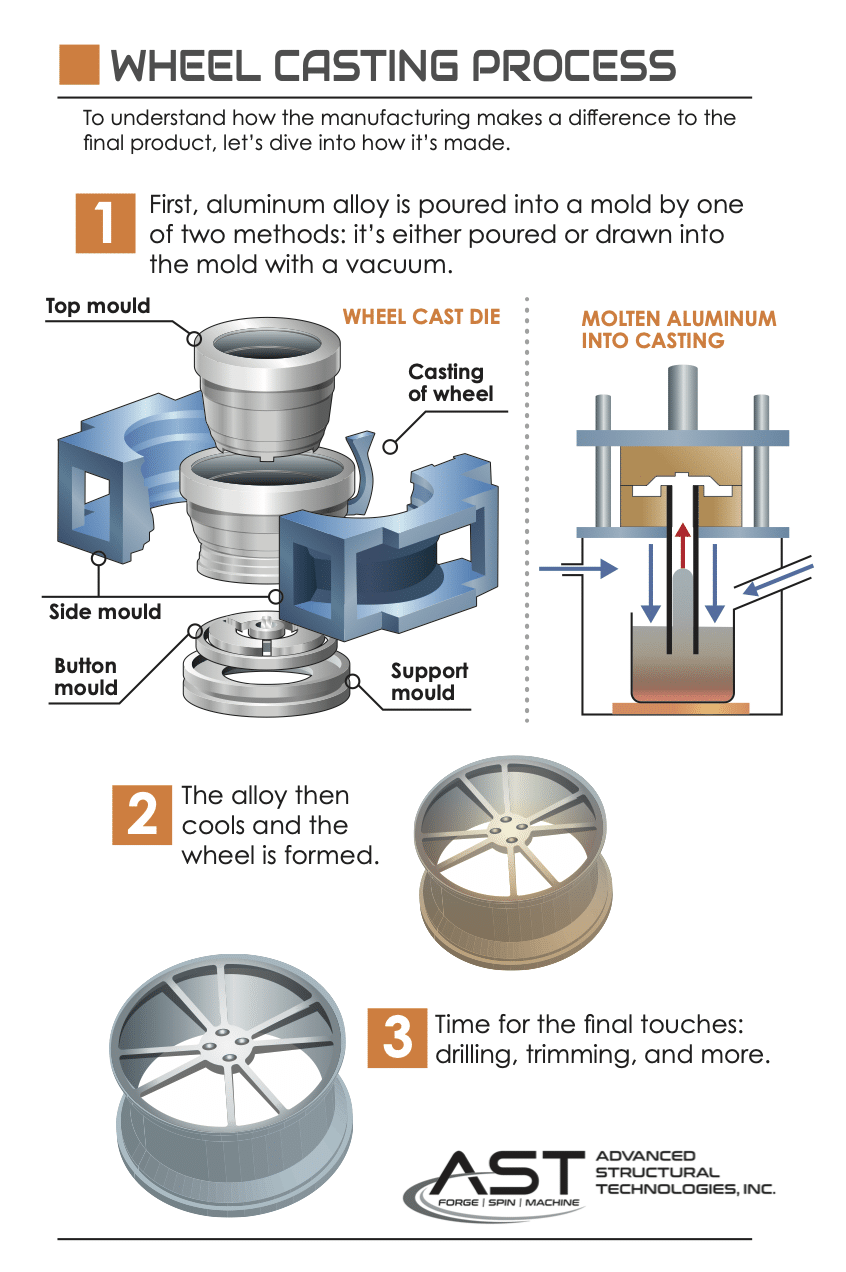

Casting Method Wheel . The flow forming process, sometimes called flow forging, rotary forging, spun rim, or rim rolling, begins with a cast wheel that is loaded into a specialized machine that spins. This involves injecting molten metal into a mold and. There are two main methods of casting used to accomplish. Casting wheels are a type of wheel that is made by a process called die casting. Cast wheels are exactly what they sound like, with molten metal being cast directly into the desired shape within a mold. Casting is the process of wheel manufacturing when aluminum is heated until it is molten. There are two methods used. In such condition it is poured into a mold where it. The wheel face is cast, taking on the smooth finish that makes a casting precise, and cost effective. One system is known as gravity casting. The casting is then heated and put on a turning die. There are multiple manufacturing methods for aluminum alloy wheels, primarily classified into two categories:

