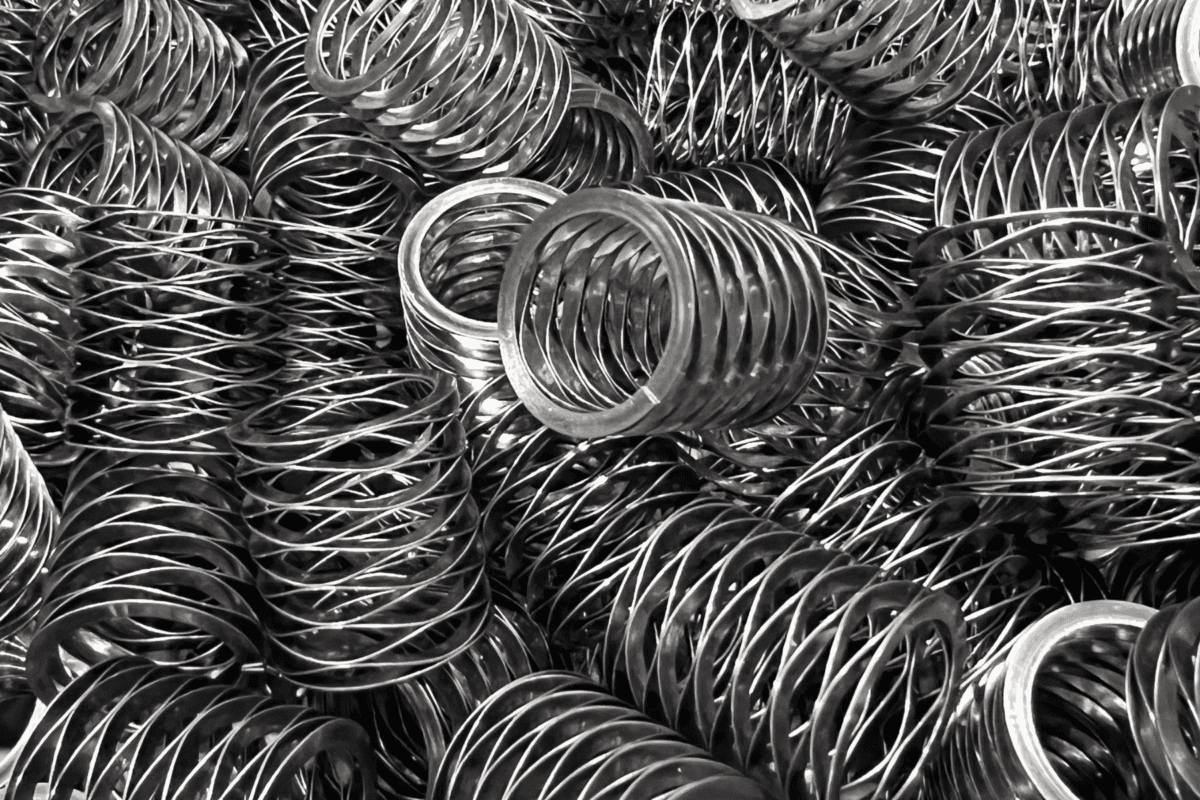

Wave Springs In Series . Wave springs offer many advantages over die stamped products. Loads and spring rates are more accurate, more predictable, and may be. These forces increase proportionally to the number of turns. Nested wave springs are coiled in parallel to form a continuous coil of layers, significantly enhancing load performance. Saves 50% in axial space compared to traditional coiled spring. The type we’ll focus on today is a compression spring. These advanced wave springs multiply loads and spring rates. Nested spirawave® springs are flat wire wave springs with multiple turns, coiled in parallel to produce higher forces. This configuration we call series, because the springs are in direct contact and therefore effect the mass by successive stretching. Higher deflection potential than single. Wave springs, often referred to as wave washers, are a unique and increasingly popular type of spring design known for their compact size,.

from www.rotorclip.com

This configuration we call series, because the springs are in direct contact and therefore effect the mass by successive stretching. Nested wave springs are coiled in parallel to form a continuous coil of layers, significantly enhancing load performance. Wave springs offer many advantages over die stamped products. Loads and spring rates are more accurate, more predictable, and may be. Wave springs, often referred to as wave washers, are a unique and increasingly popular type of spring design known for their compact size,. The type we’ll focus on today is a compression spring. These advanced wave springs multiply loads and spring rates. Saves 50% in axial space compared to traditional coiled spring. These forces increase proportionally to the number of turns. Nested spirawave® springs are flat wire wave springs with multiple turns, coiled in parallel to produce higher forces.

