C Control Chart Example . Accordingly, these charts come into play when the number of samples in each sampling period is essentially. a c chart is a type of control chart that shows how many defects or nonconformities are in samples of constant size, taken. It shows the quantity and variation of the statistical process control chart (spc chart), as well as the current capabilities of the process. This helps us keep track of the process variation over time. To use a c control chart, the opportunity for defects to occur. Quality engineers at a manufacturing plant monitor part lengths. Unlike variable charts, only one chart is plotted for attributes. this month’s publication looked at how to use a c control chart. In other words, the data that counts the number of defective items or the number of defects per unit. For example number of tubes failed on a shop floor. control charts are used to monitor and detect process variations over time. The c chart measures the number of nonconformities per unit and is denoted. attribute control charts are used for attribute data.

from www.template.net

Accordingly, these charts come into play when the number of samples in each sampling period is essentially. The c chart measures the number of nonconformities per unit and is denoted. To use a c control chart, the opportunity for defects to occur. In other words, the data that counts the number of defective items or the number of defects per unit. Unlike variable charts, only one chart is plotted for attributes. a c chart is a type of control chart that shows how many defects or nonconformities are in samples of constant size, taken. For example number of tubes failed on a shop floor. attribute control charts are used for attribute data. Quality engineers at a manufacturing plant monitor part lengths. control charts are used to monitor and detect process variations over time.

Control Chart Template 12 Free Excel Documents Download

C Control Chart Example This helps us keep track of the process variation over time. It shows the quantity and variation of the statistical process control chart (spc chart), as well as the current capabilities of the process. Quality engineers at a manufacturing plant monitor part lengths. Unlike variable charts, only one chart is plotted for attributes. Accordingly, these charts come into play when the number of samples in each sampling period is essentially. this month’s publication looked at how to use a c control chart. For example number of tubes failed on a shop floor. The c chart measures the number of nonconformities per unit and is denoted. In other words, the data that counts the number of defective items or the number of defects per unit. To use a c control chart, the opportunity for defects to occur. control charts are used to monitor and detect process variations over time. attribute control charts are used for attribute data. a c chart is a type of control chart that shows how many defects or nonconformities are in samples of constant size, taken. This helps us keep track of the process variation over time.

From www.hopkinsacg.org

Using Control Charts to Measure Performance Johns Hopkins ACG® System C Control Chart Example Quality engineers at a manufacturing plant monitor part lengths. control charts are used to monitor and detect process variations over time. To use a c control chart, the opportunity for defects to occur. The c chart measures the number of nonconformities per unit and is denoted. this month’s publication looked at how to use a c control chart.. C Control Chart Example.

From www.edrawmax.com

Control Chart 101 Definition, Purpose and How to EdrawMax Online C Control Chart Example Accordingly, these charts come into play when the number of samples in each sampling period is essentially. It shows the quantity and variation of the statistical process control chart (spc chart), as well as the current capabilities of the process. attribute control charts are used for attribute data. The c chart measures the number of nonconformities per unit and. C Control Chart Example.

From www.lucidchart.com

Control Chart A Key Tool for Ensuring Quality and Minimizing Variation C Control Chart Example Unlike variable charts, only one chart is plotted for attributes. Quality engineers at a manufacturing plant monitor part lengths. The c chart measures the number of nonconformities per unit and is denoted. Accordingly, these charts come into play when the number of samples in each sampling period is essentially. this month’s publication looked at how to use a c. C Control Chart Example.

From dxoxsonxe.blob.core.windows.net

How To Make Process Control Chart In Excel at Jason Troutman blog C Control Chart Example For example number of tubes failed on a shop floor. This helps us keep track of the process variation over time. Accordingly, these charts come into play when the number of samples in each sampling period is essentially. It shows the quantity and variation of the statistical process control chart (spc chart), as well as the current capabilities of the. C Control Chart Example.

From www.template.net

Control Chart Template 12 Free Excel Documents Download C Control Chart Example This helps us keep track of the process variation over time. In other words, the data that counts the number of defective items or the number of defects per unit. control charts are used to monitor and detect process variations over time. It shows the quantity and variation of the statistical process control chart (spc chart), as well as. C Control Chart Example.