from mattieferstapia.blogspot.com

The flow forming process, sometimes called flow forging, rotary forging, spun rim, or rim rolling, begins with a cast wheel that is loaded into a specialized machine that spins. The wheel face is cast, taking on the smooth finish that makes a casting precise, and cost effective. Casting is the process of wheel manufacturing when aluminum is heated until it is molten. In such condition it is poured into a mold where it. This involves injecting molten metal into a mold and. Cast wheels are exactly what they sound like, with molten metal being cast directly into the desired shape within a mold. Casting wheels are a type of wheel that is made by a process called die casting. There are two methods used. There are two main methods of casting used to accomplish. One system is known as gravity casting.

Alloy Wheel Casting Process

Casting Method Wheel Cast wheels are exactly what they sound like, with molten metal being cast directly into the desired shape within a mold. The casting is then heated and put on a turning die. There are multiple manufacturing methods for aluminum alloy wheels, primarily classified into two categories: There are two main methods of casting used to accomplish. This involves injecting molten metal into a mold and. There are two methods used. Cast wheels are exactly what they sound like, with molten metal being cast directly into the desired shape within a mold. Casting wheels are a type of wheel that is made by a process called die casting. The flow forming process, sometimes called flow forging, rotary forging, spun rim, or rim rolling, begins with a cast wheel that is loaded into a specialized machine that spins. Casting is the process of wheel manufacturing when aluminum is heated until it is molten. In such condition it is poured into a mold where it. One system is known as gravity casting. The wheel face is cast, taking on the smooth finish that makes a casting precise, and cost effective.

From sa-foundry.com

Technology and equipment for serial casting of aluminum wheels for Casting Method Wheel There are two main methods of casting used to accomplish. The flow forming process, sometimes called flow forging, rotary forging, spun rim, or rim rolling, begins with a cast wheel that is loaded into a specialized machine that spins. Casting is the process of wheel manufacturing when aluminum is heated until it is molten. One system is known as gravity. Casting Method Wheel.

From www.rail-wheels.com

China Maanshan Kingrail Technology Co.,Ltd. latest company news about Casting Method Wheel There are two methods used. There are multiple manufacturing methods for aluminum alloy wheels, primarily classified into two categories: The flow forming process, sometimes called flow forging, rotary forging, spun rim, or rim rolling, begins with a cast wheel that is loaded into a specialized machine that spins. In such condition it is poured into a mold where it. This. Casting Method Wheel.

From machiningtoday.com

Casting 101 Understanding the 12 Different Types of Casting Processes Casting Method Wheel There are two methods used. The casting is then heated and put on a turning die. There are multiple manufacturing methods for aluminum alloy wheels, primarily classified into two categories: Casting is the process of wheel manufacturing when aluminum is heated until it is molten. There are two main methods of casting used to accomplish. In such condition it is. Casting Method Wheel.

From mattieferstapia.blogspot.com

Alloy Wheel Casting Process Casting Method Wheel One system is known as gravity casting. Cast wheels are exactly what they sound like, with molten metal being cast directly into the desired shape within a mold. The flow forming process, sometimes called flow forging, rotary forging, spun rim, or rim rolling, begins with a cast wheel that is loaded into a specialized machine that spins. The casting is. Casting Method Wheel.

From www.heda-castings.com

What industries commonly use investment casting? Heda Castings Casting Method Wheel The casting is then heated and put on a turning die. Casting wheels are a type of wheel that is made by a process called die casting. There are multiple manufacturing methods for aluminum alloy wheels, primarily classified into two categories: One system is known as gravity casting. There are two main methods of casting used to accomplish. Cast wheels. Casting Method Wheel.