Linear Wave Springs Rotor Clip

Wave Springs In Series The type we’ll focus on today is a compression spring. Nested spirawave® springs are flat wire wave springs with multiple turns, coiled in parallel to produce higher forces. Higher deflection potential than single. These advanced wave springs multiply loads and spring rates. Wave springs, often referred to as wave washers, are a unique and increasingly popular type of spring design known for their compact size,. Loads and spring rates are more accurate, more predictable, and may be. The type we’ll focus on today is a compression spring. Nested wave springs are coiled in parallel to form a continuous coil of layers, significantly enhancing load performance. These forces increase proportionally to the number of turns. Saves 50% in axial space compared to traditional coiled spring. This configuration we call series, because the springs are in direct contact and therefore effect the mass by successive stretching. Wave springs offer many advantages over die stamped products.

From scienceres-edcp-educ.sites.olt.ubc.ca

Springs MSTLTT Wave Springs In Series The type we’ll focus on today is a compression spring. These advanced wave springs multiply loads and spring rates. Wave springs offer many advantages over die stamped products. Loads and spring rates are more accurate, more predictable, and may be. Nested spirawave® springs are flat wire wave springs with multiple turns, coiled in parallel to produce higher forces. Wave springs,. Wave Springs In Series.

From www.spiral-retainingring.com

C Series Multi Turn Wave Springs Inch Plain ends Wave Springs In Series Wave springs offer many advantages over die stamped products. The type we’ll focus on today is a compression spring. Nested wave springs are coiled in parallel to form a continuous coil of layers, significantly enhancing load performance. Loads and spring rates are more accurate, more predictable, and may be. Wave springs, often referred to as wave washers, are a unique. Wave Springs In Series.

From www.spiral-retainingring.com

RW Series Wave Springs Inch Round Wire Wave Springs Wave Springs In Series The type we’ll focus on today is a compression spring. This configuration we call series, because the springs are in direct contact and therefore effect the mass by successive stretching. These advanced wave springs multiply loads and spring rates. Loads and spring rates are more accurate, more predictable, and may be. Nested spirawave® springs are flat wire wave springs with. Wave Springs In Series.

From www.smalley.com

Top 6 Advantages of a Wave Spring Smalley Wave Springs In Series This configuration we call series, because the springs are in direct contact and therefore effect the mass by successive stretching. These advanced wave springs multiply loads and spring rates. Wave springs, often referred to as wave washers, are a unique and increasingly popular type of spring design known for their compact size,. Loads and spring rates are more accurate, more. Wave Springs In Series.

From www.rotorclip.com

Selecting The Right Wave Spring EndType Rotor Clip Wave Springs In Series Loads and spring rates are more accurate, more predictable, and may be. This configuration we call series, because the springs are in direct contact and therefore effect the mass by successive stretching. Saves 50% in axial space compared to traditional coiled spring. These forces increase proportionally to the number of turns. Nested wave springs are coiled in parallel to form. Wave Springs In Series.

From zilianmy.com

WAVE SPRINGS/Multi Turn Wave Springs Zi Lian Wave Springs In Series These forces increase proportionally to the number of turns. Nested wave springs are coiled in parallel to form a continuous coil of layers, significantly enhancing load performance. Saves 50% in axial space compared to traditional coiled spring. Wave springs offer many advantages over die stamped products. Higher deflection potential than single. Nested spirawave® springs are flat wire wave springs with. Wave Springs In Series.

From www.slideserve.com

PPT Chapter 17 Springs PowerPoint Presentation, free download ID Wave Springs In Series The type we’ll focus on today is a compression spring. This configuration we call series, because the springs are in direct contact and therefore effect the mass by successive stretching. These advanced wave springs multiply loads and spring rates. Loads and spring rates are more accurate, more predictable, and may be. Wave springs, often referred to as wave washers, are. Wave Springs In Series.