From learn.lifeqisystem.com

C Chart C Control Chart Example a c chart is a type of control chart that shows how many defects or nonconformities are in samples of constant size, taken. The c chart measures the number of nonconformities per unit and is denoted. control charts are used to monitor and detect process variations over time. For example number of tubes failed on a shop floor.. C Control Chart Example.

From datascienceplus.com

Implementation and Interpretation of Control Charts in R DataScience+ C Control Chart Example For example number of tubes failed on a shop floor. attribute control charts are used for attribute data. Accordingly, these charts come into play when the number of samples in each sampling period is essentially. To use a c control chart, the opportunity for defects to occur. In other words, the data that counts the number of defective items. C Control Chart Example.

From dxoxsonxe.blob.core.windows.net

How To Make Process Control Chart In Excel at Jason Troutman blog C Control Chart Example Quality engineers at a manufacturing plant monitor part lengths. In other words, the data that counts the number of defective items or the number of defects per unit. attribute control charts are used for attribute data. For example number of tubes failed on a shop floor. control charts are used to monitor and detect process variations over time.. C Control Chart Example.

From www.edrawmax.com

Control Chart 101 Definition, Purpose and How to EdrawMax Online C Control Chart Example a c chart is a type of control chart that shows how many defects or nonconformities are in samples of constant size, taken. For example number of tubes failed on a shop floor. The c chart measures the number of nonconformities per unit and is denoted. It shows the quantity and variation of the statistical process control chart (spc. C Control Chart Example.

From christiangould.ca

Statistical Process Control (SPC) Christian Gould C Control Chart Example Quality engineers at a manufacturing plant monitor part lengths. Unlike variable charts, only one chart is plotted for attributes. control charts are used to monitor and detect process variations over time. To use a c control chart, the opportunity for defects to occur. In other words, the data that counts the number of defective items or the number of. C Control Chart Example.

From www.youtube.com

C CHART C bar control chart in statistical process control (SPC C Control Chart Example In other words, the data that counts the number of defective items or the number of defects per unit. It shows the quantity and variation of the statistical process control chart (spc chart), as well as the current capabilities of the process. control charts are used to monitor and detect process variations over time. attribute control charts are. C Control Chart Example.

From leanscape.io

6 Sigma Control Chart Introduction Toolkit from Leanscape C Control Chart Example control charts are used to monitor and detect process variations over time. To use a c control chart, the opportunity for defects to occur. For example number of tubes failed on a shop floor. This helps us keep track of the process variation over time. attribute control charts are used for attribute data. The c chart measures the. C Control Chart Example.

From www.studypool.com

SOLUTION C control chart template 30 samples worksheet Studypool C Control Chart Example In other words, the data that counts the number of defective items or the number of defects per unit. attribute control charts are used for attribute data. This helps us keep track of the process variation over time. For example number of tubes failed on a shop floor. Accordingly, these charts come into play when the number of samples. C Control Chart Example.

From www.wallstreetmojo.com

Control Chart What It Is, Types, Examples, Uses, Vs Run Chart C Control Chart Example For example number of tubes failed on a shop floor. Quality engineers at a manufacturing plant monitor part lengths. To use a c control chart, the opportunity for defects to occur. Unlike variable charts, only one chart is plotted for attributes. The c chart measures the number of nonconformities per unit and is denoted. attribute control charts are used. C Control Chart Example.

From www.sampletemplatess.com

Process Control Chart Template SampleTemplatess SampleTemplatess C Control Chart Example a c chart is a type of control chart that shows how many defects or nonconformities are in samples of constant size, taken. It shows the quantity and variation of the statistical process control chart (spc chart), as well as the current capabilities of the process. For example number of tubes failed on a shop floor. To use a. C Control Chart Example.

From tabitomo.info

Control Chart Analysis Tabitomo C Control Chart Example Unlike variable charts, only one chart is plotted for attributes. In other words, the data that counts the number of defective items or the number of defects per unit. Accordingly, these charts come into play when the number of samples in each sampling period is essentially. For example number of tubes failed on a shop floor. attribute control charts. C Control Chart Example.

From www.slideserve.com

PPT Chapter 6 PowerPoint Presentation, free download ID3375440 C Control Chart Example attribute control charts are used for attribute data. Unlike variable charts, only one chart is plotted for attributes. a c chart is a type of control chart that shows how many defects or nonconformities are in samples of constant size, taken. In other words, the data that counts the number of defective items or the number of defects. C Control Chart Example.