From superband188.en.made-in-china.com

Gravity Die Casting Alloy Wheel Mold Car Wheel Tooling Car Wheel Die Casting Method Wheel This involves injecting molten metal into a mold and. One system is known as gravity casting. The wheel face is cast, taking on the smooth finish that makes a casting precise, and cost effective. Casting is the process of wheel manufacturing when aluminum is heated until it is molten. There are multiple manufacturing methods for aluminum alloy wheels, primarily classified. Casting Method Wheel.

From www.joohonorccr.com

Wheel Type Aluminum Billets Continuous Casting Line Casting Method Wheel There are two methods used. There are two main methods of casting used to accomplish. Casting is the process of wheel manufacturing when aluminum is heated until it is molten. The flow forming process, sometimes called flow forging, rotary forging, spun rim, or rim rolling, begins with a cast wheel that is loaded into a specialized machine that spins. Casting. Casting Method Wheel.

From www.zhycasting.com

Optimization of pouring process for Wheel Castings ZHY Casting Casting Method Wheel The flow forming process, sometimes called flow forging, rotary forging, spun rim, or rim rolling, begins with a cast wheel that is loaded into a specialized machine that spins. Casting wheels are a type of wheel that is made by a process called die casting. There are multiple manufacturing methods for aluminum alloy wheels, primarily classified into two categories: One. Casting Method Wheel.

From en.sinolandinfo.com

Casting_Wheel Casting Method Wheel This involves injecting molten metal into a mold and. There are two methods used. There are two main methods of casting used to accomplish. In such condition it is poured into a mold where it. Cast wheels are exactly what they sound like, with molten metal being cast directly into the desired shape within a mold. One system is known. Casting Method Wheel.

From dwarfracing.com.sg

Types Of Manufacturing Process Dwarf Racing® Casting Method Wheel Casting wheels are a type of wheel that is made by a process called die casting. There are multiple manufacturing methods for aluminum alloy wheels, primarily classified into two categories: There are two methods used. This involves injecting molten metal into a mold and. There are two main methods of casting used to accomplish. One system is known as gravity. Casting Method Wheel.

From m3eng.com

Anode Casting Wheel M3 Engineering & Technology Casting Method Wheel There are two methods used. The wheel face is cast, taking on the smooth finish that makes a casting precise, and cost effective. One system is known as gravity casting. There are multiple manufacturing methods for aluminum alloy wheels, primarily classified into two categories: Cast wheels are exactly what they sound like, with molten metal being cast directly into the. Casting Method Wheel.

From www.indiamart.com

Casting Wheels at best price in Kolkata by Elmecon Engineers ID Casting Method Wheel The casting is then heated and put on a turning die. Casting wheels are a type of wheel that is made by a process called die casting. One system is known as gravity casting. The wheel face is cast, taking on the smooth finish that makes a casting precise, and cost effective. There are multiple manufacturing methods for aluminum alloy. Casting Method Wheel.

From www.cjponyparts.com

Types of Wheels Rims vs Wheels Casting Method Wheel The flow forming process, sometimes called flow forging, rotary forging, spun rim, or rim rolling, begins with a cast wheel that is loaded into a specialized machine that spins. This involves injecting molten metal into a mold and. The wheel face is cast, taking on the smooth finish that makes a casting precise, and cost effective. Cast wheels are exactly. Casting Method Wheel.

From mattieferstapia.blogspot.com

Alloy Wheel Casting Process Casting Method Wheel In such condition it is poured into a mold where it. The casting is then heated and put on a turning die. Casting is the process of wheel manufacturing when aluminum is heated until it is molten. The wheel face is cast, taking on the smooth finish that makes a casting precise, and cost effective. There are multiple manufacturing methods. Casting Method Wheel.

From www.modernmusclewheels.com

The Difference between Flow Form, Cast and wheels — Modern Casting Method Wheel Cast wheels are exactly what they sound like, with molten metal being cast directly into the desired shape within a mold. Casting wheels are a type of wheel that is made by a process called die casting. One system is known as gravity casting. The casting is then heated and put on a turning die. This involves injecting molten metal. Casting Method Wheel.

