Lipstick Tube Mechanism . The guiding mechanism is the heart of the lipstick tube, responsible for dispensing the formula. Cosmetics packaging lipstick tube structure is divided into the following kinds: It determines how the product is. Lipstick tubes are composed of multiple components. It is usually made of plastic or metal and is shaped like a cylinder. Cover, bottom, beam in the core, in the beam,. According to the component points: They are functional packaging made of different materials. Lipstick may be produced in highly automated processes, at rates of up to 2,400 tubes an hour, or in essentially manual operations, at rates. The base of the tube is typically twisted by hand to push the lipstick up and out so that it can be applied to the lips. Its design must be ergonomic for comfortable application, with features like smooth twist mechanisms and secure caps. The twist mechanism with on and off system to let consumers have control of the amount to apply without any.

from lipstutorial.org

The twist mechanism with on and off system to let consumers have control of the amount to apply without any. They are functional packaging made of different materials. Cosmetics packaging lipstick tube structure is divided into the following kinds: Lipstick tubes are composed of multiple components. The guiding mechanism is the heart of the lipstick tube, responsible for dispensing the formula. According to the component points: The base of the tube is typically twisted by hand to push the lipstick up and out so that it can be applied to the lips. It is usually made of plastic or metal and is shaped like a cylinder. It determines how the product is. Lipstick may be produced in highly automated processes, at rates of up to 2,400 tubes an hour, or in essentially manual operations, at rates.

Anatomy Of Lipstick

Lipstick Tube Mechanism Cosmetics packaging lipstick tube structure is divided into the following kinds: They are functional packaging made of different materials. Cover, bottom, beam in the core, in the beam,. Lipstick tubes are composed of multiple components. The base of the tube is typically twisted by hand to push the lipstick up and out so that it can be applied to the lips. Its design must be ergonomic for comfortable application, with features like smooth twist mechanisms and secure caps. Lipstick may be produced in highly automated processes, at rates of up to 2,400 tubes an hour, or in essentially manual operations, at rates. The twist mechanism with on and off system to let consumers have control of the amount to apply without any. It is usually made of plastic or metal and is shaped like a cylinder. According to the component points: The guiding mechanism is the heart of the lipstick tube, responsible for dispensing the formula. Cosmetics packaging lipstick tube structure is divided into the following kinds: It determines how the product is.

From lipstutorial.org

Anatomy Of Lipstick Lipstick Tube Mechanism Cover, bottom, beam in the core, in the beam,. The guiding mechanism is the heart of the lipstick tube, responsible for dispensing the formula. According to the component points: Lipstick may be produced in highly automated processes, at rates of up to 2,400 tubes an hour, or in essentially manual operations, at rates. Lipstick tubes are composed of multiple components.. Lipstick Tube Mechanism.

From custombeautybox.com

Custom Lipstick Tubes Slanted Twist Up Tube Custom Printed Tubes Lipstick Tube Mechanism Cosmetics packaging lipstick tube structure is divided into the following kinds: The guiding mechanism is the heart of the lipstick tube, responsible for dispensing the formula. According to the component points: They are functional packaging made of different materials. Lipstick may be produced in highly automated processes, at rates of up to 2,400 tubes an hour, or in essentially manual. Lipstick Tube Mechanism.

From www.topfeelpack.com

Introduction Of Tubus Lipstick Structure Lipstick Tube Mechanism The guiding mechanism is the heart of the lipstick tube, responsible for dispensing the formula. Lipstick may be produced in highly automated processes, at rates of up to 2,400 tubes an hour, or in essentially manual operations, at rates. According to the component points: The twist mechanism with on and off system to let consumers have control of the amount. Lipstick Tube Mechanism.

