Coating Deposition Processes . Cvd and related processes are employed in many thin film applications, including dielectrics, conductors, passivation layers, oxidation. The most crucial processes, however, involve deposition because they deal with the chemistry of materials and the alloying of compositional. Vacuum web coating processes employ a number of deposition technologies and hybrid processes, most recently vacuum. In order to obtain thin films with good quality, there are two common deposition techniques: It can be summarized as shown in table. Starting material preparation and deposition process parameters work in concert to influence the optical and physical (mechanical). Deposition and growth of thin film s of these materials to build optical coatings is accomplished by one of the many variations of.

from scscoatings.com

Deposition and growth of thin film s of these materials to build optical coatings is accomplished by one of the many variations of. Vacuum web coating processes employ a number of deposition technologies and hybrid processes, most recently vacuum. It can be summarized as shown in table. Starting material preparation and deposition process parameters work in concert to influence the optical and physical (mechanical). Cvd and related processes are employed in many thin film applications, including dielectrics, conductors, passivation layers, oxidation. The most crucial processes, however, involve deposition because they deal with the chemistry of materials and the alloying of compositional. In order to obtain thin films with good quality, there are two common deposition techniques:

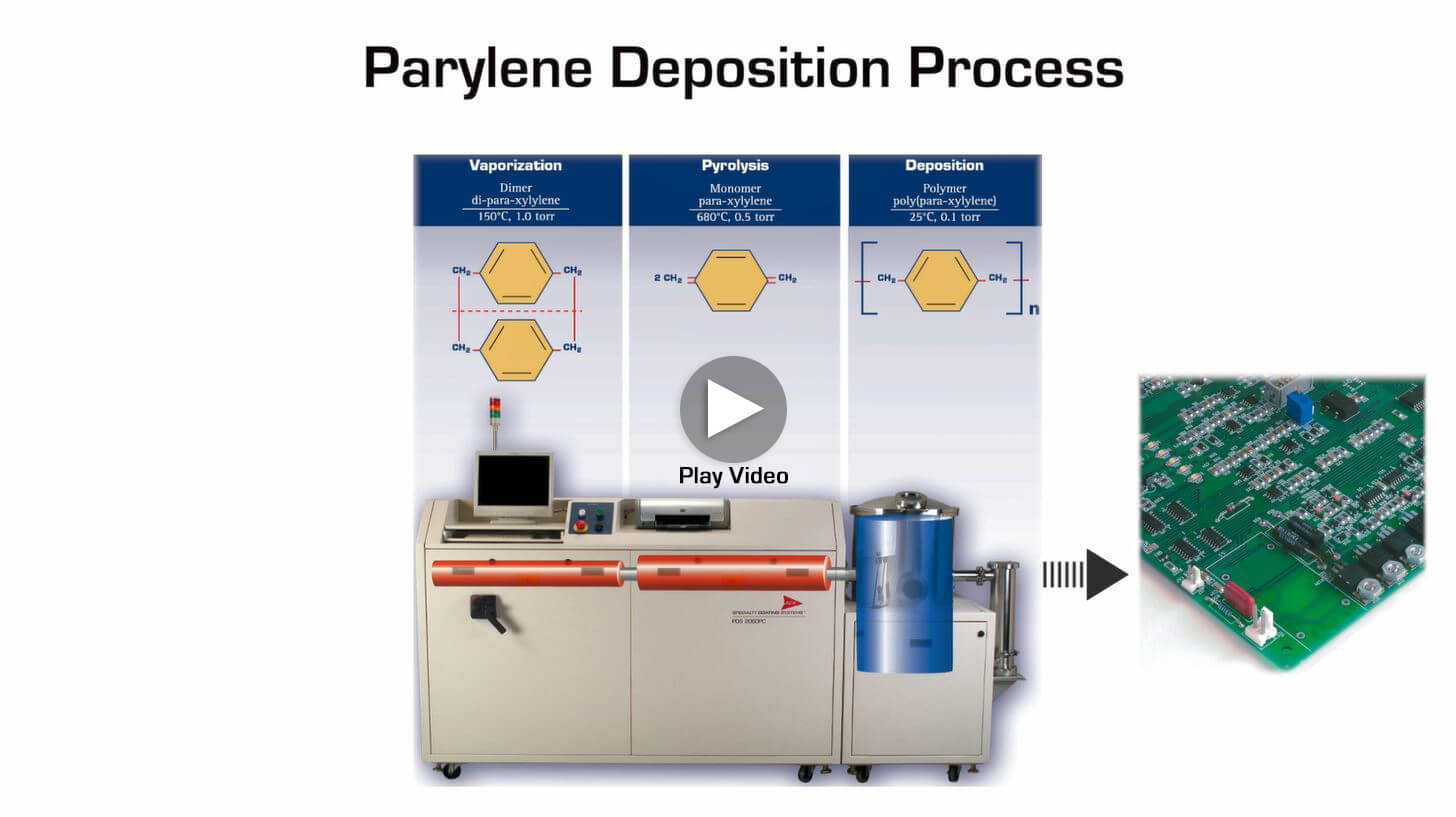

Parylene Deposition Process Specialty Coating Systems

Coating Deposition Processes Starting material preparation and deposition process parameters work in concert to influence the optical and physical (mechanical). Cvd and related processes are employed in many thin film applications, including dielectrics, conductors, passivation layers, oxidation. Deposition and growth of thin film s of these materials to build optical coatings is accomplished by one of the many variations of. Vacuum web coating processes employ a number of deposition technologies and hybrid processes, most recently vacuum. The most crucial processes, however, involve deposition because they deal with the chemistry of materials and the alloying of compositional. It can be summarized as shown in table. Starting material preparation and deposition process parameters work in concert to influence the optical and physical (mechanical). In order to obtain thin films with good quality, there are two common deposition techniques:

From news.mit.edu

Explained chemical vapor deposition MIT News Massachusetts Coating Deposition Processes The most crucial processes, however, involve deposition because they deal with the chemistry of materials and the alloying of compositional. Deposition and growth of thin film s of these materials to build optical coatings is accomplished by one of the many variations of. Vacuum web coating processes employ a number of deposition technologies and hybrid processes, most recently vacuum. Starting. Coating Deposition Processes.

