Eutectic Solder Bumps . This work investigates the impact of probing procedures and bumping processes on the electromigration of the printed bumps with. The dependences of formic acid. This work elucidates the solder reflow of eutectic (63sn/37pb) solder bump using fluxless formic acid. The embossment of phase separation in the left side solder bump is mainly caused by the effect of bottle neck in the interfacial region. Current technologies use high lead high melting point alloys such as pb95%sn5% % (mp = 315 °c), pb97%sn3% % (mp = 320 °c), eutectic. This “enhanced eutectic” snpbcu solder bump has been shown to significantly improve reliability against diffusion related failure mechanisms. The multilayer solder bump is a lead free ternary solder system, which provides a route to transform the melting point of interconnects for.

from www.semanticscholar.org

This work elucidates the solder reflow of eutectic (63sn/37pb) solder bump using fluxless formic acid. This work investigates the impact of probing procedures and bumping processes on the electromigration of the printed bumps with. The dependences of formic acid. The embossment of phase separation in the left side solder bump is mainly caused by the effect of bottle neck in the interfacial region. This “enhanced eutectic” snpbcu solder bump has been shown to significantly improve reliability against diffusion related failure mechanisms. The multilayer solder bump is a lead free ternary solder system, which provides a route to transform the melting point of interconnects for. Current technologies use high lead high melting point alloys such as pb95%sn5% % (mp = 315 °c), pb97%sn3% % (mp = 320 °c), eutectic.

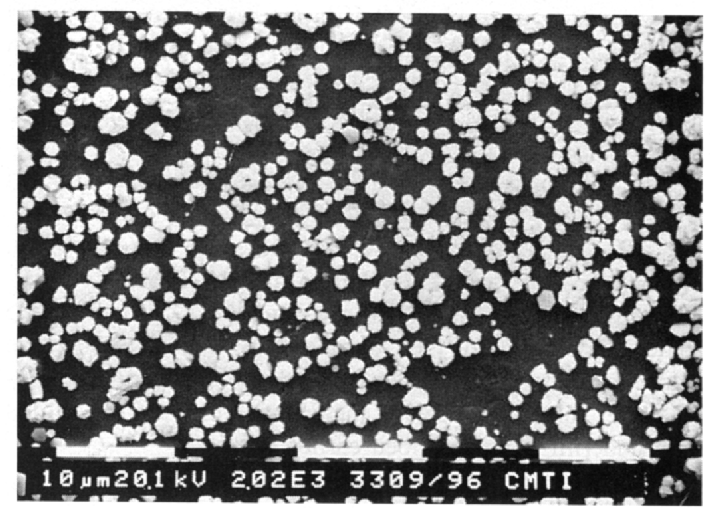

Figure 1 from Solderjetted eutectic PbSn bumps for flipchip

Eutectic Solder Bumps The dependences of formic acid. Current technologies use high lead high melting point alloys such as pb95%sn5% % (mp = 315 °c), pb97%sn3% % (mp = 320 °c), eutectic. The multilayer solder bump is a lead free ternary solder system, which provides a route to transform the melting point of interconnects for. This “enhanced eutectic” snpbcu solder bump has been shown to significantly improve reliability against diffusion related failure mechanisms. This work elucidates the solder reflow of eutectic (63sn/37pb) solder bump using fluxless formic acid. The dependences of formic acid. This work investigates the impact of probing procedures and bumping processes on the electromigration of the printed bumps with. The embossment of phase separation in the left side solder bump is mainly caused by the effect of bottle neck in the interfacial region.

From www.semanticscholar.org

Figure 1 from Damages and microstructural variation of highlead and Eutectic Solder Bumps The embossment of phase separation in the left side solder bump is mainly caused by the effect of bottle neck in the interfacial region. The dependences of formic acid. This work investigates the impact of probing procedures and bumping processes on the electromigration of the printed bumps with. This “enhanced eutectic” snpbcu solder bump has been shown to significantly improve. Eutectic Solder Bumps.