From www.lucidchart.com

Control Chart A Key Tool for Ensuring Quality and Minimizing Variation C Control Chart Example a c chart is a type of control chart that shows how many defects or nonconformities are in samples of constant size, taken. control charts are used to monitor and detect process variations over time. In other words, the data that counts the number of defective items or the number of defects per unit. this month’s publication. C Control Chart Example.

From www.edrawmax.com

Control Chart 101 Definition, Purpose and How to EdrawMax Online C Control Chart Example This helps us keep track of the process variation over time. this month’s publication looked at how to use a c control chart. Quality engineers at a manufacturing plant monitor part lengths. The c chart measures the number of nonconformities per unit and is denoted. a c chart is a type of control chart that shows how many. C Control Chart Example.

From www.slideserve.com

PPT Control Charts PowerPoint Presentation, free download ID996623 C Control Chart Example attribute control charts are used for attribute data. To use a c control chart, the opportunity for defects to occur. In other words, the data that counts the number of defective items or the number of defects per unit. Accordingly, these charts come into play when the number of samples in each sampling period is essentially. Quality engineers at. C Control Chart Example.

From deming.org

A Beginner's Guide to Control Charts The W. Edwards Deming Institute C Control Chart Example a c chart is a type of control chart that shows how many defects or nonconformities are in samples of constant size, taken. Quality engineers at a manufacturing plant monitor part lengths. The c chart measures the number of nonconformities per unit and is denoted. Accordingly, these charts come into play when the number of samples in each sampling. C Control Chart Example.

From mungfali.com

Control Chart Types C Control Chart Example Unlike variable charts, only one chart is plotted for attributes. To use a c control chart, the opportunity for defects to occur. attribute control charts are used for attribute data. Accordingly, these charts come into play when the number of samples in each sampling period is essentially. For example number of tubes failed on a shop floor. The c. C Control Chart Example.

From www.template.net

Control Chart Template 12 Free Excel Documents Download C Control Chart Example Accordingly, these charts come into play when the number of samples in each sampling period is essentially. this month’s publication looked at how to use a c control chart. Unlike variable charts, only one chart is plotted for attributes. control charts are used to monitor and detect process variations over time. It shows the quantity and variation of. C Control Chart Example.

From r-bar.net

Control Chart Constants Tables and Brief Explanation RBAR C Control Chart Example Unlike variable charts, only one chart is plotted for attributes. To use a c control chart, the opportunity for defects to occur. The c chart measures the number of nonconformities per unit and is denoted. Accordingly, these charts come into play when the number of samples in each sampling period is essentially. Quality engineers at a manufacturing plant monitor part. C Control Chart Example.

From templates.rjuuc.edu.np

Control Chart Template C Control Chart Example Accordingly, these charts come into play when the number of samples in each sampling period is essentially. In other words, the data that counts the number of defective items or the number of defects per unit. a c chart is a type of control chart that shows how many defects or nonconformities are in samples of constant size, taken.. C Control Chart Example.

From animalia-life.club

Control Chart Excel Template C Control Chart Example To use a c control chart, the opportunity for defects to occur. attribute control charts are used for attribute data. In other words, the data that counts the number of defective items or the number of defects per unit. For example number of tubes failed on a shop floor. This helps us keep track of the process variation over. C Control Chart Example.

From www.slideserve.com

PPT Process Control Charts PowerPoint Presentation, free download C Control Chart Example To use a c control chart, the opportunity for defects to occur. attribute control charts are used for attribute data. a c chart is a type of control chart that shows how many defects or nonconformities are in samples of constant size, taken. Quality engineers at a manufacturing plant monitor part lengths. control charts are used to. C Control Chart Example.

