What Is Hand Lapping . Lapping has the following characteristics: In hand lapping process, the work piece is rubbed over the lapping plate manually. How to hand lap a part. Lapping is a machining operation, in which two surfaces are rubbed together with an abrasive between them,. According to it, lapping can be divided into two types. Hand lapping on a lapping machine using a cast iron lapping plate can be effective when trying to meet the precision surface needed for a workpiece. The lapping process uses fine abrasive particles to perform the cutting action on the surface of the (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. In this video i will show you the basics of hand lapping and how easy it is.

from www.kitplanes.com

How to hand lap a part. Lapping is a machining operation, in which two surfaces are rubbed together with an abrasive between them,. According to it, lapping can be divided into two types. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. Lapping has the following characteristics: In this video i will show you the basics of hand lapping and how easy it is. The lapping process uses fine abrasive particles to perform the cutting action on the surface of the Hand lapping on a lapping machine using a cast iron lapping plate can be effective when trying to meet the precision surface needed for a workpiece. In hand lapping process, the work piece is rubbed over the lapping plate manually.

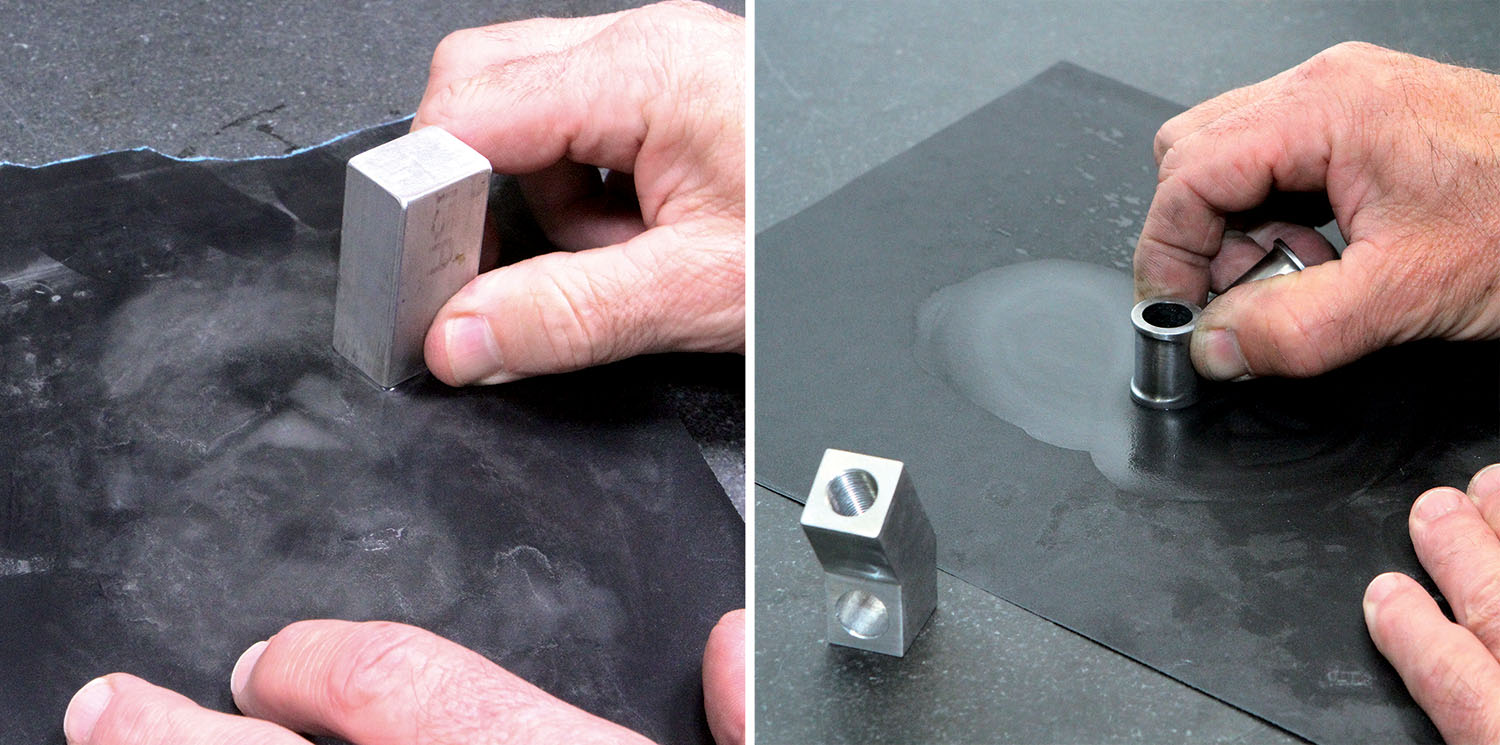

Laps and Lapping KITPLANES

What Is Hand Lapping In hand lapping process, the work piece is rubbed over the lapping plate manually. Hand lapping on a lapping machine using a cast iron lapping plate can be effective when trying to meet the precision surface needed for a workpiece. In this video i will show you the basics of hand lapping and how easy it is. How to hand lap a part. According to it, lapping can be divided into two types. In hand lapping process, the work piece is rubbed over the lapping plate manually. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. Lapping is a machining operation, in which two surfaces are rubbed together with an abrasive between them,. Lapping has the following characteristics: The lapping process uses fine abrasive particles to perform the cutting action on the surface of the