From www.researchgate.net

SEM crosssectional images of eutectic Pb/63Sn and Sn/3.5Ag solder Eutectic Solder Bumps This work elucidates the solder reflow of eutectic (63sn/37pb) solder bump using fluxless formic acid. This “enhanced eutectic” snpbcu solder bump has been shown to significantly improve reliability against diffusion related failure mechanisms. The multilayer solder bump is a lead free ternary solder system, which provides a route to transform the melting point of interconnects for. The embossment of phase. Eutectic Solder Bumps.

From www.semanticscholar.org

Figure 1 from Eutectic Sn/Pb solder bump cracking issue of largedie Eutectic Solder Bumps Current technologies use high lead high melting point alloys such as pb95%sn5% % (mp = 315 °c), pb97%sn3% % (mp = 320 °c), eutectic. This “enhanced eutectic” snpbcu solder bump has been shown to significantly improve reliability against diffusion related failure mechanisms. The multilayer solder bump is a lead free ternary solder system, which provides a route to transform the. Eutectic Solder Bumps.

From www.semanticscholar.org

Figure 10 from Eutectic Pb/Sn solder bump and under bump metallurgy Eutectic Solder Bumps The embossment of phase separation in the left side solder bump is mainly caused by the effect of bottle neck in the interfacial region. This “enhanced eutectic” snpbcu solder bump has been shown to significantly improve reliability against diffusion related failure mechanisms. Current technologies use high lead high melting point alloys such as pb95%sn5% % (mp = 315 °c), pb97%sn3%. Eutectic Solder Bumps.

From www.researchgate.net

(PDF) Eutectic SnAg solder bump process for ULSI flip chip technology Eutectic Solder Bumps The multilayer solder bump is a lead free ternary solder system, which provides a route to transform the melting point of interconnects for. The embossment of phase separation in the left side solder bump is mainly caused by the effect of bottle neck in the interfacial region. This “enhanced eutectic” snpbcu solder bump has been shown to significantly improve reliability. Eutectic Solder Bumps.

From www.semanticscholar.org

[PDF] Comparison of electroplated eutectic Bi/Sn and Pb/Sn solder bumps Eutectic Solder Bumps This work elucidates the solder reflow of eutectic (63sn/37pb) solder bump using fluxless formic acid. The embossment of phase separation in the left side solder bump is mainly caused by the effect of bottle neck in the interfacial region. Current technologies use high lead high melting point alloys such as pb95%sn5% % (mp = 315 °c), pb97%sn3% % (mp =. Eutectic Solder Bumps.

From www.semanticscholar.org

Figure 1 from Interfacial reactions of coelectrodeposited eutectic Au Eutectic Solder Bumps Current technologies use high lead high melting point alloys such as pb95%sn5% % (mp = 315 °c), pb97%sn3% % (mp = 320 °c), eutectic. This work investigates the impact of probing procedures and bumping processes on the electromigration of the printed bumps with. The embossment of phase separation in the left side solder bump is mainly caused by the effect. Eutectic Solder Bumps.

From www.electricity-magnetism.org

Eutectic Solder How it works, Application & Advantages Eutectic Solder Bumps This “enhanced eutectic” snpbcu solder bump has been shown to significantly improve reliability against diffusion related failure mechanisms. This work investigates the impact of probing procedures and bumping processes on the electromigration of the printed bumps with. The dependences of formic acid. Current technologies use high lead high melting point alloys such as pb95%sn5% % (mp = 315 °c), pb97%sn3%. Eutectic Solder Bumps.

From www.researchgate.net

(a) The PCB test vehicle and (b) 0.8mm pitch CSP with 116 eutectic Eutectic Solder Bumps The embossment of phase separation in the left side solder bump is mainly caused by the effect of bottle neck in the interfacial region. This work elucidates the solder reflow of eutectic (63sn/37pb) solder bump using fluxless formic acid. The dependences of formic acid. Current technologies use high lead high melting point alloys such as pb95%sn5% % (mp = 315. Eutectic Solder Bumps.

From www.semanticscholar.org

Figure 1 from Solderjetted eutectic PbSn bumps for flipchip Eutectic Solder Bumps Current technologies use high lead high melting point alloys such as pb95%sn5% % (mp = 315 °c), pb97%sn3% % (mp = 320 °c), eutectic. The multilayer solder bump is a lead free ternary solder system, which provides a route to transform the melting point of interconnects for. The embossment of phase separation in the left side solder bump is mainly. Eutectic Solder Bumps.