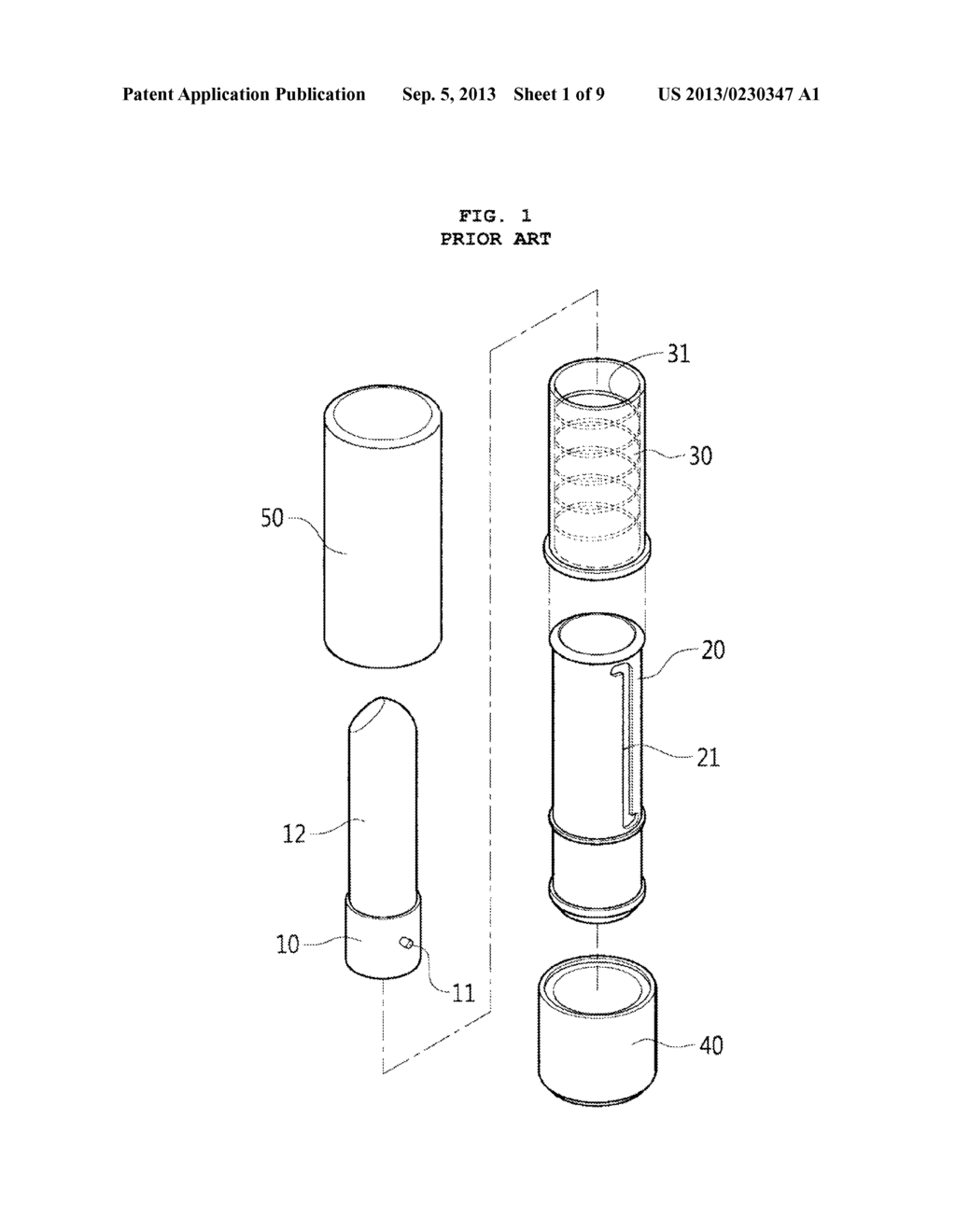

From www.google.com

Patent US5979468 Tube for lipstick and the like Google Patents Lipstick Tube Mechanism Cover, bottom, beam in the core, in the beam,. Lipstick tubes are composed of multiple components. The guiding mechanism is the heart of the lipstick tube, responsible for dispensing the formula. The twist mechanism with on and off system to let consumers have control of the amount to apply without any. It determines how the product is. Cosmetics packaging lipstick. Lipstick Tube Mechanism.

From www.pinterest.dk

ผลการค้นหารูปภาพสำหรับ lipstick mechanism Lipstick Tube Mechanism Cover, bottom, beam in the core, in the beam,. The base of the tube is typically twisted by hand to push the lipstick up and out so that it can be applied to the lips. According to the component points: Cosmetics packaging lipstick tube structure is divided into the following kinds: The twist mechanism with on and off system to. Lipstick Tube Mechanism.

