Optical Homogeneity . Homogeneity classes and their maximum variation of refractive index as well as applicability can be found in the ‘optical glass catalog’, available in the download section. Local fluctuations of these elements in fused silica are a source of variation in the material’s refractive index — a quality commonly referred to as optical homogeneity. For high precision measurement of refractive index, dispersion and optical homogeneity strict temperature stabilization of the equipment and especially the samples is a must. Quality assurance of optical homogeneity for common optical elements is done by production process control. Optical homogeneity is determined by local variations in the glass caused by the production process. An important property of processed optical glass is the excellent spatial homogeneity of the refractive index of the material. The homogeneity of an optical substrate characterizes refractive index variations, leading to a deformation of the transmitted wavefront. Increased requirements for refractive index homogeneity comprise five classes in accordance with the standard iso 10110 and iso 12123.

from www.daicel.com

Optical homogeneity is determined by local variations in the glass caused by the production process. An important property of processed optical glass is the excellent spatial homogeneity of the refractive index of the material. Quality assurance of optical homogeneity for common optical elements is done by production process control. Increased requirements for refractive index homogeneity comprise five classes in accordance with the standard iso 10110 and iso 12123. Homogeneity classes and their maximum variation of refractive index as well as applicability can be found in the ‘optical glass catalog’, available in the download section. For high precision measurement of refractive index, dispersion and optical homogeneity strict temperature stabilization of the equipment and especially the samples is a must. The homogeneity of an optical substrate characterizes refractive index variations, leading to a deformation of the transmitted wavefront. Local fluctuations of these elements in fused silica are a source of variation in the material’s refractive index — a quality commonly referred to as optical homogeneity.

Molding process Optical Lenses Smart SBU Daicel Corporation

Optical Homogeneity For high precision measurement of refractive index, dispersion and optical homogeneity strict temperature stabilization of the equipment and especially the samples is a must. Quality assurance of optical homogeneity for common optical elements is done by production process control. Homogeneity classes and their maximum variation of refractive index as well as applicability can be found in the ‘optical glass catalog’, available in the download section. For high precision measurement of refractive index, dispersion and optical homogeneity strict temperature stabilization of the equipment and especially the samples is a must. An important property of processed optical glass is the excellent spatial homogeneity of the refractive index of the material. The homogeneity of an optical substrate characterizes refractive index variations, leading to a deformation of the transmitted wavefront. Local fluctuations of these elements in fused silica are a source of variation in the material’s refractive index — a quality commonly referred to as optical homogeneity. Optical homogeneity is determined by local variations in the glass caused by the production process. Increased requirements for refractive index homogeneity comprise five classes in accordance with the standard iso 10110 and iso 12123.

From www.researchgate.net

Ultranarrow optical homogeneous linewidths a, Twopulse PE decay for Optical Homogeneity For high precision measurement of refractive index, dispersion and optical homogeneity strict temperature stabilization of the equipment and especially the samples is a must. Quality assurance of optical homogeneity for common optical elements is done by production process control. Local fluctuations of these elements in fused silica are a source of variation in the material’s refractive index — a quality. Optical Homogeneity.

From www.scientific.net

Study of ThreeDimensional Optical Homogeneity of Fused Silica Prepared Optical Homogeneity Increased requirements for refractive index homogeneity comprise five classes in accordance with the standard iso 10110 and iso 12123. An important property of processed optical glass is the excellent spatial homogeneity of the refractive index of the material. Optical homogeneity is determined by local variations in the glass caused by the production process. For high precision measurement of refractive index,. Optical Homogeneity.

From 4dtechnology.com

Optical Setups Homogeneity and Optical Thickness 4D Technology Optical Homogeneity The homogeneity of an optical substrate characterizes refractive index variations, leading to a deformation of the transmitted wavefront. For high precision measurement of refractive index, dispersion and optical homogeneity strict temperature stabilization of the equipment and especially the samples is a must. An important property of processed optical glass is the excellent spatial homogeneity of the refractive index of the. Optical Homogeneity.

From www.researchgate.net

Temperature dependences of saline water (0.08 NaCl) optical Optical Homogeneity For high precision measurement of refractive index, dispersion and optical homogeneity strict temperature stabilization of the equipment and especially the samples is a must. Optical homogeneity is determined by local variations in the glass caused by the production process. Local fluctuations of these elements in fused silica are a source of variation in the material’s refractive index — a quality. Optical Homogeneity.