From www.ien.eu

Wave Springs Wave Springs In Series Saves 50% in axial space compared to traditional coiled spring. Wave springs, often referred to as wave washers, are a unique and increasingly popular type of spring design known for their compact size,. Nested spirawave® springs are flat wire wave springs with multiple turns, coiled in parallel to produce higher forces. The type we’ll focus on today is a compression. Wave Springs In Series.

From daemar.com

Wave Springs Pack More Force Into Less Space Daemar Inc Wave Springs In Series Nested spirawave® springs are flat wire wave springs with multiple turns, coiled in parallel to produce higher forces. These advanced wave springs multiply loads and spring rates. This configuration we call series, because the springs are in direct contact and therefore effect the mass by successive stretching. Wave springs, often referred to as wave washers, are a unique and increasingly. Wave Springs In Series.

From www.engineerlive.com

Singleturn wave springs Engineer Live Wave Springs In Series Nested wave springs are coiled in parallel to form a continuous coil of layers, significantly enhancing load performance. Wave springs, often referred to as wave washers, are a unique and increasingly popular type of spring design known for their compact size,. These forces increase proportionally to the number of turns. Higher deflection potential than single. Nested spirawave® springs are flat. Wave Springs In Series.

From www.spiral-retainingring.com

C Series Multi Turn Wave Springs Inch Plain ends Wave Springs In Series These advanced wave springs multiply loads and spring rates. These forces increase proportionally to the number of turns. Higher deflection potential than single. Nested spirawave® springs are flat wire wave springs with multiple turns, coiled in parallel to produce higher forces. The type we’ll focus on today is a compression spring. Loads and spring rates are more accurate, more predictable,. Wave Springs In Series.

From www.rotorclip.com

Linear Wave Springs Rotor Clip Wave Springs In Series Loads and spring rates are more accurate, more predictable, and may be. Nested wave springs are coiled in parallel to form a continuous coil of layers, significantly enhancing load performance. Saves 50% in axial space compared to traditional coiled spring. Wave springs, often referred to as wave washers, are a unique and increasingly popular type of spring design known for. Wave Springs In Series.

From motiv8forums-forumbuzz.com

Introducing our newest Wave Spring Series Nested Spirawave® Springs! Wave Springs In Series Saves 50% in axial space compared to traditional coiled spring. Loads and spring rates are more accurate, more predictable, and may be. Nested spirawave® springs are flat wire wave springs with multiple turns, coiled in parallel to produce higher forces. Nested wave springs are coiled in parallel to form a continuous coil of layers, significantly enhancing load performance. These forces. Wave Springs In Series.

From www.spiral-retainingring.com

C Series Multi Turn Wave Springs Inch Plain ends Wave Springs In Series These advanced wave springs multiply loads and spring rates. Nested wave springs are coiled in parallel to form a continuous coil of layers, significantly enhancing load performance. Wave springs offer many advantages over die stamped products. Loads and spring rates are more accurate, more predictable, and may be. Saves 50% in axial space compared to traditional coiled spring. Wave springs,. Wave Springs In Series.

From daemar.com

Wave Springs Pack More Force Into Less Space Daemar Inc Wave Springs In Series These forces increase proportionally to the number of turns. Nested wave springs are coiled in parallel to form a continuous coil of layers, significantly enhancing load performance. Wave springs, often referred to as wave washers, are a unique and increasingly popular type of spring design known for their compact size,. Saves 50% in axial space compared to traditional coiled spring.. Wave Springs In Series.

From daemar.com

Wave Springs Pack More Force Into Less Space Daemar Inc Wave Springs In Series Higher deflection potential than single. These advanced wave springs multiply loads and spring rates. Loads and spring rates are more accurate, more predictable, and may be. Wave springs offer many advantages over die stamped products. Nested spirawave® springs are flat wire wave springs with multiple turns, coiled in parallel to produce higher forces. This configuration we call series, because the. Wave Springs In Series.

