Chemical Etching Vs Blasting . there are six basic methods of preparing a surface for bonding: It can be used to create decorative patterns, but it’s also more aggressive than diamond grinding and sandblasting and can cause more damage to the concrete if not done properly. Each has its strengths and weaknesses. This method, rooted in chemistry and metallurgy, has transcended its humble beginnings to become a cornerstone in creating intricate designs, fine patterns, and precision components. Chemical cleaning, abrasion, degreasing, atmospheric plasma,. discover why mechanical surface prep methods are surpassing acid etching in efficiency, safety, and. chemical floor prep utilizes an acid to etch and burn the surface of the concrete, opening the pores of the concretes cream and. Etching relies on chemical reactions to selectively remove material, while sandblasting employs abrasive particles for. In the intricate world of material fabrication and precision manufacturing, chemical etching is a powerful and versatile technique. Mechanically removes surface layers through abrasive. Keep reading to learn which method is best for different circumstances.

from www.slideshare.net

This method, rooted in chemistry and metallurgy, has transcended its humble beginnings to become a cornerstone in creating intricate designs, fine patterns, and precision components. In the intricate world of material fabrication and precision manufacturing, chemical etching is a powerful and versatile technique. Mechanically removes surface layers through abrasive. Chemical cleaning, abrasion, degreasing, atmospheric plasma,. It can be used to create decorative patterns, but it’s also more aggressive than diamond grinding and sandblasting and can cause more damage to the concrete if not done properly. chemical floor prep utilizes an acid to etch and burn the surface of the concrete, opening the pores of the concretes cream and. discover why mechanical surface prep methods are surpassing acid etching in efficiency, safety, and. Keep reading to learn which method is best for different circumstances. there are six basic methods of preparing a surface for bonding: Etching relies on chemical reactions to selectively remove material, while sandblasting employs abrasive particles for.

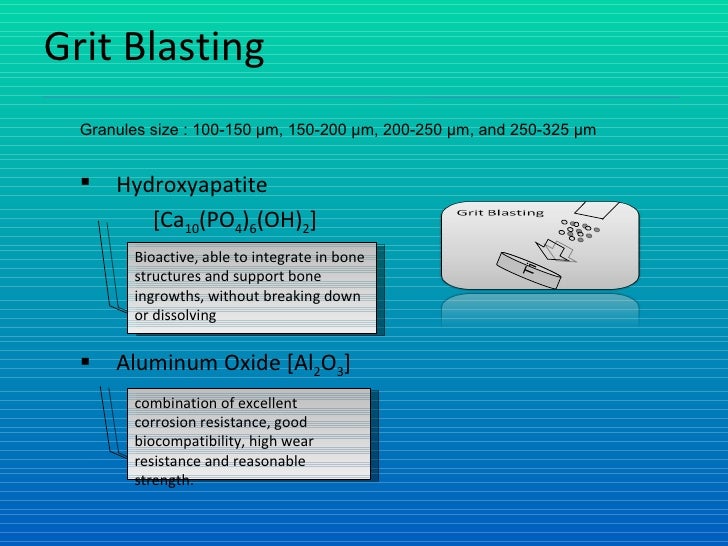

Comparative Study on Ti Surface Modified by Grit Blasting and Acid Et…

Chemical Etching Vs Blasting discover why mechanical surface prep methods are surpassing acid etching in efficiency, safety, and. there are six basic methods of preparing a surface for bonding: It can be used to create decorative patterns, but it’s also more aggressive than diamond grinding and sandblasting and can cause more damage to the concrete if not done properly. Etching relies on chemical reactions to selectively remove material, while sandblasting employs abrasive particles for. discover why mechanical surface prep methods are surpassing acid etching in efficiency, safety, and. Keep reading to learn which method is best for different circumstances. chemical floor prep utilizes an acid to etch and burn the surface of the concrete, opening the pores of the concretes cream and. Chemical cleaning, abrasion, degreasing, atmospheric plasma,. In the intricate world of material fabrication and precision manufacturing, chemical etching is a powerful and versatile technique. This method, rooted in chemistry and metallurgy, has transcended its humble beginnings to become a cornerstone in creating intricate designs, fine patterns, and precision components. Mechanically removes surface layers through abrasive. Each has its strengths and weaknesses.

