Coupling Gap Standard . Check the bore size of the coupling halves and the shafts. Some of these variables are: Simply stated, no industry standard on alignment exists because too many variables are involved. The distances that you will need to measure and plot are: Ensure that they are the correct bore size to fit the application. The distance between shaft ends (bse), or gap (g) between the driver and driven and compare this value with the ‘g’ dimension for lovejoy jaw. Distance from where the indicator rides radially on the pump hub, to the center of the. As stated in the original post, the gap spec is there for the proper operation for the specific operational parameters of that coupling. That means on a two (2) inch coupling you would be allowed a gap at the top or bottom and side to side of 0.035” thou. If we look at the table under 1,800 rpm, which is the most common rpm in the industry, it shows the allowable tolerances divided into three ranges: The other option, to allow for a different gap, is change to another type of coupling that meets the process needs and clearance.

from www.pipesandfittings.com

That means on a two (2) inch coupling you would be allowed a gap at the top or bottom and side to side of 0.035” thou. The distances that you will need to measure and plot are: Ensure that they are the correct bore size to fit the application. If we look at the table under 1,800 rpm, which is the most common rpm in the industry, it shows the allowable tolerances divided into three ranges: Simply stated, no industry standard on alignment exists because too many variables are involved. Some of these variables are: The other option, to allow for a different gap, is change to another type of coupling that meets the process needs and clearance. Distance from where the indicator rides radially on the pump hub, to the center of the. As stated in the original post, the gap spec is there for the proper operation for the specific operational parameters of that coupling. Check the bore size of the coupling halves and the shafts.

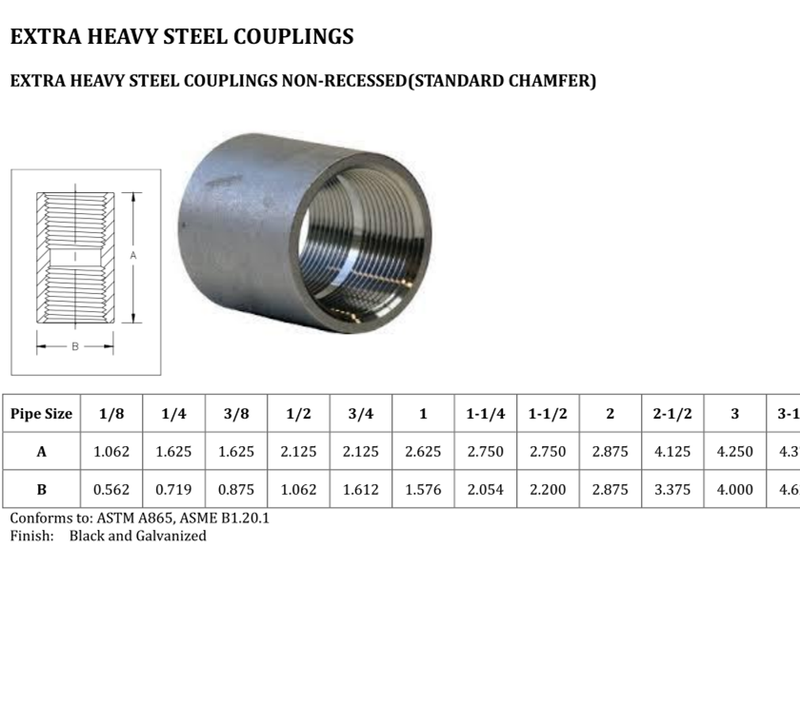

Threaded Pipe Coupling Dimensions Chart Steel Coupling SANVO

Coupling Gap Standard If we look at the table under 1,800 rpm, which is the most common rpm in the industry, it shows the allowable tolerances divided into three ranges: The other option, to allow for a different gap, is change to another type of coupling that meets the process needs and clearance. Check the bore size of the coupling halves and the shafts. Some of these variables are: Ensure that they are the correct bore size to fit the application. That means on a two (2) inch coupling you would be allowed a gap at the top or bottom and side to side of 0.035” thou. As stated in the original post, the gap spec is there for the proper operation for the specific operational parameters of that coupling. The distances that you will need to measure and plot are: Distance from where the indicator rides radially on the pump hub, to the center of the. The distance between shaft ends (bse), or gap (g) between the driver and driven and compare this value with the ‘g’ dimension for lovejoy jaw. Simply stated, no industry standard on alignment exists because too many variables are involved. If we look at the table under 1,800 rpm, which is the most common rpm in the industry, it shows the allowable tolerances divided into three ranges:

From mavink.com

Steel Pipe Coupling Dimensions Chart Coupling Gap Standard That means on a two (2) inch coupling you would be allowed a gap at the top or bottom and side to side of 0.035” thou. If we look at the table under 1,800 rpm, which is the most common rpm in the industry, it shows the allowable tolerances divided into three ranges: Check the bore size of the coupling. Coupling Gap Standard.