From www.researchgate.net

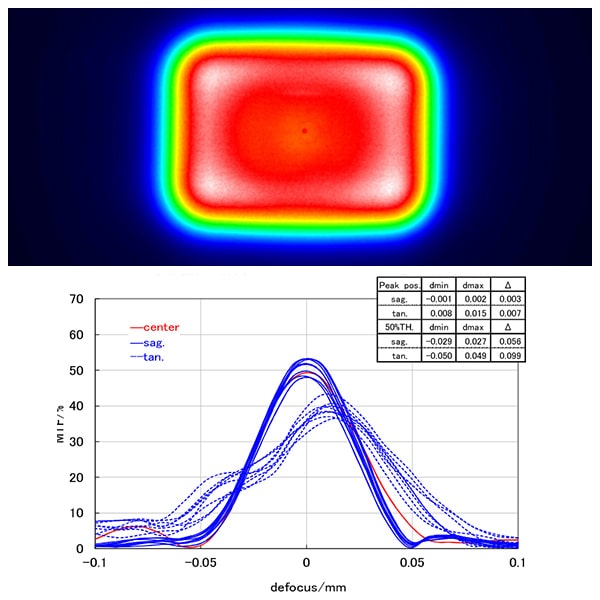

1 Results of the optical simulation on the irradiation homogeneity Optical Homogeneity The homogeneity of an optical substrate characterizes refractive index variations, leading to a deformation of the transmitted wavefront. An important property of processed optical glass is the excellent spatial homogeneity of the refractive index of the material. Optical homogeneity is determined by local variations in the glass caused by the production process. Homogeneity classes and their maximum variation of refractive. Optical Homogeneity.

From www.daicel.com

Molding process Optical Lenses Smart SBU Daicel Corporation Optical Homogeneity An important property of processed optical glass is the excellent spatial homogeneity of the refractive index of the material. Quality assurance of optical homogeneity for common optical elements is done by production process control. Increased requirements for refractive index homogeneity comprise five classes in accordance with the standard iso 10110 and iso 12123. Optical homogeneity is determined by local variations. Optical Homogeneity.

From www.semanticscholar.org

Figure 2 from The Application of Polarization Modulation Method to Optical Homogeneity For high precision measurement of refractive index, dispersion and optical homogeneity strict temperature stabilization of the equipment and especially the samples is a must. Homogeneity classes and their maximum variation of refractive index as well as applicability can be found in the ‘optical glass catalog’, available in the download section. Increased requirements for refractive index homogeneity comprise five classes in. Optical Homogeneity.

From www.researchgate.net

Wavefront data with optical material homogeneity Download Scientific Optical Homogeneity Local fluctuations of these elements in fused silica are a source of variation in the material’s refractive index — a quality commonly referred to as optical homogeneity. Quality assurance of optical homogeneity for common optical elements is done by production process control. Optical homogeneity is determined by local variations in the glass caused by the production process. The homogeneity of. Optical Homogeneity.

From www.researchgate.net

Intensity scans of the optical field used for creating the Optical Homogeneity Quality assurance of optical homogeneity for common optical elements is done by production process control. An important property of processed optical glass is the excellent spatial homogeneity of the refractive index of the material. Local fluctuations of these elements in fused silica are a source of variation in the material’s refractive index — a quality commonly referred to as optical. Optical Homogeneity.

From www.researchgate.net

2D and 3D maps of the optical homogeneity for the Er,PrGYSGG crystal Optical Homogeneity Local fluctuations of these elements in fused silica are a source of variation in the material’s refractive index — a quality commonly referred to as optical homogeneity. Optical homogeneity is determined by local variations in the glass caused by the production process. Increased requirements for refractive index homogeneity comprise five classes in accordance with the standard iso 10110 and iso. Optical Homogeneity.

From eureka.patsnap.com

Optical glass optical homogeneity test device and test method Eureka Optical Homogeneity The homogeneity of an optical substrate characterizes refractive index variations, leading to a deformation of the transmitted wavefront. Homogeneity classes and their maximum variation of refractive index as well as applicability can be found in the ‘optical glass catalog’, available in the download section. Optical homogeneity is determined by local variations in the glass caused by the production process. Local. Optical Homogeneity.

From www.researchgate.net

Optical images of surfaces I and II and cross section of homogeneous Optical Homogeneity An important property of processed optical glass is the excellent spatial homogeneity of the refractive index of the material. Homogeneity classes and their maximum variation of refractive index as well as applicability can be found in the ‘optical glass catalog’, available in the download section. Increased requirements for refractive index homogeneity comprise five classes in accordance with the standard iso. Optical Homogeneity.

From www.semanticscholar.org

Figure 1 from Testing of optical homogeneity of materials in IR Optical Homogeneity Quality assurance of optical homogeneity for common optical elements is done by production process control. For high precision measurement of refractive index, dispersion and optical homogeneity strict temperature stabilization of the equipment and especially the samples is a must. Homogeneity classes and their maximum variation of refractive index as well as applicability can be found in the ‘optical glass catalog’,. Optical Homogeneity.