From www.semanticscholar.org

Figure 1 from Al2O3 Particles on Titanium Dental Implant Systems following Sandblasting and Acid Chemical Etching Vs Blasting Each has its strengths and weaknesses. discover why mechanical surface prep methods are surpassing acid etching in efficiency, safety, and. Etching relies on chemical reactions to selectively remove material, while sandblasting employs abrasive particles for. It can be used to create decorative patterns, but it’s also more aggressive than diamond grinding and sandblasting and can cause more damage to. Chemical Etching Vs Blasting.

From www.amazemet.com

What is chemical etching? AMAZEMET Chemical Etching Vs Blasting Chemical cleaning, abrasion, degreasing, atmospheric plasma,. Keep reading to learn which method is best for different circumstances. It can be used to create decorative patterns, but it’s also more aggressive than diamond grinding and sandblasting and can cause more damage to the concrete if not done properly. Each has its strengths and weaknesses. discover why mechanical surface prep methods. Chemical Etching Vs Blasting.

From www.youtube.com

Chemical Etching Process A StepbyStep Guide to Chemical Etching Precision Micro Ltd YouTube Chemical Etching Vs Blasting This method, rooted in chemistry and metallurgy, has transcended its humble beginnings to become a cornerstone in creating intricate designs, fine patterns, and precision components. Keep reading to learn which method is best for different circumstances. Etching relies on chemical reactions to selectively remove material, while sandblasting employs abrasive particles for. there are six basic methods of preparing a. Chemical Etching Vs Blasting.

From www.precisionmicro.com

Photochemical Etching Specialists Pioneers in Photochemical Machining Chemical Etching Vs Blasting Each has its strengths and weaknesses. Chemical cleaning, abrasion, degreasing, atmospheric plasma,. Etching relies on chemical reactions to selectively remove material, while sandblasting employs abrasive particles for. In the intricate world of material fabrication and precision manufacturing, chemical etching is a powerful and versatile technique. discover why mechanical surface prep methods are surpassing acid etching in efficiency, safety, and.. Chemical Etching Vs Blasting.

From www.senhongglass.com

Difference Between Acid Etching Glass And Sandblasting Glass Senhong Glass Chemical Etching Vs Blasting there are six basic methods of preparing a surface for bonding: Etching relies on chemical reactions to selectively remove material, while sandblasting employs abrasive particles for. Each has its strengths and weaknesses. This method, rooted in chemistry and metallurgy, has transcended its humble beginnings to become a cornerstone in creating intricate designs, fine patterns, and precision components. discover. Chemical Etching Vs Blasting.

From rache.com

Laser Cutting vs. Chemical Etching Understanding the Differences Chemical Etching Vs Blasting discover why mechanical surface prep methods are surpassing acid etching in efficiency, safety, and. Keep reading to learn which method is best for different circumstances. Each has its strengths and weaknesses. This method, rooted in chemistry and metallurgy, has transcended its humble beginnings to become a cornerstone in creating intricate designs, fine patterns, and precision components. Etching relies on. Chemical Etching Vs Blasting.

From www.pcba-manufacturers.com

Chemical Etching vs. Laser Etching Unveiling Precision in Surface Marking Techniques PCBA Chemical Etching Vs Blasting This method, rooted in chemistry and metallurgy, has transcended its humble beginnings to become a cornerstone in creating intricate designs, fine patterns, and precision components. In the intricate world of material fabrication and precision manufacturing, chemical etching is a powerful and versatile technique. chemical floor prep utilizes an acid to etch and burn the surface of the concrete, opening. Chemical Etching Vs Blasting.

From www.researchgate.net

Basic etching mechanisms (a) chemical etching, (b) sputtering, (c)... Download Scientific Diagram Chemical Etching Vs Blasting Etching relies on chemical reactions to selectively remove material, while sandblasting employs abrasive particles for. Mechanically removes surface layers through abrasive. Keep reading to learn which method is best for different circumstances. there are six basic methods of preparing a surface for bonding: discover why mechanical surface prep methods are surpassing acid etching in efficiency, safety, and. This. Chemical Etching Vs Blasting.

From inprogress.website

Chemical Etching Versus Conventional Cutting Precision Micro Chemical Etching Vs Blasting Chemical cleaning, abrasion, degreasing, atmospheric plasma,. Keep reading to learn which method is best for different circumstances. Each has its strengths and weaknesses. Mechanically removes surface layers through abrasive. there are six basic methods of preparing a surface for bonding: Etching relies on chemical reactions to selectively remove material, while sandblasting employs abrasive particles for. It can be used. Chemical Etching Vs Blasting.