From www.unitedcenterlessgrinding.net

Precision Lapping Services United Centerless Grinding What Is Hand Lapping Lapping is a machining operation, in which two surfaces are rubbed together with an abrasive between them,. According to it, lapping can be divided into two types. How to hand lap a part. Lapping has the following characteristics: (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. In this video i will show you the. What Is Hand Lapping.

From www.kemet-international.com

Portable Lapping Kits Kemet Singapore What Is Hand Lapping Lapping has the following characteristics: In this video i will show you the basics of hand lapping and how easy it is. How to hand lap a part. According to it, lapping can be divided into two types. Lapping is a machining operation, in which two surfaces are rubbed together with an abrasive between them,. (1) the workpiece’s surface roughness. What Is Hand Lapping.

From slidingmotion.com

What is Lapping? How Lapping Works? slidingmotion What Is Hand Lapping According to it, lapping can be divided into two types. The lapping process uses fine abrasive particles to perform the cutting action on the surface of the (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. Lapping is a machining operation, in which two surfaces are rubbed together with an abrasive between them,. In this. What Is Hand Lapping.

From studentlesson.com

Things you need to know about lapping process studentlesson What Is Hand Lapping In hand lapping process, the work piece is rubbed over the lapping plate manually. In this video i will show you the basics of hand lapping and how easy it is. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. Lapping is a machining operation, in which two surfaces are rubbed together with an abrasive. What Is Hand Lapping.

From learningtechnologyofficial.com

Staggering of Bar and Lapping Zone problem in Building Construction I What Is Hand Lapping In this video i will show you the basics of hand lapping and how easy it is. Hand lapping on a lapping machine using a cast iron lapping plate can be effective when trying to meet the precision surface needed for a workpiece. Lapping is a machining operation, in which two surfaces are rubbed together with an abrasive between them,.. What Is Hand Lapping.

From www.lbp.co.uk

LBP Optics What we do custom lapping and polishing What Is Hand Lapping (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. According to it, lapping can be divided into two types. How to hand lap a part. Hand lapping on a lapping machine using a cast iron lapping plate can be effective when trying to meet the precision surface needed for a workpiece. Lapping is a machining. What Is Hand Lapping.

From www.youtube.com

Hand lapping Granite Plates YouTube What Is Hand Lapping (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. In this video i will show you the basics of hand lapping and how easy it is. Lapping has the following characteristics: Hand lapping on a lapping machine using a cast iron lapping plate can be effective when trying to meet the precision surface needed for. What Is Hand Lapping.

From www.stahliusa.com

Hand Lapping using Cast Iron Plate on Lapping Machine What Is Hand Lapping The lapping process uses fine abrasive particles to perform the cutting action on the surface of the Hand lapping on a lapping machine using a cast iron lapping plate can be effective when trying to meet the precision surface needed for a workpiece. According to it, lapping can be divided into two types. How to hand lap a part. In. What Is Hand Lapping.

From www.cermac.com

Lapping Machining Lapping Manufacturing CerMac Inc. What Is Hand Lapping How to hand lap a part. In this video i will show you the basics of hand lapping and how easy it is. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. Lapping is a machining operation, in which two surfaces are rubbed together with an abrasive between them,. Hand lapping on a lapping machine. What Is Hand Lapping.

From exoxtebuc.blob.core.windows.net

Hand Valve Lapping Tool at Calvin Sparrow blog What Is Hand Lapping Hand lapping on a lapping machine using a cast iron lapping plate can be effective when trying to meet the precision surface needed for a workpiece. How to hand lap a part. The lapping process uses fine abrasive particles to perform the cutting action on the surface of the Lapping is a machining operation, in which two surfaces are rubbed. What Is Hand Lapping.

From www.mechanicaddicts.com

Valve Lapping Tool Review Get a Perfect Valve Seat Every Time What Is Hand Lapping The lapping process uses fine abrasive particles to perform the cutting action on the surface of the In hand lapping process, the work piece is rubbed over the lapping plate manually. Lapping has the following characteristics: In this video i will show you the basics of hand lapping and how easy it is. Hand lapping on a lapping machine using. What Is Hand Lapping.