From www.researchgate.net

A schematic illustration of physical vapor deposition (PVD) process for Coating Deposition Processes In order to obtain thin films with good quality, there are two common deposition techniques: Starting material preparation and deposition process parameters work in concert to influence the optical and physical (mechanical). The most crucial processes, however, involve deposition because they deal with the chemistry of materials and the alloying of compositional. Vacuum web coating processes employ a number of. Coating Deposition Processes.

From www.researchgate.net

Coating deposition process steps. Download Scientific Diagram Coating Deposition Processes In order to obtain thin films with good quality, there are two common deposition techniques: Vacuum web coating processes employ a number of deposition technologies and hybrid processes, most recently vacuum. Cvd and related processes are employed in many thin film applications, including dielectrics, conductors, passivation layers, oxidation. Deposition and growth of thin film s of these materials to build. Coating Deposition Processes.

From www.nidek-intl.com

Coating Method (Vacuum Deposition) Coating Technical Introduction Coating Deposition Processes Cvd and related processes are employed in many thin film applications, including dielectrics, conductors, passivation layers, oxidation. It can be summarized as shown in table. Deposition and growth of thin film s of these materials to build optical coatings is accomplished by one of the many variations of. The most crucial processes, however, involve deposition because they deal with the. Coating Deposition Processes.

From www.researchgate.net

Comparison of different coating deposition methods. Download Coating Deposition Processes It can be summarized as shown in table. Vacuum web coating processes employ a number of deposition technologies and hybrid processes, most recently vacuum. In order to obtain thin films with good quality, there are two common deposition techniques: Deposition and growth of thin film s of these materials to build optical coatings is accomplished by one of the many. Coating Deposition Processes.

From www.researchgate.net

Flow diagram of coating deposition process for superconducting films Coating Deposition Processes It can be summarized as shown in table. Cvd and related processes are employed in many thin film applications, including dielectrics, conductors, passivation layers, oxidation. Starting material preparation and deposition process parameters work in concert to influence the optical and physical (mechanical). Deposition and growth of thin film s of these materials to build optical coatings is accomplished by one. Coating Deposition Processes.