From fractory.com

Sheet Metal Materials, Standard Sizes & Forming Processes Chemical Etching Vs Blasting Chemical cleaning, abrasion, degreasing, atmospheric plasma,. This method, rooted in chemistry and metallurgy, has transcended its humble beginnings to become a cornerstone in creating intricate designs, fine patterns, and precision components. Keep reading to learn which method is best for different circumstances. there are six basic methods of preparing a surface for bonding: Each has its strengths and weaknesses.. Chemical Etching Vs Blasting.

From www.researchgate.net

Illustration of the six steps involved in plasma etching [14]. Step 1... Download Scientific Chemical Etching Vs Blasting Each has its strengths and weaknesses. In the intricate world of material fabrication and precision manufacturing, chemical etching is a powerful and versatile technique. Etching relies on chemical reactions to selectively remove material, while sandblasting employs abrasive particles for. Keep reading to learn which method is best for different circumstances. discover why mechanical surface prep methods are surpassing acid. Chemical Etching Vs Blasting.

From www.semanticscholar.org

Figure 8 from Al2O3 Particles on Titanium Dental Implant Systems following Sandblasting and Acid Chemical Etching Vs Blasting Mechanically removes surface layers through abrasive. Chemical cleaning, abrasion, degreasing, atmospheric plasma,. there are six basic methods of preparing a surface for bonding: Each has its strengths and weaknesses. It can be used to create decorative patterns, but it’s also more aggressive than diamond grinding and sandblasting and can cause more damage to the concrete if not done properly.. Chemical Etching Vs Blasting.

From metapress.com

How is Photo Chemical Etching Performed? Chemical Etching Vs Blasting This method, rooted in chemistry and metallurgy, has transcended its humble beginnings to become a cornerstone in creating intricate designs, fine patterns, and precision components. It can be used to create decorative patterns, but it’s also more aggressive than diamond grinding and sandblasting and can cause more damage to the concrete if not done properly. Chemical cleaning, abrasion, degreasing, atmospheric. Chemical Etching Vs Blasting.

From www.metaletching.org

Stainless Steel Etching Companies Services Chemical Etching Vs Blasting Each has its strengths and weaknesses. Keep reading to learn which method is best for different circumstances. Etching relies on chemical reactions to selectively remove material, while sandblasting employs abrasive particles for. chemical floor prep utilizes an acid to etch and burn the surface of the concrete, opening the pores of the concretes cream and. discover why mechanical. Chemical Etching Vs Blasting.

From www.qualitetch.com

Chemical Etching Vs Traditional Engraving Qualitetch Chemical Etching Vs Blasting there are six basic methods of preparing a surface for bonding: This method, rooted in chemistry and metallurgy, has transcended its humble beginnings to become a cornerstone in creating intricate designs, fine patterns, and precision components. It can be used to create decorative patterns, but it’s also more aggressive than diamond grinding and sandblasting and can cause more damage. Chemical Etching Vs Blasting.

From insights.vecoprecision.com

Chemical Etching vs. CNC Machining What's the Difference? Chemical Etching Vs Blasting In the intricate world of material fabrication and precision manufacturing, chemical etching is a powerful and versatile technique. Each has its strengths and weaknesses. Etching relies on chemical reactions to selectively remove material, while sandblasting employs abrasive particles for. Keep reading to learn which method is best for different circumstances. Chemical cleaning, abrasion, degreasing, atmospheric plasma,. there are six. Chemical Etching Vs Blasting.

From www.masteretching.com

Chemical Etching Process What is Chemical Etching? Chemical Etching Vs Blasting It can be used to create decorative patterns, but it’s also more aggressive than diamond grinding and sandblasting and can cause more damage to the concrete if not done properly. Chemical cleaning, abrasion, degreasing, atmospheric plasma,. Mechanically removes surface layers through abrasive. In the intricate world of material fabrication and precision manufacturing, chemical etching is a powerful and versatile technique.. Chemical Etching Vs Blasting.

