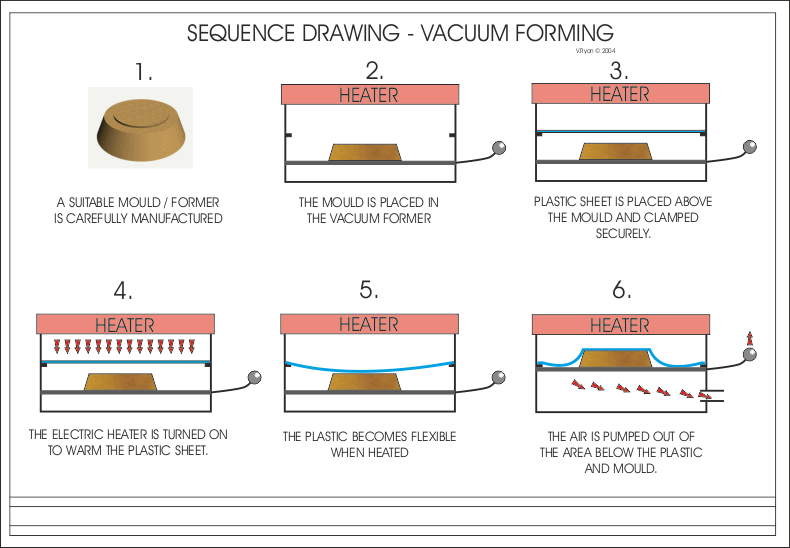

What Does A Vacuum Former Do . Put simply, vacuum forming transforms sheet plastic into an item of choice. vacuum forming is widely used across different industries, creating a wide range of vacuum formed products and can be used in panels, trays, packaging and plastic boxes for electrical appliances such as washing machines, vacuum cleaners and fridges. When it comes to choosing the materials, most. a vacuum is applied sucking the sheet into the mould. The sheet is then ejected from the mould. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. From smaller parts like pharmaceutical blister packs to larger auto parts, vacuum forming is used across many industries. vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part.

from www.goconqr.com

From smaller parts like pharmaceutical blister packs to larger auto parts, vacuum forming is used across many industries. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. Put simply, vacuum forming transforms sheet plastic into an item of choice. When it comes to choosing the materials, most. vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part. The sheet is then ejected from the mould. vacuum forming is widely used across different industries, creating a wide range of vacuum formed products and can be used in panels, trays, packaging and plastic boxes for electrical appliances such as washing machines, vacuum cleaners and fridges. a vacuum is applied sucking the sheet into the mould.

VACUUM FORMING Mapa Mental

What Does A Vacuum Former Do Put simply, vacuum forming transforms sheet plastic into an item of choice. The sheet is then ejected from the mould. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. When it comes to choosing the materials, most. a vacuum is applied sucking the sheet into the mould. From smaller parts like pharmaceutical blister packs to larger auto parts, vacuum forming is used across many industries. vacuum forming is widely used across different industries, creating a wide range of vacuum formed products and can be used in panels, trays, packaging and plastic boxes for electrical appliances such as washing machines, vacuum cleaners and fridges. Put simply, vacuum forming transforms sheet plastic into an item of choice. vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part.

From mavink.com

Parts Of A Vacuum Former What Does A Vacuum Former Do a vacuum is applied sucking the sheet into the mould. Put simply, vacuum forming transforms sheet plastic into an item of choice. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. vacuum forming is widely used across different industries, creating a wide range of vacuum formed products and can be. What Does A Vacuum Former Do.

From 3dworkshoplcc.arts.ac.uk

What vacuum forming eq... 3D London College of Communication What Does A Vacuum Former Do vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. The sheet is then ejected from the mould. a vacuum is applied sucking the sheet. What Does A Vacuum Former Do.

From www.youtube.com

In The Know Machine III Vacuum Forming Process YouTube What Does A Vacuum Former Do The sheet is then ejected from the mould. From smaller parts like pharmaceutical blister packs to larger auto parts, vacuum forming is used across many industries. vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part. a vacuum is applied sucking the. What Does A Vacuum Former Do.