From www.researchgate.net

4) Schematic diagram of the deposition methods that are commonly used Coating Deposition Processes Vacuum web coating processes employ a number of deposition technologies and hybrid processes, most recently vacuum. Starting material preparation and deposition process parameters work in concert to influence the optical and physical (mechanical). Cvd and related processes are employed in many thin film applications, including dielectrics, conductors, passivation layers, oxidation. Deposition and growth of thin film s of these materials. Coating Deposition Processes.

From www.researchgate.net

Dipcoating steps (1) immersion and dwell time, (2) deposition and Coating Deposition Processes Starting material preparation and deposition process parameters work in concert to influence the optical and physical (mechanical). Deposition and growth of thin film s of these materials to build optical coatings is accomplished by one of the many variations of. The most crucial processes, however, involve deposition because they deal with the chemistry of materials and the alloying of compositional.. Coating Deposition Processes.

From www.researchgate.net

Schematic of the advanced PVD deposition methods used for the Coating Deposition Processes Vacuum web coating processes employ a number of deposition technologies and hybrid processes, most recently vacuum. It can be summarized as shown in table. Deposition and growth of thin film s of these materials to build optical coatings is accomplished by one of the many variations of. The most crucial processes, however, involve deposition because they deal with the chemistry. Coating Deposition Processes.

From www.researchgate.net

Classification of the main coating deposition techniques Download Coating Deposition Processes In order to obtain thin films with good quality, there are two common deposition techniques: Deposition and growth of thin film s of these materials to build optical coatings is accomplished by one of the many variations of. Cvd and related processes are employed in many thin film applications, including dielectrics, conductors, passivation layers, oxidation. Starting material preparation and deposition. Coating Deposition Processes.

From www.silcotek.com

Chemical Vapor Deposition Explained. Its Benefits and Drawbacks Coating Deposition Processes Starting material preparation and deposition process parameters work in concert to influence the optical and physical (mechanical). The most crucial processes, however, involve deposition because they deal with the chemistry of materials and the alloying of compositional. Deposition and growth of thin film s of these materials to build optical coatings is accomplished by one of the many variations of.. Coating Deposition Processes.

From www.mdpi.com

Coatings Free FullText Sputtering Physical Vapour Deposition (PVD Coating Deposition Processes In order to obtain thin films with good quality, there are two common deposition techniques: Starting material preparation and deposition process parameters work in concert to influence the optical and physical (mechanical). It can be summarized as shown in table. Deposition and growth of thin film s of these materials to build optical coatings is accomplished by one of the. Coating Deposition Processes.

From www.horiba.com

Semiconductor Processing Deposition Coating Deposition Processes Cvd and related processes are employed in many thin film applications, including dielectrics, conductors, passivation layers, oxidation. In order to obtain thin films with good quality, there are two common deposition techniques: The most crucial processes, however, involve deposition because they deal with the chemistry of materials and the alloying of compositional. It can be summarized as shown in table.. Coating Deposition Processes.

From www.researchgate.net

Schematic of the process of coating deposition and consolidation Coating Deposition Processes The most crucial processes, however, involve deposition because they deal with the chemistry of materials and the alloying of compositional. It can be summarized as shown in table. Cvd and related processes are employed in many thin film applications, including dielectrics, conductors, passivation layers, oxidation. Vacuum web coating processes employ a number of deposition technologies and hybrid processes, most recently. Coating Deposition Processes.

From www.hpetch.se

The 3 Steps of the Parylene Coating Process ParaTechCoating Coating Deposition Processes The most crucial processes, however, involve deposition because they deal with the chemistry of materials and the alloying of compositional. Starting material preparation and deposition process parameters work in concert to influence the optical and physical (mechanical). Vacuum web coating processes employ a number of deposition technologies and hybrid processes, most recently vacuum. In order to obtain thin films with. Coating Deposition Processes.

From www.mdpi.com

Coatings Free FullText Deposition Mechanism and Thickness Control Coating Deposition Processes It can be summarized as shown in table. Starting material preparation and deposition process parameters work in concert to influence the optical and physical (mechanical). In order to obtain thin films with good quality, there are two common deposition techniques: Cvd and related processes are employed in many thin film applications, including dielectrics, conductors, passivation layers, oxidation. Vacuum web coating. Coating Deposition Processes.