From www.youtube.com

What is Chemical Etching? The Chemical Etching Process Explained Precision Micro Ltd YouTube Chemical Etching Vs Blasting Chemical cleaning, abrasion, degreasing, atmospheric plasma,. Mechanically removes surface layers through abrasive. Keep reading to learn which method is best for different circumstances. chemical floor prep utilizes an acid to etch and burn the surface of the concrete, opening the pores of the concretes cream and. This method, rooted in chemistry and metallurgy, has transcended its humble beginnings to. Chemical Etching Vs Blasting.

From pv-manufacturing.org

Chemical Etching Vs Blasting Each has its strengths and weaknesses. chemical floor prep utilizes an acid to etch and burn the surface of the concrete, opening the pores of the concretes cream and. In the intricate world of material fabrication and precision manufacturing, chemical etching is a powerful and versatile technique. This method, rooted in chemistry and metallurgy, has transcended its humble beginnings. Chemical Etching Vs Blasting.

From medium.com

Chemical Etching Vs Laser Engraving — Know what works for you by Otoengravers Medium Chemical Etching Vs Blasting discover why mechanical surface prep methods are surpassing acid etching in efficiency, safety, and. Chemical cleaning, abrasion, degreasing, atmospheric plasma,. It can be used to create decorative patterns, but it’s also more aggressive than diamond grinding and sandblasting and can cause more damage to the concrete if not done properly. This method, rooted in chemistry and metallurgy, has transcended. Chemical Etching Vs Blasting.

From www.slideserve.com

PPT Microelectronics Processing Plasma Etching PowerPoint Presentation ID650225 Chemical Etching Vs Blasting discover why mechanical surface prep methods are surpassing acid etching in efficiency, safety, and. Each has its strengths and weaknesses. It can be used to create decorative patterns, but it’s also more aggressive than diamond grinding and sandblasting and can cause more damage to the concrete if not done properly. Keep reading to learn which method is best for. Chemical Etching Vs Blasting.

From www.metaletching.org

Chemical Etching Companies Chemical Etching Services Chemical Etching Vs Blasting Mechanically removes surface layers through abrasive. there are six basic methods of preparing a surface for bonding: Each has its strengths and weaknesses. It can be used to create decorative patterns, but it’s also more aggressive than diamond grinding and sandblasting and can cause more damage to the concrete if not done properly. chemical floor prep utilizes an. Chemical Etching Vs Blasting.

From www.precisionmicro.com

Chemical Etching Versus Conventional Cutting Precision Micro Chemical Etching Vs Blasting Chemical cleaning, abrasion, degreasing, atmospheric plasma,. chemical floor prep utilizes an acid to etch and burn the surface of the concrete, opening the pores of the concretes cream and. Mechanically removes surface layers through abrasive. Each has its strengths and weaknesses. This method, rooted in chemistry and metallurgy, has transcended its humble beginnings to become a cornerstone in creating. Chemical Etching Vs Blasting.

From www.slideshare.net

Comparative Study on Ti Surface Modified by Grit Blasting and Acid Et… Chemical Etching Vs Blasting Etching relies on chemical reactions to selectively remove material, while sandblasting employs abrasive particles for. It can be used to create decorative patterns, but it’s also more aggressive than diamond grinding and sandblasting and can cause more damage to the concrete if not done properly. This method, rooted in chemistry and metallurgy, has transcended its humble beginnings to become a. Chemical Etching Vs Blasting.

From www.finecut.co.uk

Differences between etching vs engraving & marking Chemical Etching Vs Blasting In the intricate world of material fabrication and precision manufacturing, chemical etching is a powerful and versatile technique. Mechanically removes surface layers through abrasive. there are six basic methods of preparing a surface for bonding: Chemical cleaning, abrasion, degreasing, atmospheric plasma,. chemical floor prep utilizes an acid to etch and burn the surface of the concrete, opening the. Chemical Etching Vs Blasting.

From www.laser2etch.com

What is chemical etching? and how can you add it to your business? Chemical Etching Vs Blasting It can be used to create decorative patterns, but it’s also more aggressive than diamond grinding and sandblasting and can cause more damage to the concrete if not done properly. Etching relies on chemical reactions to selectively remove material, while sandblasting employs abrasive particles for. discover why mechanical surface prep methods are surpassing acid etching in efficiency, safety, and.. Chemical Etching Vs Blasting.