From www.youtube.com

Formech explores how vacuum forming is innovating design at Pratt What Does A Vacuum Former Do vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. The sheet is then ejected from the mould. a vacuum is applied sucking the sheet into the mould. From smaller parts like pharmaceutical blister packs to larger auto parts, vacuum forming is used across many industries. Put simply, vacuum forming transforms sheet. What Does A Vacuum Former Do.

From spottingit.com

The advantages of vacuum forming Spotting IT What Does A Vacuum Former Do From smaller parts like pharmaceutical blister packs to larger auto parts, vacuum forming is used across many industries. Put simply, vacuum forming transforms sheet plastic into an item of choice. The sheet is then ejected from the mould. When it comes to choosing the materials, most. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process. What Does A Vacuum Former Do.

From www.instructables.com

Vacuum Former 8 Steps (with Pictures) Instructables What Does A Vacuum Former Do a vacuum is applied sucking the sheet into the mould. vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part. Put simply, vacuum forming transforms sheet plastic into an item of choice. vacuum forming is widely used across different industries, creating. What Does A Vacuum Former Do.

From www.vacforming.uk.com

What Is Vacuum Forming? Process And The Practical Uses What Does A Vacuum Former Do The sheet is then ejected from the mould. vacuum forming is widely used across different industries, creating a wide range of vacuum formed products and can be used in panels, trays, packaging and plastic boxes for electrical appliances such as washing machines, vacuum cleaners and fridges. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing. What Does A Vacuum Former Do.

From www.plas-tech.co.uk

Vac Forming The Advantages of Vacuum Forming What Does A Vacuum Former Do vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. Put simply, vacuum forming transforms sheet plastic into an item of choice. When it comes to. What Does A Vacuum Former Do.

From www.youtube.com

Vacuum Forming Process Working Applications ENGINEERING STUDY What Does A Vacuum Former Do Put simply, vacuum forming transforms sheet plastic into an item of choice. From smaller parts like pharmaceutical blister packs to larger auto parts, vacuum forming is used across many industries. a vacuum is applied sucking the sheet into the mould. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. vacuum. What Does A Vacuum Former Do.

From www.madearia.com

Vacuum Forming Process, Materials & Benefit Aria Manufacturing Limited What Does A Vacuum Former Do The sheet is then ejected from the mould. vacuum forming is widely used across different industries, creating a wide range of vacuum formed products and can be used in panels, trays, packaging and plastic boxes for electrical appliances such as washing machines, vacuum cleaners and fridges. When it comes to choosing the materials, most. a vacuum is applied. What Does A Vacuum Former Do.

From interform-uk.com

Thermoplastic vacuum forming plastic with Interform Manufacturing What Does A Vacuum Former Do vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. Put simply, vacuum forming transforms sheet plastic into an item of choice. The sheet is then ejected from the mould. From smaller parts like pharmaceutical blister packs to larger auto parts, vacuum forming is used across many industries. vacuum forming is widely. What Does A Vacuum Former Do.

From ceznlwqf.blob.core.windows.net

Vacuum Forming Plastic Bottles at Alicia Moreno blog What Does A Vacuum Former Do Put simply, vacuum forming transforms sheet plastic into an item of choice. vacuum forming is widely used across different industries, creating a wide range of vacuum formed products and can be used in panels, trays, packaging and plastic boxes for electrical appliances such as washing machines, vacuum cleaners and fridges. vacuum forming heats a plastic sheet until it. What Does A Vacuum Former Do.

From www.plas-tech.co.uk

How Does Vac Forming Work? Vacuum Forming Yorkshire What Does A Vacuum Former Do Put simply, vacuum forming transforms sheet plastic into an item of choice. vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. vacuum forming is. What Does A Vacuum Former Do.

From www.youtube.com

Introduction To Vacuum Forming What is vacuum Forming and What Can I What Does A Vacuum Former Do From smaller parts like pharmaceutical blister packs to larger auto parts, vacuum forming is used across many industries. When it comes to choosing the materials, most. vacuum forming is widely used across different industries, creating a wide range of vacuum formed products and can be used in panels, trays, packaging and plastic boxes for electrical appliances such as washing. What Does A Vacuum Former Do.