From www.youtube.com

Springs in Series Verse Parallel Find Spring Constant YouTube Wave Springs In Series Wave springs offer many advantages over die stamped products. These advanced wave springs multiply loads and spring rates. Saves 50% in axial space compared to traditional coiled spring. These forces increase proportionally to the number of turns. Nested wave springs are coiled in parallel to form a continuous coil of layers, significantly enhancing load performance. The type we’ll focus on. Wave Springs In Series.

From emag.directindustry.com

SPONSORED. Top 6 Advantages of Wave Springs in Machinery (by Smalley Wave Springs In Series Saves 50% in axial space compared to traditional coiled spring. Nested wave springs are coiled in parallel to form a continuous coil of layers, significantly enhancing load performance. These advanced wave springs multiply loads and spring rates. This configuration we call series, because the springs are in direct contact and therefore effect the mass by successive stretching. Wave springs, often. Wave Springs In Series.

From www.slideserve.com

PPT Simple Harmonic Motion PowerPoint Presentation, free download Wave Springs In Series Loads and spring rates are more accurate, more predictable, and may be. These advanced wave springs multiply loads and spring rates. The type we’ll focus on today is a compression spring. Saves 50% in axial space compared to traditional coiled spring. Nested spirawave® springs are flat wire wave springs with multiple turns, coiled in parallel to produce higher forces. Wave. Wave Springs In Series.

From www.engineerlive.com

Wave springs for all applications Engineer Live Wave Springs In Series Wave springs offer many advantages over die stamped products. Higher deflection potential than single. Nested wave springs are coiled in parallel to form a continuous coil of layers, significantly enhancing load performance. These advanced wave springs multiply loads and spring rates. Nested spirawave® springs are flat wire wave springs with multiple turns, coiled in parallel to produce higher forces. These. Wave Springs In Series.

From www.youtube.com

The Wave Spring Advantage Wave Springs Pack More Force into Less Space Wave Springs In Series Nested wave springs are coiled in parallel to form a continuous coil of layers, significantly enhancing load performance. Wave springs offer many advantages over die stamped products. These advanced wave springs multiply loads and spring rates. Higher deflection potential than single. Wave springs, often referred to as wave washers, are a unique and increasingly popular type of spring design known. Wave Springs In Series.

From www.spiral-retainingring.com

C Series Multi Turn Wave Springs Inch Plain ends Wave Springs In Series Nested wave springs are coiled in parallel to form a continuous coil of layers, significantly enhancing load performance. This configuration we call series, because the springs are in direct contact and therefore effect the mass by successive stretching. These advanced wave springs multiply loads and spring rates. The type we’ll focus on today is a compression spring. These forces increase. Wave Springs In Series.

From www.smalley.com

Wave Spring Guide A Brief Overview Smalley Wave Springs In Series Wave springs, often referred to as wave washers, are a unique and increasingly popular type of spring design known for their compact size,. These forces increase proportionally to the number of turns. Loads and spring rates are more accurate, more predictable, and may be. Saves 50% in axial space compared to traditional coiled spring. These advanced wave springs multiply loads. Wave Springs In Series.

From www.smalley.com

Wave Spring vs. Coil Spring Smalley Wave Springs In Series These advanced wave springs multiply loads and spring rates. Higher deflection potential than single. The type we’ll focus on today is a compression spring. These forces increase proportionally to the number of turns. This configuration we call series, because the springs are in direct contact and therefore effect the mass by successive stretching. Wave springs offer many advantages over die. Wave Springs In Series.

From www.thestudentroom.co.uk

Springs in series/parallel, please help!!! The Student Room Wave Springs In Series Loads and spring rates are more accurate, more predictable, and may be. Higher deflection potential than single. Nested spirawave® springs are flat wire wave springs with multiple turns, coiled in parallel to produce higher forces. These forces increase proportionally to the number of turns. This configuration we call series, because the springs are in direct contact and therefore effect the. Wave Springs In Series.

From www.geniusupdates.com

Everything you need to know about Wave Springs Genius Updates Wave Springs In Series These forces increase proportionally to the number of turns. Wave springs offer many advantages over die stamped products. This configuration we call series, because the springs are in direct contact and therefore effect the mass by successive stretching. Wave springs, often referred to as wave washers, are a unique and increasingly popular type of spring design known for their compact. Wave Springs In Series.

