Groove Width Meaning . The term grooving usually applies to a process of forming a narrow cavity of a certain depth, on a cylinder, cone, or a face of the part. Horizontal and vertical counting thresholds are. Single cut grooving is the most economical and productive method of producing grooves. However, if the width of the groove is larger than the. The bottom of the groove shall be free of loose dirt, chips, rust and scale that may interfere with proper coupling assembly. Grooving is a crucial machining process that removes material from a workpiece to create grooves of a specified width and. Grooving is a machining operation performed on a lathe machine to create a narrow, linear cut or groove on the surface of a. Mean value of the width of the profile elements xs i (previously s m);

from app.aws.org

The bottom of the groove shall be free of loose dirt, chips, rust and scale that may interfere with proper coupling assembly. The term grooving usually applies to a process of forming a narrow cavity of a certain depth, on a cylinder, cone, or a face of the part. Horizontal and vertical counting thresholds are. However, if the width of the groove is larger than the. Single cut grooving is the most economical and productive method of producing grooves. Grooving is a crucial machining process that removes material from a workpiece to create grooves of a specified width and. Grooving is a machining operation performed on a lathe machine to create a narrow, linear cut or groove on the surface of a. Mean value of the width of the profile elements xs i (previously s m);

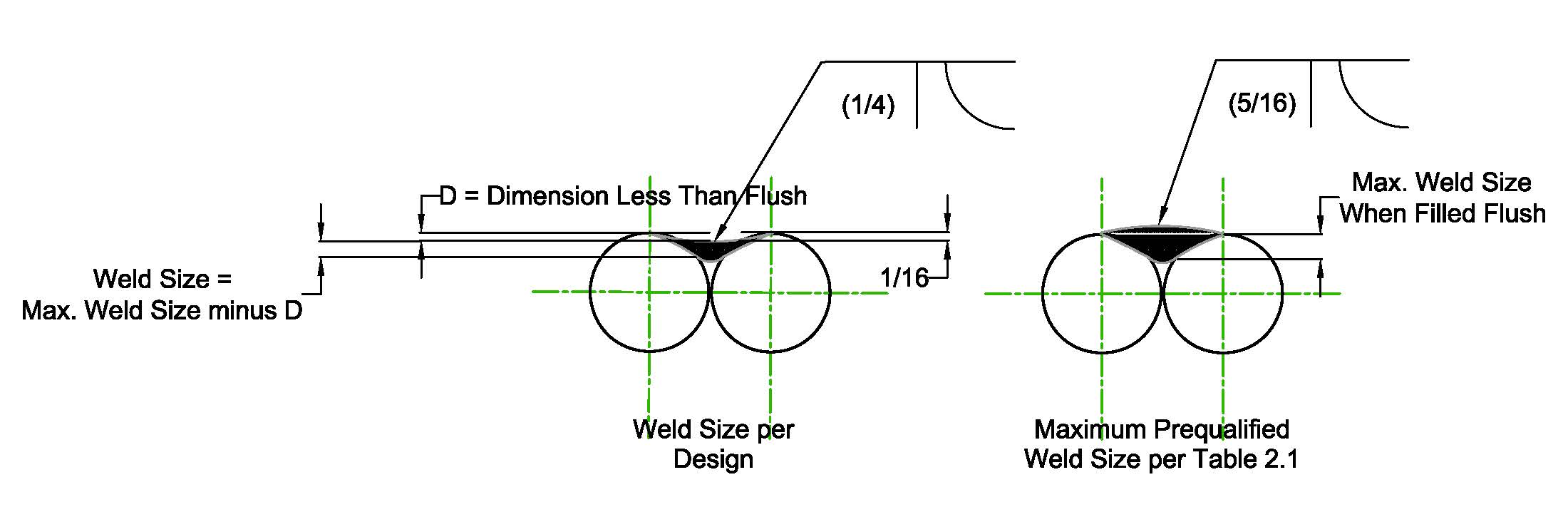

Flare Groove Weld Size Question

Groove Width Meaning Single cut grooving is the most economical and productive method of producing grooves. Grooving is a machining operation performed on a lathe machine to create a narrow, linear cut or groove on the surface of a. Grooving is a crucial machining process that removes material from a workpiece to create grooves of a specified width and. Single cut grooving is the most economical and productive method of producing grooves. The bottom of the groove shall be free of loose dirt, chips, rust and scale that may interfere with proper coupling assembly. Mean value of the width of the profile elements xs i (previously s m); The term grooving usually applies to a process of forming a narrow cavity of a certain depth, on a cylinder, cone, or a face of the part. Horizontal and vertical counting thresholds are. However, if the width of the groove is larger than the.