From www.appliedalloys.com.au

Full Coupling pdf Applied Alloys International Coupling Gap Standard As stated in the original post, the gap spec is there for the proper operation for the specific operational parameters of that coupling. Distance from where the indicator rides radially on the pump hub, to the center of the. Ensure that they are the correct bore size to fit the application. The distances that you will need to measure and. Coupling Gap Standard.

From www.coursehero.com

[Solved] Fig 2. Shows the details of an 'Universal Coupling'. Assemble Coupling Gap Standard Check the bore size of the coupling halves and the shafts. As stated in the original post, the gap spec is there for the proper operation for the specific operational parameters of that coupling. Simply stated, no industry standard on alignment exists because too many variables are involved. If we look at the table under 1,800 rpm, which is the. Coupling Gap Standard.

From www.youtube.com

Pin Bush Coupling Gap according to size Coupling me dono coupling k Coupling Gap Standard Ensure that they are the correct bore size to fit the application. Simply stated, no industry standard on alignment exists because too many variables are involved. The distance between shaft ends (bse), or gap (g) between the driver and driven and compare this value with the ‘g’ dimension for lovejoy jaw. That means on a two (2) inch coupling you. Coupling Gap Standard.

From www.pipesandfittings.com

Threaded Pipe Coupling Dimensions Chart Steel Coupling SANVO Coupling Gap Standard As stated in the original post, the gap spec is there for the proper operation for the specific operational parameters of that coupling. The distance between shaft ends (bse), or gap (g) between the driver and driven and compare this value with the ‘g’ dimension for lovejoy jaw. Some of these variables are: That means on a two (2) inch. Coupling Gap Standard.

From energy-division.kimaxcontrols.com

Permanent Coupling Manufacturer Kimax Controls Coupling Gap Standard Ensure that they are the correct bore size to fit the application. Some of these variables are: The distance between shaft ends (bse), or gap (g) between the driver and driven and compare this value with the ‘g’ dimension for lovejoy jaw. If we look at the table under 1,800 rpm, which is the most common rpm in the industry,. Coupling Gap Standard.

From www.youtube.com

What is Coupling Gap in Flexible Couplings and what is it's Function Coupling Gap Standard If we look at the table under 1,800 rpm, which is the most common rpm in the industry, it shows the allowable tolerances divided into three ranges: The other option, to allow for a different gap, is change to another type of coupling that meets the process needs and clearance. Some of these variables are: Simply stated, no industry standard. Coupling Gap Standard.

From acoem.us

Coupling Tolerances vs. Shaft Alignment Tolerances, revisited Acoem USA Coupling Gap Standard That means on a two (2) inch coupling you would be allowed a gap at the top or bottom and side to side of 0.035” thou. Some of these variables are: Simply stated, no industry standard on alignment exists because too many variables are involved. Distance from where the indicator rides radially on the pump hub, to the center of. Coupling Gap Standard.

From mighty.en.alibaba.com

L050 L070 L090 L110 Jaw Spider Coupling L type couplings, View Jaw Coupling Gap Standard The distance between shaft ends (bse), or gap (g) between the driver and driven and compare this value with the ‘g’ dimension for lovejoy jaw. Check the bore size of the coupling halves and the shafts. The other option, to allow for a different gap, is change to another type of coupling that meets the process needs and clearance. Some. Coupling Gap Standard.

From www.brighthubengineering.com

What are Bibby Couplings? Coupling Gap Standard If we look at the table under 1,800 rpm, which is the most common rpm in the industry, it shows the allowable tolerances divided into three ranges: As stated in the original post, the gap spec is there for the proper operation for the specific operational parameters of that coupling. The distance between shaft ends (bse), or gap (g) between. Coupling Gap Standard.

From engineeringlearn.com

Shaft Coupling Definition, Types, Uses, Working Principle & Advantages Coupling Gap Standard Simply stated, no industry standard on alignment exists because too many variables are involved. As stated in the original post, the gap spec is there for the proper operation for the specific operational parameters of that coupling. Some of these variables are: Check the bore size of the coupling halves and the shafts. The distances that you will need to. Coupling Gap Standard.

From suryamegateknik.com

Rexnord Elastomeric Coupling SURYA MEGA TEKNIK Coupling Gap Standard Simply stated, no industry standard on alignment exists because too many variables are involved. As stated in the original post, the gap spec is there for the proper operation for the specific operational parameters of that coupling. Some of these variables are: The distance between shaft ends (bse), or gap (g) between the driver and driven and compare this value. Coupling Gap Standard.