From www.researchgate.net

Illumination field intensity inhomogeneity with (a) fixed and (b Optical Homogeneity The homogeneity of an optical substrate characterizes refractive index variations, leading to a deformation of the transmitted wavefront. Increased requirements for refractive index homogeneity comprise five classes in accordance with the standard iso 10110 and iso 12123. Optical homogeneity is determined by local variations in the glass caused by the production process. Local fluctuations of these elements in fused silica. Optical Homogeneity.

From 4dtechnology.com

Optical Setups Homogeneity and Optical Thickness 4D Technology Optical Homogeneity Quality assurance of optical homogeneity for common optical elements is done by production process control. For high precision measurement of refractive index, dispersion and optical homogeneity strict temperature stabilization of the equipment and especially the samples is a must. Homogeneity classes and their maximum variation of refractive index as well as applicability can be found in the ‘optical glass catalog’,. Optical Homogeneity.

From 4dtechnology.com

Optical Setups Homogeneity and Optical Thickness 4D Technology Optical Homogeneity An important property of processed optical glass is the excellent spatial homogeneity of the refractive index of the material. Homogeneity classes and their maximum variation of refractive index as well as applicability can be found in the ‘optical glass catalog’, available in the download section. Local fluctuations of these elements in fused silica are a source of variation in the. Optical Homogeneity.

From journals.iucr.org

(IUCr) A novel comparative study of crystalline perfection and optical Optical Homogeneity Quality assurance of optical homogeneity for common optical elements is done by production process control. Optical homogeneity is determined by local variations in the glass caused by the production process. An important property of processed optical glass is the excellent spatial homogeneity of the refractive index of the material. Local fluctuations of these elements in fused silica are a source. Optical Homogeneity.

From www.researchgate.net

(PDF) Structure and Optical Homogeneity of LiNbO3〈Mg〉 Crystals Grown Optical Homogeneity Homogeneity classes and their maximum variation of refractive index as well as applicability can be found in the ‘optical glass catalog’, available in the download section. Quality assurance of optical homogeneity for common optical elements is done by production process control. For high precision measurement of refractive index, dispersion and optical homogeneity strict temperature stabilization of the equipment and especially. Optical Homogeneity.

From 4dtechnology.com

Optical Setups Homogeneity and Optical Thickness 4D Technology Optical Homogeneity Optical homogeneity is determined by local variations in the glass caused by the production process. Increased requirements for refractive index homogeneity comprise five classes in accordance with the standard iso 10110 and iso 12123. Homogeneity classes and their maximum variation of refractive index as well as applicability can be found in the ‘optical glass catalog’, available in the download section.. Optical Homogeneity.

From www.researchgate.net

(PDF) Characterising the homogeneity of optical glasses using the Optical Homogeneity Local fluctuations of these elements in fused silica are a source of variation in the material’s refractive index — a quality commonly referred to as optical homogeneity. Quality assurance of optical homogeneity for common optical elements is done by production process control. An important property of processed optical glass is the excellent spatial homogeneity of the refractive index of the. Optical Homogeneity.

From www.researchgate.net

a) The optical images under the polariscope demonstrate the film Optical Homogeneity Increased requirements for refractive index homogeneity comprise five classes in accordance with the standard iso 10110 and iso 12123. Optical homogeneity is determined by local variations in the glass caused by the production process. Quality assurance of optical homogeneity for common optical elements is done by production process control. Homogeneity classes and their maximum variation of refractive index as well. Optical Homogeneity.

From www.scientific.net

Analysis of the Test Method of Quartz Glass Optical Homogeneity Optical Homogeneity The homogeneity of an optical substrate characterizes refractive index variations, leading to a deformation of the transmitted wavefront. An important property of processed optical glass is the excellent spatial homogeneity of the refractive index of the material. Homogeneity classes and their maximum variation of refractive index as well as applicability can be found in the ‘optical glass catalog’, available in. Optical Homogeneity.

From www.researchgate.net

2D and 3D maps of the optical homogeneity for the Er,PrGYSGG crystal Optical Homogeneity An important property of processed optical glass is the excellent spatial homogeneity of the refractive index of the material. Increased requirements for refractive index homogeneity comprise five classes in accordance with the standard iso 10110 and iso 12123. Local fluctuations of these elements in fused silica are a source of variation in the material’s refractive index — a quality commonly. Optical Homogeneity.

From eureka.patsnap.com

Optical glass optical homogeneity test device and test method Eureka Optical Homogeneity For high precision measurement of refractive index, dispersion and optical homogeneity strict temperature stabilization of the equipment and especially the samples is a must. Local fluctuations of these elements in fused silica are a source of variation in the material’s refractive index — a quality commonly referred to as optical homogeneity. Optical homogeneity is determined by local variations in the. Optical Homogeneity.