From dmsafetygrooving.com

Services Concrete Grooving DM Safety Grooving Groove Width Meaning Single cut grooving is the most economical and productive method of producing grooves. Horizontal and vertical counting thresholds are. The term grooving usually applies to a process of forming a narrow cavity of a certain depth, on a cylinder, cone, or a face of the part. However, if the width of the groove is larger than the. Grooving is a. Groove Width Meaning.

From app.aws.org

Flare Groove Weld Size Question Groove Width Meaning Grooving is a crucial machining process that removes material from a workpiece to create grooves of a specified width and. The term grooving usually applies to a process of forming a narrow cavity of a certain depth, on a cylinder, cone, or a face of the part. Grooving is a machining operation performed on a lathe machine to create a. Groove Width Meaning.

From www.pfeiferindustries.com

Timing Belt Pulley Diameter Charts Pfeifer Industries Groove Width Meaning Mean value of the width of the profile elements xs i (previously s m); The term grooving usually applies to a process of forming a narrow cavity of a certain depth, on a cylinder, cone, or a face of the part. Grooving is a crucial machining process that removes material from a workpiece to create grooves of a specified width. Groove Width Meaning.

From engineersblog.net

What is the design criteria of Groove Joints? Explain in details step Groove Width Meaning Grooving is a crucial machining process that removes material from a workpiece to create grooves of a specified width and. However, if the width of the groove is larger than the. Horizontal and vertical counting thresholds are. Mean value of the width of the profile elements xs i (previously s m); Grooving is a machining operation performed on a lathe. Groove Width Meaning.

From sealingaustralia.com.au

O’ring Groove Design Sealing Australia Groove Width Meaning However, if the width of the groove is larger than the. Horizontal and vertical counting thresholds are. The bottom of the groove shall be free of loose dirt, chips, rust and scale that may interfere with proper coupling assembly. Single cut grooving is the most economical and productive method of producing grooves. Grooving is a crucial machining process that removes. Groove Width Meaning.

From www.researchgate.net

VGroove configuration for butt welding. Download Scientific Diagram Groove Width Meaning However, if the width of the groove is larger than the. Horizontal and vertical counting thresholds are. Grooving is a machining operation performed on a lathe machine to create a narrow, linear cut or groove on the surface of a. The term grooving usually applies to a process of forming a narrow cavity of a certain depth, on a cylinder,. Groove Width Meaning.

From www.say.com.sg

GROOVE LINES U / V SERIES S.A.Y Brothers Building System Pte Ltd Groove Width Meaning Horizontal and vertical counting thresholds are. The term grooving usually applies to a process of forming a narrow cavity of a certain depth, on a cylinder, cone, or a face of the part. Grooving is a machining operation performed on a lathe machine to create a narrow, linear cut or groove on the surface of a. Grooving is a crucial. Groove Width Meaning.

From bid.ableauctions.ca

MITUTOYO GROOVE WIDTH MICROMETER WITH CASE Able Auctions Groove Width Meaning Single cut grooving is the most economical and productive method of producing grooves. Mean value of the width of the profile elements xs i (previously s m); Horizontal and vertical counting thresholds are. The bottom of the groove shall be free of loose dirt, chips, rust and scale that may interfere with proper coupling assembly. Grooving is a machining operation. Groove Width Meaning.

From weldguru.com

Parts of A Weld Weld Components with Diagram Weld Guru Groove Width Meaning Grooving is a crucial machining process that removes material from a workpiece to create grooves of a specified width and. The bottom of the groove shall be free of loose dirt, chips, rust and scale that may interfere with proper coupling assembly. The term grooving usually applies to a process of forming a narrow cavity of a certain depth, on. Groove Width Meaning.

From www.truongquoctesaigon.edu.vn

O Ring Groove Dimensions Chart truongquoctesaigon.edu.vn Groove Width Meaning Grooving is a machining operation performed on a lathe machine to create a narrow, linear cut or groove on the surface of a. Mean value of the width of the profile elements xs i (previously s m); However, if the width of the groove is larger than the. The term grooving usually applies to a process of forming a narrow. Groove Width Meaning.

From mungfali.com

O Ring Groove Chart Groove Width Meaning Horizontal and vertical counting thresholds are. The bottom of the groove shall be free of loose dirt, chips, rust and scale that may interfere with proper coupling assembly. However, if the width of the groove is larger than the. Grooving is a crucial machining process that removes material from a workpiece to create grooves of a specified width and. Single. Groove Width Meaning.

From www.researchgate.net

(PDF) EFFECT OF GROOVE WIDTH AND SHAPE ON CONCRETE PAVEMENT SKID RESISTANCE Groove Width Meaning Single cut grooving is the most economical and productive method of producing grooves. Mean value of the width of the profile elements xs i (previously s m); Grooving is a crucial machining process that removes material from a workpiece to create grooves of a specified width and. However, if the width of the groove is larger than the. The bottom. Groove Width Meaning.