From www.pipesandfittings.com

Threaded Pipe Coupling Dimensions Chart Steel Coupling SANVO Coupling Gap Standard As stated in the original post, the gap spec is there for the proper operation for the specific operational parameters of that coupling. Some of these variables are: Ensure that they are the correct bore size to fit the application. The distances that you will need to measure and plot are: The other option, to allow for a different gap,. Coupling Gap Standard.

From suryanindo.blogspot.com

TIRE COUPLING FENAFLEX MERK FENNER MADE IN ENGLAND Coupling Gap Standard Ensure that they are the correct bore size to fit the application. That means on a two (2) inch coupling you would be allowed a gap at the top or bottom and side to side of 0.035” thou. As stated in the original post, the gap spec is there for the proper operation for the specific operational parameters of that. Coupling Gap Standard.

From www.youtube.com

Flexible Gear Coupling Gap in mm How Much Gap Should Be Kept in Gear Coupling Gap Standard The distance between shaft ends (bse), or gap (g) between the driver and driven and compare this value with the ‘g’ dimension for lovejoy jaw. If we look at the table under 1,800 rpm, which is the most common rpm in the industry, it shows the allowable tolerances divided into three ranges: Distance from where the indicator rides radially on. Coupling Gap Standard.

From hxeamfiqt.blob.core.windows.net

Tyre Coupling Gap Chart at Javier Barnhill blog Coupling Gap Standard If we look at the table under 1,800 rpm, which is the most common rpm in the industry, it shows the allowable tolerances divided into three ranges: Some of these variables are: Simply stated, no industry standard on alignment exists because too many variables are involved. The distances that you will need to measure and plot are: The other option,. Coupling Gap Standard.

From www.neminoxsteel.in

ASME B16.11 Threaded Reducing Coupling Stainless Steel Threaded Coupling Gap Standard The distances that you will need to measure and plot are: If we look at the table under 1,800 rpm, which is the most common rpm in the industry, it shows the allowable tolerances divided into three ranges: The other option, to allow for a different gap, is change to another type of coupling that meets the process needs and. Coupling Gap Standard.

From www.slideshare.net

Gear coupling catalogue Coupling Gap Standard As stated in the original post, the gap spec is there for the proper operation for the specific operational parameters of that coupling. The other option, to allow for a different gap, is change to another type of coupling that meets the process needs and clearance. The distances that you will need to measure and plot are: Ensure that they. Coupling Gap Standard.

From www.drivecomponentsllc.com

Grid Couplings Drive Components Coupling Gap Standard If we look at the table under 1,800 rpm, which is the most common rpm in the industry, it shows the allowable tolerances divided into three ranges: That means on a two (2) inch coupling you would be allowed a gap at the top or bottom and side to side of 0.035” thou. The distance between shaft ends (bse), or. Coupling Gap Standard.

From www.rubberlining.org

Which Vic Specification is best for Rubber Lining? • Rubber Lining Coupling Gap Standard If we look at the table under 1,800 rpm, which is the most common rpm in the industry, it shows the allowable tolerances divided into three ranges: Simply stated, no industry standard on alignment exists because too many variables are involved. Ensure that they are the correct bore size to fit the application. Distance from where the indicator rides radially. Coupling Gap Standard.

From www.youtube.com

tyre coupling gap chart tyre coupling fitting YouTube Coupling Gap Standard Check the bore size of the coupling halves and the shafts. Some of these variables are: As stated in the original post, the gap spec is there for the proper operation for the specific operational parameters of that coupling. Distance from where the indicator rides radially on the pump hub, to the center of the. Simply stated, no industry standard. Coupling Gap Standard.

From www.hnccoupling.com

Tyre Coupling Shaft Coupling Manufacturers HNC Coupling Coupling Gap Standard The other option, to allow for a different gap, is change to another type of coupling that meets the process needs and clearance. As stated in the original post, the gap spec is there for the proper operation for the specific operational parameters of that coupling. The distances that you will need to measure and plot are: Ensure that they. Coupling Gap Standard.

From catalog.udlvirtual.edu.pe

What Is Coupling And Types Of Coupling Catalog Library Coupling Gap Standard Simply stated, no industry standard on alignment exists because too many variables are involved. That means on a two (2) inch coupling you would be allowed a gap at the top or bottom and side to side of 0.035” thou. The other option, to allow for a different gap, is change to another type of coupling that meets the process. Coupling Gap Standard.