From info.texasfinaldrive.com

Reman Final Drives and Lapping Dr Drive Shop Video What Is Hand Lapping Lapping is a machining operation, in which two surfaces are rubbed together with an abrasive between them,. How to hand lap a part. Lapping has the following characteristics: In hand lapping process, the work piece is rubbed over the lapping plate manually. The lapping process uses fine abrasive particles to perform the cutting action on the surface of the Hand. What Is Hand Lapping.

From www.youtube.com

Precision Lapping 101 YouTube What Is Hand Lapping How to hand lap a part. Hand lapping on a lapping machine using a cast iron lapping plate can be effective when trying to meet the precision surface needed for a workpiece. In hand lapping process, the work piece is rubbed over the lapping plate manually. Lapping has the following characteristics: The lapping process uses fine abrasive particles to perform. What Is Hand Lapping.

From www.youtube.com

Lapping Process Surface Finishing Process Abrasive Machining PPT What Is Hand Lapping The lapping process uses fine abrasive particles to perform the cutting action on the surface of the Lapping has the following characteristics: In this video i will show you the basics of hand lapping and how easy it is. How to hand lap a part. Hand lapping on a lapping machine using a cast iron lapping plate can be effective. What Is Hand Lapping.

From www.youtube.com

What is Lapping? YouTube What Is Hand Lapping According to it, lapping can be divided into two types. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. Lapping is a machining operation, in which two surfaces are rubbed together with an abrasive between them,. The lapping process uses fine abrasive particles to perform the cutting action on the surface of the How to. What Is Hand Lapping.

From precisionmachinetips.blogspot.com

Precision Machine Tips The Basics of Hand Lapping Explained What Is Hand Lapping Hand lapping on a lapping machine using a cast iron lapping plate can be effective when trying to meet the precision surface needed for a workpiece. Lapping has the following characteristics: The lapping process uses fine abrasive particles to perform the cutting action on the surface of the (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1. What Is Hand Lapping.

From www.youtube.com

Hand Lapping the Blade and Spring of a Folding Knife to Final Thickness What Is Hand Lapping According to it, lapping can be divided into two types. The lapping process uses fine abrasive particles to perform the cutting action on the surface of the Lapping has the following characteristics: How to hand lap a part. In hand lapping process, the work piece is rubbed over the lapping plate manually. Hand lapping on a lapping machine using a. What Is Hand Lapping.

From www.hongteckhin.com.sg

What is Loctite Lapping Compound and How Does it Work? What Is Hand Lapping Lapping has the following characteristics: Hand lapping on a lapping machine using a cast iron lapping plate can be effective when trying to meet the precision surface needed for a workpiece. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. In hand lapping process, the work piece is rubbed over the lapping plate manually. How. What Is Hand Lapping.

From www.camaros.net

How To Lapping Your Valves At Home Team Camaro Tech What Is Hand Lapping Hand lapping on a lapping machine using a cast iron lapping plate can be effective when trying to meet the precision surface needed for a workpiece. In this video i will show you the basics of hand lapping and how easy it is. How to hand lap a part. Lapping has the following characteristics: The lapping process uses fine abrasive. What Is Hand Lapping.

From www.indiamart.com

Hand Lapping Plate at Rs 3500/piece Polishing Plates in Coimbatore What Is Hand Lapping (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. Lapping has the following characteristics: The lapping process uses fine abrasive particles to perform the cutting action on the surface of the How to hand lap a part. Hand lapping on a lapping machine using a cast iron lapping plate can be effective when trying to. What Is Hand Lapping.

From www.youtube.com

What is Lapping Process ?? YouTube What Is Hand Lapping Hand lapping on a lapping machine using a cast iron lapping plate can be effective when trying to meet the precision surface needed for a workpiece. Lapping has the following characteristics: In this video i will show you the basics of hand lapping and how easy it is. The lapping process uses fine abrasive particles to perform the cutting action. What Is Hand Lapping.

From www.vrogue.co

What Is Valve Lapping Procedure For Lapping Valves In vrogue.co What Is Hand Lapping Lapping has the following characteristics: The lapping process uses fine abrasive particles to perform the cutting action on the surface of the (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. According to it, lapping can be divided into two types. Hand lapping on a lapping machine using a cast iron lapping plate can be. What Is Hand Lapping.

From www.youtube.com

Making flat lapping plates 1 YouTube What Is Hand Lapping (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. The lapping process uses fine abrasive particles to perform the cutting action on the surface of the Lapping has the following characteristics: How to hand lap a part. Lapping is a machining operation, in which two surfaces are rubbed together with an abrasive between them,. In. What Is Hand Lapping.