From superband188.en.made-in-china.com

Automotive Wheel Tooling Lpdc Casting Wheel Mould Aluminum Alloy Wheel Casting Method Wheel One system is known as gravity casting. Cast wheels are exactly what they sound like, with molten metal being cast directly into the desired shape within a mold. There are two methods used. There are multiple manufacturing methods for aluminum alloy wheels, primarily classified into two categories: Casting wheels are a type of wheel that is made by a process. Casting Method Wheel.

From precise-cast.com

The Most Comprehensive Casting Process Summary Precise Cast Casting Method Wheel This involves injecting molten metal into a mold and. Casting wheels are a type of wheel that is made by a process called die casting. The wheel face is cast, taking on the smooth finish that makes a casting precise, and cost effective. Casting is the process of wheel manufacturing when aluminum is heated until it is molten. One system. Casting Method Wheel.

From slidetodoc.com

Metal Casting Processes Casting One of the oldest Casting Method Wheel The wheel face is cast, taking on the smooth finish that makes a casting precise, and cost effective. The casting is then heated and put on a turning die. There are two main methods of casting used to accomplish. Casting is the process of wheel manufacturing when aluminum is heated until it is molten. There are two methods used. One. Casting Method Wheel.

From www.slideserve.com

PPT CHAPTER 11 PART II PowerPoint Presentation, free download ID365573 Casting Method Wheel There are multiple manufacturing methods for aluminum alloy wheels, primarily classified into two categories: The wheel face is cast, taking on the smooth finish that makes a casting precise, and cost effective. One system is known as gravity casting. This involves injecting molten metal into a mold and. Casting is the process of wheel manufacturing when aluminum is heated until. Casting Method Wheel.

From www.indiamart.com

Aluminium Casting Wheel at Rs 350/kg Casting Wheel in Jaipur ID Casting Method Wheel The flow forming process, sometimes called flow forging, rotary forging, spun rim, or rim rolling, begins with a cast wheel that is loaded into a specialized machine that spins. There are two main methods of casting used to accomplish. One system is known as gravity casting. Casting is the process of wheel manufacturing when aluminum is heated until it is. Casting Method Wheel.

From www.pinterest.com

Continuous Casting Process It cast, Continuity, Under pressure Casting Method Wheel The wheel face is cast, taking on the smooth finish that makes a casting precise, and cost effective. Casting is the process of wheel manufacturing when aluminum is heated until it is molten. The flow forming process, sometimes called flow forging, rotary forging, spun rim, or rim rolling, begins with a cast wheel that is loaded into a specialized machine. Casting Method Wheel.

From www.sunrise-metal.com

Semisolid Die Casting What Is Rheocasting&Thixocasting&Thixomolding Casting Method Wheel There are multiple manufacturing methods for aluminum alloy wheels, primarily classified into two categories: One system is known as gravity casting. Casting wheels are a type of wheel that is made by a process called die casting. This involves injecting molten metal into a mold and. In such condition it is poured into a mold where it. Cast wheels are. Casting Method Wheel.

From sa-foundry.com

Technology and equipment for serial casting of aluminum wheels for Casting Method Wheel There are two methods used. Cast wheels are exactly what they sound like, with molten metal being cast directly into the desired shape within a mold. The wheel face is cast, taking on the smooth finish that makes a casting precise, and cost effective. There are two main methods of casting used to accomplish. In such condition it is poured. Casting Method Wheel.

From www.indiamart.com

CI Casting Wheel at Rs 75/kg Casting Wheel ID 20042606688 Casting Method Wheel Cast wheels are exactly what they sound like, with molten metal being cast directly into the desired shape within a mold. The flow forming process, sometimes called flow forging, rotary forging, spun rim, or rim rolling, begins with a cast wheel that is loaded into a specialized machine that spins. There are two main methods of casting used to accomplish.. Casting Method Wheel.

From www.omicroncasting.com

5 Different Methods Used in Casting Casting Method Wheel Cast wheels are exactly what they sound like, with molten metal being cast directly into the desired shape within a mold. Casting wheels are a type of wheel that is made by a process called die casting. In such condition it is poured into a mold where it. There are two methods used. Casting is the process of wheel manufacturing. Casting Method Wheel.