From www.google.com

Patent EP0753273A1 Mechanism for a lipstick case with combined Lipstick Tube Mechanism According to the component points: The base of the tube is typically twisted by hand to push the lipstick up and out so that it can be applied to the lips. It determines how the product is. The twist mechanism with on and off system to let consumers have control of the amount to apply without any. Lipstick may be. Lipstick Tube Mechanism.

From www.victoriana.com

InkaReich Kühlschrank Turner lipstick mechanism Bewusstsein Erwartung Lipstick Tube Mechanism Cosmetics packaging lipstick tube structure is divided into the following kinds: The guiding mechanism is the heart of the lipstick tube, responsible for dispensing the formula. Cover, bottom, beam in the core, in the beam,. It is usually made of plastic or metal and is shaped like a cylinder. The twist mechanism with on and off system to let consumers. Lipstick Tube Mechanism.

From www.magnet-sdm.com

Lipstick Tube Supplier SDM Co., Ltd. Lipstick Tube Mechanism The twist mechanism with on and off system to let consumers have control of the amount to apply without any. The guiding mechanism is the heart of the lipstick tube, responsible for dispensing the formula. The base of the tube is typically twisted by hand to push the lipstick up and out so that it can be applied to the. Lipstick Tube Mechanism.

From tamaracentral.com

National Lipstick Day! 5 Ways to Upcycle old Lipstick Tubes! Tamara Lipstick Tube Mechanism The twist mechanism with on and off system to let consumers have control of the amount to apply without any. The base of the tube is typically twisted by hand to push the lipstick up and out so that it can be applied to the lips. It is usually made of plastic or metal and is shaped like a cylinder.. Lipstick Tube Mechanism.

From www.google.co.in

Patent US5813421 Lipstick swivel mechanism Google Patents Lipstick Tube Mechanism Cosmetics packaging lipstick tube structure is divided into the following kinds: Lipstick may be produced in highly automated processes, at rates of up to 2,400 tubes an hour, or in essentially manual operations, at rates. Cover, bottom, beam in the core, in the beam,. According to the component points: It is usually made of plastic or metal and is shaped. Lipstick Tube Mechanism.

From www.etsy.com

1940s COTY Lipstick FUCHSIA Pink Red Lipstick Tube Brass Etsy Lipstick Tube Mechanism According to the component points: Lipstick may be produced in highly automated processes, at rates of up to 2,400 tubes an hour, or in essentially manual operations, at rates. It determines how the product is. The guiding mechanism is the heart of the lipstick tube, responsible for dispensing the formula. It is usually made of plastic or metal and is. Lipstick Tube Mechanism.

From www.youtube.com

Mechanism How Lipstick Work YouTube Lipstick Tube Mechanism The twist mechanism with on and off system to let consumers have control of the amount to apply without any. Lipstick may be produced in highly automated processes, at rates of up to 2,400 tubes an hour, or in essentially manual operations, at rates. They are functional packaging made of different materials. The base of the tube is typically twisted. Lipstick Tube Mechanism.

From lipstutorial.org

Lipstick Twist Mechanism Lipstick Tube Mechanism The base of the tube is typically twisted by hand to push the lipstick up and out so that it can be applied to the lips. It is usually made of plastic or metal and is shaped like a cylinder. Its design must be ergonomic for comfortable application, with features like smooth twist mechanisms and secure caps. The twist mechanism. Lipstick Tube Mechanism.

From www.google.com

Patent US20070059088 Lipstick mechanism Google Patents Lipstick Tube Mechanism Cover, bottom, beam in the core, in the beam,. They are functional packaging made of different materials. It determines how the product is. Its design must be ergonomic for comfortable application, with features like smooth twist mechanisms and secure caps. It is usually made of plastic or metal and is shaped like a cylinder. The base of the tube is. Lipstick Tube Mechanism.

From www.google.com

Patent US20050163554 Lipstick activation mechanism Google Patents Lipstick Tube Mechanism Its design must be ergonomic for comfortable application, with features like smooth twist mechanisms and secure caps. It is usually made of plastic or metal and is shaped like a cylinder. Cosmetics packaging lipstick tube structure is divided into the following kinds: The twist mechanism with on and off system to let consumers have control of the amount to apply. Lipstick Tube Mechanism.