From www.slideserve.com

PPT Plans & Prospects for W Physics with STAR PowerPoint Presentation Optical Homogeneity Local fluctuations of these elements in fused silica are a source of variation in the material’s refractive index — a quality commonly referred to as optical homogeneity. An important property of processed optical glass is the excellent spatial homogeneity of the refractive index of the material. For high precision measurement of refractive index, dispersion and optical homogeneity strict temperature stabilization. Optical Homogeneity.

From www.researchgate.net

Figure S3. Homogeneity of monolayer and bilayer InSe thin film. (a Optical Homogeneity The homogeneity of an optical substrate characterizes refractive index variations, leading to a deformation of the transmitted wavefront. An important property of processed optical glass is the excellent spatial homogeneity of the refractive index of the material. For high precision measurement of refractive index, dispersion and optical homogeneity strict temperature stabilization of the equipment and especially the samples is a. Optical Homogeneity.

From www.semanticscholar.org

Figure 4 from Optical homogeneity and second harmonic generation in Li Optical Homogeneity Homogeneity classes and their maximum variation of refractive index as well as applicability can be found in the ‘optical glass catalog’, available in the download section. For high precision measurement of refractive index, dispersion and optical homogeneity strict temperature stabilization of the equipment and especially the samples is a must. Local fluctuations of these elements in fused silica are a. Optical Homogeneity.

From www.researchgate.net

2D and 3D maps of the optical homogeneity for the Er,PrGYSGG crystal Optical Homogeneity An important property of processed optical glass is the excellent spatial homogeneity of the refractive index of the material. Optical homogeneity is determined by local variations in the glass caused by the production process. Homogeneity classes and their maximum variation of refractive index as well as applicability can be found in the ‘optical glass catalog’, available in the download section.. Optical Homogeneity.

From www.researchgate.net

(PDF) INVESTIGATION OF OPTICAL HOMOGENEITY OF LANGASITE SAMPLES Optical Homogeneity Optical homogeneity is determined by local variations in the glass caused by the production process. Homogeneity classes and their maximum variation of refractive index as well as applicability can be found in the ‘optical glass catalog’, available in the download section. For high precision measurement of refractive index, dispersion and optical homogeneity strict temperature stabilization of the equipment and especially. Optical Homogeneity.

From eureka.patsnap.com

Optical glass optical homogeneity test device and test method Eureka Optical Homogeneity The homogeneity of an optical substrate characterizes refractive index variations, leading to a deformation of the transmitted wavefront. Homogeneity classes and their maximum variation of refractive index as well as applicability can be found in the ‘optical glass catalog’, available in the download section. For high precision measurement of refractive index, dispersion and optical homogeneity strict temperature stabilization of the. Optical Homogeneity.

From www.researchgate.net

Optical homogeneity of (A) polyamideimide films through direct Optical Homogeneity Quality assurance of optical homogeneity for common optical elements is done by production process control. The homogeneity of an optical substrate characterizes refractive index variations, leading to a deformation of the transmitted wavefront. Optical homogeneity is determined by local variations in the glass caused by the production process. For high precision measurement of refractive index, dispersion and optical homogeneity strict. Optical Homogeneity.

From www.researchgate.net

(PDF) Optical homogeneity and photorefractive properties of Optical Homogeneity Increased requirements for refractive index homogeneity comprise five classes in accordance with the standard iso 10110 and iso 12123. Quality assurance of optical homogeneity for common optical elements is done by production process control. Optical homogeneity is determined by local variations in the glass caused by the production process. The homogeneity of an optical substrate characterizes refractive index variations, leading. Optical Homogeneity.

From www.researchgate.net

Ohmic contacts and twist angle homogeneity a, Optical microscope image Optical Homogeneity Homogeneity classes and their maximum variation of refractive index as well as applicability can be found in the ‘optical glass catalog’, available in the download section. Local fluctuations of these elements in fused silica are a source of variation in the material’s refractive index — a quality commonly referred to as optical homogeneity. An important property of processed optical glass. Optical Homogeneity.

From www.semanticscholar.org

Figure 1 from The Application of Polarization Modulation Method to Optical Homogeneity Homogeneity classes and their maximum variation of refractive index as well as applicability can be found in the ‘optical glass catalog’, available in the download section. Local fluctuations of these elements in fused silica are a source of variation in the material’s refractive index — a quality commonly referred to as optical homogeneity. For high precision measurement of refractive index,. Optical Homogeneity.

From www.zygo.com

Optical Material Homogeneity Optical Homogeneity For high precision measurement of refractive index, dispersion and optical homogeneity strict temperature stabilization of the equipment and especially the samples is a must. Quality assurance of optical homogeneity for common optical elements is done by production process control. Local fluctuations of these elements in fused silica are a source of variation in the material’s refractive index — a quality. Optical Homogeneity.