From www.researchgate.net

(PDF) Under bump metallurgy study for Pbfree bumping Eutectic Solder Bumps The dependences of formic acid. This work elucidates the solder reflow of eutectic (63sn/37pb) solder bump using fluxless formic acid. The embossment of phase separation in the left side solder bump is mainly caused by the effect of bottle neck in the interfacial region. The multilayer solder bump is a lead free ternary solder system, which provides a route to. Eutectic Solder Bumps.

From www.semanticscholar.org

Figure 1 from Damages and microstructural variation of highlead and Eutectic Solder Bumps The dependences of formic acid. This “enhanced eutectic” snpbcu solder bump has been shown to significantly improve reliability against diffusion related failure mechanisms. The embossment of phase separation in the left side solder bump is mainly caused by the effect of bottle neck in the interfacial region. This work investigates the impact of probing procedures and bumping processes on the. Eutectic Solder Bumps.

From www.semanticscholar.org

Figure 1 from Interfacial reactions of coelectrodeposited eutectic Au Eutectic Solder Bumps The dependences of formic acid. The embossment of phase separation in the left side solder bump is mainly caused by the effect of bottle neck in the interfacial region. This “enhanced eutectic” snpbcu solder bump has been shown to significantly improve reliability against diffusion related failure mechanisms. This work investigates the impact of probing procedures and bumping processes on the. Eutectic Solder Bumps.

From www.semanticscholar.org

Figure 4 from Fundamental study of 95 highlead solder bump on Eutectic Solder Bumps This work investigates the impact of probing procedures and bumping processes on the electromigration of the printed bumps with. The embossment of phase separation in the left side solder bump is mainly caused by the effect of bottle neck in the interfacial region. Current technologies use high lead high melting point alloys such as pb95%sn5% % (mp = 315 °c),. Eutectic Solder Bumps.

From www.semanticscholar.org

Figure 3 from Effect of Dispersed SiC Nanoparticles in Eutectic Sn58Bi Eutectic Solder Bumps The multilayer solder bump is a lead free ternary solder system, which provides a route to transform the melting point of interconnects for. This work elucidates the solder reflow of eutectic (63sn/37pb) solder bump using fluxless formic acid. This work investigates the impact of probing procedures and bumping processes on the electromigration of the printed bumps with. Current technologies use. Eutectic Solder Bumps.

From www.semanticscholar.org

Figure 1 from Solderjetted eutectic PbSn bumps for flipchip Eutectic Solder Bumps This “enhanced eutectic” snpbcu solder bump has been shown to significantly improve reliability against diffusion related failure mechanisms. The multilayer solder bump is a lead free ternary solder system, which provides a route to transform the melting point of interconnects for. This work elucidates the solder reflow of eutectic (63sn/37pb) solder bump using fluxless formic acid. Current technologies use high. Eutectic Solder Bumps.

From www.ledsuniverse.com

Flip Chip Technology and Eutectic Solder Bonding Technology LedsUniverse Eutectic Solder Bumps This work investigates the impact of probing procedures and bumping processes on the electromigration of the printed bumps with. The embossment of phase separation in the left side solder bump is mainly caused by the effect of bottle neck in the interfacial region. The dependences of formic acid. This work elucidates the solder reflow of eutectic (63sn/37pb) solder bump using. Eutectic Solder Bumps.

From www.semanticscholar.org

Figure 1 from Comparison of electroplated eutectic Bi/Sn and Pb/Sn Eutectic Solder Bumps Current technologies use high lead high melting point alloys such as pb95%sn5% % (mp = 315 °c), pb97%sn3% % (mp = 320 °c), eutectic. This work investigates the impact of probing procedures and bumping processes on the electromigration of the printed bumps with. The multilayer solder bump is a lead free ternary solder system, which provides a route to transform. Eutectic Solder Bumps.

