuge Rotor.

From orionlabs.net

6 Place Rotor, 50ml Centrifuge Tubes, 6000rpm max, Aluminum, for GCCMP Tube Stuck In Centrifuge Rotor This tool will remove a stuck centrifuge rotor and these maintenance tips that help prevent it from happening. Apply a small amount of lubricant near the rotor axis to help loosen it. Glass tubes can break during centrifugation, due either to improper loading or inherent defects. If the centrifuge is not receiving power, check the circuit breaker or fuse. Buckets. Tube Stuck In Centrifuge Rotor.

From mattbaker.blog

The Balanced Centrifuge Problem Matt Baker's Math Blog Tube Stuck In Centrifuge Rotor Glass tubes can break during centrifugation, due either to improper loading or inherent defects. This tool will remove a stuck centrifuge rotor and these maintenance tips that help prevent it from happening. If the centrifuge is not receiving power, check the circuit breaker or fuse. Position and align the rotor properly. Buckets must be loaded symetrically and the tubes or. Tube Stuck In Centrifuge Rotor.

From spectrofuge.com

Centrifuge Care and Maintenance in the Lab Spectrofuge Tube Stuck In Centrifuge Rotor If the centrifuge is not receiving power, check the circuit breaker or fuse. Position and align the rotor properly. Buckets must be loaded symetrically and the tubes or containers should be distributed evenly on all rotor positions. Examine the rotor area for any visible obstructions, such as debris, broken parts or tubes. Glass tubes can break during centrifugation, due either. Tube Stuck In Centrifuge Rotor.

From exosjnqag.blob.core.windows.net

Centrifuge Tube Meaning In Chemistry at Frank Samuel blog Tube Stuck In Centrifuge Rotor Spinning balanced loads will extend the life of the centrifuge and produce better. Inspect the centrifuge assembly for. Position and align the rotor properly. The main cause of an imbalanced centrifuge is usually because the rotor is unevenly loaded. Apply a small amount of lubricant near the rotor axis to help loosen it. If the centrifuge is not receiving power,. Tube Stuck In Centrifuge Rotor.

From data.epo.org

Centrifuge rotor with liquid supported swinging tubes Patent 0051991 Tube Stuck In Centrifuge Rotor Your centrifuge must contain a balanced load to work properly. Inspect the centrifuge assembly for. Position and align the rotor properly. Centrifugal force may cause improperly filled or sealed tubes to collapse. If the centrifuge is not receiving power, check the circuit breaker or fuse. Any glass fragments must be. The main cause of an imbalanced centrifuge is usually because. Tube Stuck In Centrifuge Rotor.

From www.youtube.com

How To Remove Stuck Rotors YouTube Tube Stuck In Centrifuge Rotor Centrifugal force may cause improperly filled or sealed tubes to collapse. Any glass fragments must be. Spinning balanced loads will extend the life of the centrifuge and produce better. Inspect the centrifuge assembly for. Examine the rotor area for any visible obstructions, such as debris, broken parts or tubes. This tool will remove a stuck centrifuge rotor and these maintenance. Tube Stuck In Centrifuge Rotor.

From www.slideserve.com

PPT Filtering and Centrifugation PowerPoint Presentation, free Tube Stuck In Centrifuge Rotor Apply a small amount of lubricant near the rotor axis to help loosen it. Buckets must be loaded symetrically and the tubes or containers should be distributed evenly on all rotor positions. This tool will remove a stuck centrifuge rotor and these maintenance tips that help prevent it from happening. If the centrifuge is not receiving power, check the circuit. Tube Stuck In Centrifuge Rotor.

From www.scimetricsinc.com

LC8 Laboratory Centrifuge with 8x15ml rotor, up to 3500rpm Tube Stuck In Centrifuge Rotor Buckets must be loaded symetrically and the tubes or containers should be distributed evenly on all rotor positions. Glass tubes can break during centrifugation, due either to improper loading or inherent defects. Centrifugal force may cause improperly filled or sealed tubes to collapse. Any glass fragments must be. Apply a small amount of lubricant near the rotor axis to help. Tube Stuck In Centrifuge Rotor.

From www.aliexpress.com

50 ml rund Boden Kunststoff centrigue Tube Schraubdeckel Graduated Tube Stuck In Centrifuge Rotor The tubes or bottles should loosen or soften enough to slide out. Any glass fragments must be. Centrifugal force may cause improperly filled or sealed tubes to collapse. Glass tubes can break during centrifugation, due either to improper loading or inherent defects. Inspect the centrifuge assembly for. Position and align the rotor properly. Spinning balanced loads will extend the life. Tube Stuck In Centrifuge Rotor.

From www.fishersci.co.uk

Thermo Scientific™ 8 x 50mL Fixed Angle Rotor 8 x 50mL Fixed Angle Tube Stuck In Centrifuge Rotor Wait for the centrifuge to cool down before opening it. Spinning balanced loads will extend the life of the centrifuge and produce better. The tubes or bottles should loosen or soften enough to slide out. The main cause of an imbalanced centrifuge is usually because the rotor is unevenly loaded. Buckets must be loaded symetrically and the tubes or containers. Tube Stuck In Centrifuge Rotor.

From www.richmondscientific.com

Fixed Angle vs. Swing Out Rotors What’s the difference? Richmond Tube Stuck In Centrifuge Rotor Position and align the rotor properly. Buckets must be loaded symetrically and the tubes or containers should be distributed evenly on all rotor positions. Wait for the centrifuge to cool down before opening it. Centrifugal force may cause improperly filled or sealed tubes to collapse. Inspect the centrifuge assembly for. Your centrifuge must contain a balanced load to work properly.. Tube Stuck In Centrifuge Rotor.