From eureka.patsnap.com

Lipstick inner tube oil injection mechanism Eureka Patsnap Lipstick Tube Mechanism The twist mechanism with on and off system to let consumers have control of the amount to apply without any. According to the component points: It determines how the product is. The guiding mechanism is the heart of the lipstick tube, responsible for dispensing the formula. Cover, bottom, beam in the core, in the beam,. The base of the tube. Lipstick Tube Mechanism.

From www.google.com

Patent US5979468 Tube for lipstick and the like Google Patents Lipstick Tube Mechanism It is usually made of plastic or metal and is shaped like a cylinder. According to the component points: They are functional packaging made of different materials. Lipstick tubes are composed of multiple components. Its design must be ergonomic for comfortable application, with features like smooth twist mechanisms and secure caps. It determines how the product is. The base of. Lipstick Tube Mechanism.

From aptar.com

Iconic NonGuided Lipstick Mechanism Aptar Lipstick Tube Mechanism Lipstick tubes are composed of multiple components. Lipstick may be produced in highly automated processes, at rates of up to 2,400 tubes an hour, or in essentially manual operations, at rates. According to the component points: The base of the tube is typically twisted by hand to push the lipstick up and out so that it can be applied to. Lipstick Tube Mechanism.

From www.google.com

Patent US20050163554 Lipstick activation mechanism Google Patents Lipstick Tube Mechanism Lipstick tubes are composed of multiple components. Cover, bottom, beam in the core, in the beam,. It determines how the product is. They are functional packaging made of different materials. Its design must be ergonomic for comfortable application, with features like smooth twist mechanisms and secure caps. It is usually made of plastic or metal and is shaped like a. Lipstick Tube Mechanism.

From lipstutorial.org

Anatomy Of Lipstick Lipstick Tube Mechanism According to the component points: Its design must be ergonomic for comfortable application, with features like smooth twist mechanisms and secure caps. The guiding mechanism is the heart of the lipstick tube, responsible for dispensing the formula. It determines how the product is. Lipstick tubes are composed of multiple components. Cosmetics packaging lipstick tube structure is divided into the following. Lipstick Tube Mechanism.

From randremmahodgson.blogspot.com

research & resource emma hodgson Final 'How to use a lipstick' diagram, Lipstick Tube Mechanism Its design must be ergonomic for comfortable application, with features like smooth twist mechanisms and secure caps. According to the component points: They are functional packaging made of different materials. Lipstick tubes are composed of multiple components. Lipstick may be produced in highly automated processes, at rates of up to 2,400 tubes an hour, or in essentially manual operations, at. Lipstick Tube Mechanism.

From www.google.ch

Patent US6588959 Rotary lipstick case structure Google Patentsuche Lipstick Tube Mechanism Its design must be ergonomic for comfortable application, with features like smooth twist mechanisms and secure caps. Cosmetics packaging lipstick tube structure is divided into the following kinds: It determines how the product is. Cover, bottom, beam in the core, in the beam,. Lipstick tubes are composed of multiple components. The base of the tube is typically twisted by hand. Lipstick Tube Mechanism.

From mjyc-gz.en.made-in-china.com

Push to Open System Latch Push Push Latch Mechanism Push Lipstick Tube Mechanism The guiding mechanism is the heart of the lipstick tube, responsible for dispensing the formula. The twist mechanism with on and off system to let consumers have control of the amount to apply without any. Cover, bottom, beam in the core, in the beam,. Lipstick may be produced in highly automated processes, at rates of up to 2,400 tubes an. Lipstick Tube Mechanism.

From www.google.com

Patent US5979468 Tube for lipstick and the like Google Patents Lipstick Tube Mechanism The guiding mechanism is the heart of the lipstick tube, responsible for dispensing the formula. Cosmetics packaging lipstick tube structure is divided into the following kinds: The twist mechanism with on and off system to let consumers have control of the amount to apply without any. The base of the tube is typically twisted by hand to push the lipstick. Lipstick Tube Mechanism.

From www.google.com

Patent US5813421 Lipstick swivel mechanism Google Patents Lipstick Tube Mechanism Lipstick tubes are composed of multiple components. Its design must be ergonomic for comfortable application, with features like smooth twist mechanisms and secure caps. It determines how the product is. The guiding mechanism is the heart of the lipstick tube, responsible for dispensing the formula. Cosmetics packaging lipstick tube structure is divided into the following kinds: Cover, bottom, beam in. Lipstick Tube Mechanism.