From www.researchgate.net

Schematic diagram of the coating deposition experiment. Download Coating Deposition Processes The most crucial processes, however, involve deposition because they deal with the chemistry of materials and the alloying of compositional. Cvd and related processes are employed in many thin film applications, including dielectrics, conductors, passivation layers, oxidation. Deposition and growth of thin film s of these materials to build optical coatings is accomplished by one of the many variations of.. Coating Deposition Processes.

From vaccoat.com

Chemical Vapor Deposition (CVD) Deposition Method VacCoat Coating Deposition Processes In order to obtain thin films with good quality, there are two common deposition techniques: Deposition and growth of thin film s of these materials to build optical coatings is accomplished by one of the many variations of. It can be summarized as shown in table. Cvd and related processes are employed in many thin film applications, including dielectrics, conductors,. Coating Deposition Processes.

From www.northeastcoating.com

Find Out About Diamond Like Carbon & The DLC Process Coating Deposition Processes Deposition and growth of thin film s of these materials to build optical coatings is accomplished by one of the many variations of. The most crucial processes, however, involve deposition because they deal with the chemistry of materials and the alloying of compositional. Vacuum web coating processes employ a number of deposition technologies and hybrid processes, most recently vacuum. Cvd. Coating Deposition Processes.

From www.researchgate.net

Schematic representation of the main coating deposition methods (a Coating Deposition Processes Starting material preparation and deposition process parameters work in concert to influence the optical and physical (mechanical). Deposition and growth of thin film s of these materials to build optical coatings is accomplished by one of the many variations of. Vacuum web coating processes employ a number of deposition technologies and hybrid processes, most recently vacuum. The most crucial processes,. Coating Deposition Processes.

From www.researchgate.net

7 Schematic illustration of physical vapor deposition (PVD) process Coating Deposition Processes Cvd and related processes are employed in many thin film applications, including dielectrics, conductors, passivation layers, oxidation. Deposition and growth of thin film s of these materials to build optical coatings is accomplished by one of the many variations of. Vacuum web coating processes employ a number of deposition technologies and hybrid processes, most recently vacuum. Starting material preparation and. Coating Deposition Processes.

From www.researchgate.net

Broad classification of coating processing methods. Download Coating Deposition Processes Deposition and growth of thin film s of these materials to build optical coatings is accomplished by one of the many variations of. It can be summarized as shown in table. Cvd and related processes are employed in many thin film applications, including dielectrics, conductors, passivation layers, oxidation. Starting material preparation and deposition process parameters work in concert to influence. Coating Deposition Processes.

From www.findlight.net

AR Coating Techniques Thin Film Deposition Methods Coating Deposition Processes In order to obtain thin films with good quality, there are two common deposition techniques: Cvd and related processes are employed in many thin film applications, including dielectrics, conductors, passivation layers, oxidation. Starting material preparation and deposition process parameters work in concert to influence the optical and physical (mechanical). The most crucial processes, however, involve deposition because they deal with. Coating Deposition Processes.

From www.mdpi.com

Coatings Free FullText A Review on Sustainable Manufacturing of Coating Deposition Processes Deposition and growth of thin film s of these materials to build optical coatings is accomplished by one of the many variations of. Vacuum web coating processes employ a number of deposition technologies and hybrid processes, most recently vacuum. It can be summarized as shown in table. Starting material preparation and deposition process parameters work in concert to influence the. Coating Deposition Processes.

From korvustech.com

What is PVD Coating Physical Vapour Deposition explained Coating Deposition Processes Deposition and growth of thin film s of these materials to build optical coatings is accomplished by one of the many variations of. It can be summarized as shown in table. Vacuum web coating processes employ a number of deposition technologies and hybrid processes, most recently vacuum. Cvd and related processes are employed in many thin film applications, including dielectrics,. Coating Deposition Processes.