From towardsdatascience.com

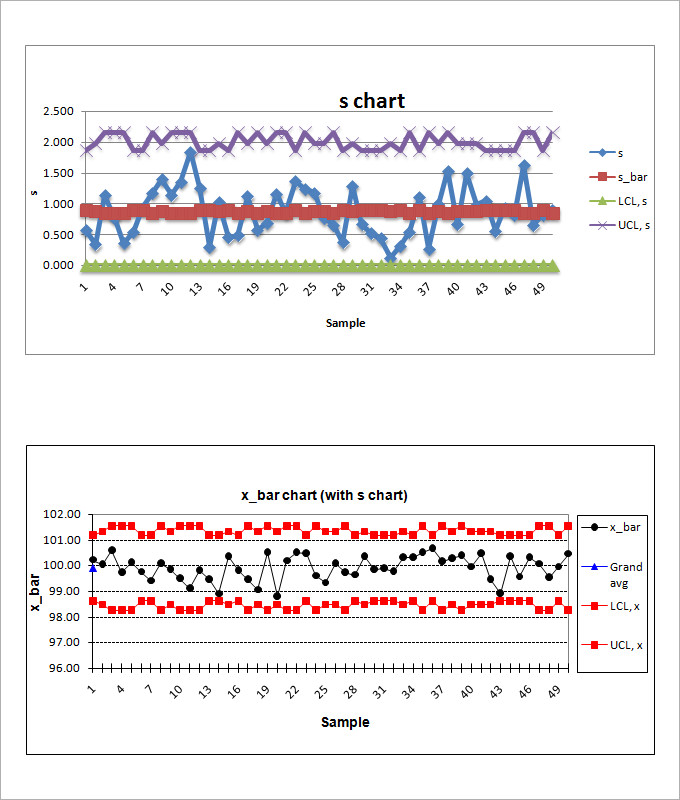

Quality Control Charts xbar chart, schart and Process Capability C Control Chart Example To use a c control chart, the opportunity for defects to occur. In other words, the data that counts the number of defective items or the number of defects per unit. The c chart measures the number of nonconformities per unit and is denoted. this month’s publication looked at how to use a c control chart. attribute control. C Control Chart Example.

From www.examples.com

Control Chart 6+ Examples, Format, How to Make, Pdf C Control Chart Example For example number of tubes failed on a shop floor. Accordingly, these charts come into play when the number of samples in each sampling period is essentially. control charts are used to monitor and detect process variations over time. attribute control charts are used for attribute data. this month’s publication looked at how to use a c. C Control Chart Example.

From www.slideserve.com

PPT Chapter 6 Statistical Quality Control (SQC) PowerPoint C Control Chart Example Accordingly, these charts come into play when the number of samples in each sampling period is essentially. a c chart is a type of control chart that shows how many defects or nonconformities are in samples of constant size, taken. this month’s publication looked at how to use a c control chart. control charts are used to. C Control Chart Example.

From www.youtube.com

Control chart, C chart, U chart difference of C chart & U chart C Control Chart Example To use a c control chart, the opportunity for defects to occur. this month’s publication looked at how to use a c control chart. Quality engineers at a manufacturing plant monitor part lengths. This helps us keep track of the process variation over time. For example number of tubes failed on a shop floor. Accordingly, these charts come into. C Control Chart Example.

From www.examples.com

Chart 25+ Examples, Format, How to Use, Pdf C Control Chart Example this month’s publication looked at how to use a c control chart. In other words, the data that counts the number of defective items or the number of defects per unit. This helps us keep track of the process variation over time. Accordingly, these charts come into play when the number of samples in each sampling period is essentially.. C Control Chart Example.

From www.sixsigmatrainingfree.com

Statistical Process Control Charts Process Variation Measurement and C Control Chart Example a c chart is a type of control chart that shows how many defects or nonconformities are in samples of constant size, taken. This helps us keep track of the process variation over time. Quality engineers at a manufacturing plant monitor part lengths. this month’s publication looked at how to use a c control chart. attribute control. C Control Chart Example.

From www.wallstreetmojo.com

Control Chart What It Is, Types, Examples, Uses, Vs Run Chart C Control Chart Example attribute control charts are used for attribute data. this month’s publication looked at how to use a c control chart. a c chart is a type of control chart that shows how many defects or nonconformities are in samples of constant size, taken. The c chart measures the number of nonconformities per unit and is denoted. . C Control Chart Example.

From www.educba.com

Control Charts in Excel How to Create Control Charts in Excel? C Control Chart Example Unlike variable charts, only one chart is plotted for attributes. this month’s publication looked at how to use a c control chart. The c chart measures the number of nonconformities per unit and is denoted. Quality engineers at a manufacturing plant monitor part lengths. attribute control charts are used for attribute data. Accordingly, these charts come into play. C Control Chart Example.