From www.stellarscientific.com

6 x 50mL conical tube rotor for Hermle Centrifuges Lab Equipment Tube Stuck In Centrifuge Rotor This tool will remove a stuck centrifuge rotor and these maintenance tips that help prevent it from happening. Apply a small amount of lubricant near the rotor axis to help loosen it. The main cause of an imbalanced centrifuge is usually because the rotor is unevenly loaded. Buckets must be loaded symetrically and the tubes or containers should be distributed. Tube Stuck In Centrifuge Rotor.

From druckerdiagnostics.com

A Guide to Balanced Centrifuge Loads Drucker Diagnostics Tube Stuck In Centrifuge Rotor Glass tubes can break during centrifugation, due either to improper loading or inherent defects. Examine the rotor area for any visible obstructions, such as debris, broken parts or tubes. Any glass fragments must be. This tool will remove a stuck centrifuge rotor and these maintenance tips that help prevent it from happening. Apply a small amount of lubricant near the. Tube Stuck In Centrifuge Rotor.

From www.researchgate.net

Modified centrifugeholding tube to the rim of the centrifuge rotor Tube Stuck In Centrifuge Rotor Inspect the centrifuge assembly for. The tubes or bottles should loosen or soften enough to slide out. Spinning balanced loads will extend the life of the centrifuge and produce better. Apply a small amount of lubricant near the rotor axis to help loosen it. The main cause of an imbalanced centrifuge is usually because the rotor is unevenly loaded. Wait. Tube Stuck In Centrifuge Rotor.

From microbenotes.com

Centrifuge Principle, Parts, Types, Uses, Examples Tube Stuck In Centrifuge Rotor Wait for the centrifuge to cool down before opening it. Centrifugal force may cause improperly filled or sealed tubes to collapse. Any glass fragments must be. Examine the rotor area for any visible obstructions, such as debris, broken parts or tubes. Buckets must be loaded symetrically and the tubes or containers should be distributed evenly on all rotor positions. Your. Tube Stuck In Centrifuge Rotor.

From www.stellarscientific.com

Fixed Angle Rotor Z2061215 Holds 12 x 15mL Conical Tubes in the Hermle Tube Stuck In Centrifuge Rotor Buckets must be loaded symetrically and the tubes or containers should be distributed evenly on all rotor positions. Examine the rotor area for any visible obstructions, such as debris, broken parts or tubes. The tubes or bottles should loosen or soften enough to slide out. Inspect the centrifuge assembly for. Spinning balanced loads will extend the life of the centrifuge. Tube Stuck In Centrifuge Rotor.

From www.iqsdirectory.com

Centrifuges Types, Classifications, Applications, and Benefits Tube Stuck In Centrifuge Rotor Spinning balanced loads will extend the life of the centrifuge and produce better. Glass tubes can break during centrifugation, due either to improper loading or inherent defects. Apply a small amount of lubricant near the rotor axis to help loosen it. The main cause of an imbalanced centrifuge is usually because the rotor is unevenly loaded. Position and align the. Tube Stuck In Centrifuge Rotor.

From microbenotes.com

Centrifuge Principle, Parts, Types, Uses, Examples Tube Stuck In Centrifuge Rotor This tool will remove a stuck centrifuge rotor and these maintenance tips that help prevent it from happening. Your centrifuge must contain a balanced load to work properly. Wait for the centrifuge to cool down before opening it. The main cause of an imbalanced centrifuge is usually because the rotor is unevenly loaded. Position and align the rotor properly. Spinning. Tube Stuck In Centrifuge Rotor.

From universe84a.com

Centrifuge Introduction, Principle, Types, Handling Procedure, Uses and Tube Stuck In Centrifuge Rotor Examine the rotor area for any visible obstructions, such as debris, broken parts or tubes. Glass tubes can break during centrifugation, due either to improper loading or inherent defects. This tool will remove a stuck centrifuge rotor and these maintenance tips that help prevent it from happening. The tubes or bottles should loosen or soften enough to slide out. If. Tube Stuck In Centrifuge Rotor.

From slidetodoc.com

CENTRIFUGATION THEORY AND PRACTICE Routine centrifuge rotors Calculation Tube Stuck In Centrifuge Rotor Spinning balanced loads will extend the life of the centrifuge and produce better. Position and align the rotor properly. If the centrifuge is not receiving power, check the circuit breaker or fuse. Centrifugal force may cause improperly filled or sealed tubes to collapse. Apply a small amount of lubricant near the rotor axis to help loosen it. Glass tubes can. Tube Stuck In Centrifuge Rotor.

From www.beckman.com

Balancing Your Rotor Tube Stuck In Centrifuge Rotor Wait for the centrifuge to cool down before opening it. This tool will remove a stuck centrifuge rotor and these maintenance tips that help prevent it from happening. Centrifugal force may cause improperly filled or sealed tubes to collapse. Glass tubes can break during centrifugation, due either to improper loading or inherent defects. Apply a small amount of lubricant near. Tube Stuck In Centrifuge Rotor.

From shop.unigreenscheme.co.uk

2x Laboratory Centrifuge Rotors With tubes and accessories Tube Stuck In Centrifuge Rotor This tool will remove a stuck centrifuge rotor and these maintenance tips that help prevent it from happening. Position and align the rotor properly. Inspect the centrifuge assembly for. Centrifugal force may cause improperly filled or sealed tubes to collapse. Spinning balanced loads will extend the life of the centrifuge and produce better. Buckets must be loaded symetrically and the. Tube Stuck In Centrifuge Rotor.