From www.researchgate.net

Different parameters governing the groove dimensions. g is groove Groove Width Meaning Horizontal and vertical counting thresholds are. Single cut grooving is the most economical and productive method of producing grooves. The term grooving usually applies to a process of forming a narrow cavity of a certain depth, on a cylinder, cone, or a face of the part. The bottom of the groove shall be free of loose dirt, chips, rust and. Groove Width Meaning.

From www.slideserve.com

PPT Firearms PowerPoint Presentation, free download ID2160581 Groove Width Meaning Horizontal and vertical counting thresholds are. Grooving is a machining operation performed on a lathe machine to create a narrow, linear cut or groove on the surface of a. Grooving is a crucial machining process that removes material from a workpiece to create grooves of a specified width and. However, if the width of the groove is larger than the.. Groove Width Meaning.

From www.researchgate.net

Relationship between groove width and diameter of industrial tool Groove Width Meaning However, if the width of the groove is larger than the. The bottom of the groove shall be free of loose dirt, chips, rust and scale that may interfere with proper coupling assembly. Mean value of the width of the profile elements xs i (previously s m); Grooving is a crucial machining process that removes material from a workpiece to. Groove Width Meaning.

From alysiapolk.blogspot.com

high tread tires meaning Alysia Polk Groove Width Meaning Grooving is a crucial machining process that removes material from a workpiece to create grooves of a specified width and. The bottom of the groove shall be free of loose dirt, chips, rust and scale that may interfere with proper coupling assembly. Grooving is a machining operation performed on a lathe machine to create a narrow, linear cut or groove. Groove Width Meaning.

From www.researchgate.net

Die design in Solid Works for the 40° groove angle and 3 mm groove Groove Width Meaning Grooving is a machining operation performed on a lathe machine to create a narrow, linear cut or groove on the surface of a. Mean value of the width of the profile elements xs i (previously s m); Grooving is a crucial machining process that removes material from a workpiece to create grooves of a specified width and. Single cut grooving. Groove Width Meaning.

From www.bowersgroup.co.uk

Groove Gauging Bowers Groove Width Meaning Mean value of the width of the profile elements xs i (previously s m); Single cut grooving is the most economical and productive method of producing grooves. Horizontal and vertical counting thresholds are. However, if the width of the groove is larger than the. Grooving is a machining operation performed on a lathe machine to create a narrow, linear cut. Groove Width Meaning.

From www.researchgate.net

Schematic diagram of the groove pattern to be patterning Download Groove Width Meaning Grooving is a crucial machining process that removes material from a workpiece to create grooves of a specified width and. The term grooving usually applies to a process of forming a narrow cavity of a certain depth, on a cylinder, cone, or a face of the part. Mean value of the width of the profile elements xs i (previously s. Groove Width Meaning.

From www.buffalo-lumber.com

Tongue and Groove Siding T&G Siding Patterns and Pictures Groove Width Meaning The bottom of the groove shall be free of loose dirt, chips, rust and scale that may interfere with proper coupling assembly. Single cut grooving is the most economical and productive method of producing grooves. Grooving is a crucial machining process that removes material from a workpiece to create grooves of a specified width and. However, if the width of. Groove Width Meaning.

From www.researchgate.net

Schematic view of the smooth groove. Download Scientific Diagram Groove Width Meaning However, if the width of the groove is larger than the. Mean value of the width of the profile elements xs i (previously s m); Horizontal and vertical counting thresholds are. Grooving is a machining operation performed on a lathe machine to create a narrow, linear cut or groove on the surface of a. Single cut grooving is the most. Groove Width Meaning.

From www.researchgate.net

The effect of groove width and height on the capillary rise in a Groove Width Meaning However, if the width of the groove is larger than the. Grooving is a crucial machining process that removes material from a workpiece to create grooves of a specified width and. Mean value of the width of the profile elements xs i (previously s m); The bottom of the groove shall be free of loose dirt, chips, rust and scale. Groove Width Meaning.

From www.researchgate.net

Relationship between the groove width W and cutting force F y Groove Width Meaning Grooving is a crucial machining process that removes material from a workpiece to create grooves of a specified width and. The term grooving usually applies to a process of forming a narrow cavity of a certain depth, on a cylinder, cone, or a face of the part. The bottom of the groove shall be free of loose dirt, chips, rust. Groove Width Meaning.