From www.cadillacforums.com

How To Lapping Your Valves At Home Cadillac Owners Forum What Is Hand Lapping In this video i will show you the basics of hand lapping and how easy it is. The lapping process uses fine abrasive particles to perform the cutting action on the surface of the Lapping is a machining operation, in which two surfaces are rubbed together with an abrasive between them,. How to hand lap a part. In hand lapping. What Is Hand Lapping.

From www.hahn-kolb.de

Diamond hand lapping tools HAHN+KOLB What Is Hand Lapping In hand lapping process, the work piece is rubbed over the lapping plate manually. Hand lapping on a lapping machine using a cast iron lapping plate can be effective when trying to meet the precision surface needed for a workpiece. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. The lapping process uses fine abrasive. What Is Hand Lapping.

From www.kitplanes.com

Laps and Lapping KITPLANES What Is Hand Lapping How to hand lap a part. In hand lapping process, the work piece is rubbed over the lapping plate manually. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. Lapping is a machining operation, in which two surfaces are rubbed together with an abrasive between them,. Lapping has the following characteristics: Hand lapping on a. What Is Hand Lapping.

From www.youtube.com

Making a Lapping Plate for Sharpening YouTube What Is Hand Lapping How to hand lap a part. In hand lapping process, the work piece is rubbed over the lapping plate manually. Lapping is a machining operation, in which two surfaces are rubbed together with an abrasive between them,. According to it, lapping can be divided into two types. Lapping has the following characteristics: The lapping process uses fine abrasive particles to. What Is Hand Lapping.

From madchem.com

Lapping Madison Chemical What Is Hand Lapping Lapping is a machining operation, in which two surfaces are rubbed together with an abrasive between them,. How to hand lap a part. The lapping process uses fine abrasive particles to perform the cutting action on the surface of the Lapping has the following characteristics: Hand lapping on a lapping machine using a cast iron lapping plate can be effective. What Is Hand Lapping.

From www.reddit.com

Found a creative solution to valve lapping by hand. r/MechanicAdvice What Is Hand Lapping Hand lapping on a lapping machine using a cast iron lapping plate can be effective when trying to meet the precision surface needed for a workpiece. (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. According to it, lapping can be divided into two types. The lapping process uses fine abrasive particles to perform the. What Is Hand Lapping.

From www.youtube.com

Lapping and Checking Valves (EASY WAY) YouTube What Is Hand Lapping In this video i will show you the basics of hand lapping and how easy it is. According to it, lapping can be divided into two types. In hand lapping process, the work piece is rubbed over the lapping plate manually. How to hand lap a part. Lapping has the following characteristics: Lapping is a machining operation, in which two. What Is Hand Lapping.

From exoxtebuc.blob.core.windows.net

Hand Valve Lapping Tool at Calvin Sparrow blog What Is Hand Lapping How to hand lap a part. In this video i will show you the basics of hand lapping and how easy it is. According to it, lapping can be divided into two types. In hand lapping process, the work piece is rubbed over the lapping plate manually. Lapping has the following characteristics: Lapping is a machining operation, in which two. What Is Hand Lapping.

From www.joke-technology.com

Internal lapping tool HELICAL LAP with radial groove Internal What Is Hand Lapping Lapping has the following characteristics: The lapping process uses fine abrasive particles to perform the cutting action on the surface of the According to it, lapping can be divided into two types. In hand lapping process, the work piece is rubbed over the lapping plate manually. Lapping is a machining operation, in which two surfaces are rubbed together with an. What Is Hand Lapping.

From discover.hubpages.com

Difference Between Lapping and Honing Process HubPages What Is Hand Lapping In hand lapping process, the work piece is rubbed over the lapping plate manually. Lapping is a machining operation, in which two surfaces are rubbed together with an abrasive between them,. Hand lapping on a lapping machine using a cast iron lapping plate can be effective when trying to meet the precision surface needed for a workpiece. The lapping process. What Is Hand Lapping.

From www.youtube.com

Hand Lapping by Don Bailey YouTube What Is Hand Lapping In this video i will show you the basics of hand lapping and how easy it is. Lapping has the following characteristics: The lapping process uses fine abrasive particles to perform the cutting action on the surface of the (1) the workpiece’s surface roughness can reach ra = 0.006 to 0.1 μm, and. Lapping is a machining operation, in which. What Is Hand Lapping.

From games.udlvirtual.edu.pe

What Is The Hand Clapping Game Called BEST GAMES WALKTHROUGH What Is Hand Lapping According to it, lapping can be divided into two types. In hand lapping process, the work piece is rubbed over the lapping plate manually. How to hand lap a part. Lapping is a machining operation, in which two surfaces are rubbed together with an abrasive between them,. In this video i will show you the basics of hand lapping and. What Is Hand Lapping.