From www.mdpi.com

Coatings Free FullText A Review on Sustainable Manufacturing of Coating Deposition Processes Vacuum web coating processes employ a number of deposition technologies and hybrid processes, most recently vacuum. Deposition and growth of thin film s of these materials to build optical coatings is accomplished by one of the many variations of. In order to obtain thin films with good quality, there are two common deposition techniques: It can be summarized as shown. Coating Deposition Processes.

From instrumentationtools.com

What is Chemical Vapor Deposition? The Ultimate Guide Coating Deposition Processes The most crucial processes, however, involve deposition because they deal with the chemistry of materials and the alloying of compositional. Vacuum web coating processes employ a number of deposition technologies and hybrid processes, most recently vacuum. Cvd and related processes are employed in many thin film applications, including dielectrics, conductors, passivation layers, oxidation. It can be summarized as shown in. Coating Deposition Processes.

From www.northeastcoating.com

Find Out About Diamond Like Carbon & The DLC Process Coating Deposition Processes The most crucial processes, however, involve deposition because they deal with the chemistry of materials and the alloying of compositional. Cvd and related processes are employed in many thin film applications, including dielectrics, conductors, passivation layers, oxidation. Starting material preparation and deposition process parameters work in concert to influence the optical and physical (mechanical). In order to obtain thin films. Coating Deposition Processes.

From scscoatings.com

Parylene Deposition Process Specialty Coating Systems Coating Deposition Processes Cvd and related processes are employed in many thin film applications, including dielectrics, conductors, passivation layers, oxidation. Starting material preparation and deposition process parameters work in concert to influence the optical and physical (mechanical). The most crucial processes, however, involve deposition because they deal with the chemistry of materials and the alloying of compositional. Vacuum web coating processes employ a. Coating Deposition Processes.

From www.researchgate.net

Schematic of electrophoretic deposition process for coating polyaniline Coating Deposition Processes Vacuum web coating processes employ a number of deposition technologies and hybrid processes, most recently vacuum. In order to obtain thin films with good quality, there are two common deposition techniques: It can be summarized as shown in table. Deposition and growth of thin film s of these materials to build optical coatings is accomplished by one of the many. Coating Deposition Processes.

From www.researchgate.net

Technological parameters of coating deposition processes. Download Coating Deposition Processes In order to obtain thin films with good quality, there are two common deposition techniques: It can be summarized as shown in table. Deposition and growth of thin film s of these materials to build optical coatings is accomplished by one of the many variations of. The most crucial processes, however, involve deposition because they deal with the chemistry of. Coating Deposition Processes.

From www.researchgate.net

A schematic illustration of physical vapor deposition (PVD) process for Coating Deposition Processes Cvd and related processes are employed in many thin film applications, including dielectrics, conductors, passivation layers, oxidation. Deposition and growth of thin film s of these materials to build optical coatings is accomplished by one of the many variations of. The most crucial processes, however, involve deposition because they deal with the chemistry of materials and the alloying of compositional.. Coating Deposition Processes.

From www.researchgate.net

Illustrations of the (a) onestep and (b) twostep spincoating Coating Deposition Processes In order to obtain thin films with good quality, there are two common deposition techniques: Cvd and related processes are employed in many thin film applications, including dielectrics, conductors, passivation layers, oxidation. Deposition and growth of thin film s of these materials to build optical coatings is accomplished by one of the many variations of. Starting material preparation and deposition. Coating Deposition Processes.

From www.slideserve.com

PPT The Deposition Process PowerPoint Presentation, free download Coating Deposition Processes Vacuum web coating processes employ a number of deposition technologies and hybrid processes, most recently vacuum. Deposition and growth of thin film s of these materials to build optical coatings is accomplished by one of the many variations of. It can be summarized as shown in table. Cvd and related processes are employed in many thin film applications, including dielectrics,. Coating Deposition Processes.

From www.researchgate.net

Schematic diagrams of the selective deposition process of the CVD Coating Deposition Processes It can be summarized as shown in table. In order to obtain thin films with good quality, there are two common deposition techniques: Starting material preparation and deposition process parameters work in concert to influence the optical and physical (mechanical). Cvd and related processes are employed in many thin film applications, including dielectrics, conductors, passivation layers, oxidation. Deposition and growth. Coating Deposition Processes.