From www.buffalo-lumber.com

Tongue and Groove Siding T&G Siding Patterns and Pictures Groove Width Meaning Mean value of the width of the profile elements xs i (previously s m); Single cut grooving is the most economical and productive method of producing grooves. Grooving is a machining operation performed on a lathe machine to create a narrow, linear cut or groove on the surface of a. However, if the width of the groove is larger than. Groove Width Meaning.

From learnmech.com

Difference Between Slot, Holes ,Groove, Keyway Basic Of Mechanical Groove Width Meaning Mean value of the width of the profile elements xs i (previously s m); Grooving is a machining operation performed on a lathe machine to create a narrow, linear cut or groove on the surface of a. However, if the width of the groove is larger than the. Horizontal and vertical counting thresholds are. Grooving is a crucial machining process. Groove Width Meaning.

From www.youtube.com

Features of the Completed Groove Weld Part 2 Dimension of the Groove Groove Width Meaning The term grooving usually applies to a process of forming a narrow cavity of a certain depth, on a cylinder, cone, or a face of the part. However, if the width of the groove is larger than the. Horizontal and vertical counting thresholds are. Mean value of the width of the profile elements xs i (previously s m); Single cut. Groove Width Meaning.

From eureka.patsnap.com

Groove width detection device and method for semiclosed annular Groove Width Meaning Horizontal and vertical counting thresholds are. Grooving is a crucial machining process that removes material from a workpiece to create grooves of a specified width and. Mean value of the width of the profile elements xs i (previously s m); The bottom of the groove shall be free of loose dirt, chips, rust and scale that may interfere with proper. Groove Width Meaning.

From www.storyofmathematics.com

Width Definition & Meaning Groove Width Meaning However, if the width of the groove is larger than the. The term grooving usually applies to a process of forming a narrow cavity of a certain depth, on a cylinder, cone, or a face of the part. Grooving is a machining operation performed on a lathe machine to create a narrow, linear cut or groove on the surface of. Groove Width Meaning.

From www.redbubble.com

"Groove Definition Dictionary Collection" Poster by Designschmiede Groove Width Meaning Grooving is a crucial machining process that removes material from a workpiece to create grooves of a specified width and. The term grooving usually applies to a process of forming a narrow cavity of a certain depth, on a cylinder, cone, or a face of the part. Single cut grooving is the most economical and productive method of producing grooves.. Groove Width Meaning.

From www.chegg.com

Solved Consider the following grooves, each of width W, that Groove Width Meaning Horizontal and vertical counting thresholds are. However, if the width of the groove is larger than the. Grooving is a machining operation performed on a lathe machine to create a narrow, linear cut or groove on the surface of a. The term grooving usually applies to a process of forming a narrow cavity of a certain depth, on a cylinder,. Groove Width Meaning.

From www.researchgate.net

Schematic diagram of groove width measurement position Download Groove Width Meaning The bottom of the groove shall be free of loose dirt, chips, rust and scale that may interfere with proper coupling assembly. Grooving is a machining operation performed on a lathe machine to create a narrow, linear cut or groove on the surface of a. However, if the width of the groove is larger than the. Horizontal and vertical counting. Groove Width Meaning.

From www.storyofmathematics.com

Width Definition & Meaning Groove Width Meaning The bottom of the groove shall be free of loose dirt, chips, rust and scale that may interfere with proper coupling assembly. The term grooving usually applies to a process of forming a narrow cavity of a certain depth, on a cylinder, cone, or a face of the part. Grooving is a machining operation performed on a lathe machine to. Groove Width Meaning.

From www.truongquoctesaigon.edu.vn

O Ring Groove Dimensions Chart truongquoctesaigon.edu.vn Groove Width Meaning However, if the width of the groove is larger than the. Mean value of the width of the profile elements xs i (previously s m); The bottom of the groove shall be free of loose dirt, chips, rust and scale that may interfere with proper coupling assembly. Grooving is a machining operation performed on a lathe machine to create a. Groove Width Meaning.

From informacionpublica.svet.gob.gt

TREAD DEPTH MEASUREMENT (Con't) TM9261020014_62 Groove Width Meaning Horizontal and vertical counting thresholds are. The bottom of the groove shall be free of loose dirt, chips, rust and scale that may interfere with proper coupling assembly. However, if the width of the groove is larger than the. Grooving is a crucial machining process that removes material from a workpiece to create grooves of a specified width and. The. Groove Width Meaning.

From www.pinterest.com

tongue and groove dimensions in mm Google Search Tongue and groove Groove Width Meaning Single cut grooving is the most economical and productive method of producing grooves. Grooving is a machining operation performed on a lathe machine to create a narrow, linear cut or groove on the surface of a. The term grooving usually applies to a process of forming a narrow cavity of a certain depth, on a cylinder, cone, or a face. Groove Width Meaning.