From www.techsoft.co.uk

Vacuum Forming TechSoft What Does A Vacuum Former Do Put simply, vacuum forming transforms sheet plastic into an item of choice. a vacuum is applied sucking the sheet into the mould. When it comes to choosing the materials, most. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. The sheet is then ejected from the mould. vacuum forming heats. What Does A Vacuum Former Do.

From www.brayplastics.co.uk

What is Vacuum Forming? Bray Plastics What Does A Vacuum Former Do The sheet is then ejected from the mould. a vacuum is applied sucking the sheet into the mould. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain. What Does A Vacuum Former Do.

From foammolders.com

Vacuum Forming The Processes Foam Molders Uses To Create HighQuality What Does A Vacuum Former Do When it comes to choosing the materials, most. The sheet is then ejected from the mould. a vacuum is applied sucking the sheet into the mould. vacuum forming is widely used across different industries, creating a wide range of vacuum formed products and can be used in panels, trays, packaging and plastic boxes for electrical appliances such as. What Does A Vacuum Former Do.

From phase-2.org

What are the benefits of vacuum forming? Move to a new phase What Does A Vacuum Former Do When it comes to choosing the materials, most. a vacuum is applied sucking the sheet into the mould. Put simply, vacuum forming transforms sheet plastic into an item of choice. From smaller parts like pharmaceutical blister packs to larger auto parts, vacuum forming is used across many industries. vacuum forming is widely used across different industries, creating a. What Does A Vacuum Former Do.

From www.youtube.com

What is Vacuum Forming? YouTube What Does A Vacuum Former Do vacuum forming is widely used across different industries, creating a wide range of vacuum formed products and can be used in panels, trays, packaging and plastic boxes for electrical appliances such as washing machines, vacuum cleaners and fridges. The sheet is then ejected from the mould. Put simply, vacuum forming transforms sheet plastic into an item of choice. . What Does A Vacuum Former Do.

From the-shed.nz

Make a simple vacuum former The Shed What Does A Vacuum Former Do a vacuum is applied sucking the sheet into the mould. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. From smaller parts like pharmaceutical blister packs to larger auto parts, vacuum forming is used across many industries. vacuum forming heats a plastic sheet until it becomes pliable, stretches the material. What Does A Vacuum Former Do.

From www.youtube.com

Vacuum Forming YouTube What Does A Vacuum Former Do Put simply, vacuum forming transforms sheet plastic into an item of choice. From smaller parts like pharmaceutical blister packs to larger auto parts, vacuum forming is used across many industries. When it comes to choosing the materials, most. vacuum forming is widely used across different industries, creating a wide range of vacuum formed products and can be used in. What Does A Vacuum Former Do.

From www.youtube.com

Vacuum forming 01 main process YouTube What Does A Vacuum Former Do vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part. vacuum forming is widely used across different industries, creating a wide range of vacuum formed products and can be used in panels, trays, packaging and plastic boxes for electrical appliances such as. What Does A Vacuum Former Do.

From www.makerspace.uq.edu.au

Vacuum Former Maker Space University of Queensland What Does A Vacuum Former Do vacuum forming is widely used across different industries, creating a wide range of vacuum formed products and can be used in panels, trays, packaging and plastic boxes for electrical appliances such as washing machines, vacuum cleaners and fridges. vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum. What Does A Vacuum Former Do.

From electricalworkbook.com

What is Vacuum Forming? Process, Applications, Products & Advantages What Does A Vacuum Former Do vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part. From smaller parts like pharmaceutical blister packs to larger auto parts, vacuum forming is used across many industries. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where. What Does A Vacuum Former Do.

From formlabs.com

Introduction to Vacuum Forming What Does A Vacuum Former Do The sheet is then ejected from the mould. From smaller parts like pharmaceutical blister packs to larger auto parts, vacuum forming is used across many industries. vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part. Put simply, vacuum forming transforms sheet plastic. What Does A Vacuum Former Do.