From www.slideserve.com

PPT Chemical Etching and Laser Engraving_ Mastering the Techniques.docx PowerPoint Chemical Etching Vs Blasting Each has its strengths and weaknesses. discover why mechanical surface prep methods are surpassing acid etching in efficiency, safety, and. chemical floor prep utilizes an acid to etch and burn the surface of the concrete, opening the pores of the concretes cream and. In the intricate world of material fabrication and precision manufacturing, chemical etching is a powerful. Chemical Etching Vs Blasting.

From www.metaletching.org

Chemical Etching Companies Chemical Etching Services Chemical Etching Vs Blasting discover why mechanical surface prep methods are surpassing acid etching in efficiency, safety, and. In the intricate world of material fabrication and precision manufacturing, chemical etching is a powerful and versatile technique. there are six basic methods of preparing a surface for bonding: chemical floor prep utilizes an acid to etch and burn the surface of the. Chemical Etching Vs Blasting.

From www.researchgate.net

Surface morphological image of sandblasting and acid etching... Download Scientific Diagram Chemical Etching Vs Blasting Etching relies on chemical reactions to selectively remove material, while sandblasting employs abrasive particles for. This method, rooted in chemistry and metallurgy, has transcended its humble beginnings to become a cornerstone in creating intricate designs, fine patterns, and precision components. It can be used to create decorative patterns, but it’s also more aggressive than diamond grinding and sandblasting and can. Chemical Etching Vs Blasting.

From www.pcba-manufacturers.com

Chemical Etching vs. Laser Etching Unveiling Precision in Surface Marking Techniques PCBA Chemical Etching Vs Blasting Each has its strengths and weaknesses. Etching relies on chemical reactions to selectively remove material, while sandblasting employs abrasive particles for. there are six basic methods of preparing a surface for bonding: Mechanically removes surface layers through abrasive. discover why mechanical surface prep methods are surpassing acid etching in efficiency, safety, and. It can be used to create. Chemical Etching Vs Blasting.

From www.slideserve.com

PPT Chemical Etching Vs Laser Engraving Know what works for you..docx PowerPoint Chemical Etching Vs Blasting there are six basic methods of preparing a surface for bonding: It can be used to create decorative patterns, but it’s also more aggressive than diamond grinding and sandblasting and can cause more damage to the concrete if not done properly. Chemical cleaning, abrasion, degreasing, atmospheric plasma,. This method, rooted in chemistry and metallurgy, has transcended its humble beginnings. Chemical Etching Vs Blasting.

From www.masteretching.com

Chemical Etching Process What is Chemical Etching? Chemical Etching Vs Blasting there are six basic methods of preparing a surface for bonding: Keep reading to learn which method is best for different circumstances. This method, rooted in chemistry and metallurgy, has transcended its humble beginnings to become a cornerstone in creating intricate designs, fine patterns, and precision components. chemical floor prep utilizes an acid to etch and burn the. Chemical Etching Vs Blasting.

From www.pcba-manufacturers.com

Chemical Etching vs. Laser Etching Unveiling Precision in Surface Marking Techniques PCBA Chemical Etching Vs Blasting Keep reading to learn which method is best for different circumstances. Mechanically removes surface layers through abrasive. chemical floor prep utilizes an acid to etch and burn the surface of the concrete, opening the pores of the concretes cream and. This method, rooted in chemistry and metallurgy, has transcended its humble beginnings to become a cornerstone in creating intricate. Chemical Etching Vs Blasting.

From www.precisionmicro.com

Chemical Etching Versus Conventional Cutting Precision Micro Chemical Etching Vs Blasting there are six basic methods of preparing a surface for bonding: Chemical cleaning, abrasion, degreasing, atmospheric plasma,. Mechanically removes surface layers through abrasive. chemical floor prep utilizes an acid to etch and burn the surface of the concrete, opening the pores of the concretes cream and. It can be used to create decorative patterns, but it’s also more. Chemical Etching Vs Blasting.

From metaletching.com

Chemical Etching VS Laser Cutting Advanced Metal Etching® Chemical Etching Vs Blasting Keep reading to learn which method is best for different circumstances. It can be used to create decorative patterns, but it’s also more aggressive than diamond grinding and sandblasting and can cause more damage to the concrete if not done properly. chemical floor prep utilizes an acid to etch and burn the surface of the concrete, opening the pores. Chemical Etching Vs Blasting.