From www.customalloywheel.com

Wheel Casting Automotive Rims And Wheels Casting Method Wheel The flow forming process, sometimes called flow forging, rotary forging, spun rim, or rim rolling, begins with a cast wheel that is loaded into a specialized machine that spins. The wheel face is cast, taking on the smooth finish that makes a casting precise, and cost effective. There are two methods used. Casting is the process of wheel manufacturing when. Casting Method Wheel.

From www.thelibraryofmanufacturing.com

Semicentrifugal Casting Casting Method Wheel There are multiple manufacturing methods for aluminum alloy wheels, primarily classified into two categories: There are two methods used. Cast wheels are exactly what they sound like, with molten metal being cast directly into the desired shape within a mold. In such condition it is poured into a mold where it. The casting is then heated and put on a. Casting Method Wheel.

From www.zhycasting.com

Casting process of mining flat car wheel castings ZHY Casting Casting Method Wheel The wheel face is cast, taking on the smooth finish that makes a casting precise, and cost effective. The flow forming process, sometimes called flow forging, rotary forging, spun rim, or rim rolling, begins with a cast wheel that is loaded into a specialized machine that spins. In such condition it is poured into a mold where it. Casting wheels. Casting Method Wheel.

From www.pro-touring.com

Wheel Construction Types Explained w/ Pics Casting Method Wheel There are two main methods of casting used to accomplish. In such condition it is poured into a mold where it. The casting is then heated and put on a turning die. Casting is the process of wheel manufacturing when aluminum is heated until it is molten. This involves injecting molten metal into a mold and. The wheel face is. Casting Method Wheel.

From www.iqsdirectory.com

Types of Casting Processes Casting Methods Casting Method Wheel One system is known as gravity casting. The flow forming process, sometimes called flow forging, rotary forging, spun rim, or rim rolling, begins with a cast wheel that is loaded into a specialized machine that spins. There are two methods used. Casting is the process of wheel manufacturing when aluminum is heated until it is molten. Cast wheels are exactly. Casting Method Wheel.

From precise-cast.com

The Most Comprehensive Casting Process Summary Precise Cast Casting Method Wheel This involves injecting molten metal into a mold and. One system is known as gravity casting. There are multiple manufacturing methods for aluminum alloy wheels, primarily classified into two categories: The casting is then heated and put on a turning die. Casting is the process of wheel manufacturing when aluminum is heated until it is molten. Casting wheels are a. Casting Method Wheel.

From encyclopedia.pub

Texturing Methods of Abrasive Grinding Wheels Encyclopedia MDPI Casting Method Wheel One system is known as gravity casting. This involves injecting molten metal into a mold and. The flow forming process, sometimes called flow forging, rotary forging, spun rim, or rim rolling, begins with a cast wheel that is loaded into a specialized machine that spins. The casting is then heated and put on a turning die. Cast wheels are exactly. Casting Method Wheel.

From www.youtube.com

What Are The Common Types Of Metal Casting Process In Engineering and Casting Method Wheel Casting is the process of wheel manufacturing when aluminum is heated until it is molten. The flow forming process, sometimes called flow forging, rotary forging, spun rim, or rim rolling, begins with a cast wheel that is loaded into a specialized machine that spins. There are multiple manufacturing methods for aluminum alloy wheels, primarily classified into two categories: One system. Casting Method Wheel.

From ppcpinc.com

Pennsylvania Precision Cast Parts Investment Casting Process Casting Method Wheel Cast wheels are exactly what they sound like, with molten metal being cast directly into the desired shape within a mold. The flow forming process, sometimes called flow forging, rotary forging, spun rim, or rim rolling, begins with a cast wheel that is loaded into a specialized machine that spins. There are multiple manufacturing methods for aluminum alloy wheels, primarily. Casting Method Wheel.

From www.mdpi.com

Metals Free FullText Numerical Simulation of Latent Heat of Casting Method Wheel The flow forming process, sometimes called flow forging, rotary forging, spun rim, or rim rolling, begins with a cast wheel that is loaded into a specialized machine that spins. There are two main methods of casting used to accomplish. The casting is then heated and put on a turning die. Cast wheels are exactly what they sound like, with molten. Casting Method Wheel.