From www.youtube.com

Vacuum Forming Step By Step Guide YouTube What Does A Vacuum Former Do From smaller parts like pharmaceutical blister packs to larger auto parts, vacuum forming is used across many industries. When it comes to choosing the materials, most. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. The sheet is then ejected from the mould. Put simply, vacuum forming transforms sheet plastic into an. What Does A Vacuum Former Do.

From www.techsoft.co.uk

Clarke Vacuum Formers What Does A Vacuum Former Do The sheet is then ejected from the mould. From smaller parts like pharmaceutical blister packs to larger auto parts, vacuum forming is used across many industries. Put simply, vacuum forming transforms sheet plastic into an item of choice. vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure. What Does A Vacuum Former Do.

From www.techsoft.co.uk

Vacuum Forming TechSoft What Does A Vacuum Former Do When it comes to choosing the materials, most. The sheet is then ejected from the mould. Put simply, vacuum forming transforms sheet plastic into an item of choice. a vacuum is applied sucking the sheet into the mould. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. From smaller parts like. What Does A Vacuum Former Do.

From electricalworkbook.com

What is Vacuum Forming? Process, Applications, Products & Advantages What Does A Vacuum Former Do vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part. The sheet is then ejected from the mould. Put simply, vacuum forming transforms sheet plastic into an item of choice. vacuum forming is widely used across different industries, creating a wide range. What Does A Vacuum Former Do.

From www.techsoft.co.uk

Vacuum Forming TechSoft What Does A Vacuum Former Do vacuum forming is widely used across different industries, creating a wide range of vacuum formed products and can be used in panels, trays, packaging and plastic boxes for electrical appliances such as washing machines, vacuum cleaners and fridges. a vacuum is applied sucking the sheet into the mould. When it comes to choosing the materials, most. vacuum. What Does A Vacuum Former Do.

From designitforyou.com

WHAT IS VACUUM FORMING What Does A Vacuum Former Do vacuum forming heats a plastic sheet until it becomes pliable, stretches the material onto a mold, and then uses vacuum pressure to obtain the desired part. From smaller parts like pharmaceutical blister packs to larger auto parts, vacuum forming is used across many industries. a vacuum is applied sucking the sheet into the mould. When it comes to. What Does A Vacuum Former Do.

From sites.wit.edu

stepbystep guide to vacuum forming Center for Applied Research What Does A Vacuum Former Do The sheet is then ejected from the mould. a vacuum is applied sucking the sheet into the mould. vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. Put simply, vacuum forming transforms sheet plastic into an item of choice. From smaller parts like pharmaceutical blister packs to larger auto parts, vacuum. What Does A Vacuum Former Do.

From schoutengroup.com

Vacuum forming Schouten Group What Does A Vacuum Former Do a vacuum is applied sucking the sheet into the mould. vacuum forming is widely used across different industries, creating a wide range of vacuum formed products and can be used in panels, trays, packaging and plastic boxes for electrical appliances such as washing machines, vacuum cleaners and fridges. The sheet is then ejected from the mould. When it. What Does A Vacuum Former Do.

From www.goconqr.com

VACUUM FORMING Mapa Mental What Does A Vacuum Former Do vacuum forming, also known as vacuum molding, is a flexible plastic manufacturing process where a heated. When it comes to choosing the materials, most. From smaller parts like pharmaceutical blister packs to larger auto parts, vacuum forming is used across many industries. a vacuum is applied sucking the sheet into the mould. vacuum forming is widely used. What Does A Vacuum Former Do.

From sites.wit.edu

stepbystep guide to vacuum forming Center for Applied Research What Does A Vacuum Former Do Put simply, vacuum forming transforms sheet plastic into an item of choice. When it comes to choosing the materials, most. a vacuum is applied sucking the sheet into the mould. From smaller parts like pharmaceutical blister packs to larger auto parts, vacuum forming is used across many industries. The sheet is then ejected from the mould. vacuum forming. What Does A Vacuum Former Do.