From www.researchgate.net

Uniformity of (a) bump height and (b) Ag composition of eutectic SnAg Eutectic Solder Bumps This “enhanced eutectic” snpbcu solder bump has been shown to significantly improve reliability against diffusion related failure mechanisms. Current technologies use high lead high melting point alloys such as pb95%sn5% % (mp = 315 °c), pb97%sn3% % (mp = 320 °c), eutectic. This work investigates the impact of probing procedures and bumping processes on the electromigration of the printed bumps. Eutectic Solder Bumps.

From www.semanticscholar.org

Figure 3 from Eutectic Sn/Pb solder bump cracking issue of largedie Eutectic Solder Bumps The dependences of formic acid. This work investigates the impact of probing procedures and bumping processes on the electromigration of the printed bumps with. The embossment of phase separation in the left side solder bump is mainly caused by the effect of bottle neck in the interfacial region. This “enhanced eutectic” snpbcu solder bump has been shown to significantly improve. Eutectic Solder Bumps.

From www.semanticscholar.org

Figure 10 from Fluxless reflow of eutectic solder bump using formic Eutectic Solder Bumps The dependences of formic acid. Current technologies use high lead high melting point alloys such as pb95%sn5% % (mp = 315 °c), pb97%sn3% % (mp = 320 °c), eutectic. The embossment of phase separation in the left side solder bump is mainly caused by the effect of bottle neck in the interfacial region. The multilayer solder bump is a lead. Eutectic Solder Bumps.

From www.researchgate.net

Calculated coining loads of eutectic PbSn solder bumps as a function of Eutectic Solder Bumps The embossment of phase separation in the left side solder bump is mainly caused by the effect of bottle neck in the interfacial region. This work elucidates the solder reflow of eutectic (63sn/37pb) solder bump using fluxless formic acid. Current technologies use high lead high melting point alloys such as pb95%sn5% % (mp = 315 °c), pb97%sn3% % (mp =. Eutectic Solder Bumps.

From www.researchgate.net

(a) Schematic picture and (b) SEM photograph of eutectic PbSn solder Eutectic Solder Bumps This work elucidates the solder reflow of eutectic (63sn/37pb) solder bump using fluxless formic acid. The dependences of formic acid. This “enhanced eutectic” snpbcu solder bump has been shown to significantly improve reliability against diffusion related failure mechanisms. Current technologies use high lead high melting point alloys such as pb95%sn5% % (mp = 315 °c), pb97%sn3% % (mp = 320. Eutectic Solder Bumps.

From www.semanticscholar.org

Figure 5 from Solderjetted eutectic PbSn bumps for flipchip Eutectic Solder Bumps This “enhanced eutectic” snpbcu solder bump has been shown to significantly improve reliability against diffusion related failure mechanisms. The dependences of formic acid. This work elucidates the solder reflow of eutectic (63sn/37pb) solder bump using fluxless formic acid. This work investigates the impact of probing procedures and bumping processes on the electromigration of the printed bumps with. The multilayer solder. Eutectic Solder Bumps.

From www.semanticscholar.org

[PDF] Reliability of Eutectic SnPb Solder Bumps and Flip Chip Eutectic Solder Bumps This work investigates the impact of probing procedures and bumping processes on the electromigration of the printed bumps with. The embossment of phase separation in the left side solder bump is mainly caused by the effect of bottle neck in the interfacial region. Current technologies use high lead high melting point alloys such as pb95%sn5% % (mp = 315 °c),. Eutectic Solder Bumps.

From www.semanticscholar.org

Figure 1 from Damages and microstructural variation of highlead and Eutectic Solder Bumps This “enhanced eutectic” snpbcu solder bump has been shown to significantly improve reliability against diffusion related failure mechanisms. This work elucidates the solder reflow of eutectic (63sn/37pb) solder bump using fluxless formic acid. Current technologies use high lead high melting point alloys such as pb95%sn5% % (mp = 315 °c), pb97%sn3% % (mp = 320 °c), eutectic. This work investigates. Eutectic Solder Bumps.

From www.researchgate.net

Color online a Schematic diagram of 11 solder bumps with one pair of Eutectic Solder Bumps The dependences of formic acid. This “enhanced eutectic” snpbcu solder bump has been shown to significantly improve reliability against diffusion related failure mechanisms. The multilayer solder bump is a lead free ternary solder system, which provides a route to transform the melting point of interconnects for. This work elucidates the solder reflow of eutectic (63sn/37pb) solder bump using fluxless formic. Eutectic Solder Bumps.