From www.spiral-retainingring.com

Precision Spiral Stainless Steel LS Series Wave Springs Inch Linear Springs Wave Springs In Series Wave springs, often referred to as wave washers, are a unique and increasingly popular type of spring design known for their compact size,. These advanced wave springs multiply loads and spring rates. This configuration we call series, because the springs are in direct contact and therefore effect the mass by successive stretching. Nested spirawave® springs are flat wire wave springs. Wave Springs In Series.

From www.rotorclip.com

Wave Springs Rotor Clip Wave Springs In Series These forces increase proportionally to the number of turns. Saves 50% in axial space compared to traditional coiled spring. Nested wave springs are coiled in parallel to form a continuous coil of layers, significantly enhancing load performance. Wave springs, often referred to as wave washers, are a unique and increasingly popular type of spring design known for their compact size,.. Wave Springs In Series.

From www.smalley.co.in

Single Turn Wave Springs Narrow Section Single Turn Wave Springs Wave Springs In Series Loads and spring rates are more accurate, more predictable, and may be. These forces increase proportionally to the number of turns. This configuration we call series, because the springs are in direct contact and therefore effect the mass by successive stretching. Saves 50% in axial space compared to traditional coiled spring. These advanced wave springs multiply loads and spring rates.. Wave Springs In Series.

From www.advancedengineeringuk.com

How and why you should use a wave spring for bearing preload Advanced Wave Springs In Series This configuration we call series, because the springs are in direct contact and therefore effect the mass by successive stretching. These forces increase proportionally to the number of turns. Nested wave springs are coiled in parallel to form a continuous coil of layers, significantly enhancing load performance. Wave springs, often referred to as wave washers, are a unique and increasingly. Wave Springs In Series.

From studylib.net

Combinations of Springs Springs in Series Wave Springs In Series Higher deflection potential than single. This configuration we call series, because the springs are in direct contact and therefore effect the mass by successive stretching. Saves 50% in axial space compared to traditional coiled spring. The type we’ll focus on today is a compression spring. These advanced wave springs multiply loads and spring rates. Nested wave springs are coiled in. Wave Springs In Series.

From www.spiral-retainingring.com

Multi Turn Wave Springs With Plain Ends , Wave Disc Spring 5mm 1000m Wave Springs In Series Wave springs, often referred to as wave washers, are a unique and increasingly popular type of spring design known for their compact size,. This configuration we call series, because the springs are in direct contact and therefore effect the mass by successive stretching. Saves 50% in axial space compared to traditional coiled spring. Wave springs offer many advantages over die. Wave Springs In Series.

From www.slideserve.com

PPT Chapter 17 Springs PowerPoint Presentation, free download ID Wave Springs In Series The type we’ll focus on today is a compression spring. These forces increase proportionally to the number of turns. Higher deflection potential than single. Loads and spring rates are more accurate, more predictable, and may be. These advanced wave springs multiply loads and spring rates. Nested wave springs are coiled in parallel to form a continuous coil of layers, significantly. Wave Springs In Series.

From uk-manufacturing-online.co.uk

Wave springs in medical applications UK Manufacturing Wave Springs In Series This configuration we call series, because the springs are in direct contact and therefore effect the mass by successive stretching. Saves 50% in axial space compared to traditional coiled spring. Nested spirawave® springs are flat wire wave springs with multiple turns, coiled in parallel to produce higher forces. Nested wave springs are coiled in parallel to form a continuous coil. Wave Springs In Series.

From www.da-yi.com.tw

Multi Turn Wave Springs Spring Manufacturers Tech Spring / TSI / TSMC Wave Springs In Series Nested spirawave® springs are flat wire wave springs with multiple turns, coiled in parallel to produce higher forces. These forces increase proportionally to the number of turns. Saves 50% in axial space compared to traditional coiled spring. The type we’ll focus on today is a compression spring. These advanced wave springs multiply loads and spring rates. Wave springs, often referred. Wave Springs In Series.