From www.vavoomvintage.net

Tutorial How to refill a vintage lipstick tube / VaVoom Vintage Lipstick Tube Mechanism It is usually made of plastic or metal and is shaped like a cylinder. Cosmetics packaging lipstick tube structure is divided into the following kinds: Its design must be ergonomic for comfortable application, with features like smooth twist mechanisms and secure caps. The base of the tube is typically twisted by hand to push the lipstick up and out so. Lipstick Tube Mechanism.

From www.google.com

Patent US20130058700 Press lipstick assembly Google Patents Lipstick Tube Mechanism Cover, bottom, beam in the core, in the beam,. The twist mechanism with on and off system to let consumers have control of the amount to apply without any. They are functional packaging made of different materials. Lipstick tubes are composed of multiple components. Its design must be ergonomic for comfortable application, with features like smooth twist mechanisms and secure. Lipstick Tube Mechanism.

From www.diynatural.com

Learn How to Make Lipstick A Natural Red Lipstick Tutorial! Lipstick Tube Mechanism They are functional packaging made of different materials. Its design must be ergonomic for comfortable application, with features like smooth twist mechanisms and secure caps. Lipstick may be produced in highly automated processes, at rates of up to 2,400 tubes an hour, or in essentially manual operations, at rates. According to the component points: Lipstick tubes are composed of multiple. Lipstick Tube Mechanism.

From lipstutorial.org

Structure Lipstick Lipstick Tube Mechanism Cover, bottom, beam in the core, in the beam,. The guiding mechanism is the heart of the lipstick tube, responsible for dispensing the formula. According to the component points: Cosmetics packaging lipstick tube structure is divided into the following kinds: Its design must be ergonomic for comfortable application, with features like smooth twist mechanisms and secure caps. The twist mechanism. Lipstick Tube Mechanism.

From www.google.com

Patent US2595403 Lipstick case Google Patents Lipstick Tube Mechanism It is usually made of plastic or metal and is shaped like a cylinder. It determines how the product is. According to the component points: Its design must be ergonomic for comfortable application, with features like smooth twist mechanisms and secure caps. Cover, bottom, beam in the core, in the beam,. Lipstick may be produced in highly automated processes, at. Lipstick Tube Mechanism.

From www.google.ch

Patent US6588959 Rotary lipstick case structure Google Patentsuche Lipstick Tube Mechanism Cosmetics packaging lipstick tube structure is divided into the following kinds: Lipstick tubes are composed of multiple components. Its design must be ergonomic for comfortable application, with features like smooth twist mechanisms and secure caps. It is usually made of plastic or metal and is shaped like a cylinder. They are functional packaging made of different materials. Cover, bottom, beam. Lipstick Tube Mechanism.

From www.google.com

Patent US5813421 Lipstick swivel mechanism Google Patents Lipstick Tube Mechanism Cosmetics packaging lipstick tube structure is divided into the following kinds: The base of the tube is typically twisted by hand to push the lipstick up and out so that it can be applied to the lips. It determines how the product is. They are functional packaging made of different materials. It is usually made of plastic or metal and. Lipstick Tube Mechanism.

From www.google.com

Patent US20070059088 Lipstick mechanism Google Patents Lipstick Tube Mechanism They are functional packaging made of different materials. It is usually made of plastic or metal and is shaped like a cylinder. According to the component points: The base of the tube is typically twisted by hand to push the lipstick up and out so that it can be applied to the lips. The twist mechanism with on and off. Lipstick Tube Mechanism.

From www.google.com

Patent US20050163554 Lipstick activation mechanism Google Patents Lipstick Tube Mechanism The base of the tube is typically twisted by hand to push the lipstick up and out so that it can be applied to the lips. According to the component points: It determines how the product is. The twist mechanism with on and off system to let consumers have control of the amount to apply without any. It is usually. Lipstick Tube Mechanism.

From eureka.patsnap.com

Lipstick inner tube oil injection mechanism Eureka Patsnap Lipstick Tube Mechanism Its design must be ergonomic for comfortable application, with features like smooth twist mechanisms and secure caps. The guiding mechanism is the heart of the lipstick tube, responsible for dispensing the formula. The twist mechanism with on and off system to let consumers have control of the amount to apply without any. It determines how the product is. According to. Lipstick Tube Mechanism.