From www.zzfittings.com

Socket Weld Coupling Class 3000 Stainless Steel Socket Weld Fittings Coupling Gap Standard If we look at the table under 1,800 rpm, which is the most common rpm in the industry, it shows the allowable tolerances divided into three ranges: Distance from where the indicator rides radially on the pump hub, to the center of the. The other option, to allow for a different gap, is change to another type of coupling that. Coupling Gap Standard.

From www.epowermetals.com

Pipe Coupling China piping solution supplier China piping solution Coupling Gap Standard Distance from where the indicator rides radially on the pump hub, to the center of the. If we look at the table under 1,800 rpm, which is the most common rpm in the industry, it shows the allowable tolerances divided into three ranges: As stated in the original post, the gap spec is there for the proper operation for the. Coupling Gap Standard.

From www.researchgate.net

Coupler gap vs. coupling length of standard, pulley and racetrack Coupling Gap Standard Simply stated, no industry standard on alignment exists because too many variables are involved. If we look at the table under 1,800 rpm, which is the most common rpm in the industry, it shows the allowable tolerances divided into three ranges: Ensure that they are the correct bore size to fit the application. The other option, to allow for a. Coupling Gap Standard.

From www.youtube.com

Tyre Coupling Gap How to Fix Gap of Tyre Coupling during Alignment Coupling Gap Standard If we look at the table under 1,800 rpm, which is the most common rpm in the industry, it shows the allowable tolerances divided into three ranges: Distance from where the indicator rides radially on the pump hub, to the center of the. Check the bore size of the coupling halves and the shafts. The other option, to allow for. Coupling Gap Standard.

From mavink.com

Falk Coupling Gap Chart Coupling Gap Standard Ensure that they are the correct bore size to fit the application. Distance from where the indicator rides radially on the pump hub, to the center of the. As stated in the original post, the gap spec is there for the proper operation for the specific operational parameters of that coupling. The distances that you will need to measure and. Coupling Gap Standard.

From magnadrive.com

Fixed Gap Couplings Custom Specifications MagnaDrive Coupling Gap Standard The distance between shaft ends (bse), or gap (g) between the driver and driven and compare this value with the ‘g’ dimension for lovejoy jaw. The other option, to allow for a different gap, is change to another type of coupling that meets the process needs and clearance. Check the bore size of the coupling halves and the shafts. Simply. Coupling Gap Standard.

From www.youtube.com

What Are The Minimum & Maximum Shaft Gaps for a Coupling? YouTube Coupling Gap Standard As stated in the original post, the gap spec is there for the proper operation for the specific operational parameters of that coupling. Distance from where the indicator rides radially on the pump hub, to the center of the. The distances that you will need to measure and plot are: That means on a two (2) inch coupling you would. Coupling Gap Standard.

From www.slideshare.net

Gear coupling catalogue Coupling Gap Standard As stated in the original post, the gap spec is there for the proper operation for the specific operational parameters of that coupling. If we look at the table under 1,800 rpm, which is the most common rpm in the industry, it shows the allowable tolerances divided into three ranges: The distances that you will need to measure and plot. Coupling Gap Standard.

From www.pipesandfittings.com

Threaded Pipe Coupling Dimensions Chart Steel Coupling SANVO Coupling Gap Standard That means on a two (2) inch coupling you would be allowed a gap at the top or bottom and side to side of 0.035” thou. Simply stated, no industry standard on alignment exists because too many variables are involved. Some of these variables are: The distance between shaft ends (bse), or gap (g) between the driver and driven and. Coupling Gap Standard.

From www.iqsdirectory.com

Shaft Coupling What Is It? How Is it Used? Types Of, Roles Coupling Gap Standard The distance between shaft ends (bse), or gap (g) between the driver and driven and compare this value with the ‘g’ dimension for lovejoy jaw. Simply stated, no industry standard on alignment exists because too many variables are involved. That means on a two (2) inch coupling you would be allowed a gap at the top or bottom and side. Coupling Gap Standard.

From www.slideshare.net

CMD Couplings Coupling Gap Standard Distance from where the indicator rides radially on the pump hub, to the center of the. If we look at the table under 1,800 rpm, which is the most common rpm in the industry, it shows the allowable tolerances divided into three ranges: Check the bore size of the coupling halves and the shafts. Ensure that they are the correct. Coupling Gap Standard.

From dokumen.tips

(DOCX) Tyre Couplings DOKUMEN.TIPS Coupling Gap Standard As stated in the original post, the gap spec is there for the proper operation for the specific operational parameters of that coupling. Check the bore size of the coupling halves and the shafts. The distances that you will need to measure and plot are: If we look at the table under 1,800 rpm, which is the most common rpm. Coupling Gap Standard.