From www.researchgate.net

Top view images of eutectic AuSn solder spreading on the Ni/Auplated Eutectic Solder Bumps This “enhanced eutectic” snpbcu solder bump has been shown to significantly improve reliability against diffusion related failure mechanisms. The multilayer solder bump is a lead free ternary solder system, which provides a route to transform the melting point of interconnects for. Current technologies use high lead high melting point alloys such as pb95%sn5% % (mp = 315 °c), pb97%sn3% %. Eutectic Solder Bumps.

From www.researchgate.net

(a) Crosssection of an ascontrol 97Pb/Sn37Pb/Sn solder joint, (b Eutectic Solder Bumps Current technologies use high lead high melting point alloys such as pb95%sn5% % (mp = 315 °c), pb97%sn3% % (mp = 320 °c), eutectic. The dependences of formic acid. This work elucidates the solder reflow of eutectic (63sn/37pb) solder bump using fluxless formic acid. The embossment of phase separation in the left side solder bump is mainly caused by the. Eutectic Solder Bumps.

From www.semanticscholar.org

Figure 1 from Fluxless reflow of eutectic solder bump using formic acid Eutectic Solder Bumps This “enhanced eutectic” snpbcu solder bump has been shown to significantly improve reliability against diffusion related failure mechanisms. This work investigates the impact of probing procedures and bumping processes on the electromigration of the printed bumps with. The multilayer solder bump is a lead free ternary solder system, which provides a route to transform the melting point of interconnects for.. Eutectic Solder Bumps.

From pubs.acs.org

ThreeDimensional Composition Analysis of SnAg Solder Bumps Using Eutectic Solder Bumps The dependences of formic acid. Current technologies use high lead high melting point alloys such as pb95%sn5% % (mp = 315 °c), pb97%sn3% % (mp = 320 °c), eutectic. This work elucidates the solder reflow of eutectic (63sn/37pb) solder bump using fluxless formic acid. This work investigates the impact of probing procedures and bumping processes on the electromigration of the. Eutectic Solder Bumps.

From www.semanticscholar.org

Figure 1 from Damages and microstructural variation of highlead and Eutectic Solder Bumps The embossment of phase separation in the left side solder bump is mainly caused by the effect of bottle neck in the interfacial region. This work elucidates the solder reflow of eutectic (63sn/37pb) solder bump using fluxless formic acid. The dependences of formic acid. This work investigates the impact of probing procedures and bumping processes on the electromigration of the. Eutectic Solder Bumps.

From www.semanticscholar.org

Figure 6 from Bump nonwet issue in largedie flip chip package with Eutectic Solder Bumps The embossment of phase separation in the left side solder bump is mainly caused by the effect of bottle neck in the interfacial region. This “enhanced eutectic” snpbcu solder bump has been shown to significantly improve reliability against diffusion related failure mechanisms. This work investigates the impact of probing procedures and bumping processes on the electromigration of the printed bumps. Eutectic Solder Bumps.

From www.semanticscholar.org

Figure 4 from Fundamental study of 95 highlead solder bump on Eutectic Solder Bumps The dependences of formic acid. This work investigates the impact of probing procedures and bumping processes on the electromigration of the printed bumps with. The embossment of phase separation in the left side solder bump is mainly caused by the effect of bottle neck in the interfacial region. The multilayer solder bump is a lead free ternary solder system, which. Eutectic Solder Bumps.

From www.semanticscholar.org

Figure 10 from Electromigration behavior in fine pitch SnBi eutectic Eutectic Solder Bumps This work investigates the impact of probing procedures and bumping processes on the electromigration of the printed bumps with. This work elucidates the solder reflow of eutectic (63sn/37pb) solder bump using fluxless formic acid. Current technologies use high lead high melting point alloys such as pb95%sn5% % (mp = 315 °c), pb97%sn3% % (mp = 320 °c), eutectic. The dependences. Eutectic Solder Bumps.